Method for manufacturing touch screen

A manufacturing method and touch screen technology, applied in the input/output process of data processing, printing, printing devices, etc., can solve the problems of waste, glass screen or conductive film scrapping, glass screen or conductive film dirty, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

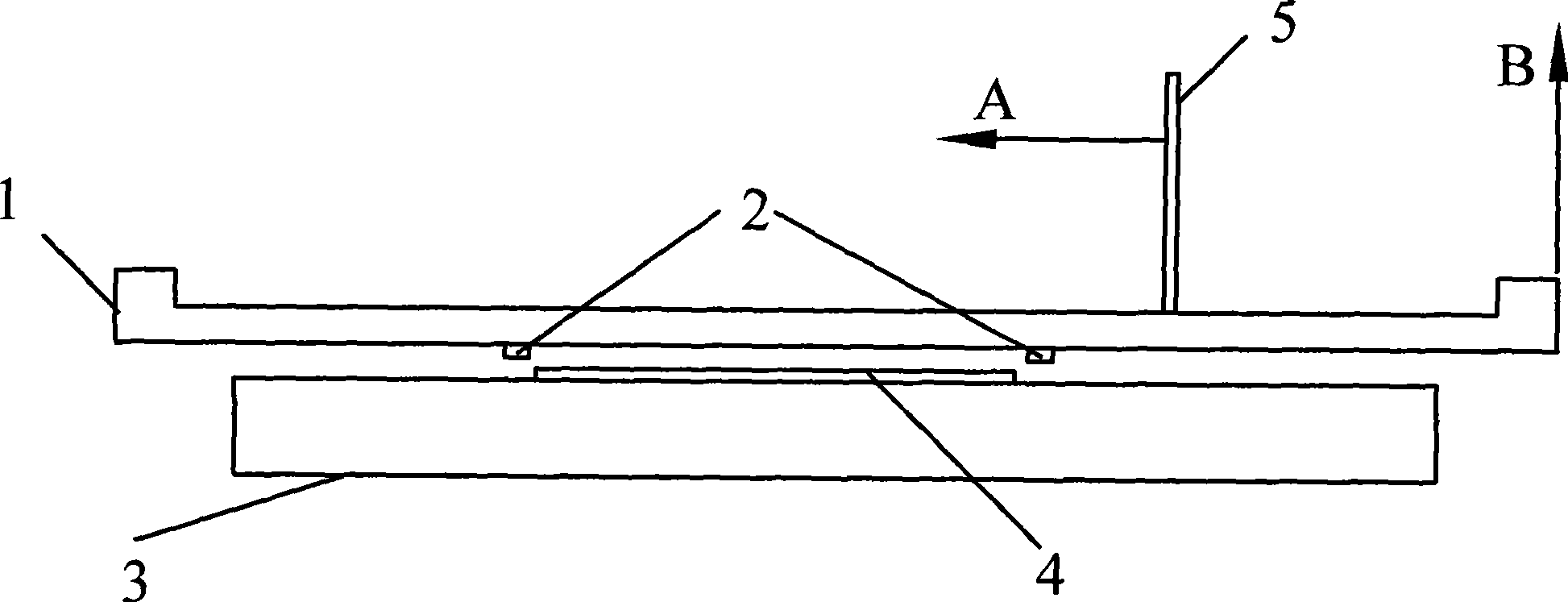

[0012] The manufacturing method of the touch screen of the present invention will be further described in detail with reference to the accompanying drawings.

[0013] Take a screen plate 1 and first clean the screen plate 1 with a dust-free cloth with plate washing water, and then take a silver tape 2 with a thickness of 0.08MM and a width of 5cm. The inner edge of the silver tape 2 must be parallel to the surrounding of the screen pattern and be pasted flat. The distance between the four sides of the silver tape and the surrounding of the screen pattern should be 1.0CM-1.5CM.

[0014] Such as figure 1 As shown, the touch screen product 3 with conductive film, glass screen and printed matter 4 is placed flat on the printing machine table and the printing machine is started, wherein the touch screen product 3 is adsorbed on the printing machine table. One side of the plate 1 moves along the horizontal direction A, and the screen plate 1 gradually separates from the printed mat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com