Application of black phosphorus composite material

A composite material, black phosphorus technology, used in applications, chemicals for biological control, animal repellants, etc., can solve the problems of harsh reaction conditions, low efficiency, toxicity, etc. expansive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

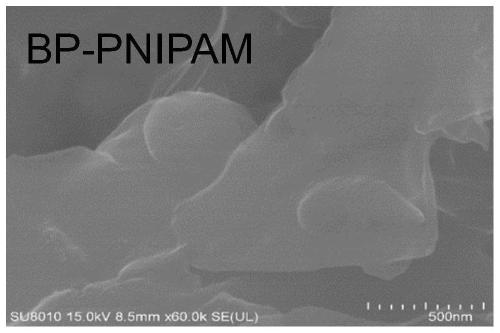

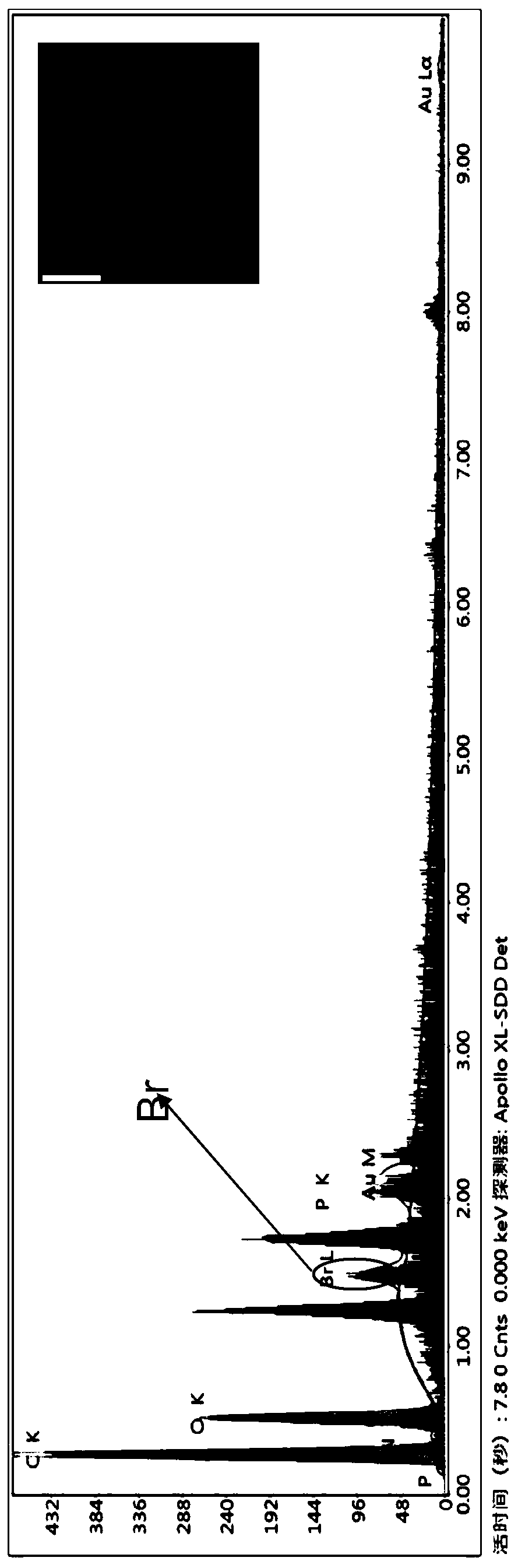

[0034] The synthesis of black phosphorus composites includes the following steps:

[0035] (1) The bulk black phosphorus crystals were ground into black phosphorus powder and transferred into a glass bottle containing DMF. The mixture was then sonicated by an ultrasonic cell disruption system for 12 h, and the temperature of the dispersion was kept below 16 °C using an ice bath. Finally, the suspension was centrifuged to obtain black phosphorus nanosheets in the range of 1000-4000 rpm. Disperse black phosphorus nanosheets in anhydrous acetonitrile at a concentration of 1 mg / mL for synthesis.

[0036] (2) Use p-ethanolyl aryl diazonium salt (0.619g), tetrabutylammonium hexafluorophosphate (1.977g) and black phosphorus solution (1mg / mL, 10mL) in the dark under nitrogen and stir for 3h.

