Patents

Literature

46results about How to "Reduce the generation of static electricity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

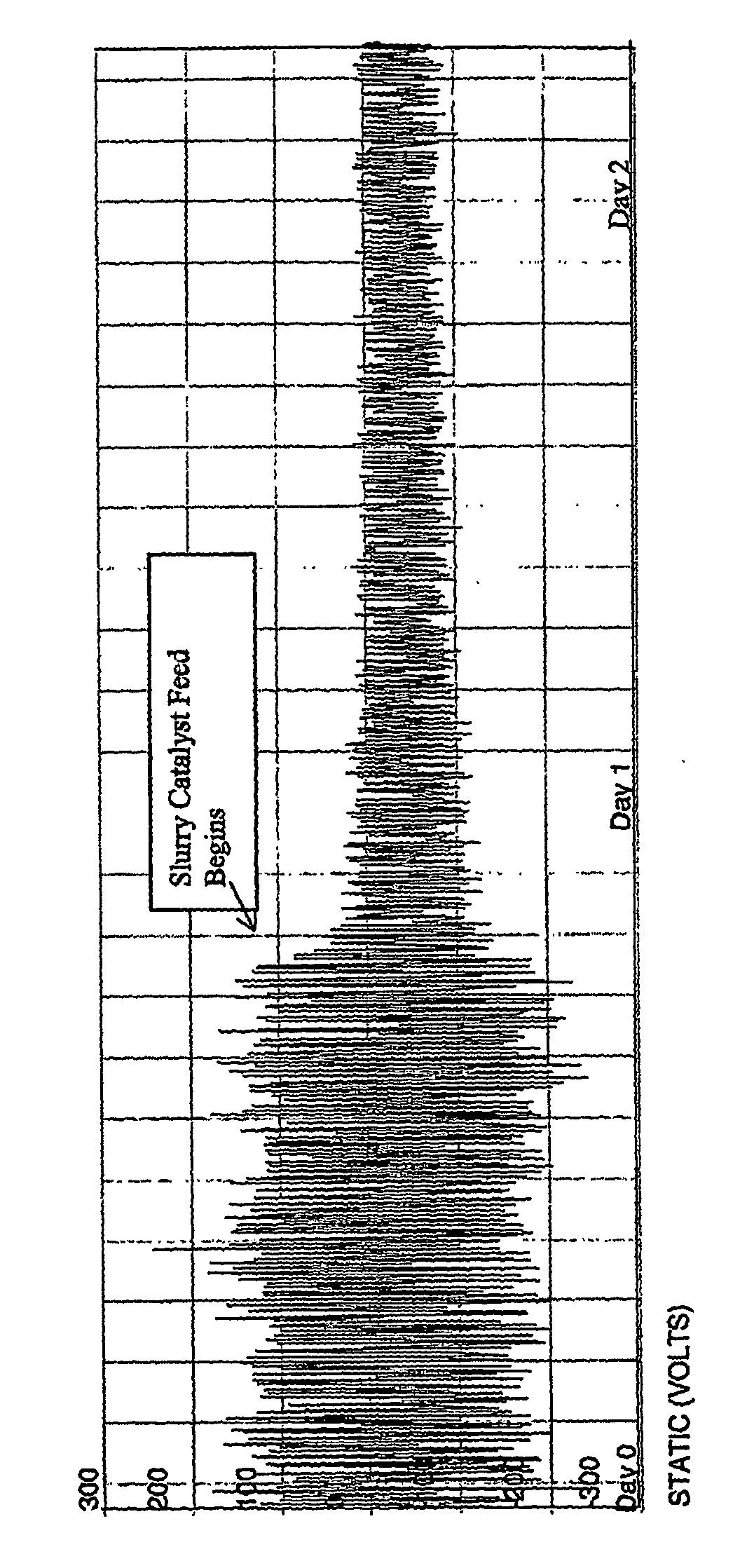

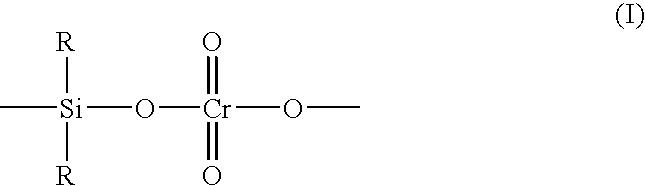

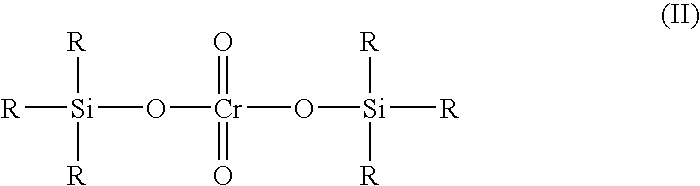

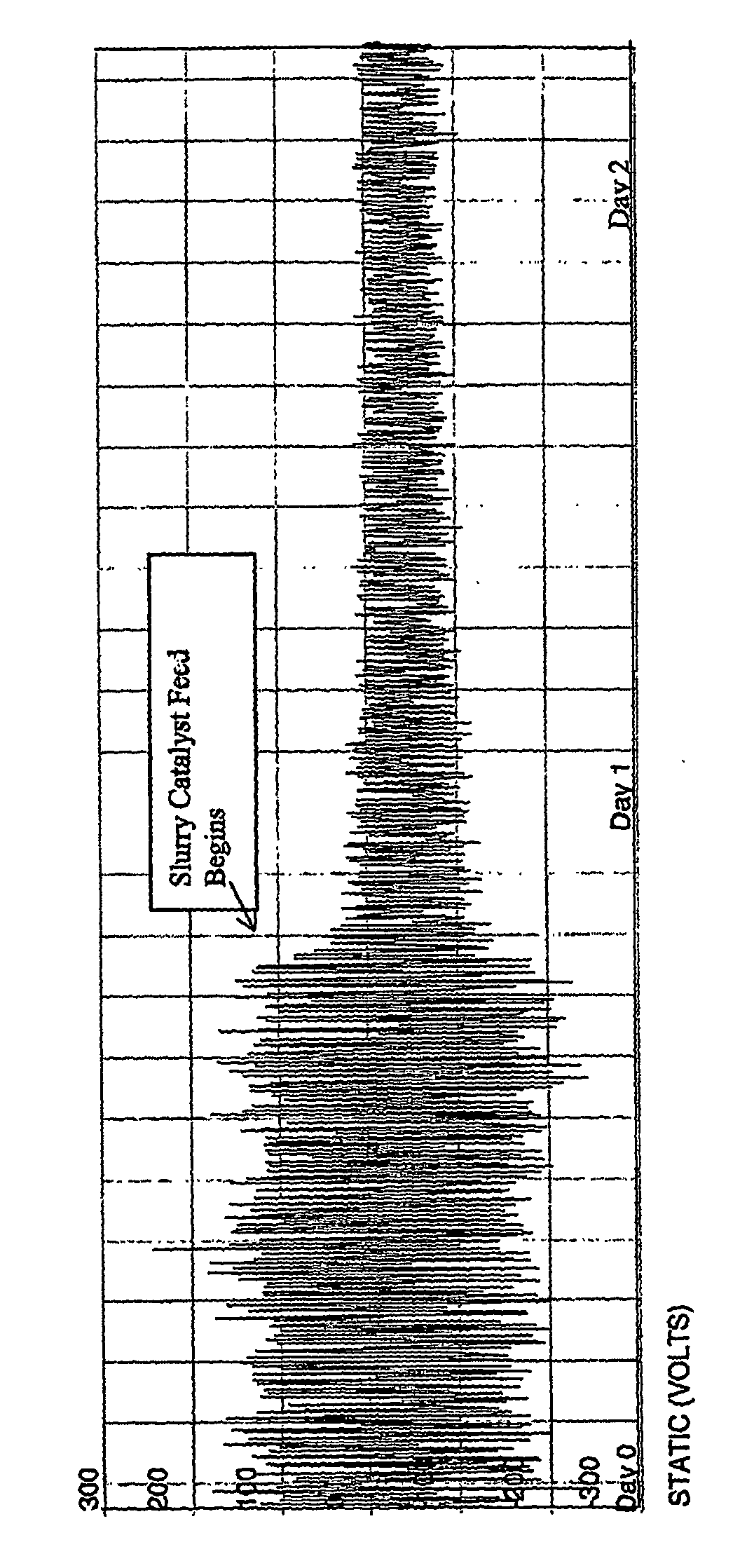

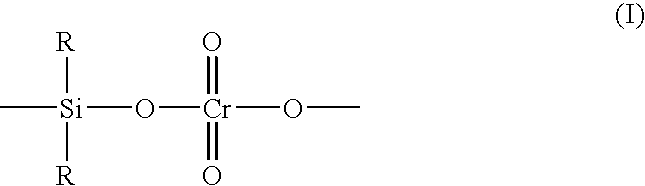

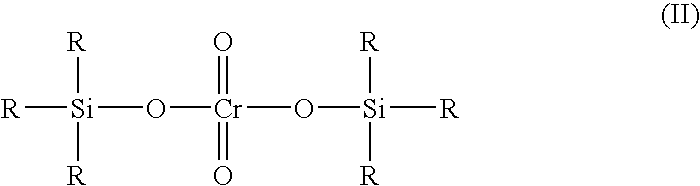

Chromium-based catalysts in mineral oil for production of polyethylene

A process for polymerizing polyethylene with chromium-based catalysts wherein one or more supported chromium-based catalysts is mixed with mineral oil to form a slurry and the slurry is then introduced into a polymerization reactor, especially a gas-phase polymerization reactor.

