Chitosan-black phosphorus composite hydrogel and preparation method thereof

A composite hydrogel and chitosan technology, applied in medical science, absorbent pads, bandages, etc., can solve the problems of high cytotoxicity and long-term action process, and achieve enhanced photocatalysis, less resource consumption, and equipment investment little effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0018] A first aspect of the present invention provides a method for preparing chitosan-black phosphorus composite hydrogel, the steps comprising:

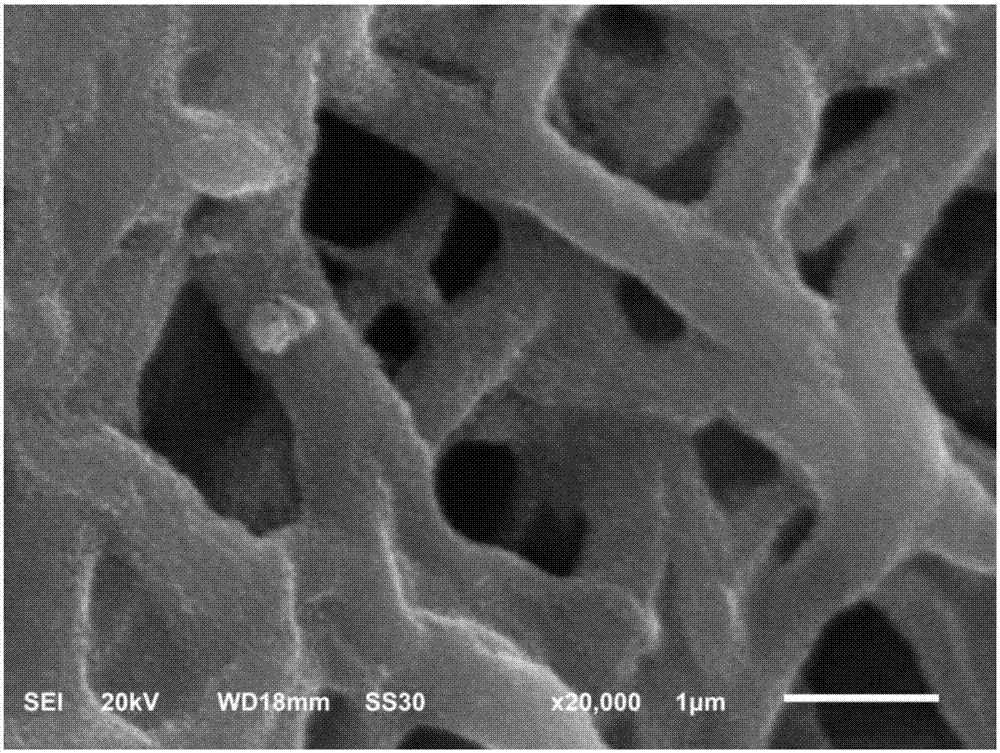

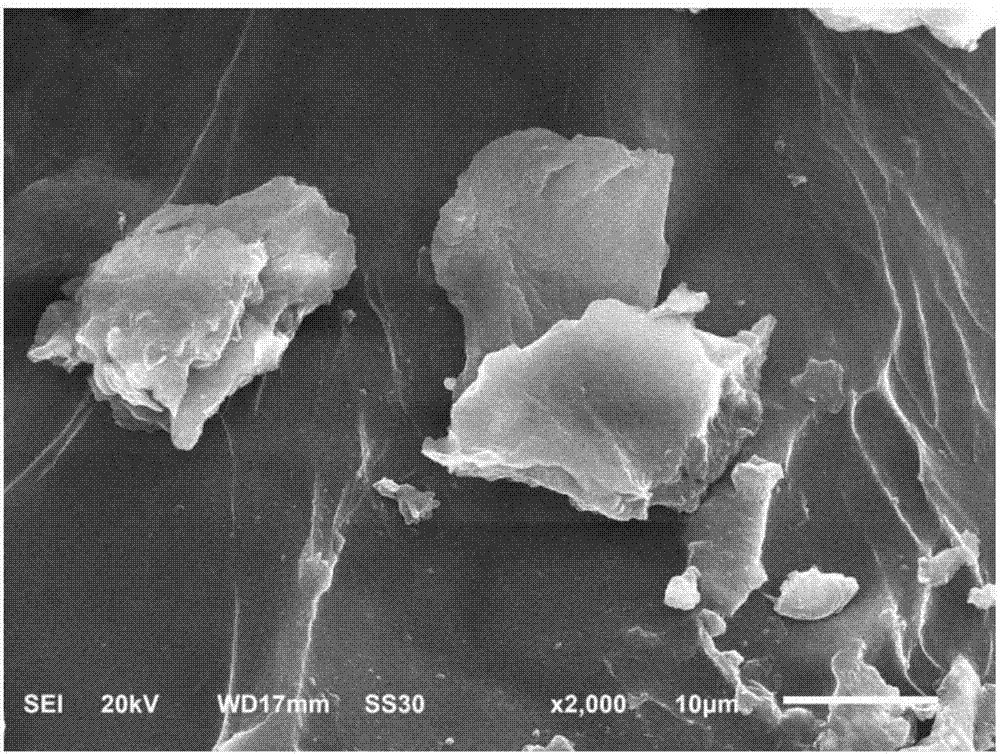

[0019] S1. Disperse the black phosphorus crystal powder in deionized water and inject protective gas, then sonicate for 8-12 hours in an ice bath, and finally centrifuge to obtain an aqueous solution of the upper layer of nano black phosphorus flakes for later use;

[0020] S2, dissolving chitosan in acetic acid aqueous solution, stirring, then adding aloe vera powder, polyethylene glycol and glycerin at 45-55°C, stirring evenly, injecting glutaraldehyde aqueous solution with a volume concentration of 1-2%, stirring Place in an oven at 40-60°C for 6-9 hours to prepare chitosan hydrogel;

[0021] S3. Soak the chitosan hydrogel prepared in step S2 as a carrier in the aqueous solution of nanometer black phosphorus sheets for 10-20 minutes to obtain chitosan-black phosphorus composite hydrogel.

