Antibacterial composite fabric and manufacturing process thereof

A technology of composite fabric and manufacturing process, which is applied in the field of textile fabrics, can solve the problems of poor durability, single sterilization method, and single function, and achieve the effects of short sterilization time, improved sterilization effect, and efficient sterilization method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

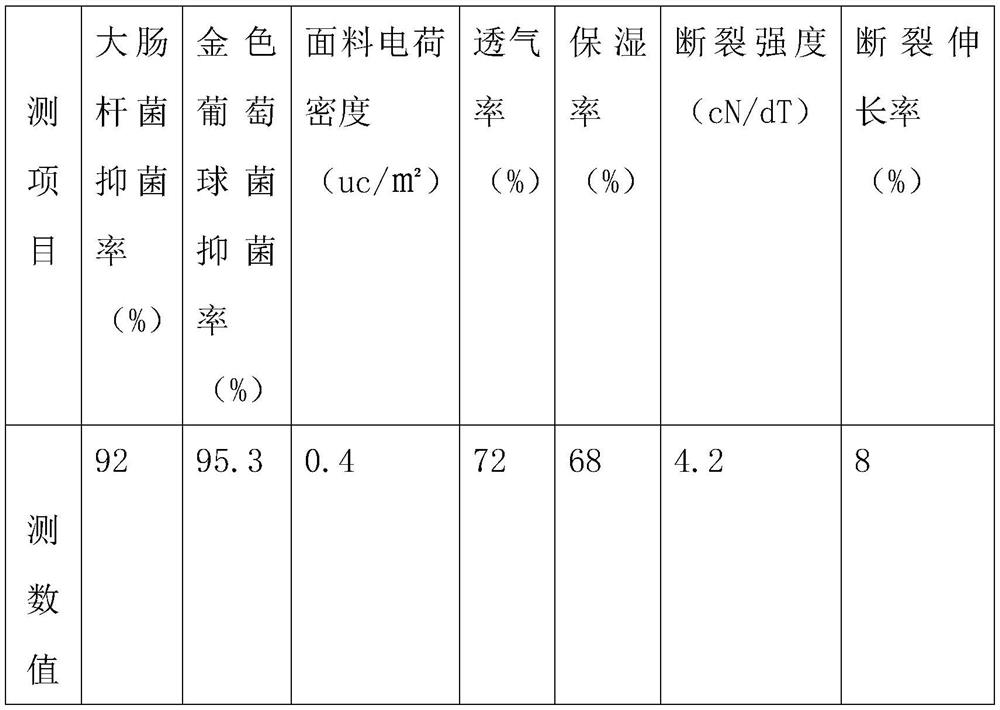

Embodiment 1

[0030] An antibacterial composite fabric, comprising a fabric layer and an impregnating solution, the fabric layer comprising hollow polyester fiber, jade fiber, activated carbon fiber, superfine sea-island fiber; the impregnating solution comprises a metal inorganic salt solution and an antibacterial zeolite solution; wherein, the hollow polyester fiber and jade The fibers are the surface layer and the inner layer of the fabric warp, the activated carbon fiber and the ultra-fine sea-island fiber are spirally wound into the weft thread, the weft thread and the warp thread are interwoven to form the initial fabric, and the impregnation solution is used to soak the initial fabric.

[0031] The proportion of fabric layer raw materials includes the following: hollow polyester fiber 10%; jade fiber 40%; activated carbon fiber 5%; %.

[0032] The arrangement ratio of warp and weft is 1:1.

[0033] When metal inorganic salts are used to sterilize the woven fabric, the positive charg...