Owner:UNIVATION TECH LLC

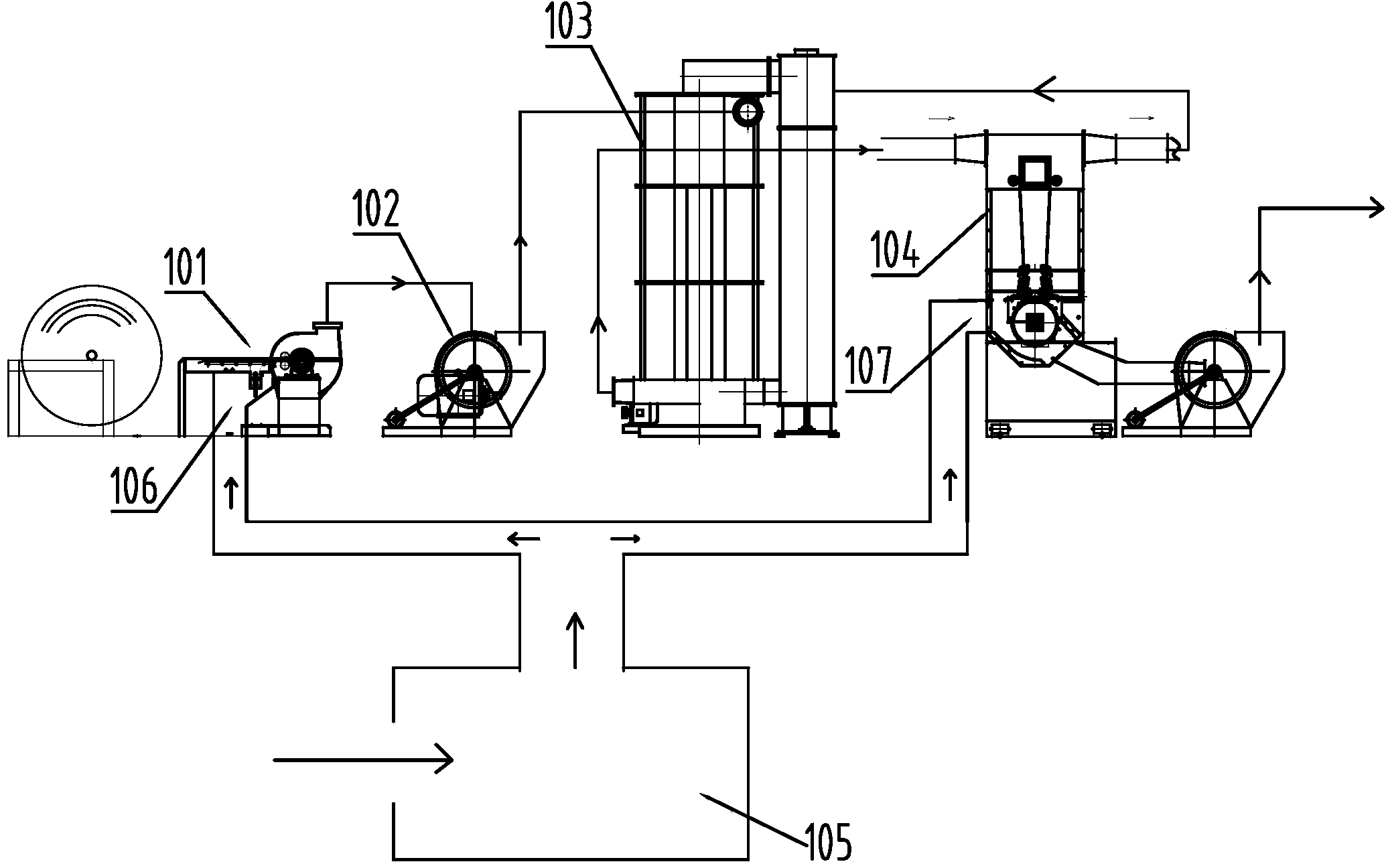

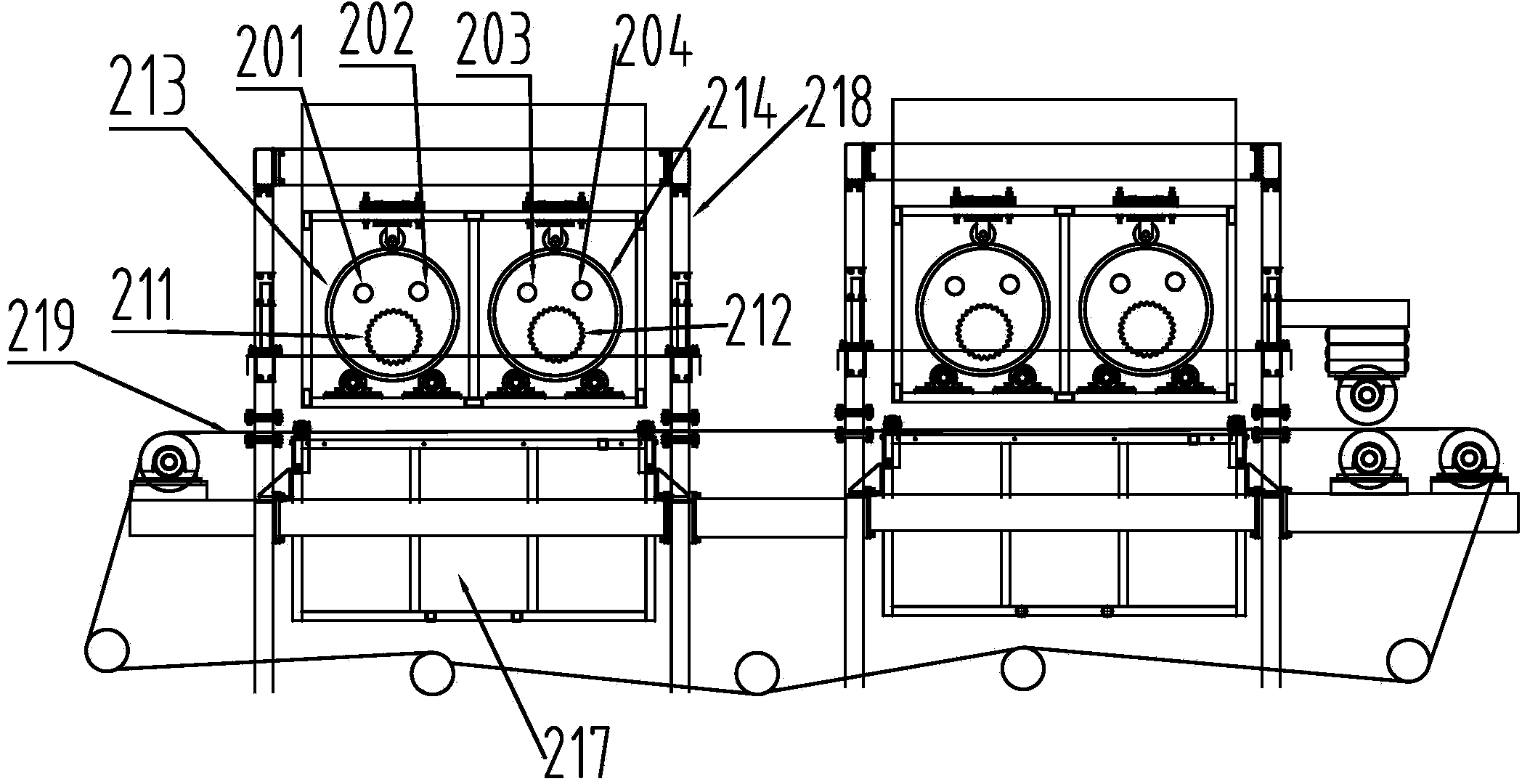

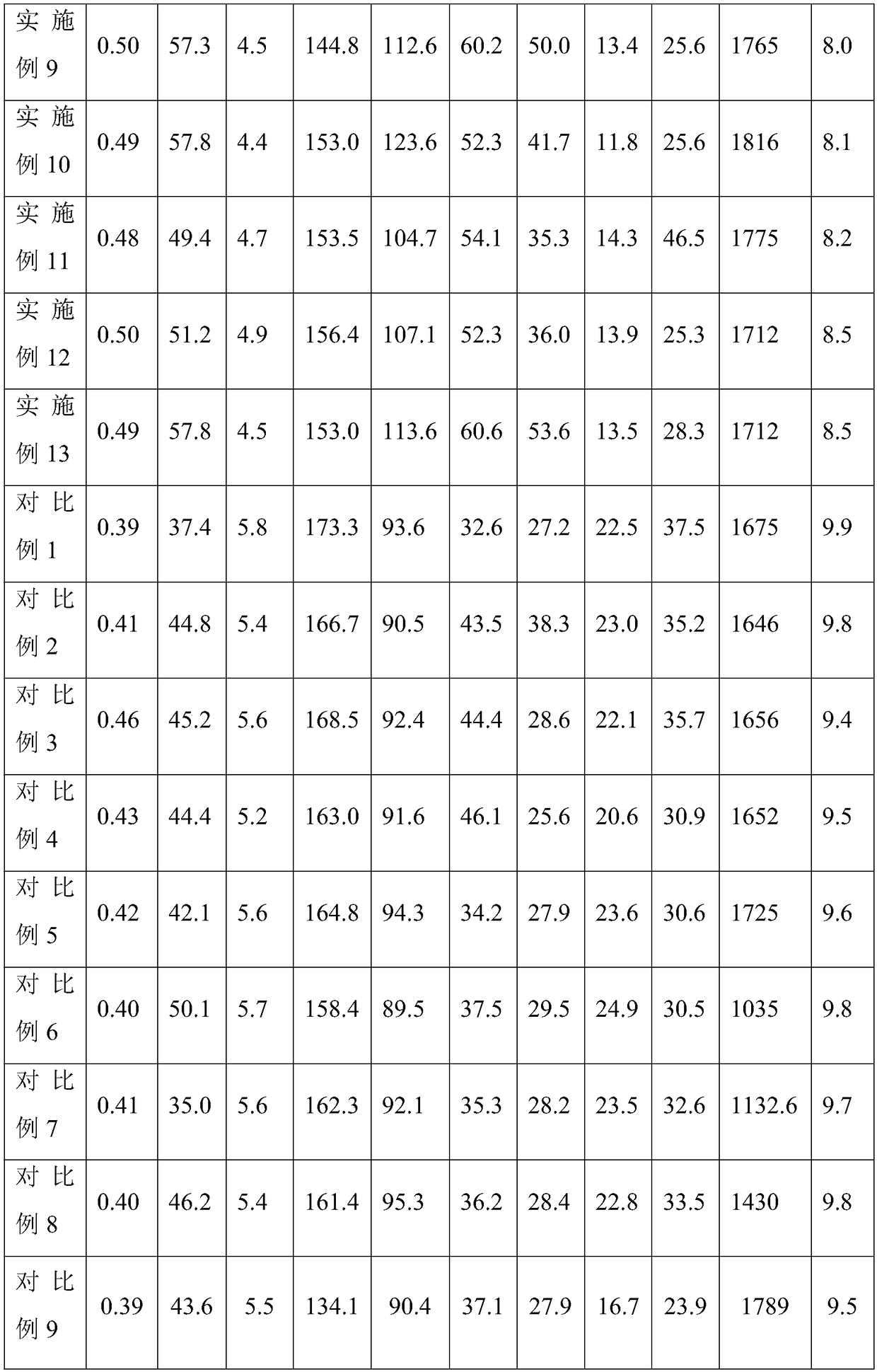

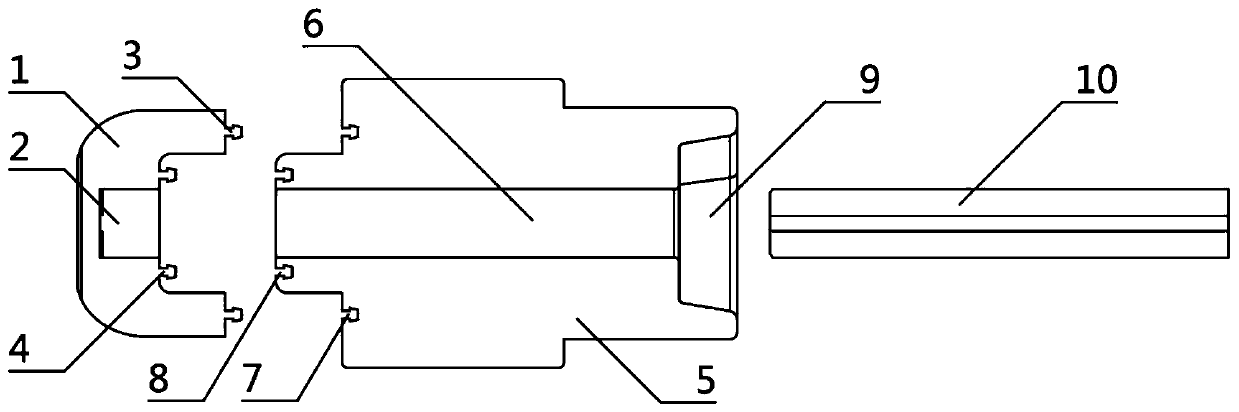

Equipment for producing reconstituted tobacco through dry-method paper making method

The invention relates to equipment for producing reconstituted tobacco through a dry-method paper making method. The equipment comprises a fiber decomposing device, a basal piece forming device, a pulp spraying device and a drying device. The production equipment is provided with various types of material ports and a built-in pipeline humidifying device, and a multi-pipeline feeding mode is adopted to enable the feeding uniformity and controllability to be improved; sprayed pulp contains much tobacco powder, tobacco extracts and adhesives and is large in viscosity; through the equipment, the pulp can be fully dispersed, and the phenomenon that hot air flowing in a drying oven is distributed unevenly to cause the pulp to be partially over-dried can be avoided.

Owner:GUANGDONG GOLDEN LEAF TECH DEV

Chromium-based catalysts in mineral oil for production of polyethylene

A process for polymerizing polyethylene with chromium-based catalysts wherein one or more supported chromium-based catalysts is mixed with mineral oil to form a slurry and the slurry is then introduced into a polymerization reactor, especially a gas-phase polymerization reactor.

Owner:UNIVATION TECH LLC

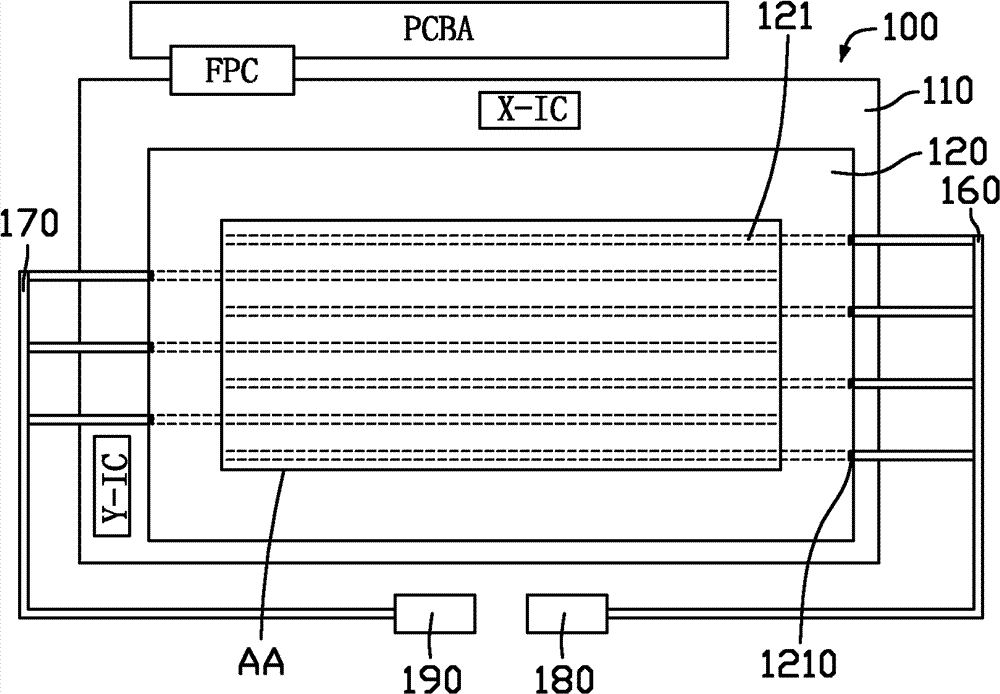

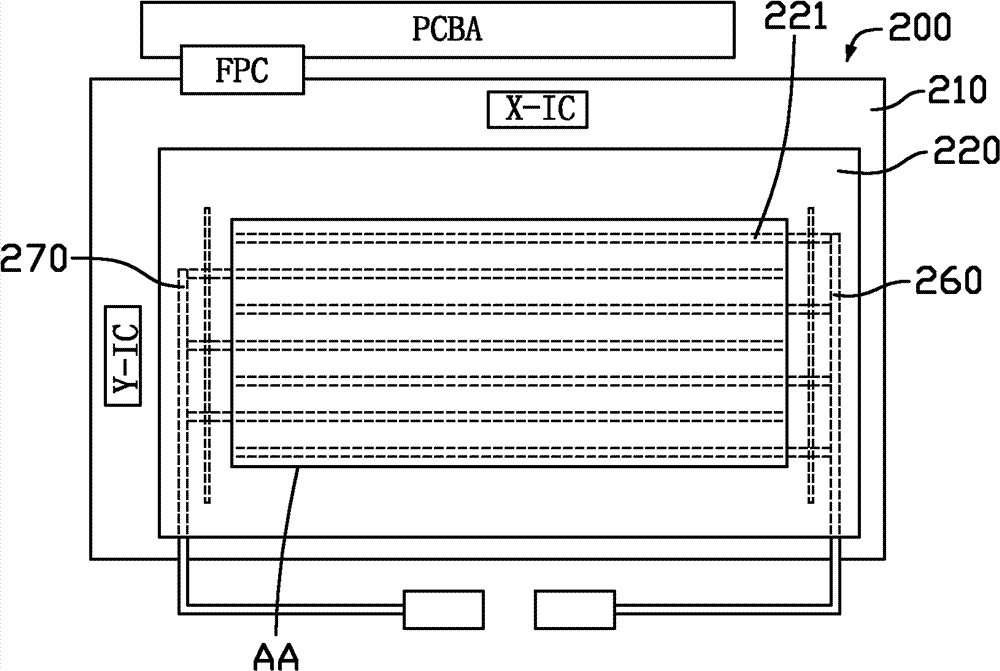

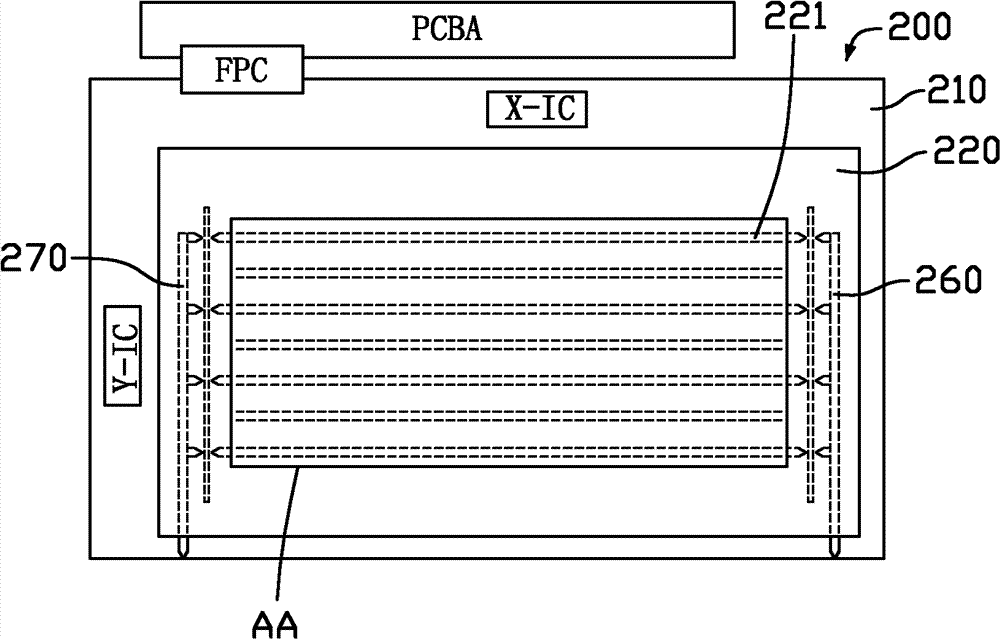

Three-dimensional display switchover panel and static electricity protecting method thereof

InactiveCN102789072AReduce the generation of static electricityReduce the harm of static electricityNon-linear opticsElectrostatic chargesElectricityEngineering

The invention provides a static electricity protecting method for a three-dimensional display switchover panel and a corresponding three-dimensional display switchover panel. The three-dimensional display switchover panel comprises a lower substrate, an upper substrate and at least a residual testing wire; and a plurality of line electrodes parallel to each other are arranged on the upper substrate. With the adoption of the static electricity protecting method, the residual testing wire is electrically connected with ground electrical level, therefore, the residual testing wires of the three-dimensional display switchover panel are all connected with the ground electrical level, and the static electricity generated by the residual testing wires is dismissed rapidly, so that the static electricity is reduced, the harm of the static electricity is reduced greatly, and the whole three-dimensional display switchover panel is protected.

