Foil plate miniature composite component micro punching forming and connecting device and Foil plate miniature composite component micro punching forming and connecting method

A technology of composite components and connection devices, which is applied in the field of micro-stamping forming-connection devices of foil plate micro-composite components, can solve the problems of low work efficiency and poor precision, and achieve the goal of improving production efficiency, surface flatness and positioning accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

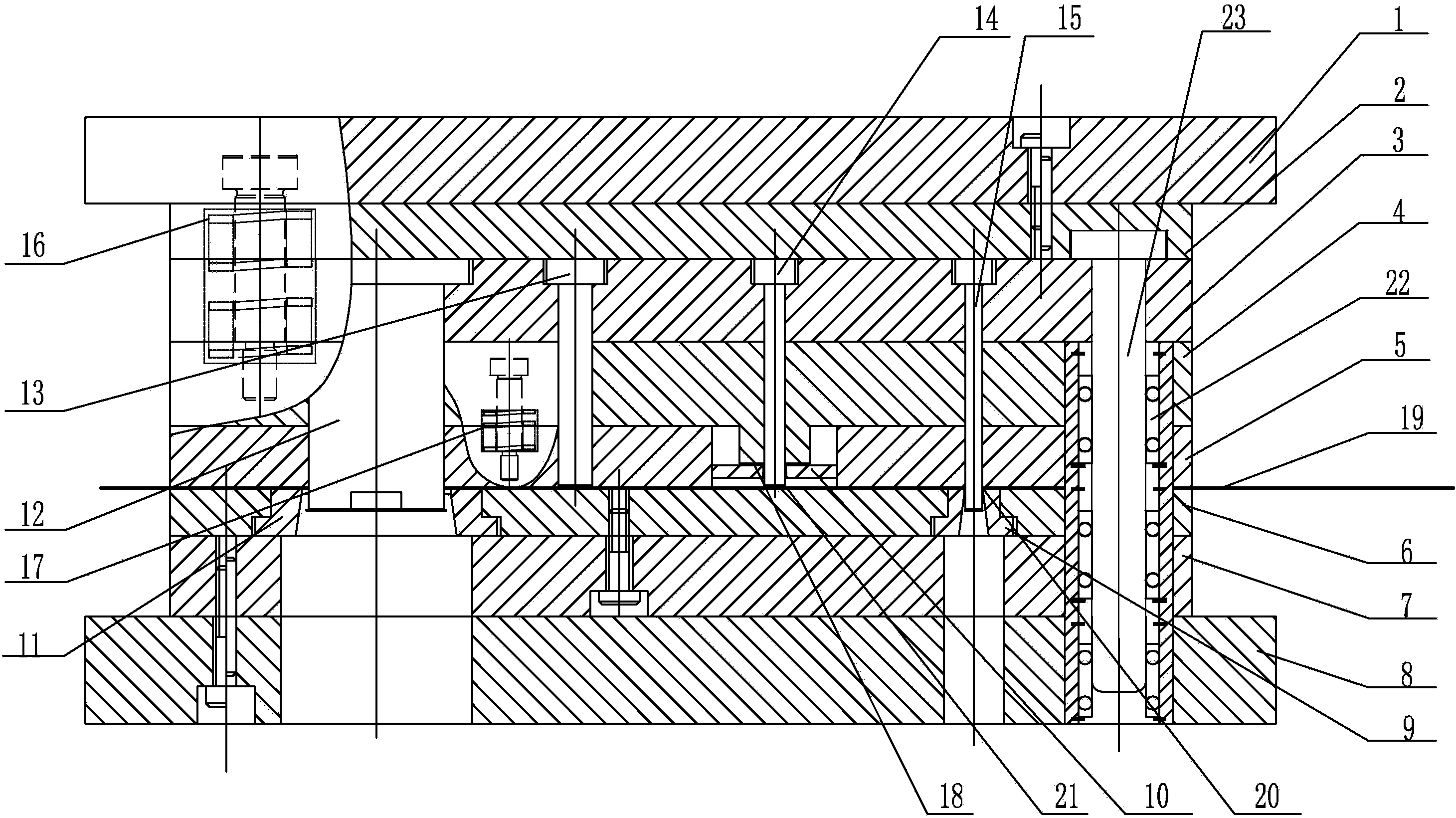

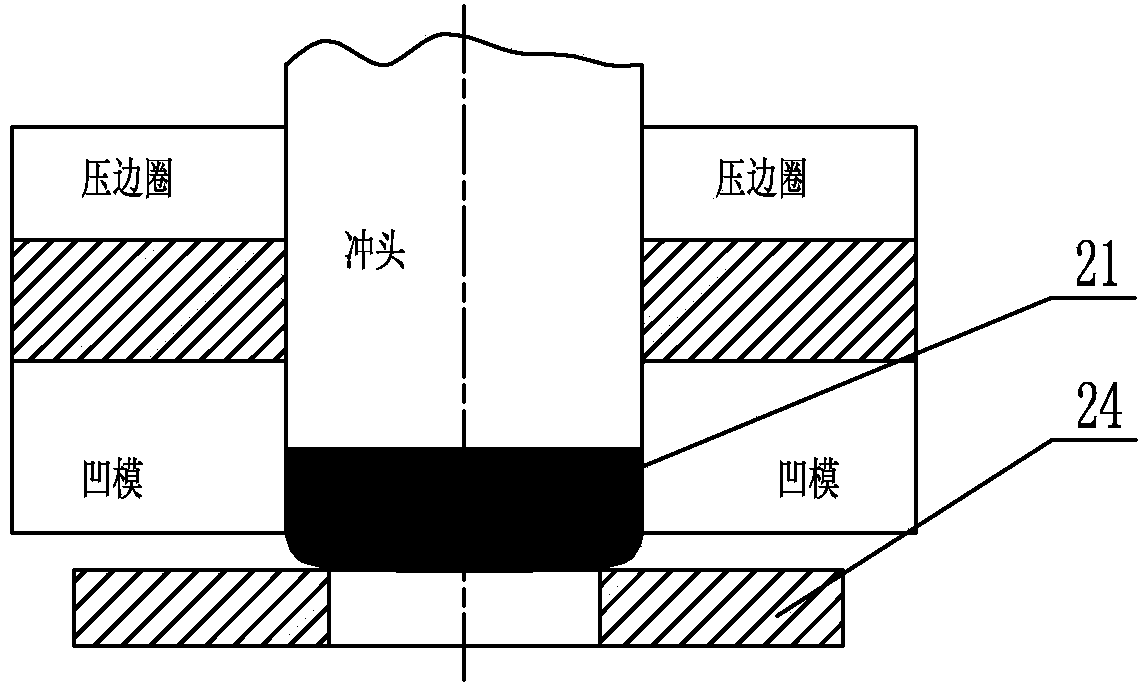

[0022] Specific implementation manner one: such as Figure 1~5 As shown, the foil plate micro-composite member micro-stamping forming-connection device of this embodiment includes an upper template 1, an upper backing plate 2, a convex mold fixing plate 3, a discharge backing plate 4, a discharge plate 5, and a concave mold fixing plate 6. , Lower plate 7, lower template 8, punching die 9, first blanking die 10, second blanking die 11, second blanking punch 12, indenter 13, first blanking punch 14. Blanking punch 15, first spring 16 and second spring 17;

[0023] The die fixing plate 6, the lower backing plate 7 and the lower template 8 are sequentially set up on the lower worktable of the precision stamping machine from top to bottom, the discharge plate 5, the discharge backing plate 4, the convex mold fixing plate 3, the upper cushion The plate 2 and the upper template 1 are arranged on the upper worktable of the precision stamping machine from bottom to top. The blanking die...

specific Embodiment approach 2

[0024] Specific implementation manner two: such as figure 1 As shown, the micro-stamping forming-connecting device of this embodiment further includes a plurality of guide sleeves 22 and a plurality of guide posts 23. The number of guide sleeves 22 and the number of guide posts 23 are set in the same manner, and the upper end of the guide post 23 is installed on the On the backing plate 2, the guide sleeve 22 is sequentially embedded in the discharge backing plate 4, the discharge plate 5, the die fixing plate 6, the lower backing plate 7 and the lower template 8 from top to bottom. Each guide post 23 corresponds to One of the guide sleeves 22 is slidingly fitted with each other. This design can play a role in precise positioning. The other components and connection relationships are the same as in the first embodiment.