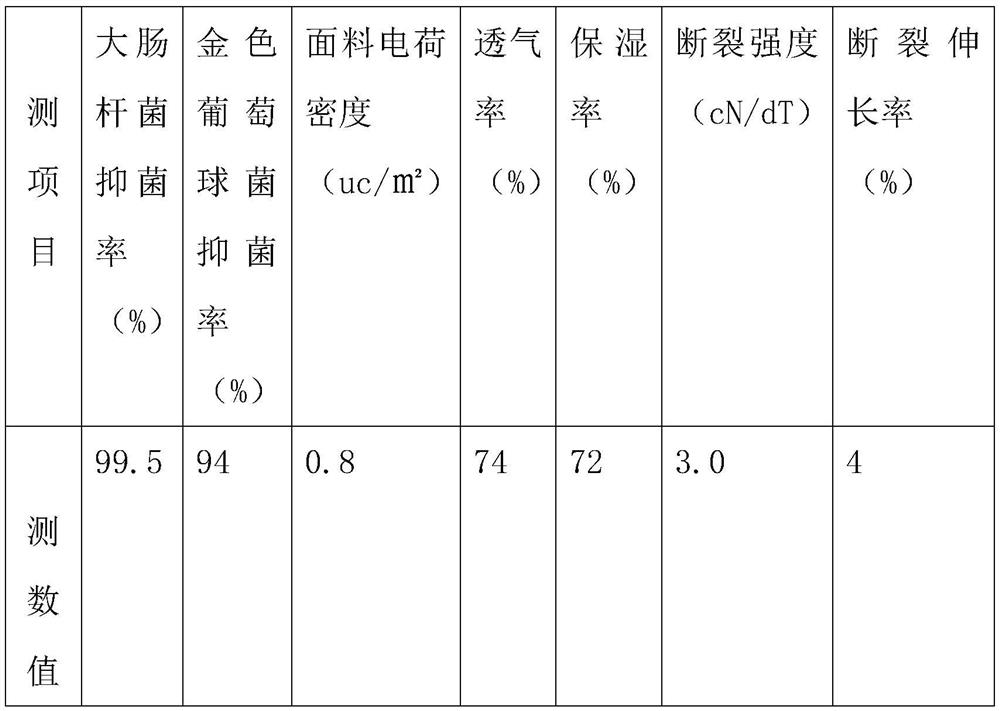

Embodiment 2

[0051] An antibacterial composite fabric, comprising a fabric layer and an impregnating solution, the fabric layer comprising hollow polyester fiber, jade fiber, activated carbon fiber, superfine sea-island fiber; the impregnating solution comprises a metal inorganic salt solution and an antibacterial zeolite solution; wherein, the hollow polyester fiber and jade The fibers are the surface layer and the inner layer of the fabric warp, the activated carbon fiber and the ultra-fine sea-island fiber are spirally wound into the weft thread, the weft thread and the warp thread are interwoven to form the initial fabric, and the impregnation solution is used to soak the initial fabric.

[0052] The raw materials of the fabric layer include the following: 13% hollow polyester fiber; 37% jade fiber; 8% activated carbon fiber; %.

[0053] The arrangement ratio of warp and weft is 1:1.

[0054] When metal inorganic salts are used to sterilize the woven fabric, the positive charge added ...

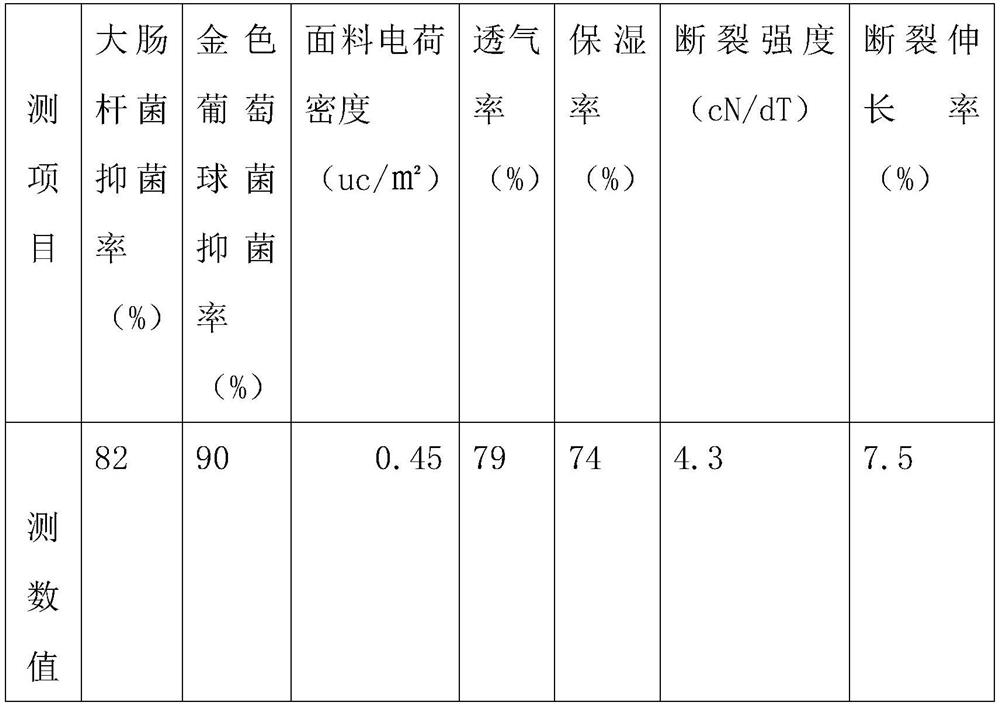

Embodiment 3

[0072] An antibacterial composite fabric, comprising a fabric layer and an impregnating solution, the fabric layer comprising hollow polyester fiber, jade fiber, activated carbon fiber, superfine sea-island fiber; the impregnating solution comprises a metal inorganic salt solution and an antibacterial zeolite solution; wherein, the hollow polyester fiber and jade The fibers are the surface layer and the inner layer of the fabric warp, the activated carbon fiber and the ultra-fine sea-island fiber are spirally wound into the weft thread, the weft thread and the warp thread are interwoven to form the initial fabric, and the impregnation solution is used to soak the initial fabric.

[0073] The proportion of fabric layer raw materials includes the following: hollow polyester fiber 15%; jade fiber 35%; activated carbon fiber 10%; %.

[0074] The arrangement ratio of warp and weft is 1:1.

[0075] When metal inorganic salts are used to sterilize the woven fabric, the positive char...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com