Owner:AU OPTRONICS CORP

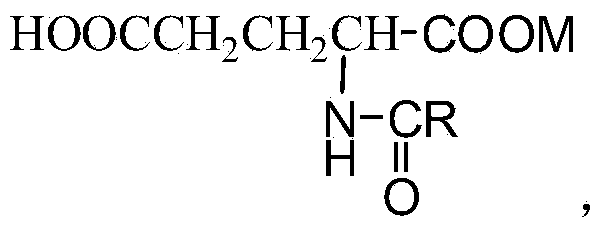

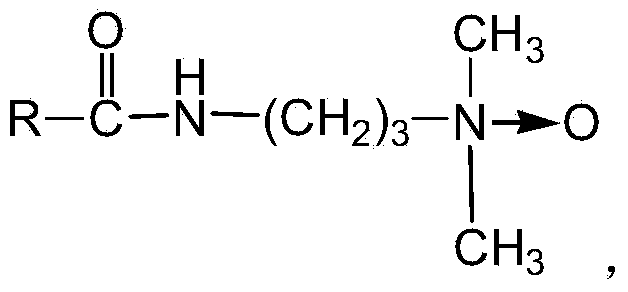

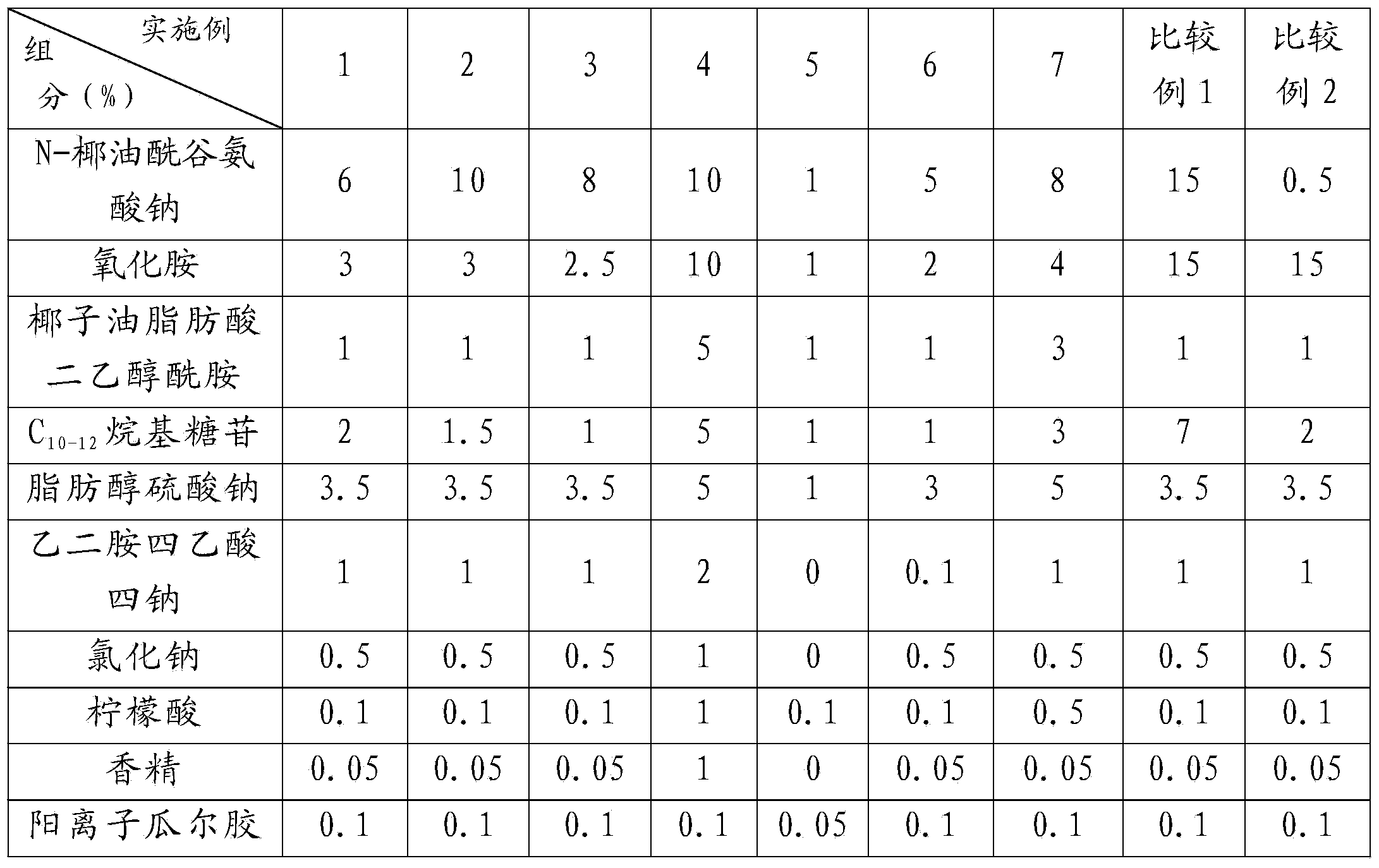

Liquid laundry detergent for infants and preparation method thereof

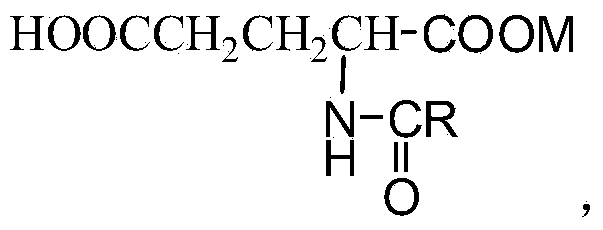

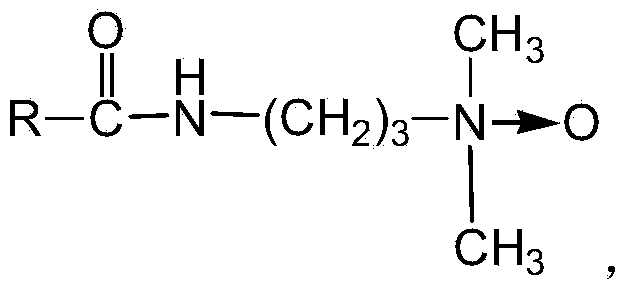

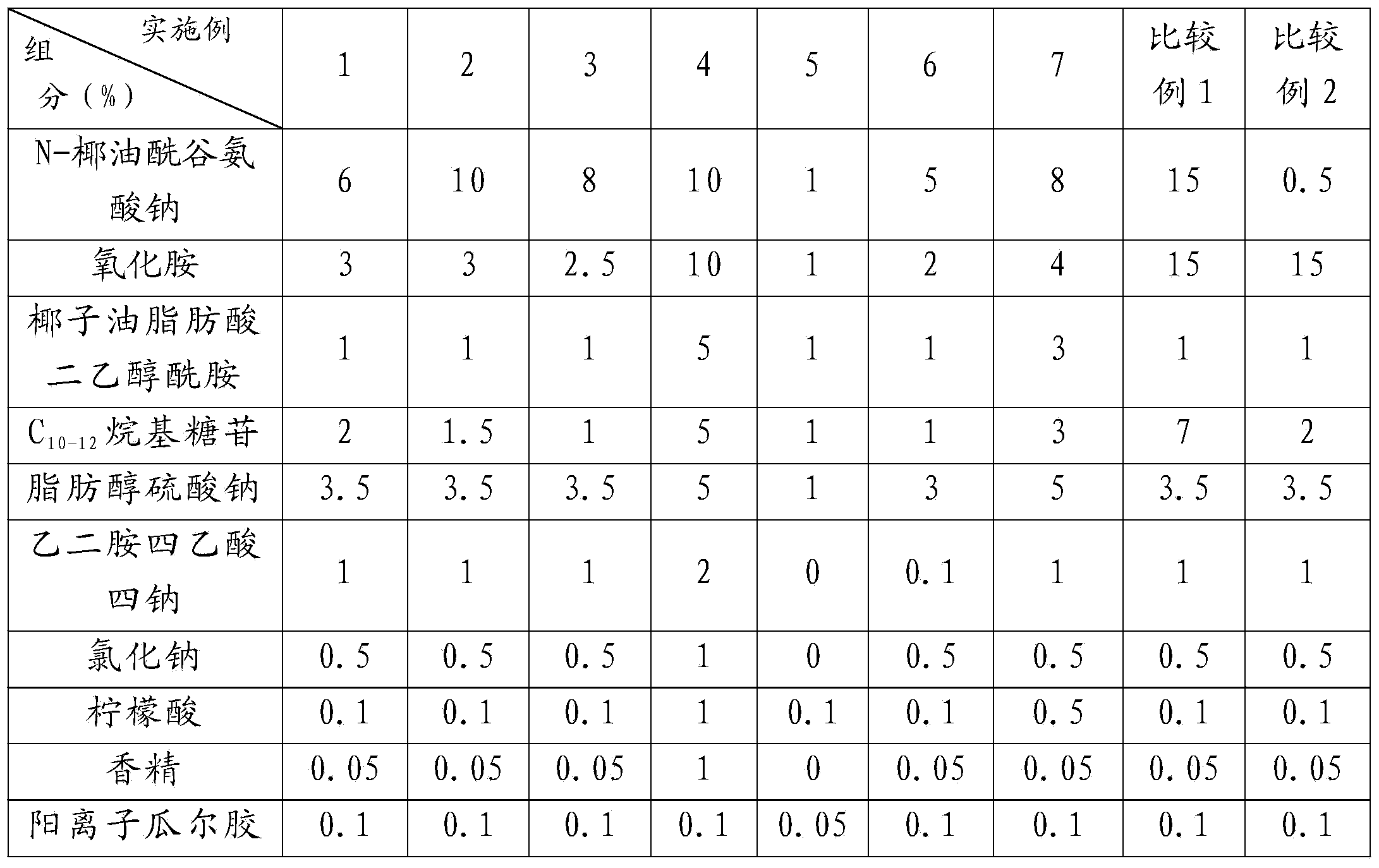

ActiveCN103710167AStrong emulsificationEfficient removalOrganic detergent compounding agentsNon-ionic surface-active compoundsFiberFatty alcohol

The invention relates to the technical field of liquid laundry detergents and in particular relates to a liquid laundry detergent for infants and a preparation method thereof. The liquid laundry detergent mainly comprises an amino acid based surfactant, amine oxide, coconut oil fatty acid diethanol amide, alkyl glycoside and sodium fatty alcohol sulfate. The liquid laundry detergent is prepared by mixing and dissolving the components and carrying out other steps. By mutually matching the components disclosed in the invention and the ratios of the components, a mild and skin-friendly protective film is formed on the fabric fiber surfaces of the clothes which are washed with the liquid laundry detergent and dried, thus the friction between fabric fibers can be reduced, and the formed protective film is combined with the moisture in the air, so that the clothes have certain wettability, the static electricity can be reduced and the washed clothes are softer and smoother; therefore the prepared liquid laundry detergent enables the clothes washed with the liquid laundry detergent to have good softness, has good affinity with infant skins and can effectively wash off the stubborn stains on the clothes of the infants.

Owner:WALCH GUANGZHOU COMMODITY

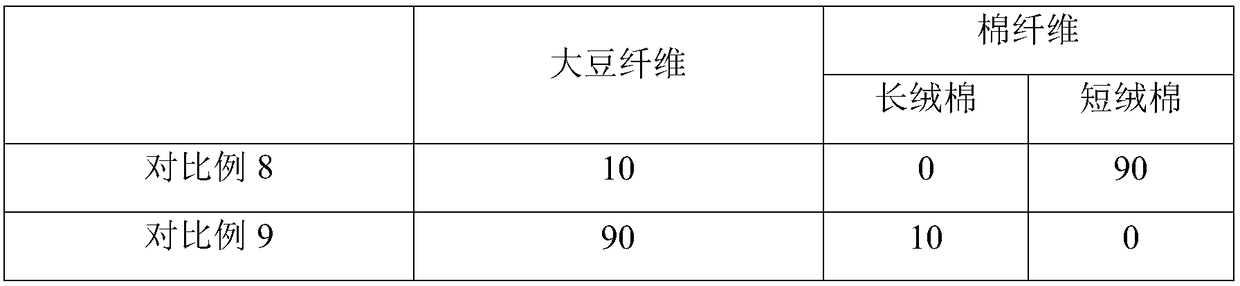

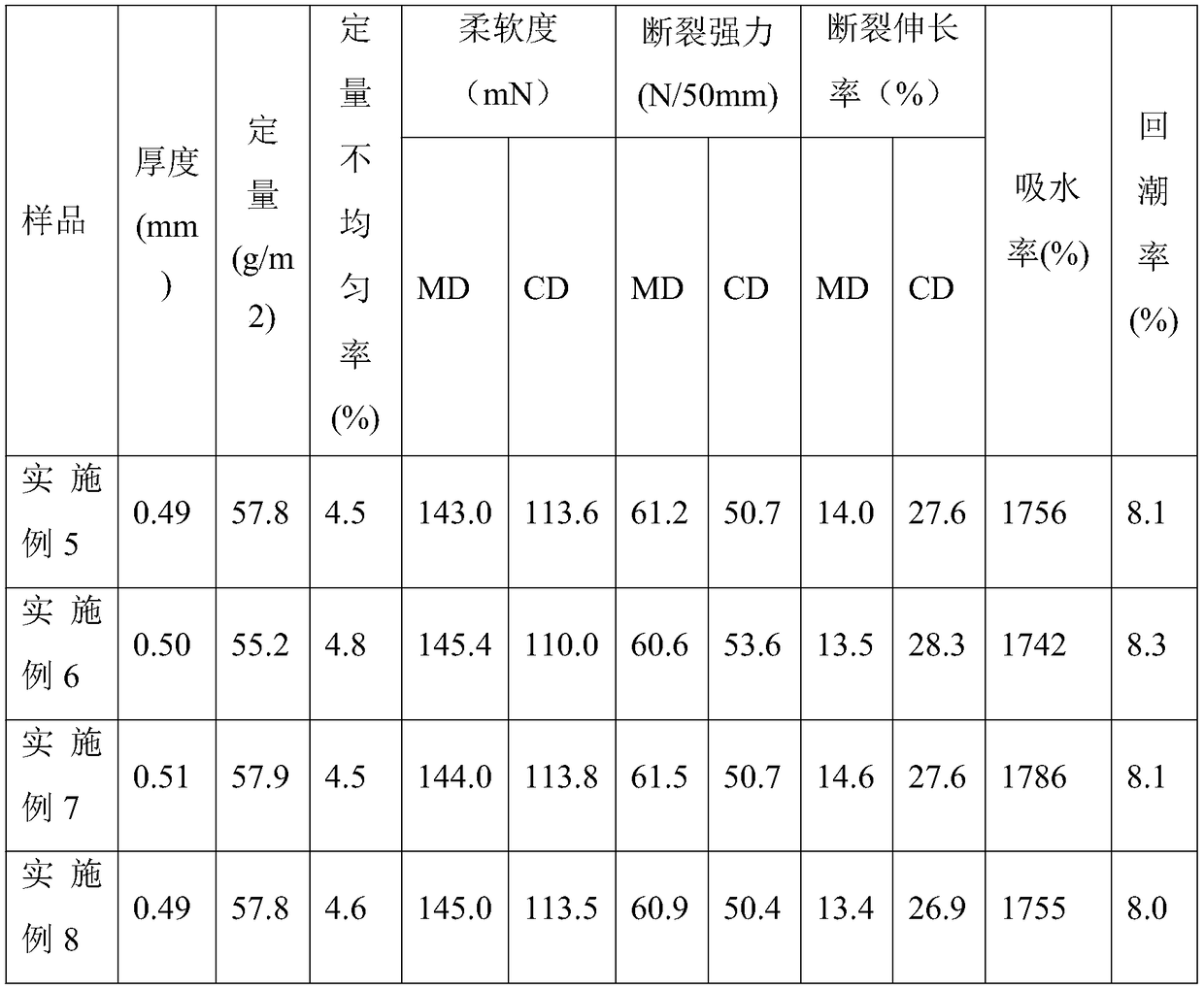

Preparation method of cotton soft towel and cotton soft towel

InactiveCN109457392AReduce static electricityImprove dispersion uniformityNon-woven fabricsVegetal fibresChemistryFiber strength

The invention discloses a preparation method of cotton soft towel and the cotton soft towel. The preparation raw materials of the cotton soft towel comprise pure cotton fiber and soybean fiber. The preparation method of the cotton soft towel and the cotton soft towel have the advantages that through scientific treatment, the technical problems that the soybean fiber and the cotton fiber are different in fiber strength, fineness and the like, and blending is difficult, the primary color of the soybean fiber is ensured after blending, the blending performance of the cotton fiber and soybean fiber is effectively improved, non-woven cloth is prepared from blend fiber, the disadvantages of the insufficient strength of the soybean fiber and poor air permeability of the cotton fiber are overcome,and the cotton soft towel prepared from the non-woven cloth has better soft and skin-friendly performance.

Owner:ZHUZHOU QIANJIN PHARMA +1

Method for manufacturing touch screen

InactiveCN101462423AReduce the generation of static electricityReduce bad appearanceOther printing apparatusInput/output processes for data processingEngineeringPrinting press

The invention relates to a method for manufacturing a touch screen. The method comprises the following steps: taking a clean screen; attaching a silver adhesive tape to the periphery of the screen; arranging the screen with a print on a printer; and moving a screen along the vertical upward direction, while moving a scraper along the horizontal direction from one side of the screen. The method for manufacturing the touch screen can reduce generation of static electricity during printing, and reduce poor appearance of the product caused by adhesive drawing.

Owner:SHANGHAI CHENXING ELECTRONICS SCI & TECH CO LTD

Environment protection spinning thread wax ring and its producing method

InactiveCN101050596AReduce earth pollutionReduce static electricityFibre treatmentKnittingParaffin waxFiber

The present invention relates to an environment-protecting thread-spinning wax ring and its preparation method, belonging to the field of physical treatment technology of fiber and threads. It is made up by using (by wt%) 0.1%-99.9% of plant wax, 0.1%-99.9% of paraffin wax and 0%-99.8% of vegetable oil through the processes of mixing, heating and moulding. Its heating temperature is 60-110 deg.C.

