Method for keeping rotary sealing cover head of PET product sterile

A rotary, capping technology, used in packaging, liquid handling, bottling machines, etc., can solve the problems of reducing the cost of renovation and maintenance, unable to completely eliminate the dead corners of the inner wall of the capping head, etc., and achieve the effect of low price and operating cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

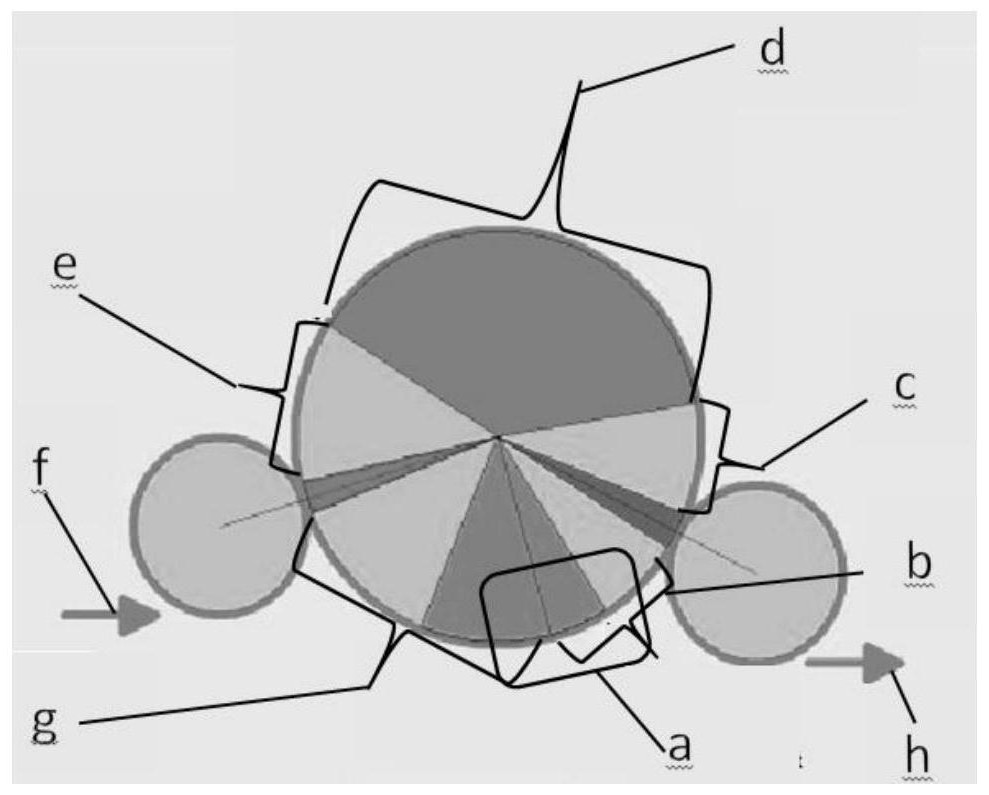

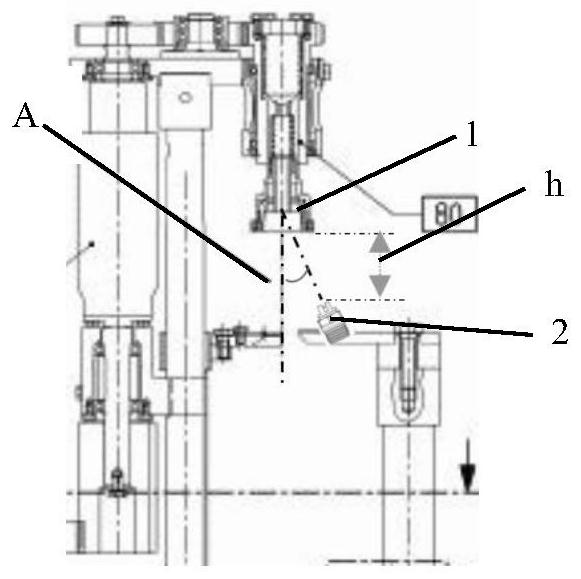

[0037]A method to keep the capping heads of rotary PET products sterile. A nozzle for washing and disinfecting the capping heads is added around the capping heads on the production line, and a disinfectant is sprayed out of the nozzles to kill the hidden microorganisms inside the capping heads and maintain the capping heads throughout the process. The inner wall is sterile. The nozzle is a universal nozzle, and the shape of the sprayed disinfectant is fan-shaped; the universal nozzle is equipped with a nozzle ball, and the unilateral rotation angle of the nozzle ball is limited to 22.5°. The angle range between the center line of the nozzle and the center vertical line of the capping head is 20°, and the distance between the top of the nozzle and the lowest point of the capping head is 2-5cm. The running speed of the capping head on the production line is 30,000 bottles / h; the inner diameter of the capping head is 28mm; the pressure of the disinfectant injection is 3bar, and t...

Embodiment 2

[0039] A method to keep the capping heads of rotary PET products sterile. A nozzle for washing and disinfecting the capping heads is added around the capping heads on the production line, and a disinfectant is sprayed out of the nozzles to kill the hidden microorganisms inside the capping heads and maintain the capping heads throughout the process. The inner wall is sterile. The nozzle is a universal nozzle, and the shape of the sprayed disinfectant is fan-shaped; the universal nozzle is equipped with a nozzle ball, and the unilateral rotation angle of the nozzle ball is limited to 23°. The angle range between the center line of the nozzle and the center vertical line of the capping head is 10°, and the distance between the top of the nozzle and the lowest point of the capping head is 2cm. The running speed of the capping head on the production line is 36,000 bottles / h; the inner diameter of the capping head is 28mm; the pressure of the disinfectant injection is 2bar, and the ...

Embodiment 3

[0041] A method to keep the capping heads of rotary PET products sterile. A nozzle for washing and disinfecting the capping heads is added around the capping heads on the production line, and a disinfectant is sprayed out of the nozzles to kill the hidden microorganisms inside the capping heads and maintain the capping heads throughout the process. The inner wall is sterile. The nozzle is a universal nozzle, and the shape of the sprayed disinfectant is fan-shaped; the universal nozzle is equipped with a nozzle ball, and the unilateral rotation angle of the nozzle ball is limited to 22°. The angle range between the center line of the nozzle and the center vertical line of the capping head is 30°, and the distance between the top of the nozzle and the lowest point of the capping head is 5cm. The running speed of the capping head on the production line is 36,000 bottles / h; the inner diameter of the capping head is 38mm; the pressure of the disinfectant injection is 4bar, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com