Fluorine-containing fabric waterproof agent and preparation method thereof

A technology of fluorine-containing fabrics and water repellents, applied in the directions of plant fibers, textiles and papermaking, fiber types, etc., can solve problems such as unsatisfactory oil-repellent performance, reduce pilling and static electricity, reduce friction, and good scratch resistance. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] The preparation method of the above-mentioned fluorine-containing fabric waterproofing agent specifically comprises the following steps:

[0047] Step 1, take the following raw materials respectively by mass percentage:

[0048] Perfluoroalkyl ethyl acrylate 6% to 14%, acrylic resin 9% to 17%, octamethyltetrasiloxane 9% to 13%, carboxymethyl cellulose 1% to 5%, polyvinyl alcohol 5 %~13%, cross-linking monomer 1%~9%, surfactant 0.2%~0.5%, initiator 0.5%~0.9%, deionized water 60%~70%;

[0049] The total content of the above raw materials is 100%;

[0050] Among the above raw materials:

[0051] Acrylic resin adopts methyl methacrylate or octadecyl methacrylate;

[0052] N, N-methylenebisacrylamide is used as the crosslinking agent;

[0053] The surfactant adopts reactive allyloxy nonylphenol polyoxyethylene (10) ether ammonium sulfate;

[0054] The initiator adopts potassium persulfate;

[0055] Step 2, mixing the surfactant weighed in step 1 with deionized water, s...

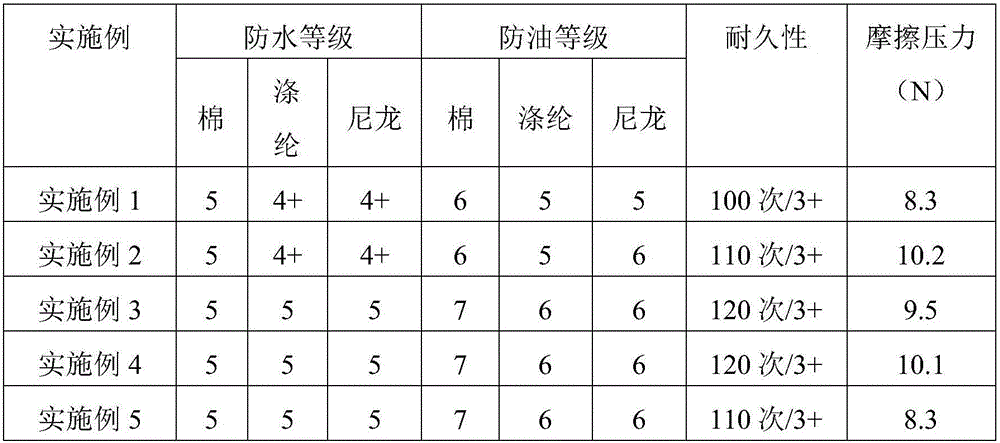

Embodiment 1

[0062] Weigh the following raw materials according to mass percentage: 7.5% perfluoroalkyl ethyl acrylate, 10.5% methyl methacrylate, 10.5% octamethyltetrasiloxane, 1% carboxymethyl cellulose, 5.5% polyvinyl alcohol %, N, N-methylenebisacrylamide 1%, allyloxy nonylphenol polyoxyethylene (10) ether ammonium sulfate 0.2%, potassium persulfate 0.8%, deionized water 63%.

[0063] The sum of the contents of the above raw materials is 100%.

[0064] Mixing the weighed surfactant and deionized water, so that the surfactant is completely dissolved in the deionized water, to obtain an aqueous surfactant solution;

[0065] Add the weighed perfluoroalkyl ethyl acrylate, acrylic resin, octamethyltetrasiloxane, carboxymethyl cellulose and cross-linking monomer into the aqueous surfactant solution, and stir to obtain a mixed solution; Mechanical stirring is used during the stirring process, and the stirring time is 25 minutes;

[0066] Add the weighed polyvinyl alcohol and initiator to th...

Embodiment 2

[0068] Weigh the following raw materials according to mass percentage: 6% perfluoroalkyl ethyl acrylate, 12% methyl methacrylate, 12% octamethyltetrasiloxane, 1% carboxymethyl cellulose, 7% polyvinyl alcohol %, N, N-methylenebisacrylamide 1%, allyloxy nonylphenol polyoxyethylene (10) ether ammonium sulfate 0.3%, potassium persulfate 0.7%, deionized water 60%.

[0069] The sum of the contents of the above raw materials is 100%.

[0070] Mixing the weighed surfactant and deionized water, so that the surfactant is completely dissolved in the deionized water, to obtain an aqueous surfactant solution;

[0071] Add the weighed perfluoroalkyl ethyl acrylate, acrylic resin, octamethyltetrasiloxane, carboxymethyl cellulose and cross-linking monomer into the aqueous surfactant solution, and stir to obtain a mixed solution; Mechanical stirring was used during the stirring process, and the stirring time was 28 minutes;

[0072] Add the weighed polyvinyl alcohol and initiator to the mixe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com