Owner:杨建

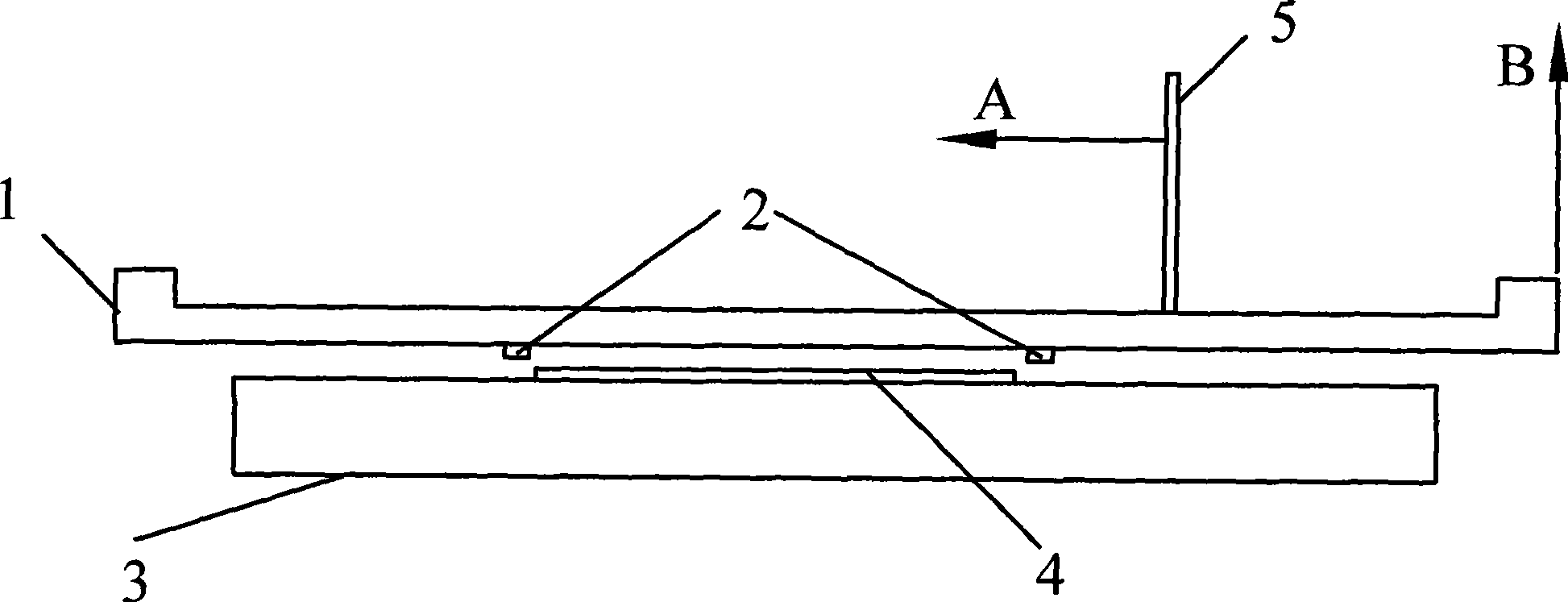

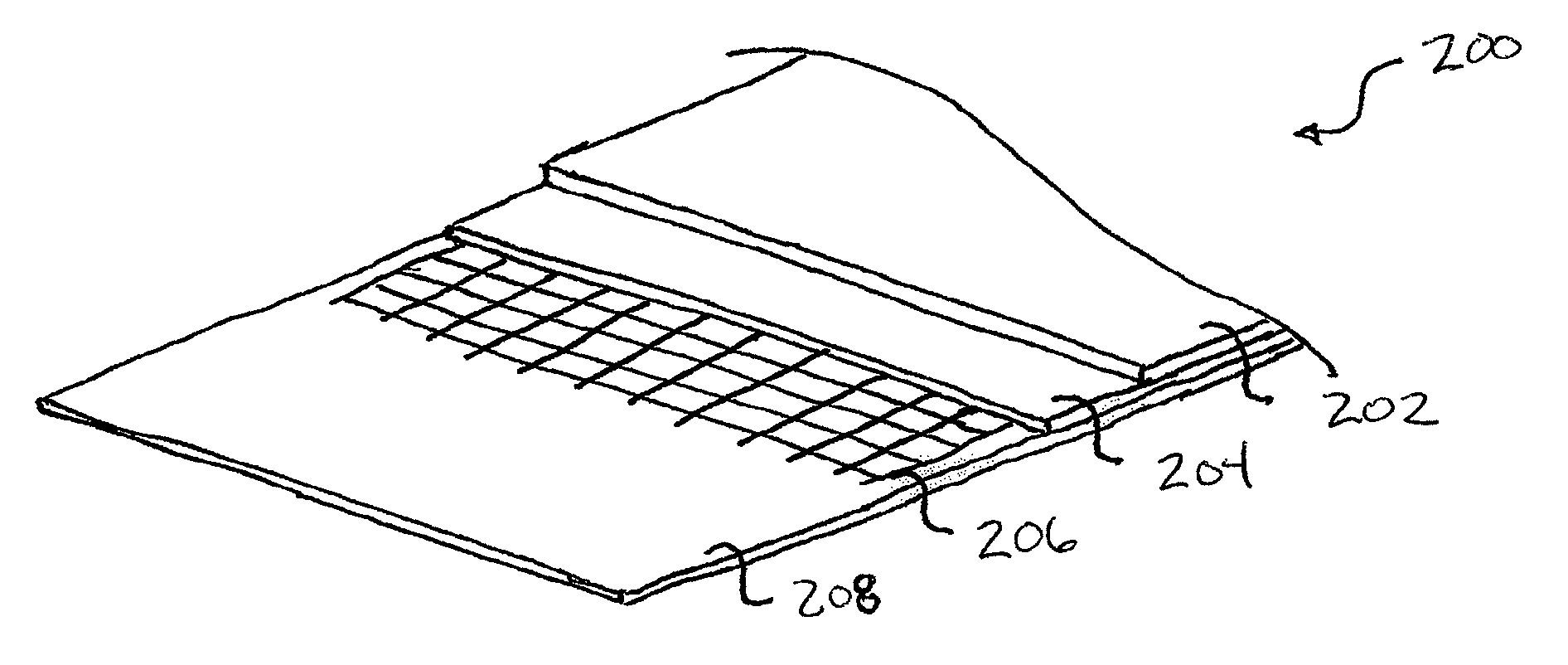

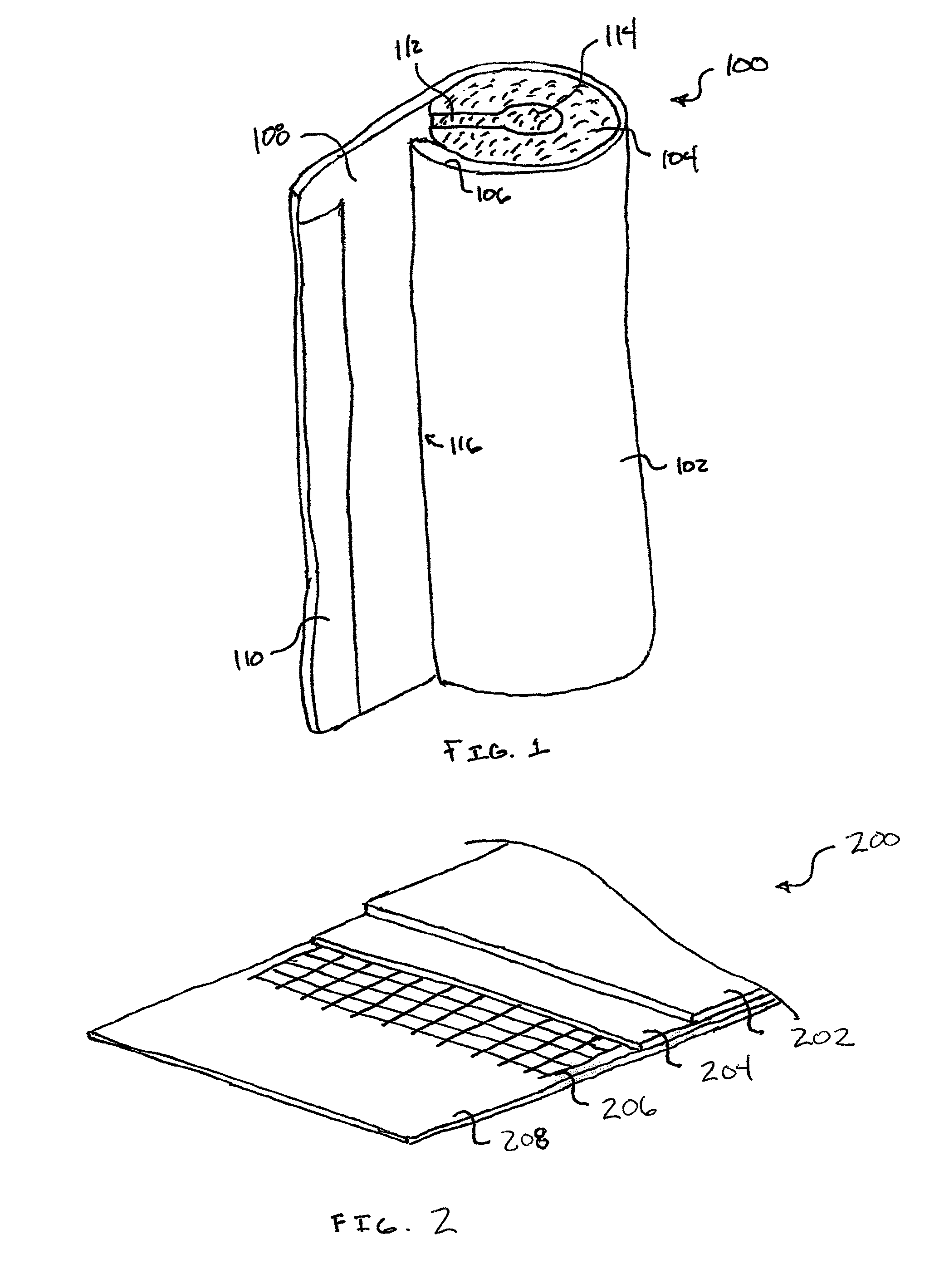

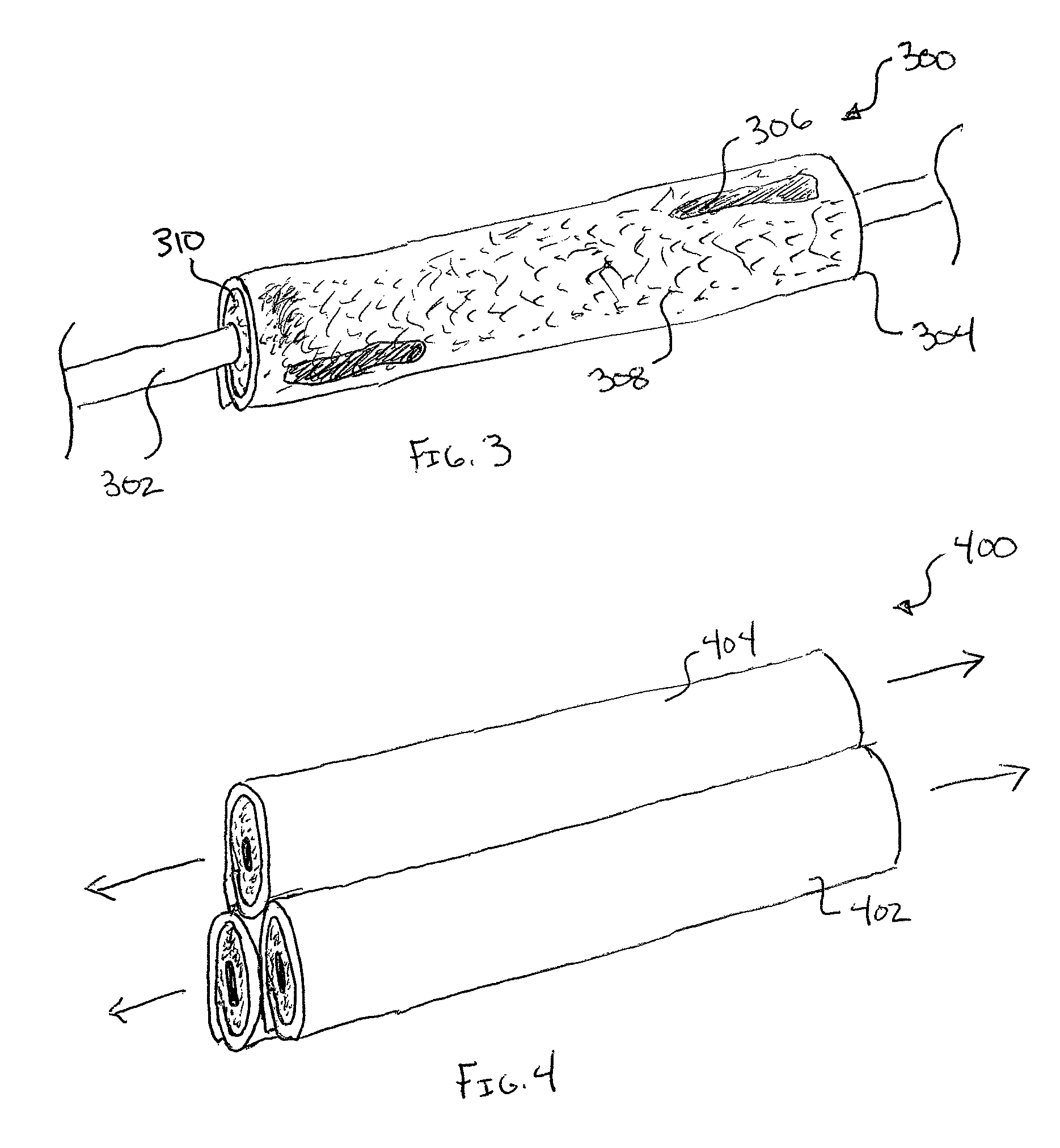

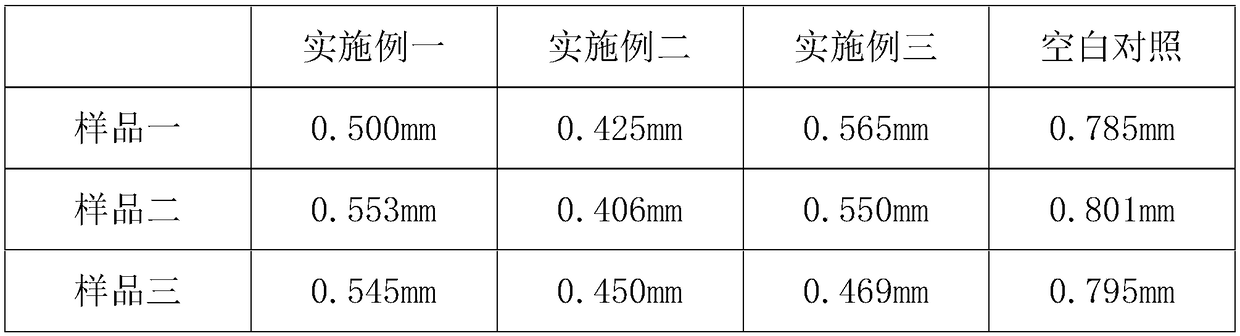

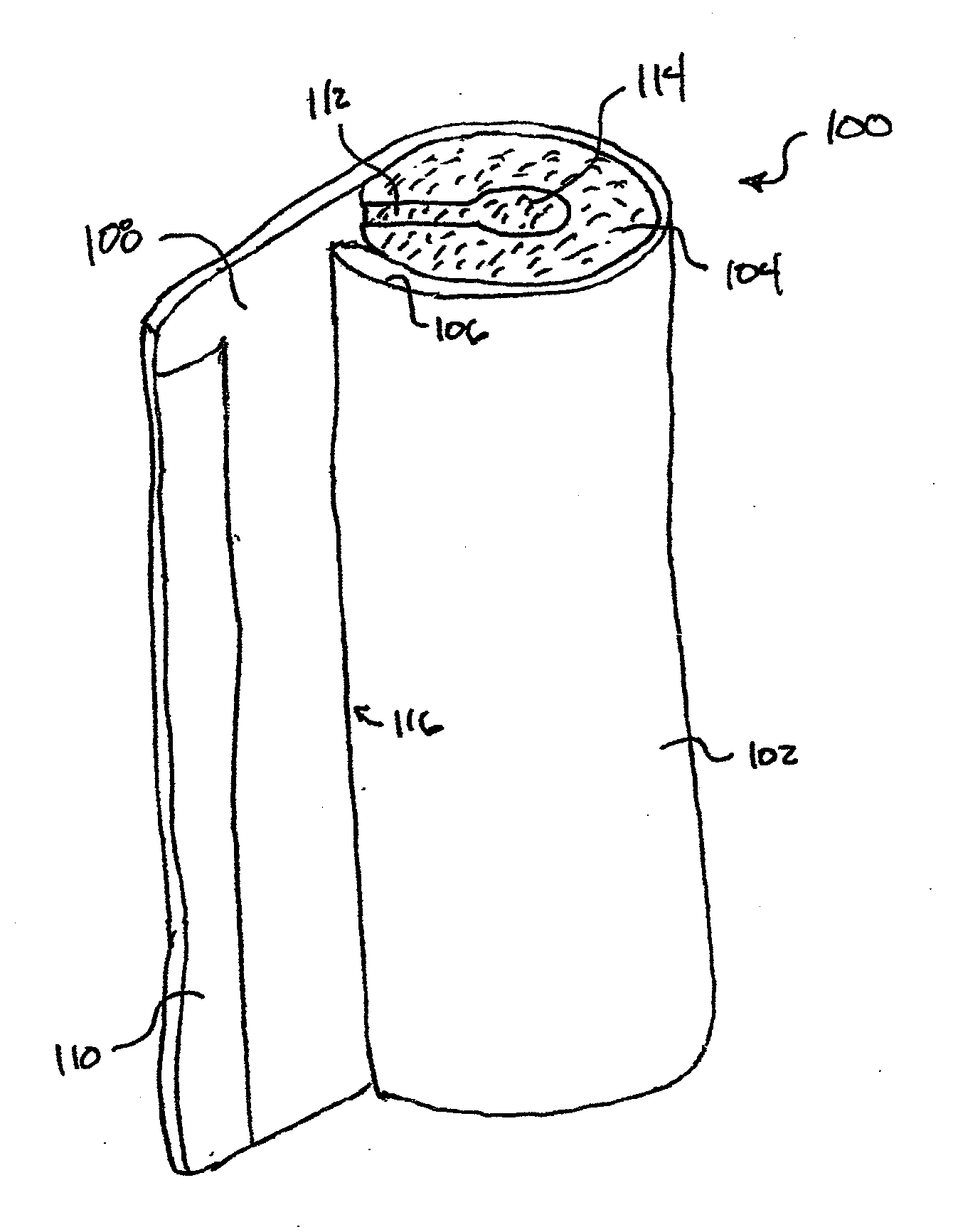

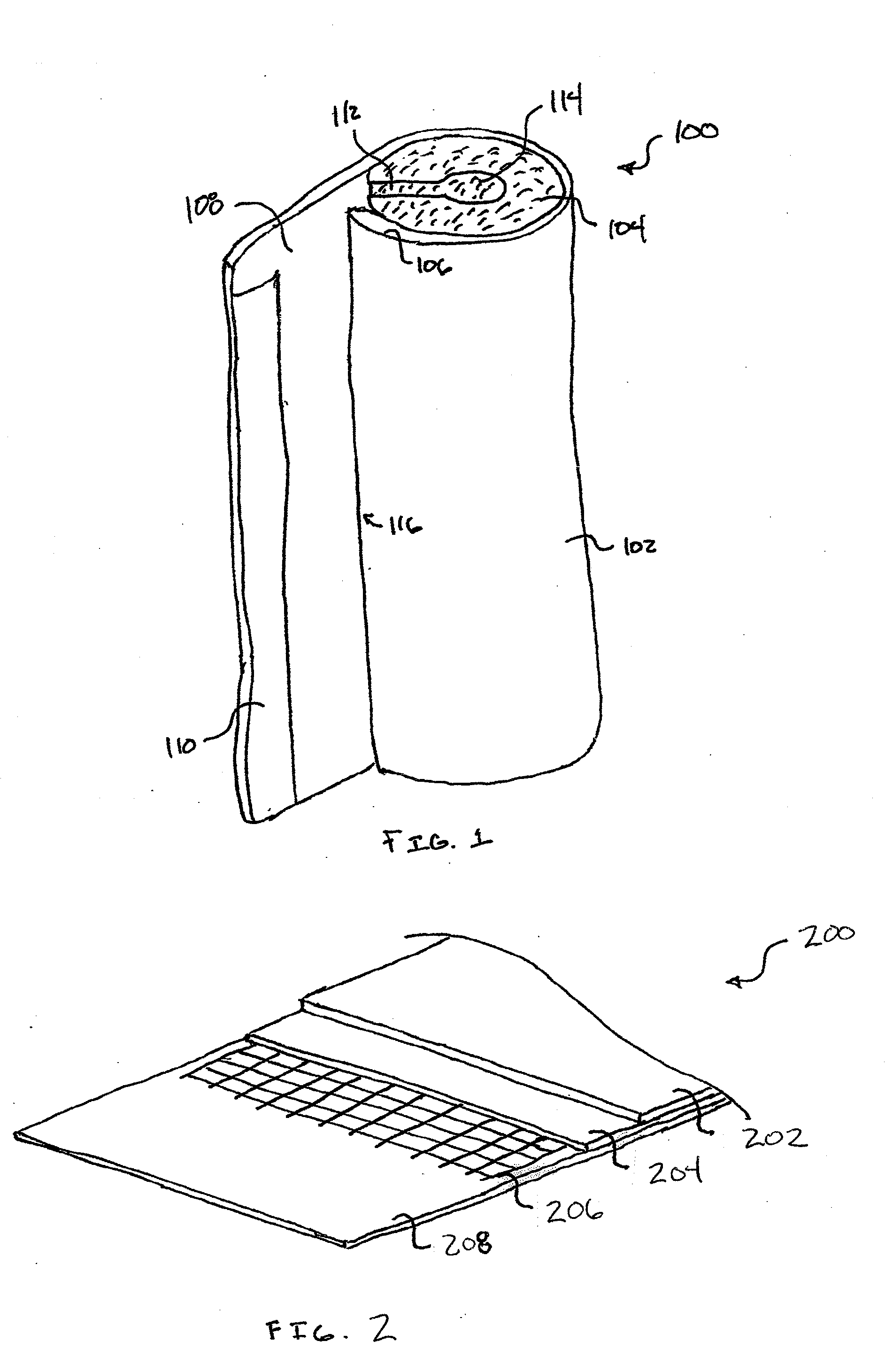

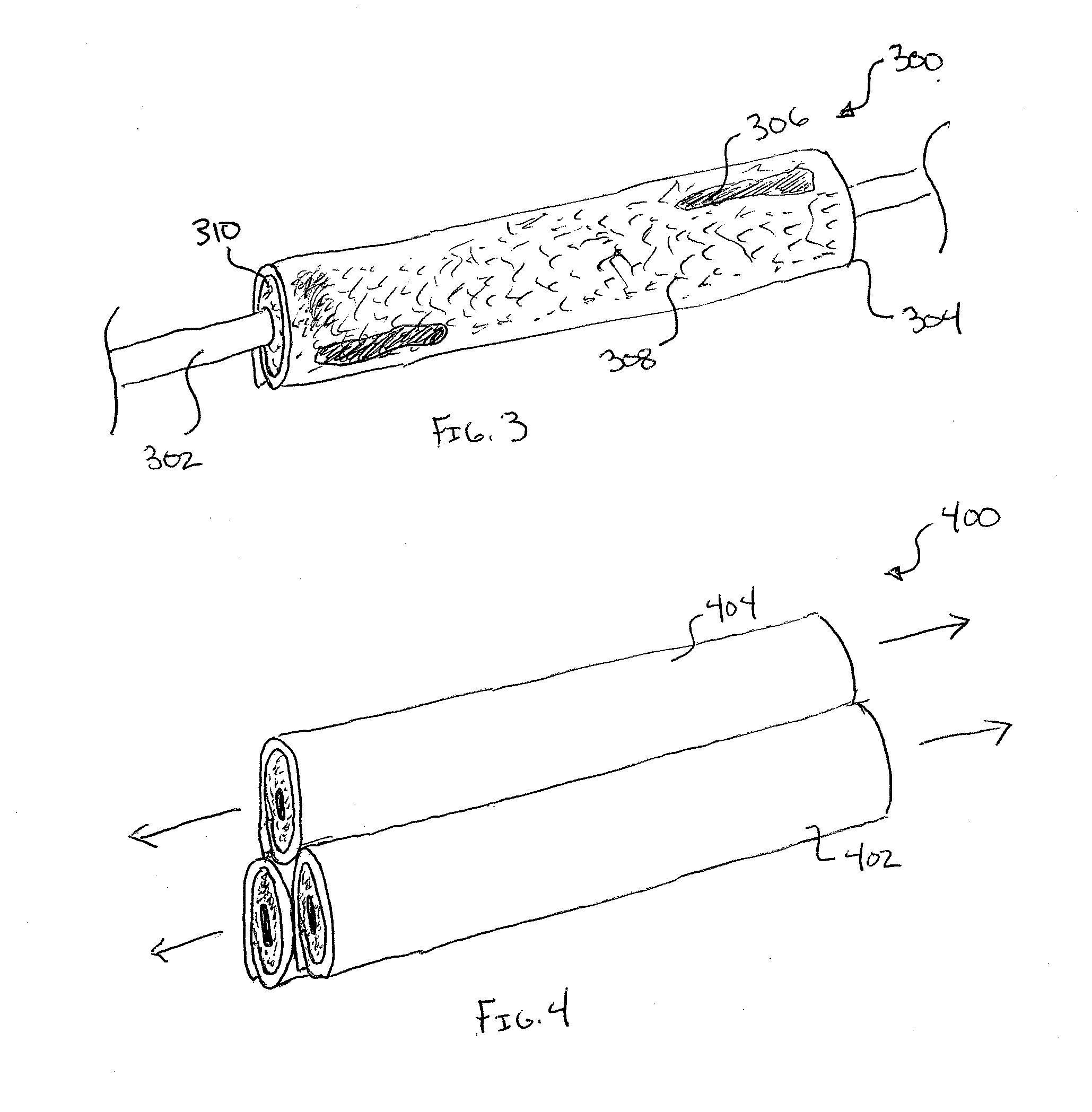

Pipe insulation product with charge dissipater

ActiveUS8104519B1Reduce the generation of static electricityImprove the immunityPipe protection by thermal insulationGlass/slag layered productsPorous mediumPolymer thin films

A pipe insulation product including a core of insulating material and a roughly rectangular laminate. The core may include an outer surface; an inner surface; and a wall extending between the outer and inner surfaces. The laminate may include a foil or metallized polymeric film sheet layer, a scrim, a porous media sheet layer, and a polymeric film sheet layer bonded together via an adhesive. The polymeric film sheet layer may also include a closure flap that adhesively couples opposite ends of the laminate together to form a cylindrical tube with the core enclosed therein. A charge dissipator may be applied to the polymeric film sheet layer in an amount sufficient to reduce generation of a static charge on the laminate's exterior surface without affecting the closure flap's ability to adhesively couple the opposite ends of the laminate.

Owner:JOHNS MANVILLE CORP

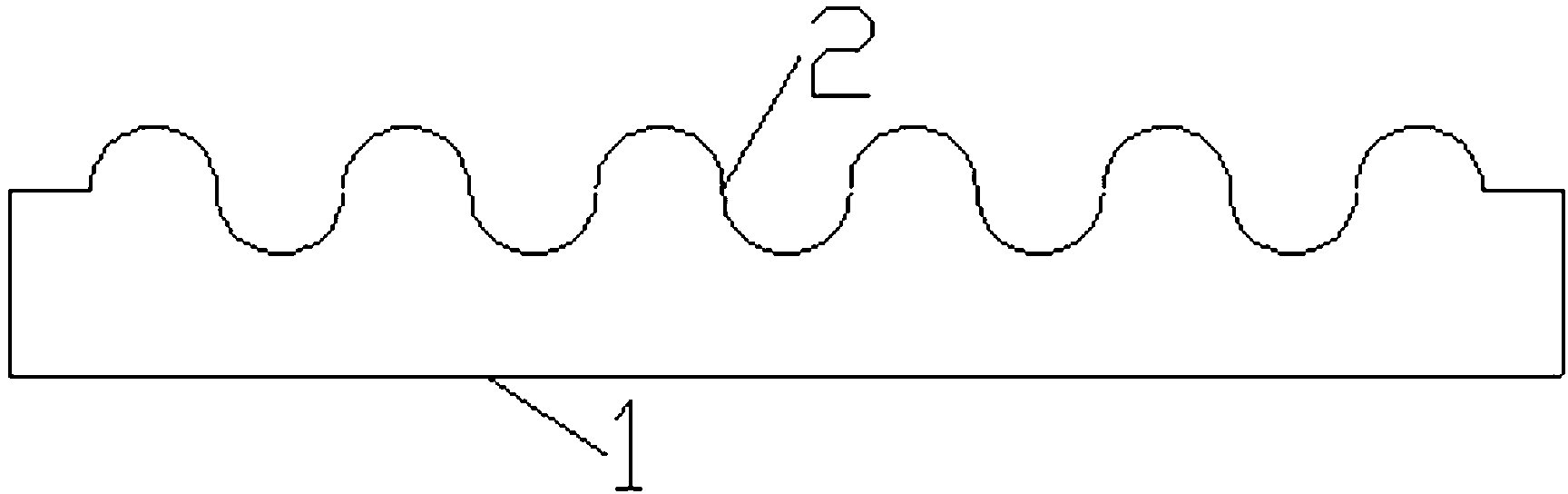

Preparation method of base material for foam tape

InactiveCN109504299AAffecting the beauty is the quality of useImprove aestheticsFilm/foil adhesivesAntistatic agentViscosity

The invention discloses a preparation method of a base material for a foam tape, and relates to the technical fields of the production and the processing of foam tapes. The preparation method comprises the following steps of putting raw materials of the base material for the foam tape into a mixing mill, mixing, and carrying out granulation processing at a certain temperature, so that a master batch of the base material is made; adding an antistatic agent into water to obtain a solution and adjusting a mass fraction to be 0.5% to 2% by utilizing water; adding the solution into a spraying device, carrying out spraying treatment on an environment of an extrusion forming procedure, then feeding the master batch of the base material into an extrusion forming device, and forming a sheet material through uniform-speed extrusion forming; soaking the sheet material into the solution, then taking out and oven-drying; pressing one surface of the oven-dried sheet material by utilizing a pressingdevice, so that the sheet material with a pattern on the surface is formed; and coating high-viscosity acrylic glue on the other surface of the sheet material with the pattern on the surface, and thencollecting and coiling the sheet material together with release paper. The preparation method can reduce the generation of static in the production process of a foam base material; and the adhesion of dust due to the existence of the static is effectively avoided.

Owner:江苏朗臣新材料科技有限公司

Antistatic anti-aging polyimide explosion-proof membrane

InactiveCN112745520AImprove antistatic performanceImprove aging resistanceOrganic compound preparationPolyurea/polyurethane coatingsImidePolymer science

The invention belongs to the technical field of explosion-proof membranes, and particularly relates to an antistatic anti-aging polyimide explosion-proof membrane which comprises a polyimide layer and a hardened layer. The hardened layer is prepared from the following components in parts by weight: 80 to 100 parts of high-functionality polyurethane acrylate, 15 to 25 parts of an antistatic flexible anti-aging agent, 10 to 20 parts of a reactive diluent, 1 to 3 parts of a photoinitiator, 10 to 20 parts of nanoparticles, 0.05 to 1 part of an anti-fingerprint agent and 80 to 150 parts of a solvent. According to the explosion-proof membrane, the hardened layer is coated on the polyimide layer; polyimide is good in foldability but not good in hardness, and high-functionality polyurethane acrylate in the hardened layer can effectively improve the hardness and abrasion resistance of the hardened layer; and the antistatic flexible anti-aging agent not only can ensure that the hardened layer can be well bent along with the polyimide layer, but also can improve the antistatic performance and aging resistance of the anti-explosion membrane, so that the explosion-proof membrane is high in hardness and foldability, can effectively reduce static electricity generated in the production and use process, and is long in service life.

Owner:苏州欧纳克纳米科技有限公司

Lens cylindrical strip storing box