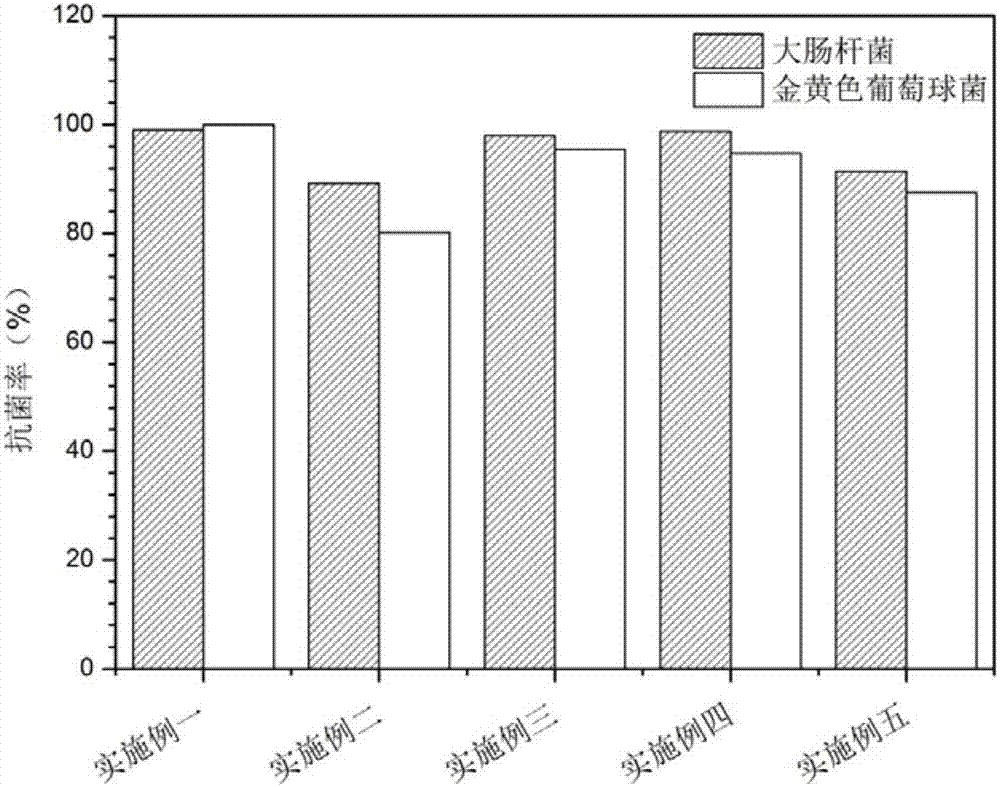

[0022] Reactive oxygen species (ROS),...

Embodiment 1

[0036] S1. Disperse 50 mg of black phosphorus (BP) crystal powder in 80 mL of deionized water and pass through the protective gas argon, then sonicate for 10 h under ice bath conditions, and finally centrifuge for 20 min to obtain the upper nano black phosphorus flake aqueous solution for later use;

[0037] S2. Dissolve 2.5% chitosan in 100mL of acetic acid aqueous solution with a volume concentration of 2%, and continuously mechanically stir for 20min, then place it in a water bath at 50°C, then add 1g of aloe vera powder and 2g of polyethylene glycol in turn. Diol and 1mL of glycerin, after stirring evenly, inject 20mL of a glutaraldehyde aqueous solution with a volume concentration of 2%, pour it into a mold after rapid mechanical stirring for 5s and place it in a 50°C oven for 9h to obtain a chitosan hydrogel;

[0038] S3, soak the chitosan hydrogel prepared in step S2 as a carrier in 2mL of nano black phosphorus sheet aqueous solution for 15min, utilize the negative charg...

Embodiment 2

[0043] S1. Disperse 40mg of black phosphorus (BP) crystal powder in 80mL of deionized water and pass through the protective gas argon, then sonicate under ice bath conditions for 8h, and finally centrifuge for 20min to obtain an aqueous solution of the upper nanometer black phosphorus tablet for later use;

[0044] S2, dissolving 2g of chitosan in 100mL of acetic acid aqueous solution with a volume concentration of 3%, and constantly mechanically stirring for 15min, then placing it in a water bath at 50°C, then adding 0.5g of aloe powder and 1g of polysaccharide Ethylene glycol and 1 mL of glycerin, after stirring evenly, inject 20 mL of glutaraldehyde aqueous solution with a volume concentration of 1%, pour it into a mold after rapid mechanical stirring for 6 seconds, and place it in a 40°C oven for 6 hours to obtain a chitosan hydrogel;

[0045] S3. Soak the chitosan hydrogel prepared in step S2 as a carrier in 1 mL of nano black phosphorus sheet aqueous solution for 10 min, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of deacetylation | aaaaa | aaaaa |

| antibacterial rate | aaaaa | aaaaa |

| antibacterial rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com