Lens cylindrical strip storing box

A cylindrical bar and storage box technology, applied in the field of lens cylindrical bar storage box, can solve the problems of destroying product cleanliness, increasing workload, easy to absorb dust, etc., to improve product cleanliness, reduce static electricity generation, and not easily collide with each other Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

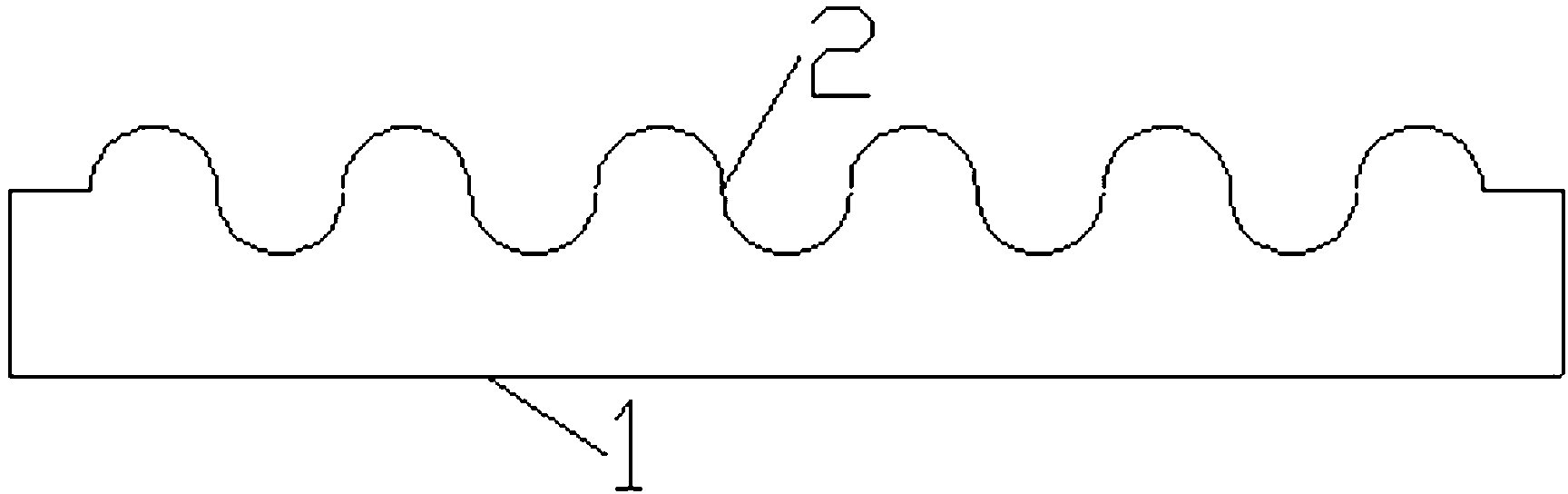

[0014] As shown in the accompanying drawings, the storage box for the lens cylinder includes a base, and the base is provided with multiple rows of compartments for storing the lens cylinder. The compartments are arc-shaped; the bottom of the compartments is semicircular.

[0015] When in use, the present invention is provided with multiple rows of compartments for storing lens cylinders on the base, and one kind of lens is placed in each box or even in each slot, which is convenient for lens classification, counting and faceting, and reduces the mutual collision and friction of lens columns. The groove is arc-shaped, especially the bottom of the groove is semicircular, so that the contact area between the lens column and the box is larger, the placement is more stable, and the lens columns are not easy to collide with each other, which reduces the generation of static electricity and improves the cleanliness of the product.

[0016] In addition, the base and the compartment ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com