InactiveCN102837869AEasy to classifyEasy to countTray containersDamagable goods packagingEngineeringMechanical engineering

The invention relates to a lens cylindrical strip storing box, which comprises a base, wherein the base is provided with multiple rows of spacing grooves for storing lens cylindrical strips; and the spacing grooves are arc-shaped. The base is provided with the multiple rows of spacing grooves for storing the lens cylindrical strips, one type of lens is placed into every box, even every groove, so that convenience is brought to classification and counting of lenses, and mutual collision and friction among lens columns are reduced; and the spacing grooves are arc-shaped, and particularly the bottoms of the spacing grooves are semicircular, so that the contact area between a lens column and the box is larger, the placing stability is enhanced, collision among the lens columns is avoided, static electricity is reduced, and the product cleanliness is enhanced.

Owner:HUBEI W OLF PHOTOELECTRIC TECH CO LTD

Textile slipping agent and preparation method thereof

The invention discloses a textile slipping agent and a preparation method thereof and belongs to the field of textile materials. Silicone oil base prepared herein endows the textile slipping agent with better slipping resistance, and can permeate fibers to provide better bonding for the fibers, thereby improving toughness of the fibers and improving mechanical properties of the fibers; a wetting modifier prepared herein can protect the fibers, hydrophilic groups in the wetting modifier enable the textile slipping agent to self-emulsify in water, it is rare that demulsification and floating oilcause refractory silicone oil spots on a fabric, binding with water is good, and layering rarely occurs; auxiliary additives help achieved good electrolyte stability; cationic additives can bind withnegative charge on the surface of the fibers to balance the surface charge, so that less static electricity is generated, the textile slipping agent can attach and serve well, and service performanceis improved. The problems that existing slipping agents easily experience demulsifying and floating oil and easily form refractory silicone oil spots, and toughness is insufficient are solved.

Owner:常州市雄泰纺织品有限公司

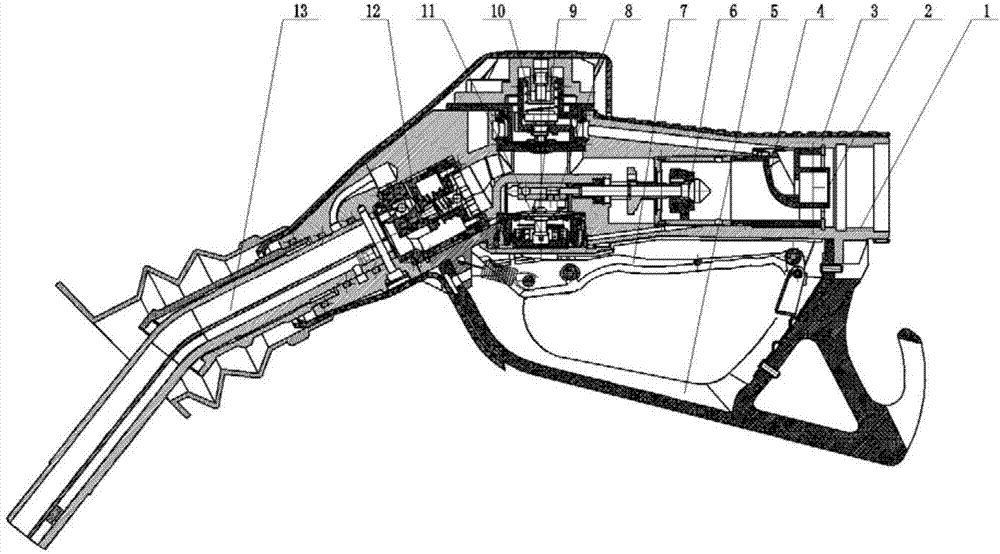

Oil and gas recovery oil filling gun with non-pressure self-sealing function and oil filling method thereof

InactiveCN104743492ANice appearanceGood installation compatibilityLiquid transferring devicesFuel oilRecovery stage

The invention relates to an oil and gas recovery oil filling gun with a non-pressure self-sealing function and an oil filling method thereof. The oil and gas recovery oil filling gun comprises a connecting thread, a gas path connector, a gun body, an oil and gas separator, a handle sleeve, a valve, a trigger, a roller pin, a diaphragm, a gas adjusting device, a non-pressure self-sealing device, a one-way valve and an oil outlet pipe. According to the technical scheme, the oil and gas recovery oil filling gun can be applied to the secondary oil and gas recovery stage, has the non-pressure self-sealing function and is suitable for a self-help oil filling machine; the oil filling gun can seal an oil path automatically after the oil filling machine is completely stopped, and therefore the situation that because the oil filling gun is not self-sealed after the last time of oil filling, fuel oil leaks in the process of secondary oil filling and danger is caused will not occur; the one-way valve arranged in the oil filling gun can be synchronously opened in the process of oil filling and can be completely closed after the oil filling gun is self-sealed, and therefore oil dripping occurring after the oil filling gun is self-sealed can be effectively prevented.

Owner:LUOYANG PRIMEMAN AUTOMATIC CONTROL TECH

Environmentally friendly, safe and economical fireworks material and application thereof

InactiveCN109211028APromote environmental protectionImprove antistatic performanceFireworksSilicon dioxideTitanium oxide

The invention discloses an environmentally friendly, safe and economical fireworks material and an application thereof, and belongs to the technical field of fireworks material development. The raw material components of the environmentally friendly, safe and economical fireworks material include silica, alumina, iron oxide, magnesium oxide, calcium oxide, titanium oxide, potassium oxide, phosphorus pentoxide, bamboo vinegar powder, amylase and tourmaline powder. According to the invention, the bamboo vinegar powder, amylose and tourmaline powder are used as reinforcement to improve the environmental protection performance and antistatic performance of the environmentally friendly, safe and economical fireworks material.