specific Embodiment approach 3

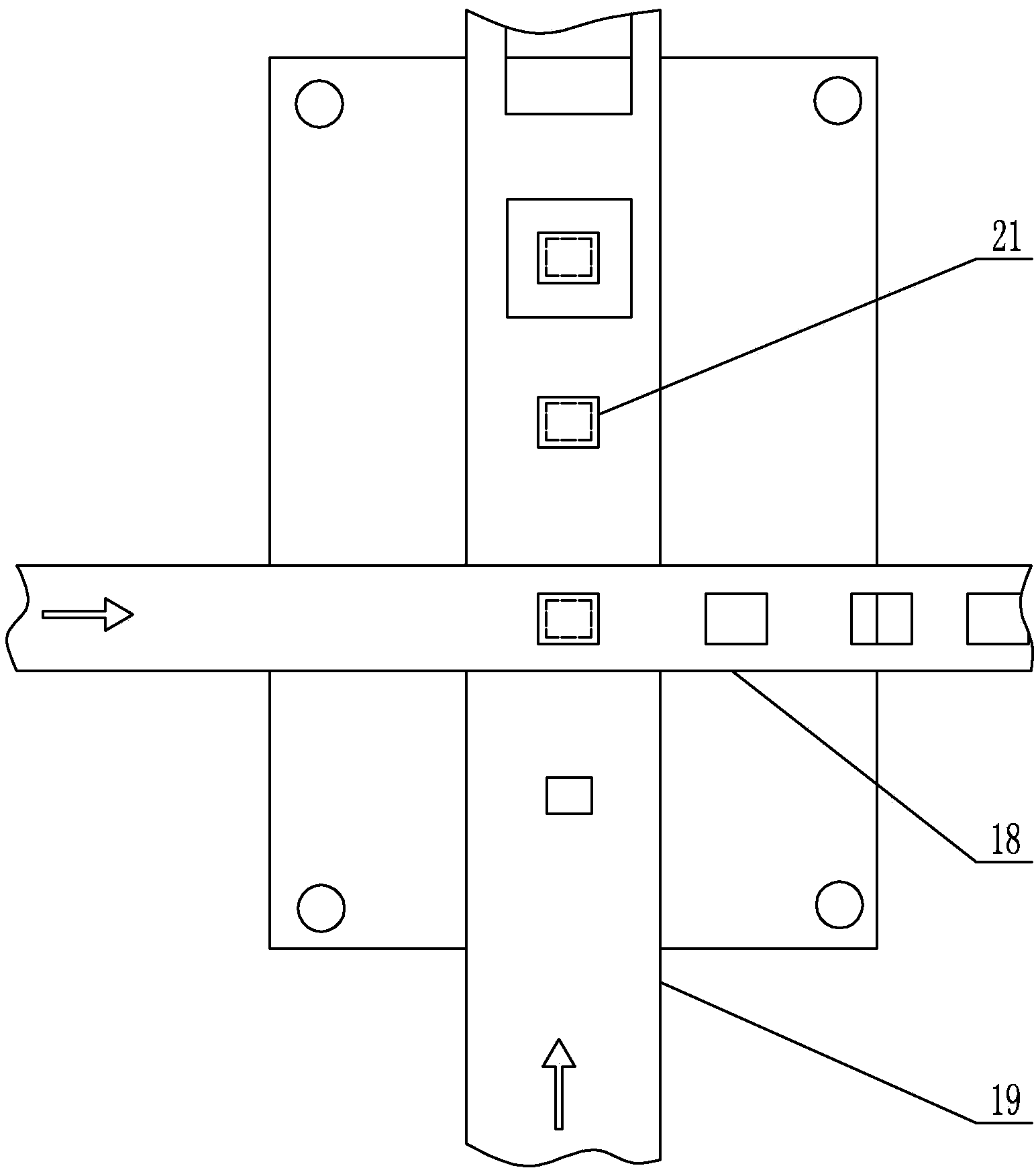

[0025] Specific implementation manner three: such as figure 2 As shown, the number of guide sleeves 22 and the number of guide posts 23 are both three. This design has a good guiding effect, which is beneficial to ensure the forming quality of precision micro-punching and the accuracy of connection positioning. Other components and connection relationships are the same as in the second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com