Method for preparing liquid oxygen explosive

A liquid oxygen explosive and liquid oxygen technology, applied in explosives, explosive processing equipment, offensive equipment, etc., can solve the problems of waste, liquid leakage, etc., reduce the probability of static electricity generation, suppress dust particle splashing, and reduce accidental explosions effect of possibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Embodiment one: A method of making liquid oxygen explosives:

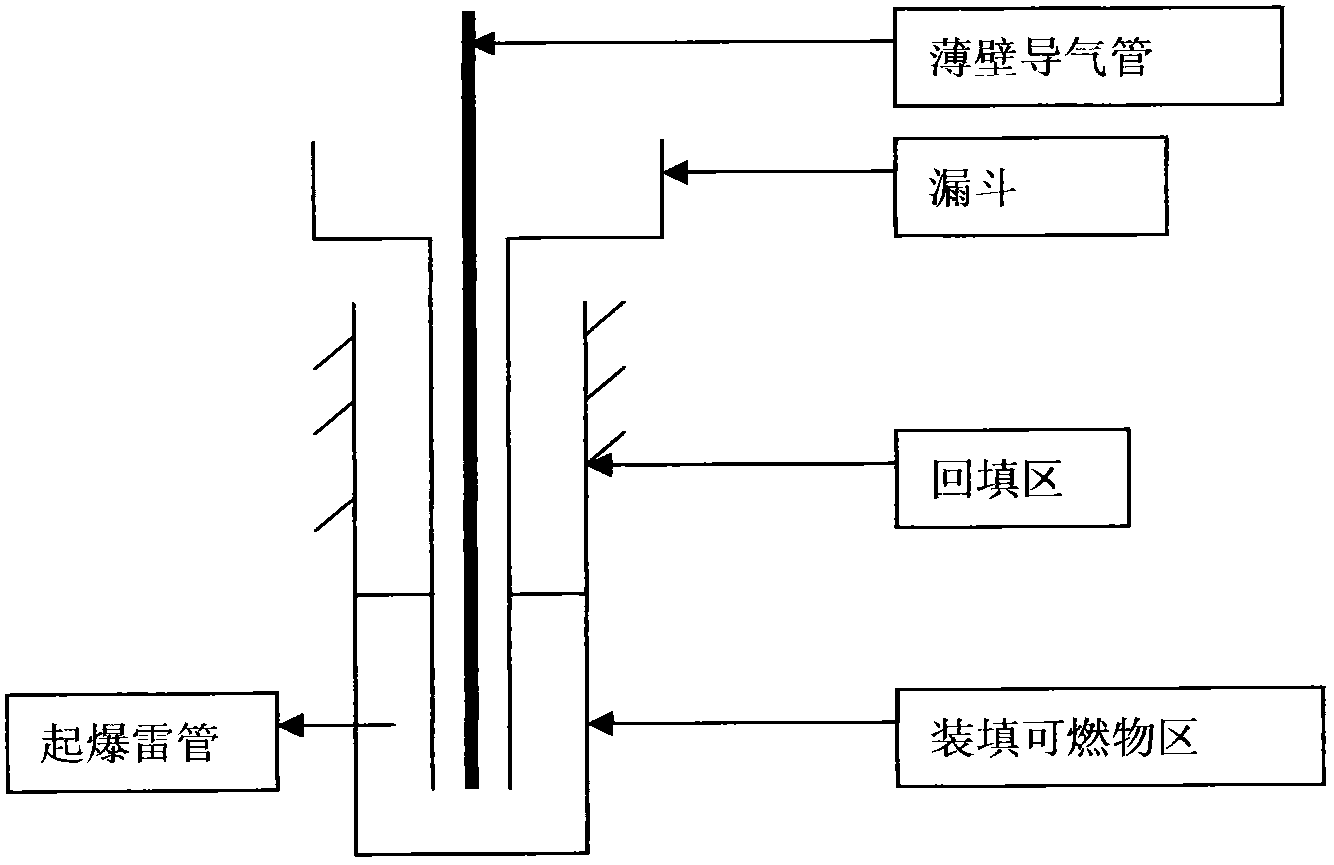

[0033] Such as figure 1 Shown, a kind of method of making liquid oxygen explosive comprises the steps:

[0034] (1) Place a funnel vertically in the center of the metal sheet open container, and set holes through the pipe wall in the part of the funnel tube in contact with the combustibles in a form of sparse bottom and dense top, and the lower part of the funnel is a closed pointed tip;

[0035] (2) Install the detonator in the area where the combustibles are filled in the container;

[0036] (3), combustibles are poured into the container for charging, and after the charging is completed, the blast hole is backfilled; the combustibles are 50%-70% coal powder and 50%-30% wet sawdust by mass percentage or combustible fibers, the wet sawdust contains 5% sodium chloride solution, the concentration of the sodium chloride solution is 20%; the diameter of the coal powder is 20-30 microns;

[0037] (4) Insert...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com