Owner:长沙浩然医疗科技有限公司

Anti-static lace fabric

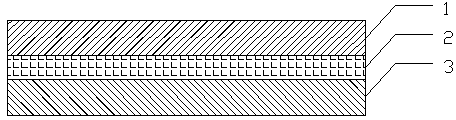

InactiveCN102991005AReduce coefficient of frictionReduce the generation of static electricityLayered productsWoven fabricsElectrostatic dischargeWeft yarn

The invention discloses an anti-static lace fabric. The anti-static lace fabric comprises an anti-static layer, a breathable layer and a lace base layer which are sequentially arranged, wherein the anti-static layer, the breathable layer and the lace base layer are connected through the bonding layers, the anti-static layer is formed by interweaving warp yarns and weft yarns, the warp yarns are composed of cotton yarns, and the weft yarns are composed of conductive fibers, and the breathable layer is compounded of a macromolecule breathable material and a cloth material. The anti-static lace fabric provided by the invention can effectively prevent electrostatic discharge phenomenon, is beneficial to the health of human bodies and simple in structure and is a novel healthy and environment-friendly fabric.

Owner:尹磊

Optical lens assembly storage box

InactiveCN102837900AConvenient classificationReduce collisionDamagable goods packagingPhysicsEngineering

The invention relates to an optical lens assembly storage box, which comprises a base, wherein multiple rows of separation slots for storing lens cylindrical bars are arranged on the base, and are respectively in an arc shape. According to the optical lens assembly, the multiple rows of separation slots for storing the lens cylindrical bars are arranged on the base, and one kind of lens is put in each box and even each slot, so that the lenses can be classified and counted conveniently, and the mutual collision and friction of the lens bars can be reduced; and the separation slots are in arc shapes, especially a bottom part of each separation slot is in a semi-circular shape, so that the contact area of the lens bars and the box is bigger, the placement is stabler, mutual collision between the lens bars is not easy to occur, the generation of the static electricity is reduced, and the cleanliness of a product is improved.

Owner:HUBEI W OLF PHOTOELECTRIC TECH CO LTD

Liquid laundry detergent for infants and preparation method thereof

ActiveCN103710167BStrong emulsificationEfficient removalNon-ionic surface-active compoundsOrganic detergent compounding agentsFiberFatty alcohol

The invention relates to the technical field of liquid laundry detergents and in particular relates to a liquid laundry detergent for infants and a preparation method thereof. The liquid laundry detergent mainly comprises an amino acid based surfactant, amine oxide, coconut oil fatty acid diethanol amide, alkyl glycoside and sodium fatty alcohol sulfate. The liquid laundry detergent is prepared by mixing and dissolving the components and carrying out other steps. By mutually matching the components disclosed in the invention and the ratios of the components, a mild and skin-friendly protective film is formed on the fabric fiber surfaces of the clothes which are washed with the liquid laundry detergent and dried, thus the friction between fabric fibers can be reduced, and the formed protective film is combined with the moisture in the air, so that the clothes have certain wettability, the static electricity can be reduced and the washed clothes are softer and smoother; therefore the prepared liquid laundry detergent enables the clothes washed with the liquid laundry detergent to have good softness, has good affinity with infant skins and can effectively wash off the stubborn stains on the clothes of the infants.

Owner:WALCH GUANGZHOU COMMODITY

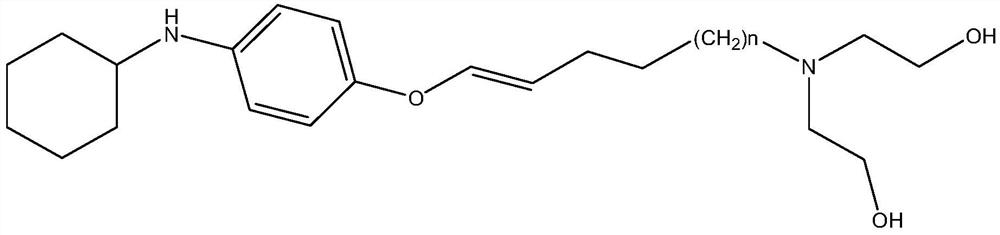

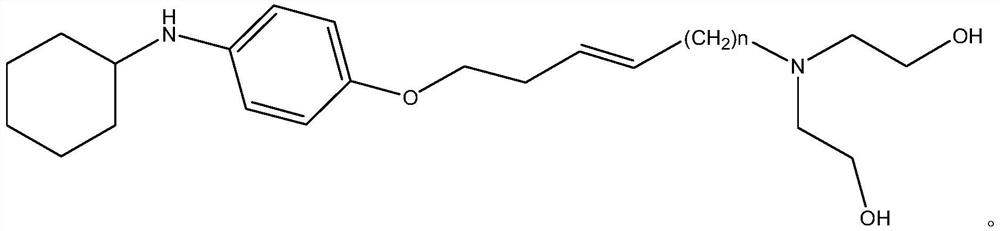

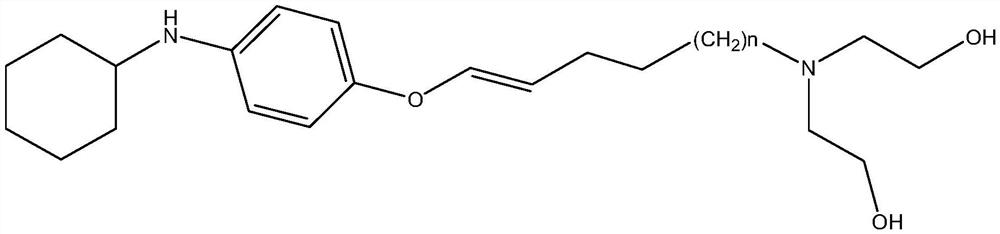

Antistatic finishing agent for wool fabric and preparation method thereof

InactiveCN108951163AReduce static electricityImprove antistatic performanceAnimal fibresChemistryDiphenyl ether

The invention discloses an antistatic finishing agent for a wool fabric and a preparation method thereof, the preparation method comprises the following steps: taking a polyurethane emulsion, heatingup to 80 to 90 DEG C, dropwise adding a pre-emulsion and an initiator into the polyurethane emulsion, continuing reflux and heat preservation reaction for 2-3h after the completion of the dropwise addition of the pre-emulsion and the initiator, adding citric acid to adjust the pH to 3-4, adding polyethylene glycol-200, stirring for reaction for 1-2h, adjusting to neutral, adding water to dilute, sieving, adding dodecyl diphenyl ether disulfonate ammonia, stirring and mixing uniformly, then cooling to room temperature, and removing air bubbles to obtain the antistatic finishing agent for the wool fabric. The wool fabric after being finished by the antistatic finishing agent has good antistatic property, is easy to process, reduces static electricity generation during use, has good water washing and abrasion resistance, and has a long service life.

Owner:SUZHOU INSILK CO LTD

Pipe insulation product with charge dissipater

ActiveUS20120037256A1Reduce staticImprove the immunityPipe protection by thermal insulationPreformed elementsPorous mediumEngineering

A pipe insulation product including a core of insulating material and a roughly rectangular laminate. The core may include an outer surface; an inner surface; and a wall extending between the outer and inner surfaces. The laminate may include a foil or metallized polymeric film sheet layer, a scrim, a porous media sheet layer, and a polymeric film sheet layer bonded together via an adhesive. The polymeric film sheet layer may also include a closure flap that adhesively couples opposite ends of the laminate together to form a cylindrical tube with the core enclosed therein. A charge dissipator may be applied to the polymeric film sheet layer in an amount sufficient to reduce generation of a static charge on the laminate's exterior surface without affecting the closure flap's ability to adhesively couple the opposite ends of the laminate.

Owner:JOHNS MANVILLE CORP

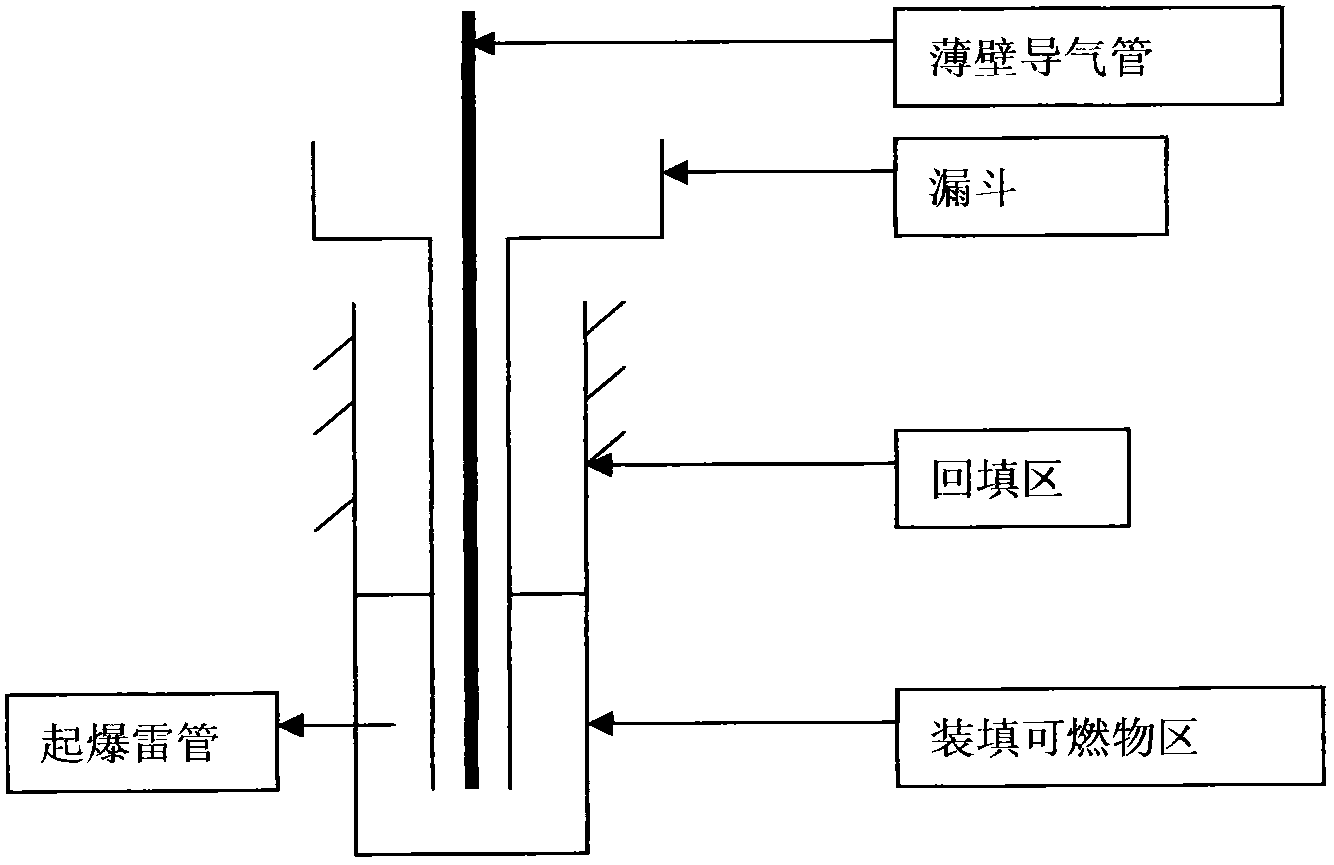

Method for preparing liquid oxygen explosive

InactiveCN103193558AEfficient exclusionEasy to primeExplosive working-up apparatusDetonatorEngineering

The invention discloses a method for preparing a liquid oxygen explosive, belonging to a method for preparing or treating an explosive composition. The method comprises the following steps of: (1) vertically placing a funnel at the center of a pressure container, and forming a hole in a part where a funnel pipe is in contact with a combustible material, wherein the hole passes through the wall of the funnel pipe, and the lower part of the funnel is sealed; (2) arranging a primer detonator in a combustible material filling region in the pressure container; (3) pouring the combustible material into the container, charging powder, and backfilling a blast hole after the powder charging operation is finished; (4) inserting a thin-wall gas guide tube into the funnel, pouring liquid oxygen into the funnel, and pulling out the thin-wall gas guide tube and the funnel after the liquid oxygen filling operation is finished, wherein the side of the bottom of the thin-wall gas guide tube is provided with a plurality of small holes; and (5) filling a gap generated by the funnel to be solid again to obtain the liquid oxygen explosive. The method disclosed by the invention has the advantages that gaseous oxygen accumulated at the bottom can be effectively discharged, so that liquid oxygen can be favorably filled and can not be wasted; and the static electricity generating probability, namely the accidental explosion probability, is reduced, so that the preparation safety is ensured.

Owner:乔新明

Manufacturing method of low-smoke, low-toxicity and antistatic hook-and-loop fastener

InactiveCN111920146AImprove flame retardant performanceReduce security risksFireproof paintsPolyurea/polyurethane coatingsChemistryFlame resistance

The invention provides a manufacturing method of a low-smoke, low-toxicity and antistatic hook-and-loop fastener. The manufacturing method comprises the following specific steps of: firstly, putting anylon hook-and-loop fastener into a dip dyeing machine for cleaning; dyeing the nylon hook-and-loop fastener; dehydrating the nylon hook-and-loop fastener; respectively dipping a hook surface hook-and-loop fastener and a loop surface hook-and-loop fastener; drying the nylon hook-and-loop fastener; coating the hook-and-loop fastener with an antistatic flame-retardant coating adhesive; drying the nylon hook-and-loop fastener; and finishing the nylon hook-and-loop fastener in a gluing machine by using a hot melt adhesive containing a halogen-free flame retardant. The flame retardant performanceof the hook-and-loop fastener is improved through flame retardant finishing agent dipping, coating by an antistatic flame-retardant coating and finishing by the hot melt adhesive containing the halogen-free flame retardant, the added flame retardant finishing agent, antistatic flame-retardant coating and halogen-free flame retardant are all low-smoke and low-toxicity components, and potential safety hazards during combustion are reduced; and meanwhile, the antistatic flame-retardant coating can reduce static electricity generation, accelerate static electricity dissipation and reduce the electrostatic effect, so that the antistatic flame-retardant coating is suitable for flammable and combustible environments.

Owner:天津兴华织造有限公司

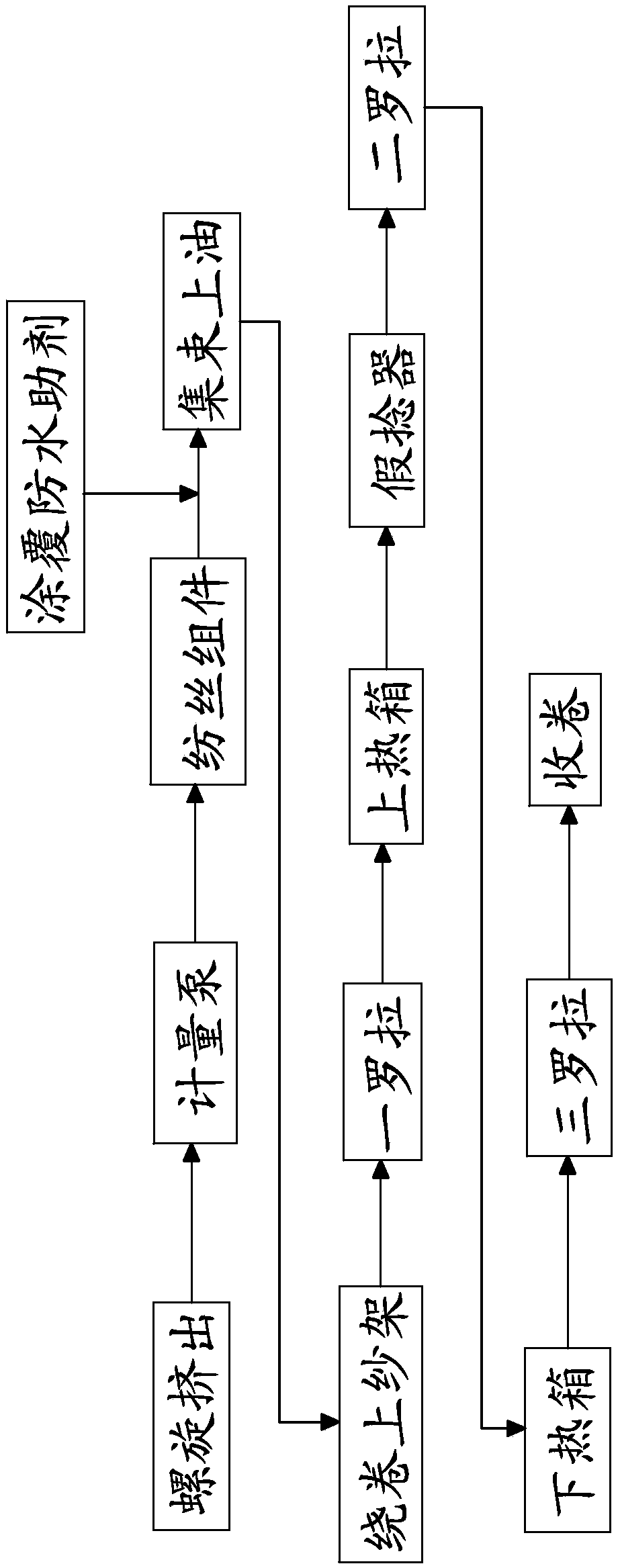

Manufacturing method of three-proofing fibers

ActiveCN109457307AReduce static electricitySimple processArtificial filament heat treatmentMelt spinning methodsMelt spinningCoating

The invention relates to a manufacturing method of three-proofing fibers. The manufacturing method includes a melt spinning procedure, a bundling and oiling procedure and a winding forming procedure,all of which are sequentially carried out. The manufacturing method further includes a waterproof agent coating procedure, wherein the waterproof agent coating procedure is set between the melt spinning procedure and the bundling and oiling procedure or in the bundling and oiling procedure. By the adoption of the technical scheme, the surfaces of nascent fibers delivered from the melt spinning procedure are free of impurities, a waterproof agent is easily absorbed, the waterproof agent is uniformly adsorbed, then the nascent fibers are coated with waterproof oil in the bundling and oiling procedure, the surfaces of tows are protected, the friction coefficient of the tows is reduced, the embracing performance of the tows is improved, static is reduced, coating of the waterproof agent is directly added after ingenious melt spinning is completed, the manufacturing method has the beneficial effect of being simple in process, meanwhile, by means of the manufacturing method, the waterproof oil is further protected through the waterproof agent, and the fibers still can have good protection performance after being washed multiple times.