[0037] (3) In the presence of triethylamine (120mmoL / L), react the above-mentioned terminal hydroxyl black phosphorus material with a dichloromethane solution (100mmoL / L) of 2-bromopropionyl b...

Embodiment 2

[0041] The application of black phosphorus composite materials in capturing and killing bacteria, the capturing of bacteria includes the following steps:

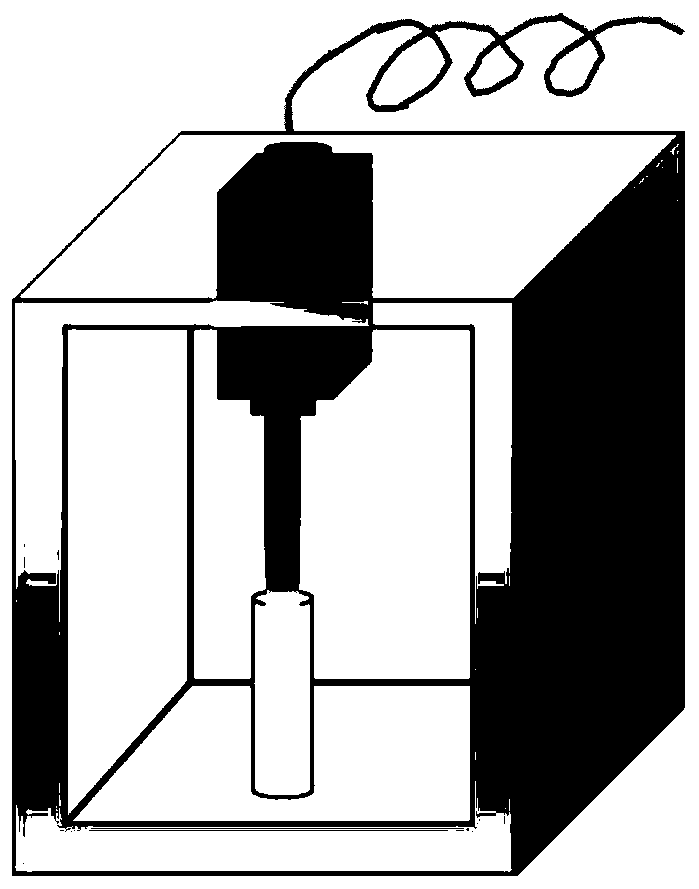

[0042] (1) Take different amounts of BP-PNIPAM solution (100 μL or 200 μL) with a concentration of 1 mg / mL and mix them with E. 6 CFU), at the place where the vertical distance between the top of the mixed solution and the liquid surface is 10cm, it is irradiated by a near-infrared light source for 5min; wherein, the near-infrared light source (see image 3 ) is 808nm, 2W / cm 2 .

[0043] Control group: Take 100 μL or 200 μL black phosphorus solution (1mg / mL) and mix them with E. coli bacterial liquid respectively until the mixed system is 1 mL (the final concentration of E. coli is 106 CFU), and put it at a place where the vertical distance between the top of the mixed solution and the liquid surface is 10cm , irradiated by a near-infrared light source for 5 minutes; wherein, the near-infrared light source (see image 3 ...

Embodiment 3

[0047] The application of black phosphorus composite material in killing bacteria includes the following steps:

[0048] (1) Take the aqueous solutions (1 mg / mL) of the above-mentioned different amounts of black phosphorus composite materials and mix them with the E. 7 CFU); above the mixed solution and the vertical distance from the liquid surface is 10cm, irradiated by a near-infrared light source for 20min, wherein the near-infrared light source is 808nm, 2W / cm 2 ; At the same time, no near-infrared light source was used as a control.

[0049] The aqueous solutions of different amounts of black phosphorus composite materials are respectively 0 μL, 5 μL, 10 μL, 20 μL, 50 μL, 100 μL or 200 μL;

[0050] (2) To dilute the above mixture 4 times. Take the 3rd and 4th solutions and spread them on the plates, incubate the plates in an incubator at 37°C for 14 hours, then count and perform statistical analysis (see Figure 6-7).

[0051] As can be seen from Figures 6 and 7, the ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com