Sugarcane leaf collecting and bundling device

A bundling device and technology of sugarcane leaves, applied in the direction of harvesters, separate bundling machines, agricultural machinery and implements, etc., can solve problems such as environmental pollution, inability to collect and bundle sugarcane leaves at the same time, threats to sugarcane production, etc., and achieve convenient reuse , The effect of convenient collection and transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments:

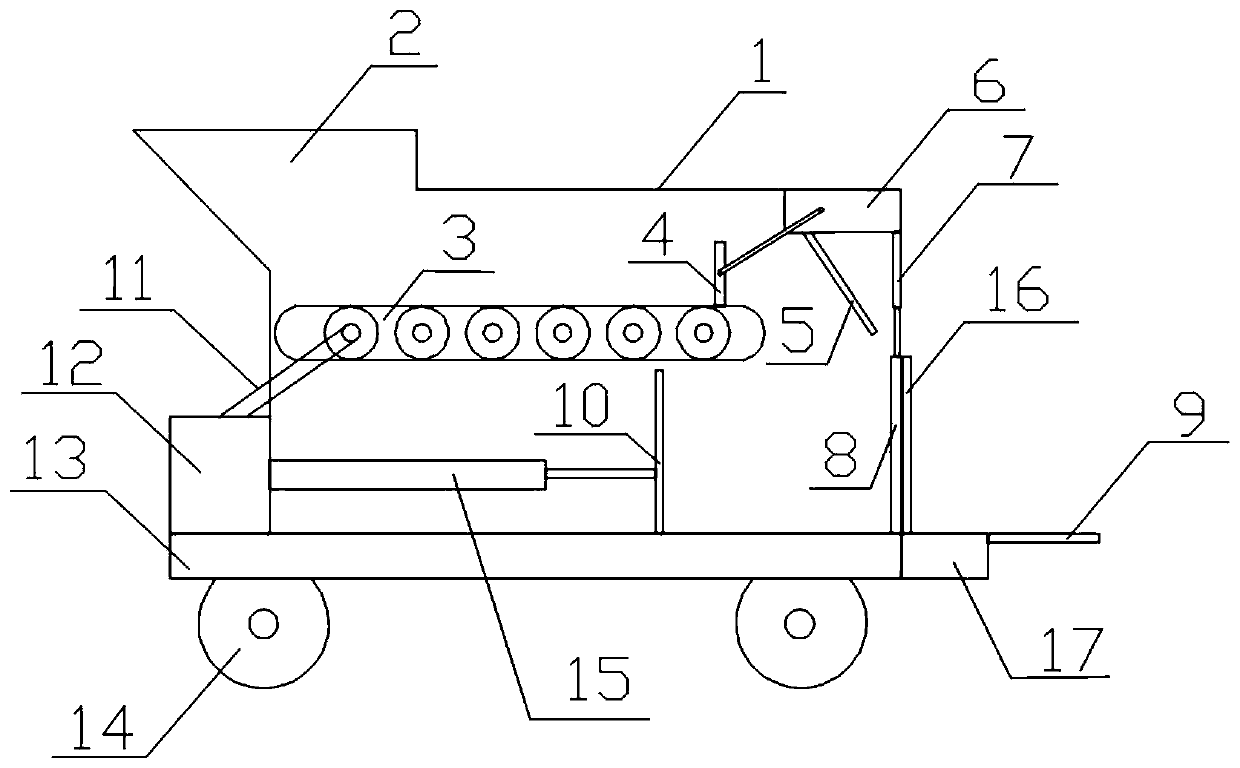

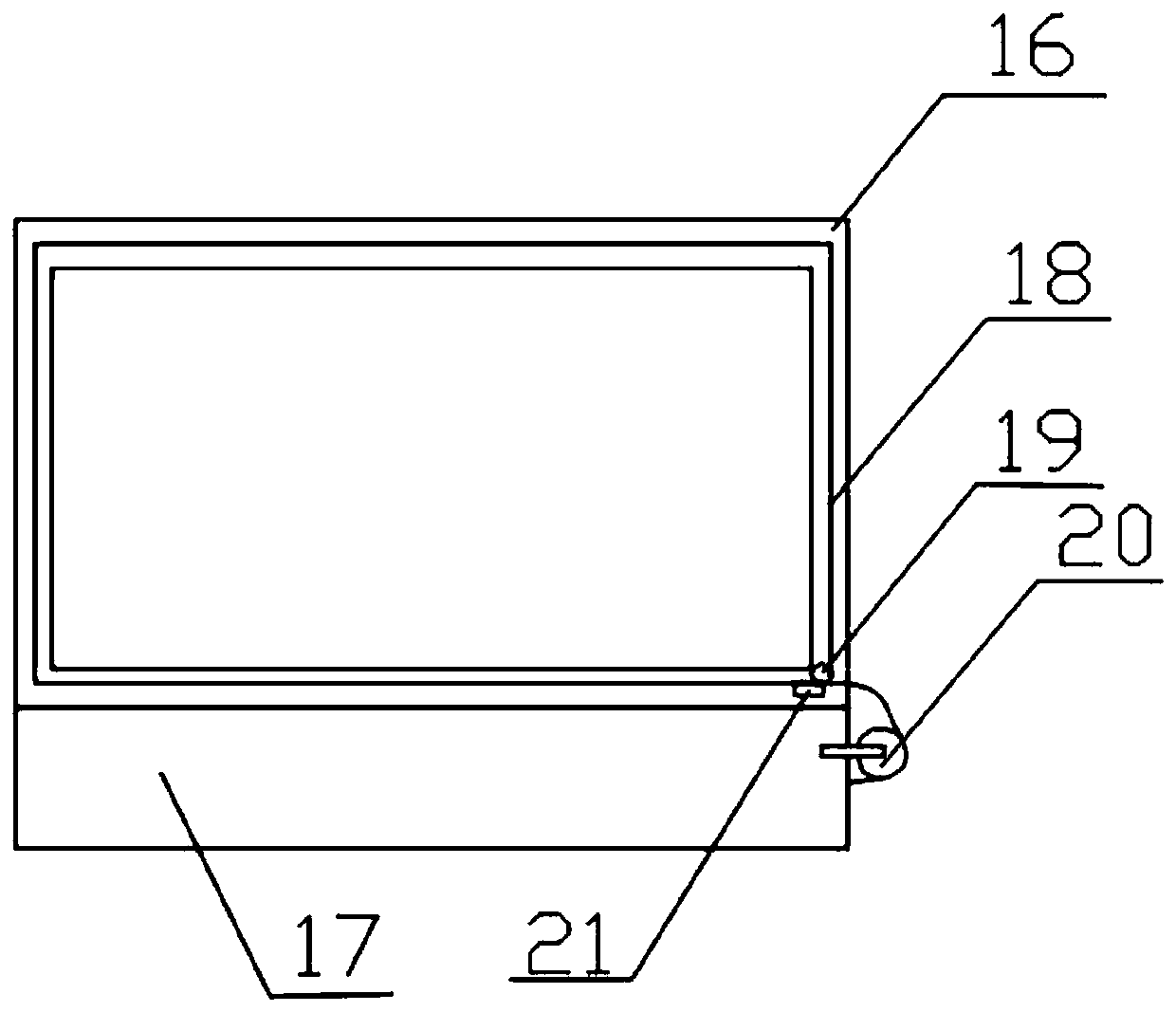

[0019] Such as Figure 1 ~ Figure 2 As shown, a sugarcane leaf collecting and binding device includes a box body 1, a bottom plate 13, a collection port 2, a conveyor belt 3, a leaf collecting plate 4, a controller 6, a guide plate 5, a vertical hydraulic rod 7, a power unit 12, and a horizontal Hydraulic rod 15, push plate 10, baffle plate 8, strapping device, strapping table 9; collection port 2 is located at the front and top of box body 1; conveyor belt 3 is provided below collection port 2, and leaf collecting plate 4 is provided at the rear of conveyor belt 3 , the leaf collecting plate 4 is connected to the controller 6, and the controller 6 is provided with a guide plate 5; the baffle plate 8 is located at the rear of the box body 1, and the upper end of the baffle plate 8 is connected to the vertical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com