Owner:FUJIAN BAICHUAN RESOURCES RECYCLING TECH

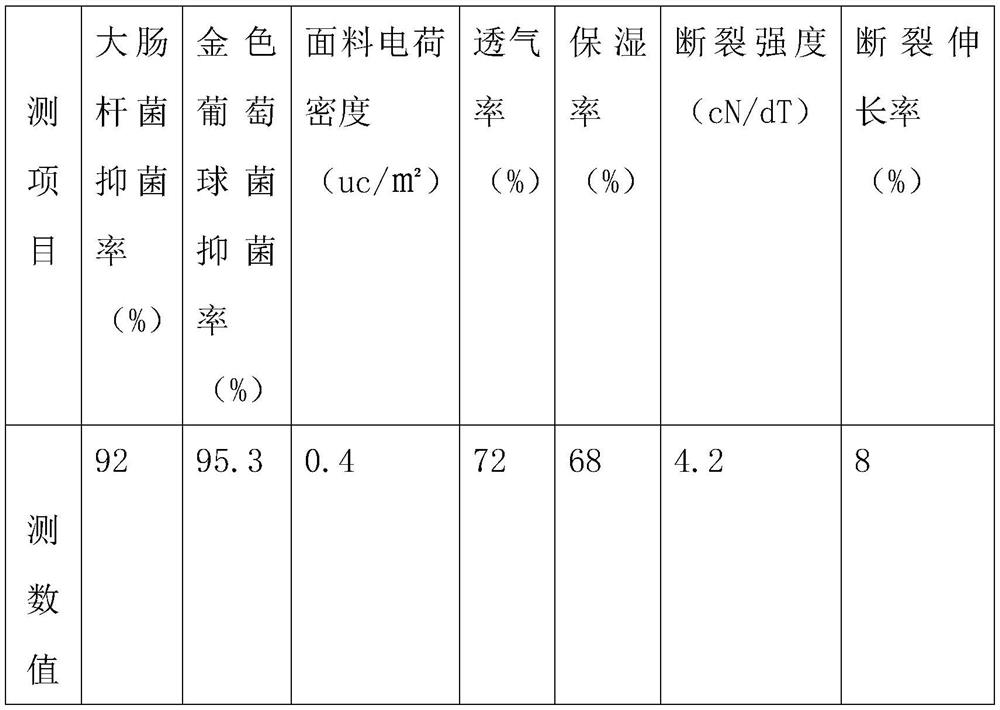

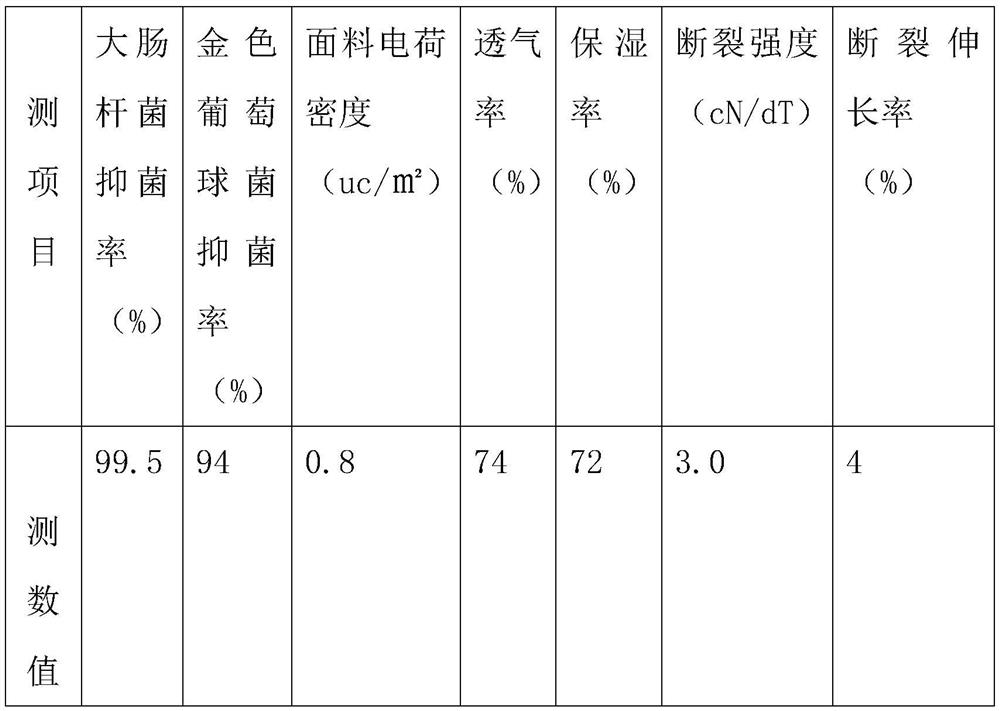

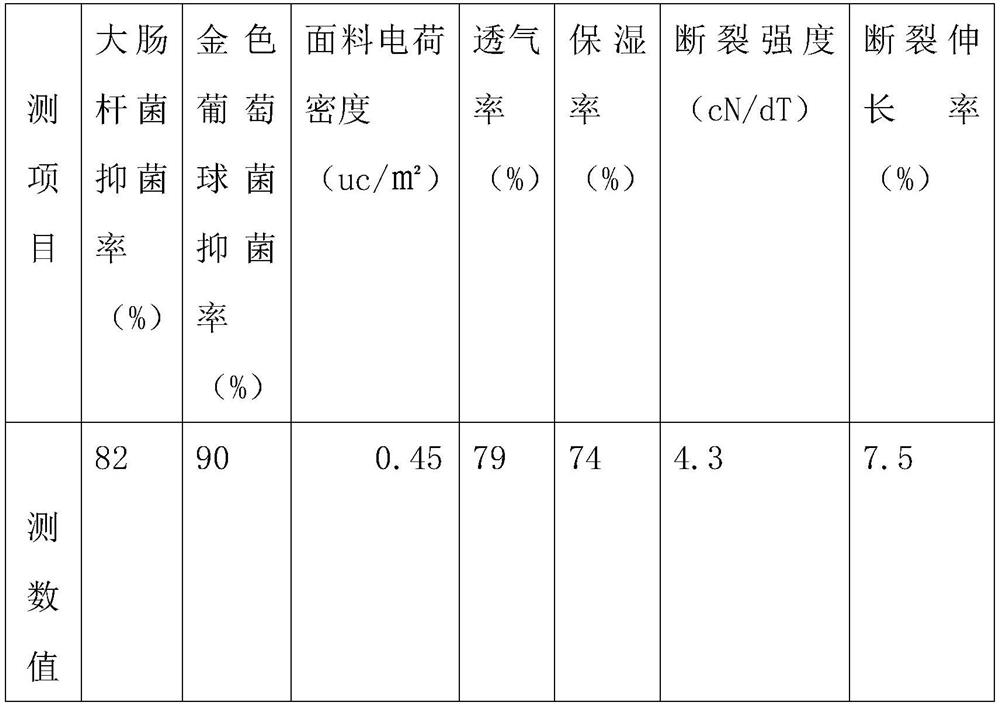

Antibacterial composite fabric and manufacturing process thereof

PendingCN113249958ANon-polluting sterilization methodEfficient sterilization methodPhysical treatmentCarbon fibresMoisture retentionPolyester

The invention discloses an antibacterial composite fabric and a manufacturing process thereof, and belongs to the technical field of textile fabrics. The antibacterial composite fabric comprises a fabric layer and an impregnation liquid; the fabric layer comprises hollow polyester fibers, jade fibers, activated carbon fibers and superfine sea-island fibers; the impregnation liquid comprises a metal inorganic salt solution and an antibacterial zeolite solution, wherein the hollow polyester fibers and the jade fibers are a surface layer and an inner layer of fabric warps respectively; the activated carbon fibers and the superfine sea-island fibers are spirally wound into wefts; the wefts and the warps are intersected to weave an initial fabric; and the impregnation liquid is used for soaking the initial fabric. While effective sterilization and bacteriostasis are guaranteed, the breathability and moisture retention of the fabric are greatly improved, and the safety and comfort of long-term wearing in the later period are guaranteed.

