Tail gas collecting and conveying device with pneumatic clamping and joint adjusting

A pneumatic clamping and joint technology, applied in the direction of adjustable connection, pipe/pipe joint/pipe fitting, passing element, etc., can solve the problem that the exhaust gas cannot be effectively solved and transported, achieve simple structure, high standardization, ensure safe production Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

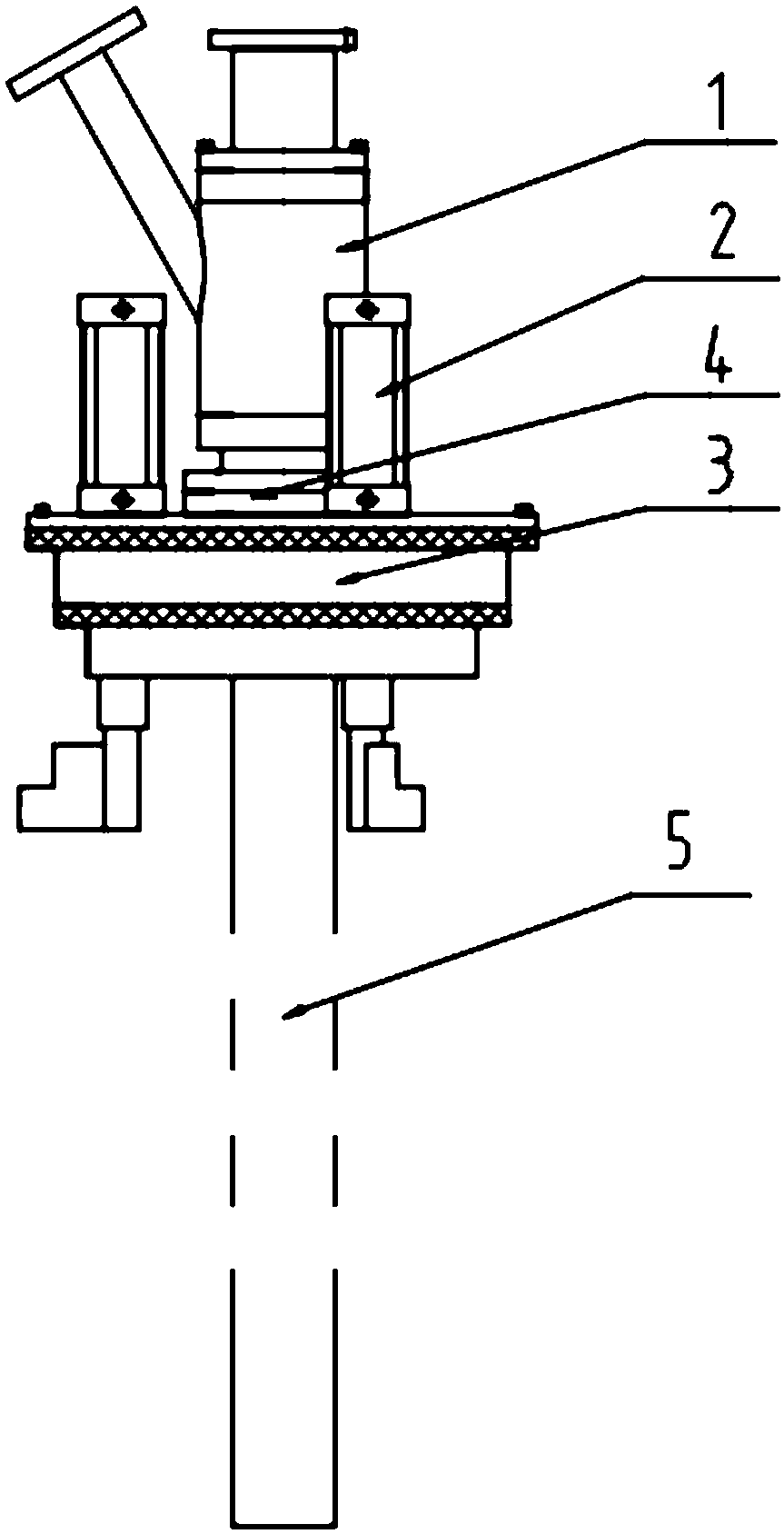

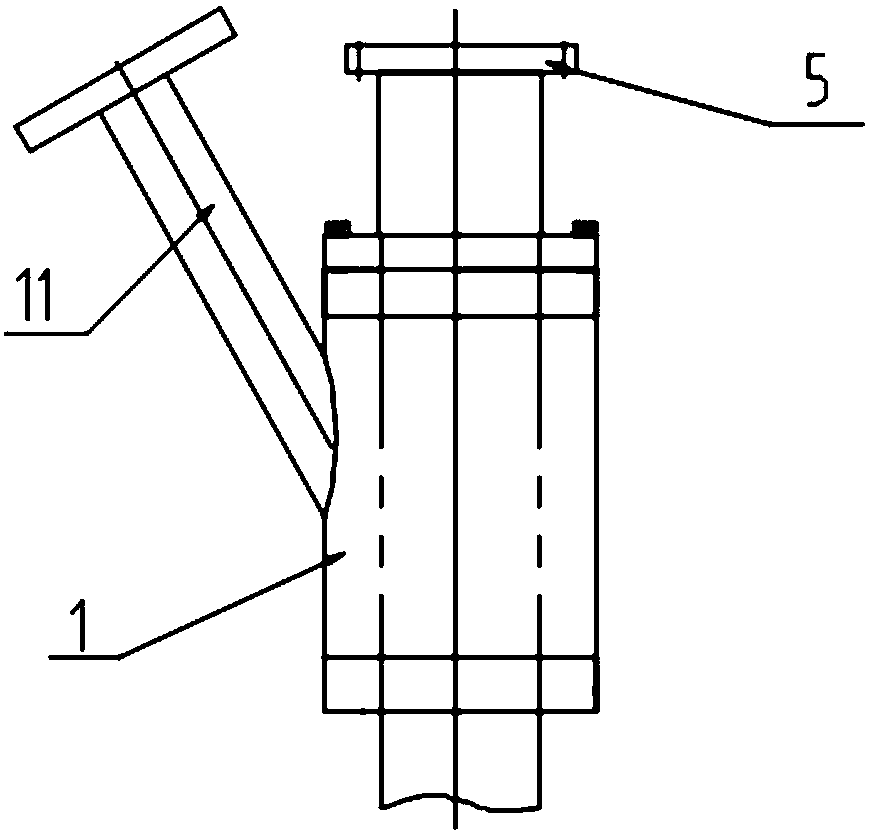

[0049] In the specific implementation process, the tank mouth of the tanker is connected with the gas collection hood, and then the tank mouth of the tanker is sealed and connected with the gas collection hood through a pneumatic clamping device, and then the fluid medium enters from the gas transmission interface 11 of the gas transmission hood, thereby realizing Fluid loading operations.

[0050] The working status of the pneumatic clamping device is as follows:

[0051] see Figure 8 The expansion diagram of the rotation groove on the middle guide sleeve. When the limit point 28 is set on the guide rod and placed at the lowest point of the rotation groove, the pneumatic clamping device 2 is in the initial state at this time. Then under the action of the cylinder, the limit point 28 moves upward along the rotating groove, and the clamping tongue 26 rotates toward the tank mouth of the tank car, and the cylinder is continuously pressurized so that the limit point 28 reaches ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com