Activating treatment method for optical film, method for producing optical laminated-film, optical laminated-film, and image display device

A technology of optical film and processing method, which is applied in thin material processing, chemical instruments and methods, optics, etc. It can solve the problems of unpredictable foreign matter defects, no records or revelations of prevention methods, etc., and achieve reduced appearance defects and excellent adhesion , Improve the effect of adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

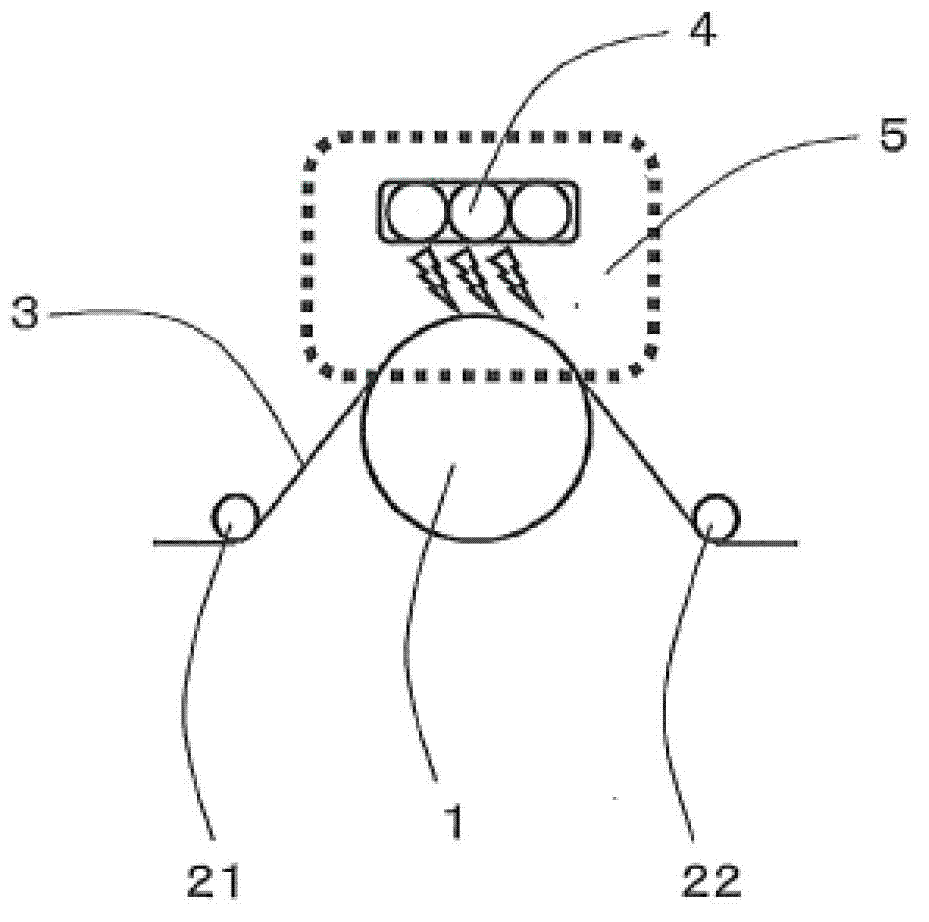

[0131] use figure 1 In the shown device, the optical film 3 laminated so that the thin polarizing plate is on the front side (the surface side where the compensation plate contacts the ground roll 1 ) is used, and the optical film 3 is conveyed while being adhered to the outer peripheral surface of the ground roll 1 , while using the treatment electrode 4 to perform corona discharge treatment. The surface temperature of the ground roller 1 is cooled to 25°C, and the discharge capacity during corona discharge is (250) W / m 2 .

Embodiment 2~5

[0133] Activation treatment was performed in the same manner as in Example 1 except that the amount of discharge treatment during the corona discharge treatment was changed to the amount described in Table 1.

Embodiment 6

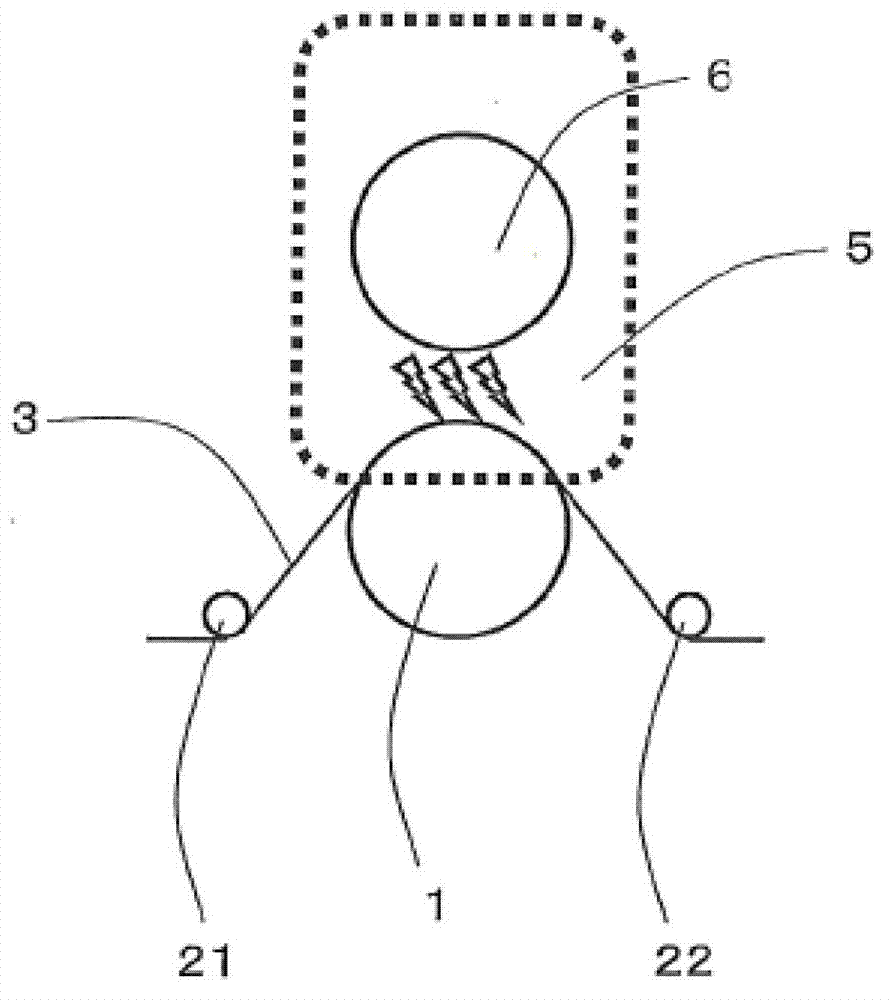

[0135] In addition to changing corona discharge treatment to atmospheric pressure plasma treatment (discharge capacity 250W·min / m 2 ) except that the activation treatment was performed by the same method as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com