Owner:雷雨新

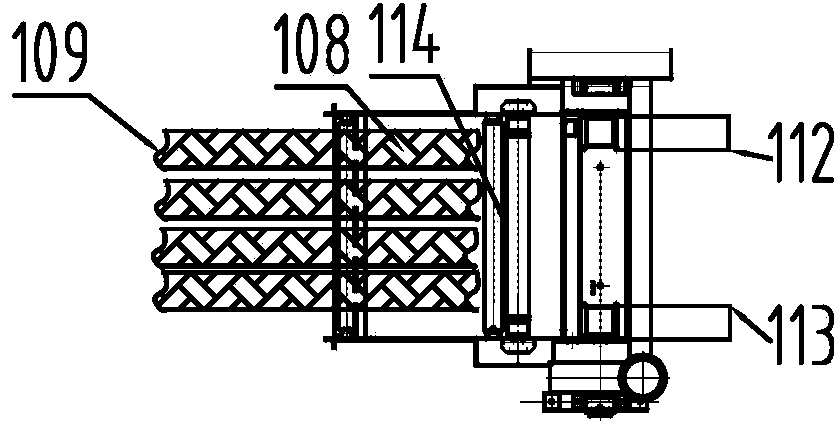

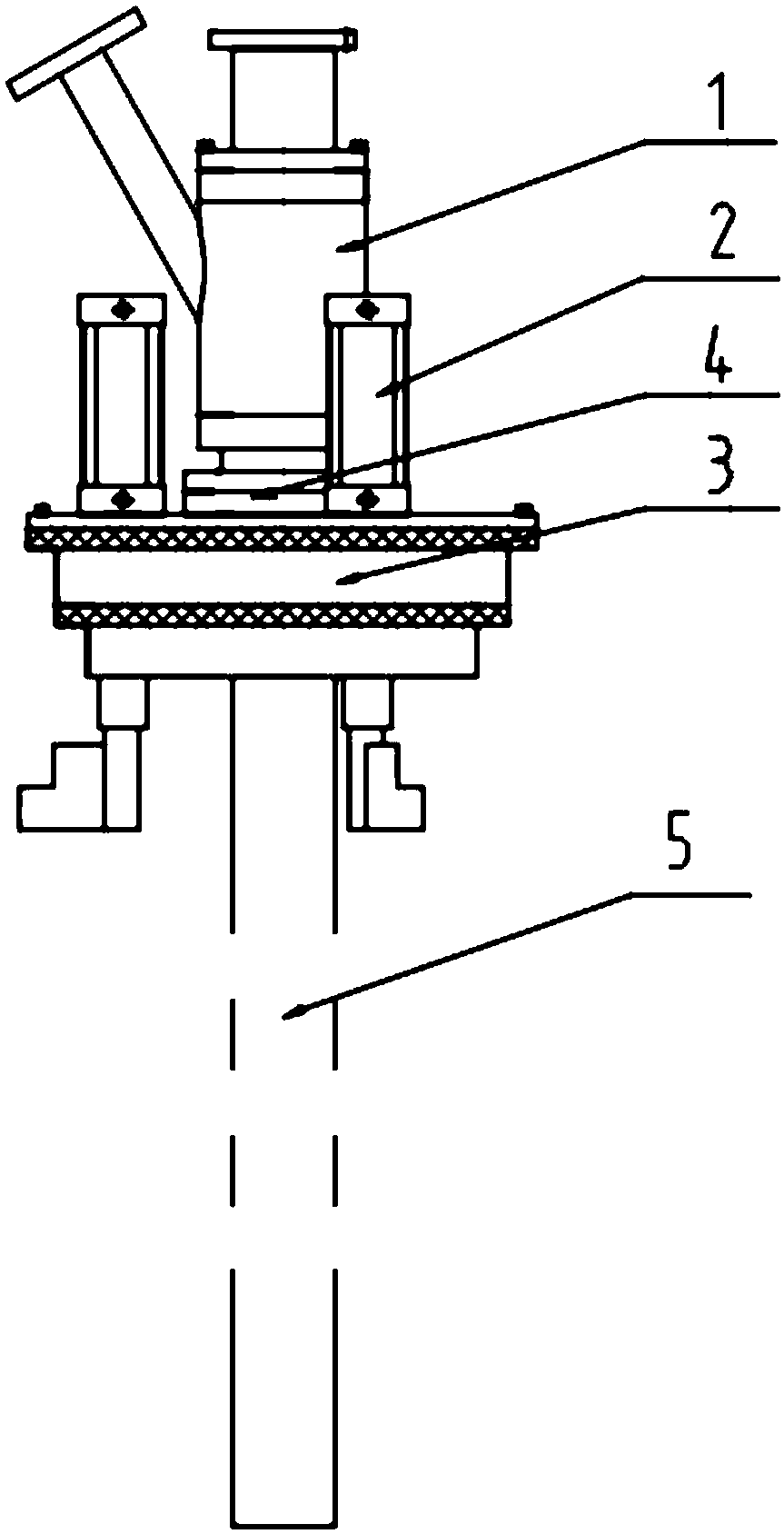

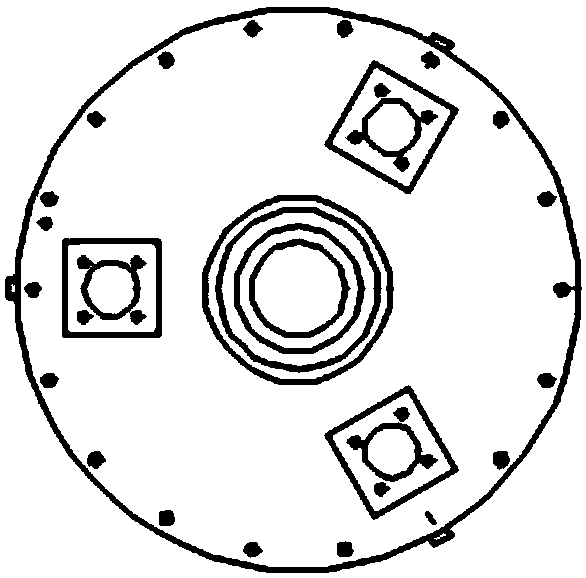

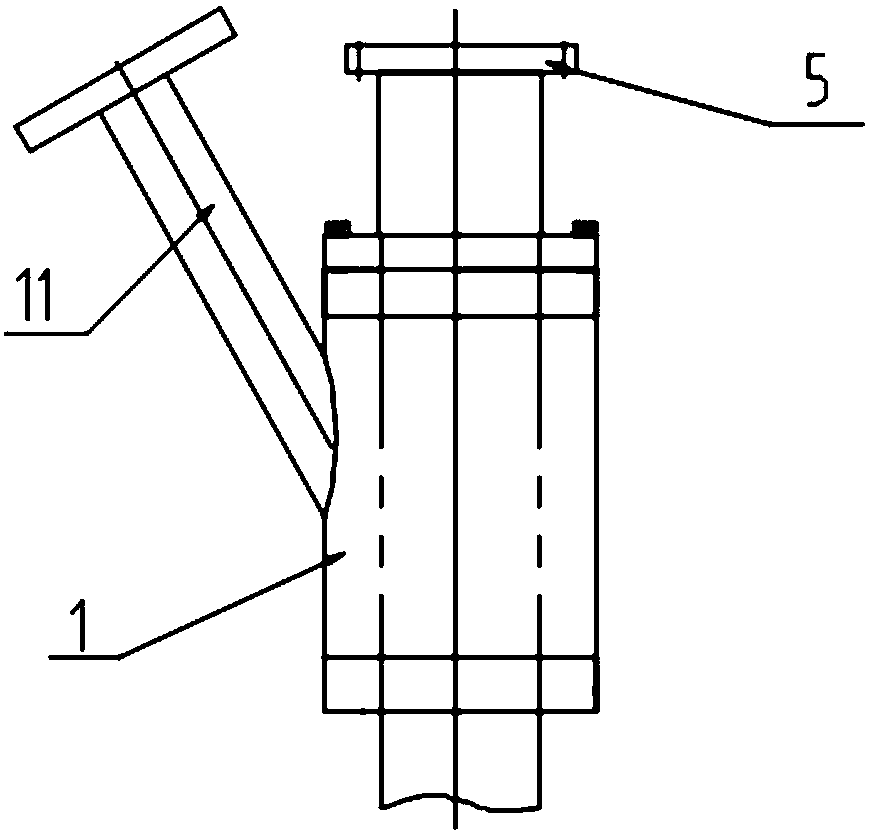

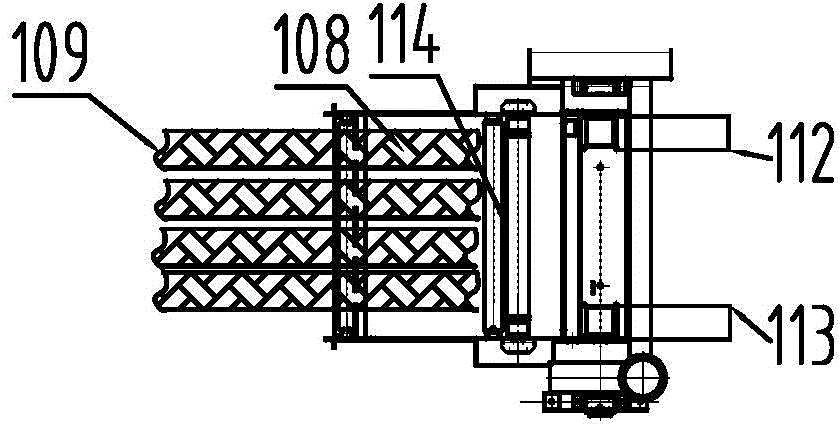

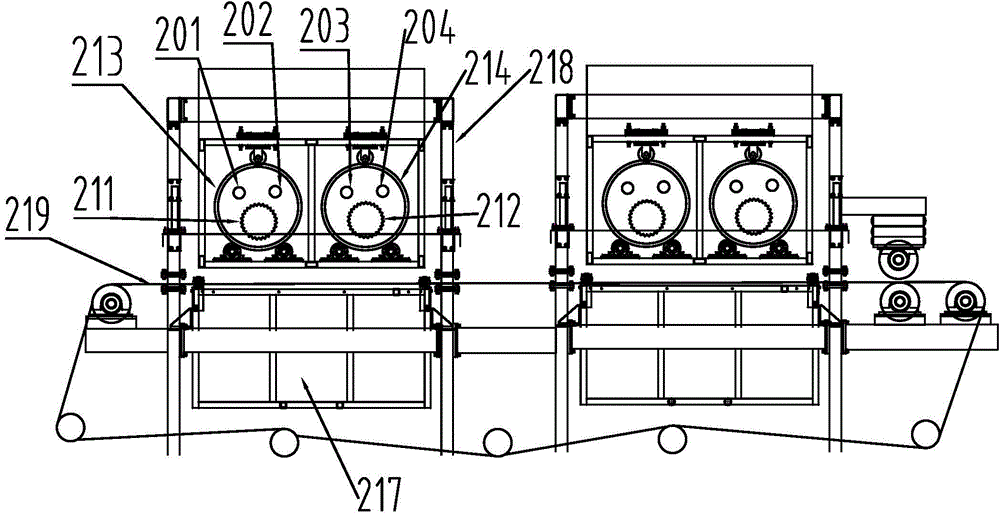

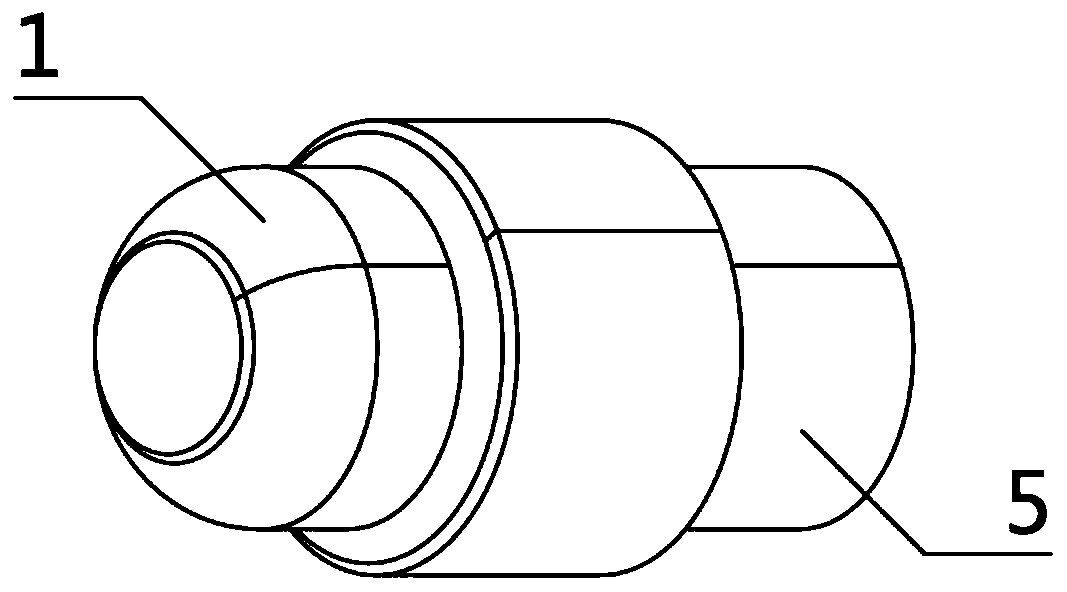

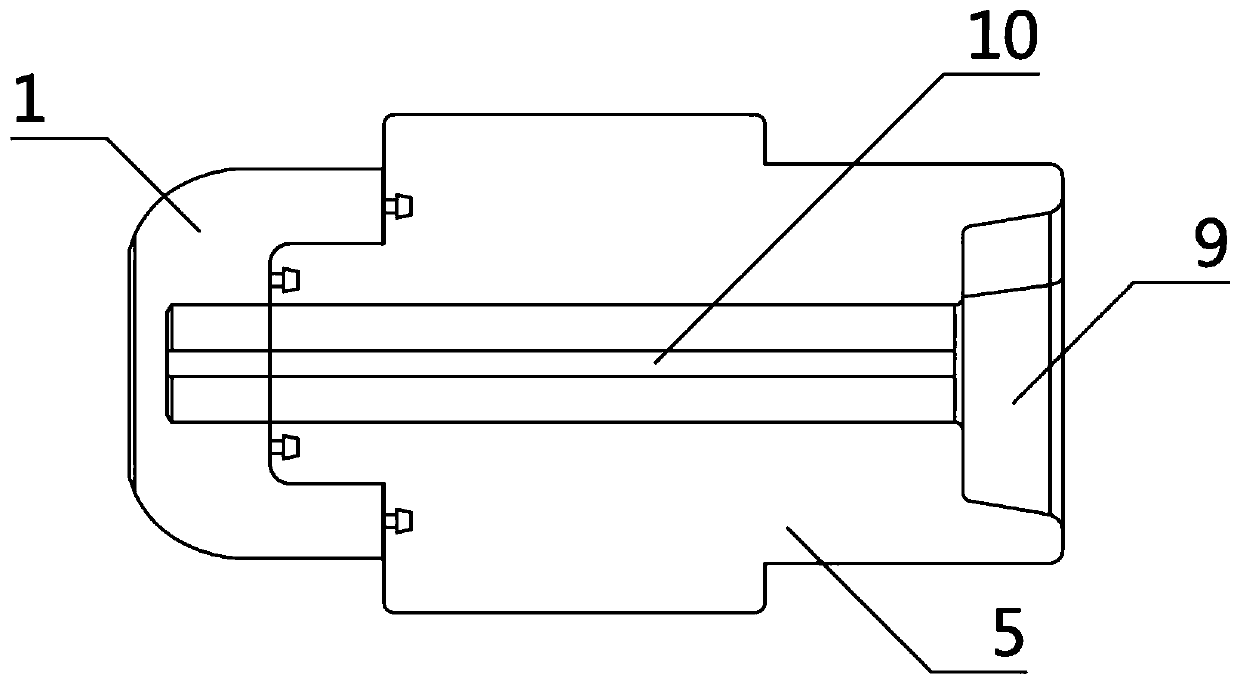

Tail gas collecting and conveying device with pneumatic clamping and joint adjusting

PendingCN108223938ASolve Collection IssuesSolve delivery problemsAdjustable jointsTank truckProduct gas

The invention discloses a tail gas collecting and conveying device with pneumatic clamping and joint adjusting. The tail gas collecting and conveying device with pneumatic clamping and joint adjustingis characterized by comprises a gas conveying cover for sealing a gas, a pneumatic clamping device for clamping a tank port of a tank truck and a gas collecting cover, a gas for fixing a medium conveying pipe, and the gas collecting cover for sealing the gas and supporting a pneumatic clamping device or the joint, wherein the joint is arranged above the middle of the gas collecting cover and fixes the medium conveying pipe onto the as collecting cover; the gas conveying cover is arranged above the joint; and the gas collecting cover is further provided with the pneumatic clamping device. Thetail gas collecting and conveying device with pneumatic clamping and joint adjusting provided by the invention is simple in structure, convenient to maintain, and high in standardization level, and can be used for collecting and conveying the tail gas produced during a truck loading process, so that the safety production by operators is ensured, and the environment is effectively protected; and with the pneumatic clamping device, the effective connection of the tail gas collecting and conveying covers and the tank truck is ensured, and the surface contact of cover bodies and a manhole flange of the tank truck is ensured through three-point stress.

Owner:连云港宏泽机械设备有限公司

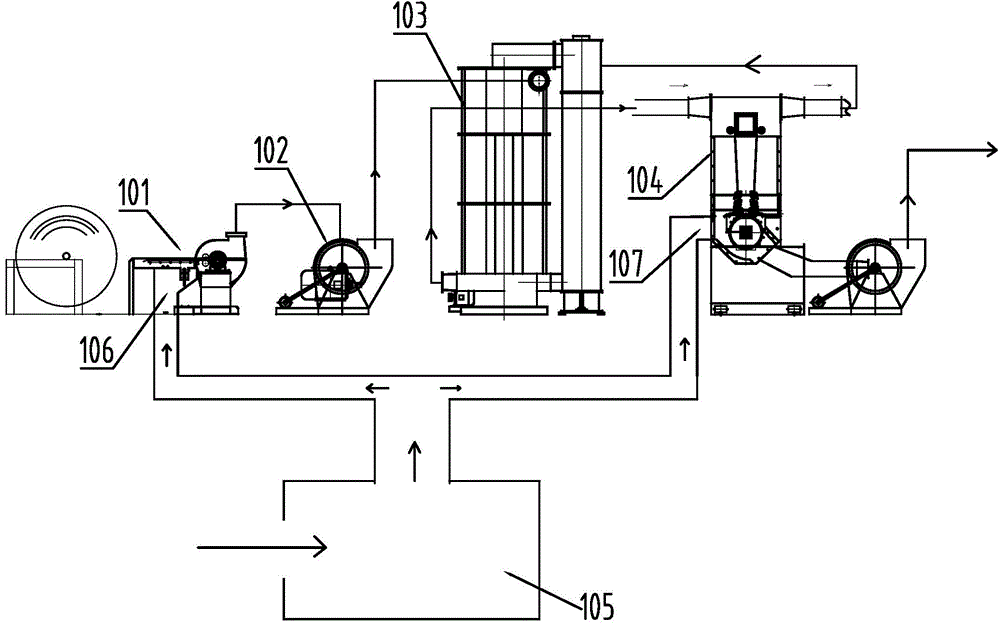

Equipment for producing reconstituted tobacco through dry-method paper making method

The invention relates to equipment for producing reconstituted tobacco through a dry-method paper making method. The equipment comprises a fiber decomposing device, a basal piece forming device, a pulp spraying device and a drying device. The production equipment is provided with various types of material ports and a built-in pipeline humidifying device, and a multi-pipeline feeding mode is adopted to enable the feeding uniformity and controllability to be improved; sprayed pulp contains much tobacco powder, tobacco extracts and adhesives and is large in viscosity; through the equipment, the pulp can be fully dispersed, and the phenomenon that hot air flowing in a drying oven is distributed unevenly to cause the pulp to be partially over-dried can be avoided.

Owner:GUANGDONG GOLDEN LEAF TECHNOLOGY DEVELOPMENT CO LTD

Environment protection spinning thread wax ring and its producing method

The present invention relates to an environment-protecting thread-spinning wax ring and its preparation method, belonging to the field of physical treatment technology of fiber and threads. It is made up by using (by wt%) 0.1%-99.9% of plant wax, 0.1%-99.9% of paraffin wax and 0%-99.8% of vegetable oil through the processes of mixing, heating and moulding. Its heating temperature is 60-110 deg.C.

Owner:杨建

A kind of production technology of anti-ultraviolet sportswear Jin ammonia air-covered silk

Owner:浙江世纪晨星纤维科技有限公司

Rubber connecting piece structure for keys

The invention aims to provide a rubber connecting piece structure for keys. The rubber connecting piece structure is composed of a soft-head part, a hard-end part and a series-connection rod core, thesoft-head part is further provided with a soft-head part series-connection positioning groove, an extension back-off ring and an inner-delay reverse buckle ring; the hard-end part is further providedwith a hard end part series positioning hole, an epitaxial reverse back-off groove, an inner delay back-off groove and a through groove. The soft head part of the part adopts a silica gel part, so that the flexibility of the integral part at the position of the cross key can be improved, the hard end part adopts a copper plating metal part, so that a good supporting effect is achieved; the part is simple in overall structure and convenient to mount; the whole body splicing mold is convenient to assemble and disassemble, so that replacement and cleaning of the parts are facilitated; the flexible and hard combined structural form is more convenient for the flexibility of the cross keys, the connecting pieces made of silica gel can also reduce static electricity, so that the service life ofthe keys is prolonged.

Owner:SYNERGY HANIL PRECISION POLYMER TECH CO LTD

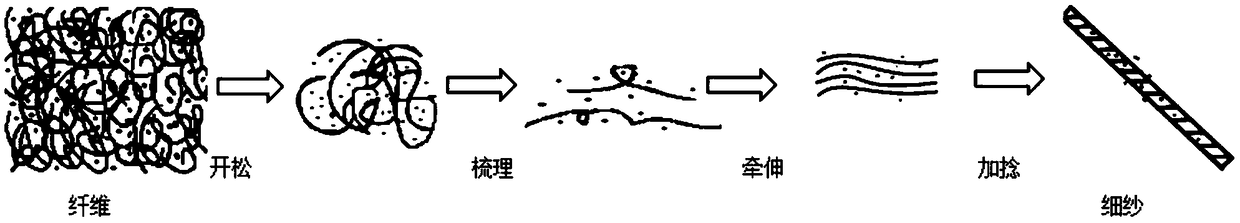

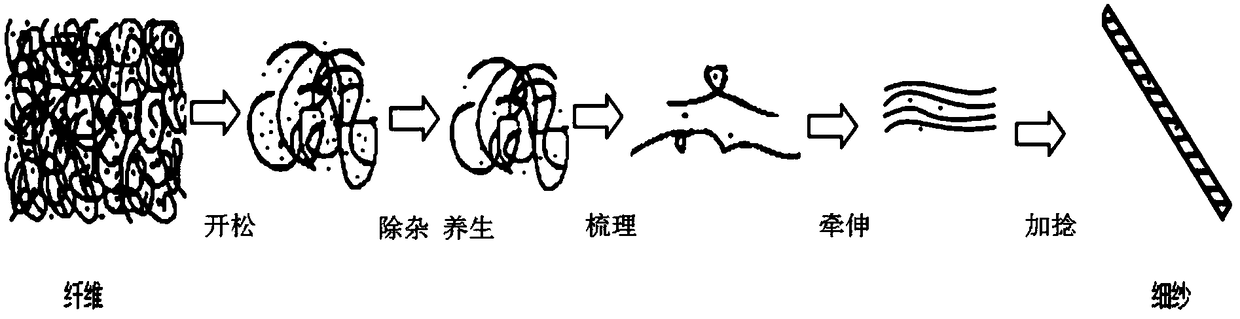

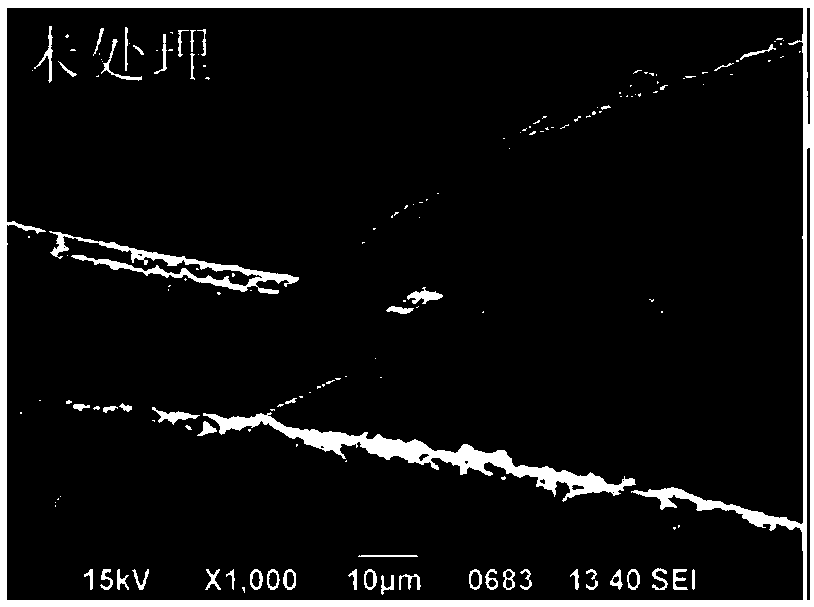

Spinning method for blue fibers dyed through indigo plants

InactiveCN109402910AEfficient removalImprove the finishDyeing processTextile treatment by spraying/projectingYarnCarding

The invention discloses a spinning method for blue fibers dyed through indigo plants. The method comprises the steps of opening picking, ultrasonic impurity removal, drying, care, carding, drawing, roving and spinning. The problems of high impurity content, poor spinnability and the like of fibers dyed through plants are solved. The fibers dyed through plants are subjected to ultrasonic impurity removal, dried and cared after being subjected to opening picking in sequence, the content of fiber impurities is reduced, the surface performance of the fibers is improved, the spinnability of the fibers is improved, and finally spinning of the yarn dyed through plants is achieved, wherein the spinning process is smooth, and the yarn quality is high.

Owner:DEZHOU HENGFENG TEXTILES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com