Equipment for producing reconstituted tobacco through dry-method paper making method

A technology of reconstituted tobacco leaves and dry papermaking, which is applied in the fields of tobacco, tobacco preparation, application, etc., can solve the problems of loss of smoke taste and aroma, low coating rate of tobacco substances, sewage discharge, etc., and achieve the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0095] The present invention will be further explained below in conjunction with examples. The following examples are used to explain the technical solutions of the present invention without limitation. The protection scope of the present invention should be determined by the claims.

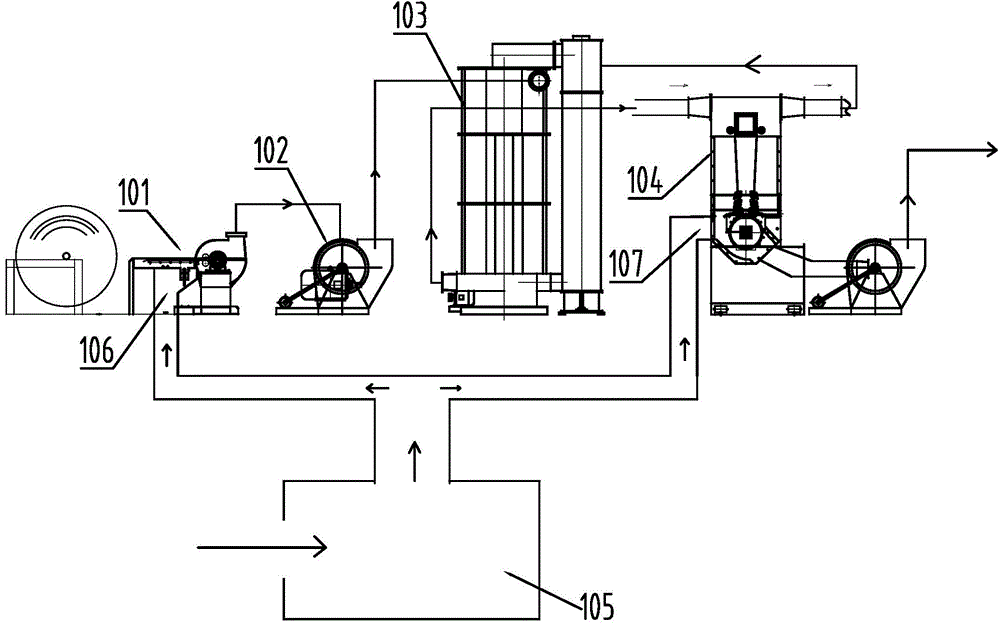

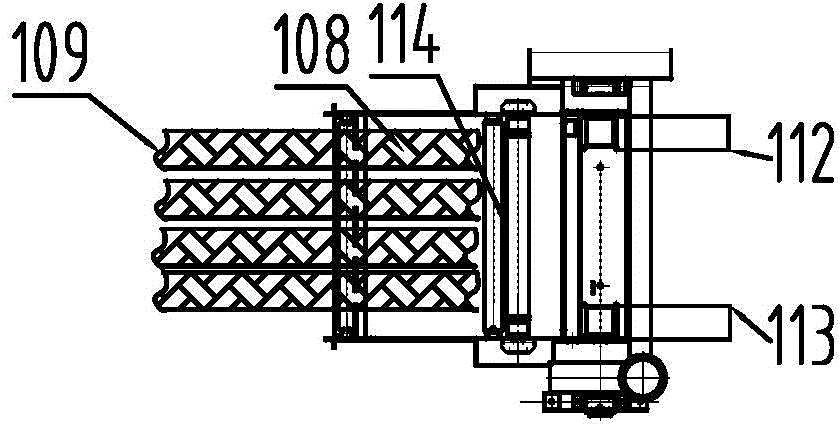

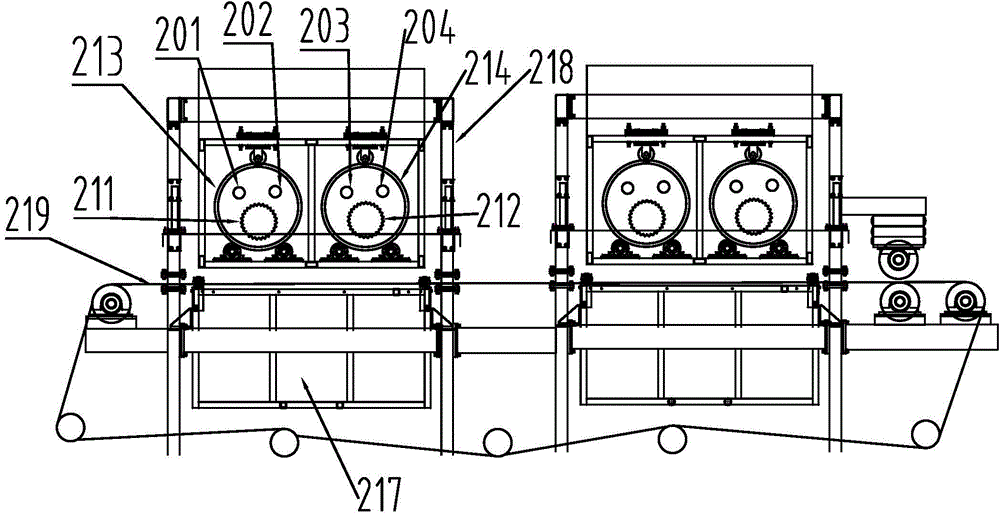

[0096] Defibrating device such as Figure 1-2 As shown, it includes a coarse crusher 101, a fine crusher 102, a fiber storage tank 103, and a fiber counter 104 connected in sequence. The front end of the coarse crusher 101 is a material inlet, and the material outlet of the fiber counter 104 is connected To the forming device for the dry papermaking method to produce reconstituted tobacco, wherein the defibration device further includes a high-humidity air generator 105 and a high-humidity air pipeline, and the output ends of the humid air generator 105 respectively pass through the high-humidity air pipe The road is connected to the material inlet of the coarse crusher 101 and the material outlet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com