Manufacturing method of three-proofing fibers

A production method and fiber technology, applied in fiber processing, fiber chemical characteristics, melt spinning, etc., can solve the problems of complex production methods, poor waterproof and anti-fouling effects, etc., achieve good protection performance, reduce static electricity generation, and simple process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to further explain the technical solution of the present invention, the following will be described in detail in conjunction with the examples.

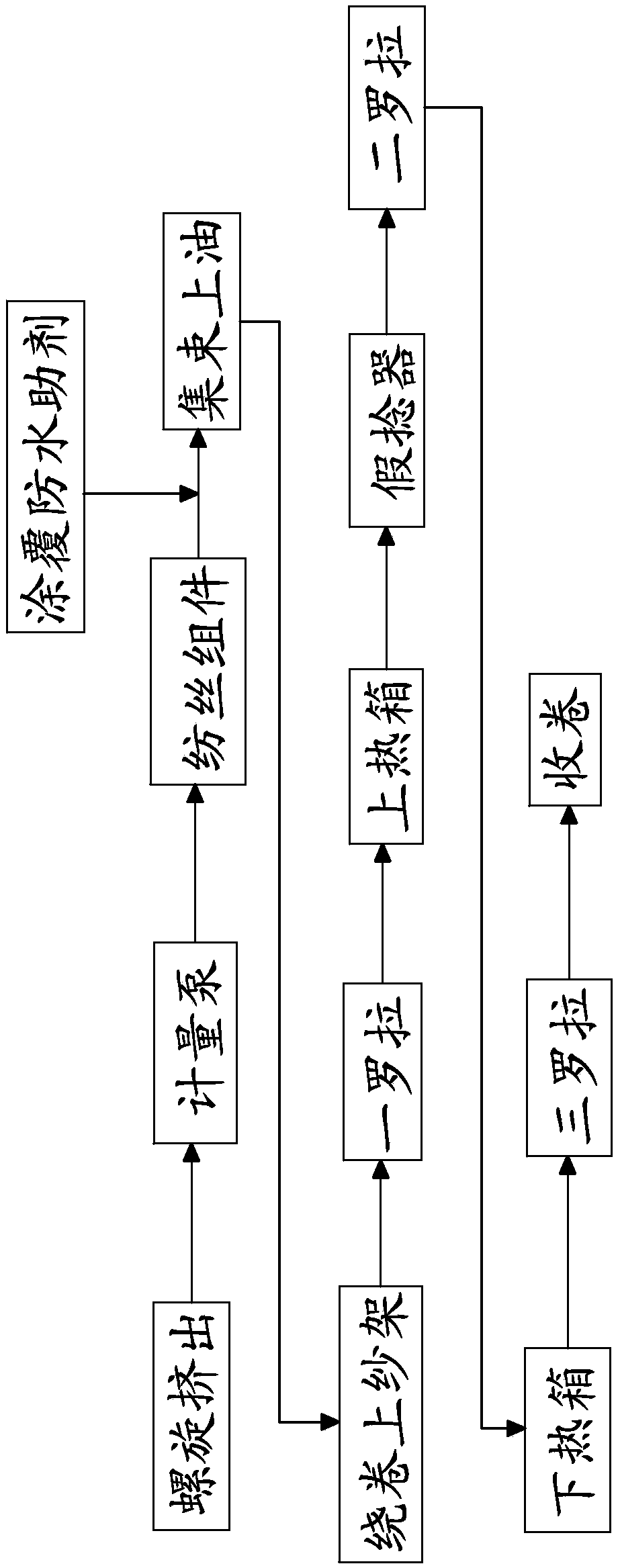

[0018] refer to figure 1 , a method for making three-proof fibers, comprising a melt-spinning process, a cluster oiling process, and a winding forming process carried out in sequence, and also includes a coating waterproofing additive process, and the coating waterproofing additive process is arranged in the melt-spinning process Between the process of cluster oiling, or the process of coating waterproof additives is set in the process of cluster oiling. The clustering and oiling process includes a clustering process for collecting the as-spun fibers into as-spun tows and a process for coating the as-spun tows with waterproof oil, wherein the waterproof oil can adopt the conventional waterproofing oil in the existing melt-spinning method. Oil.

[0019] In the present invention, the process of coating the waterproofi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com