Floating waste cutter mechanism and trimming method of trimming mold provided with floating waste cutter mechanism

A technology of trimming dies and scrap knives, applied in the field of stamping dies, can solve the problems of not being able to cut scraps at the same time, appearance defects of plates, affecting the quality of plates, etc., so as to avoid appearance defects, protect product quality, and have good application prospects. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

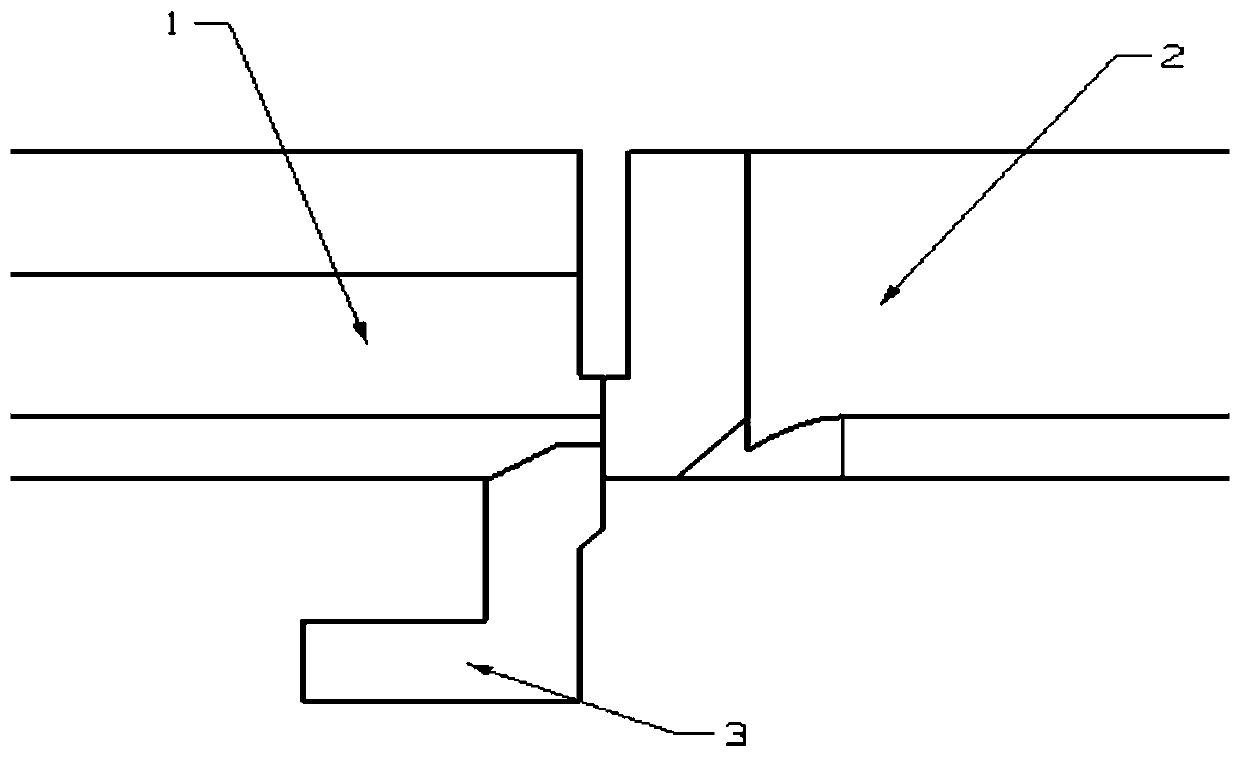

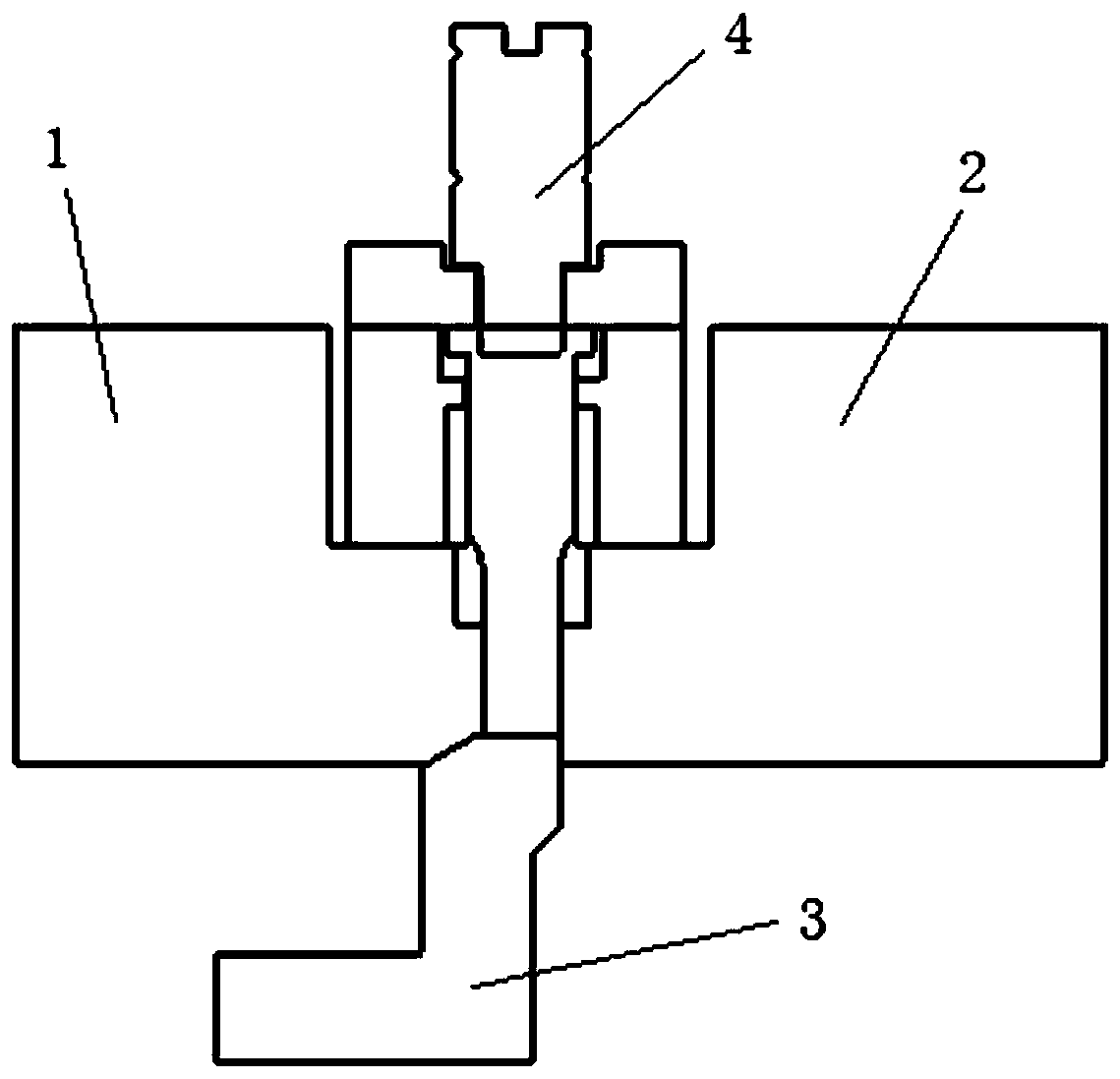

[0020] The specific implementation manner of the present invention will be described in further detail below by describing the embodiments with reference to the accompanying drawings.

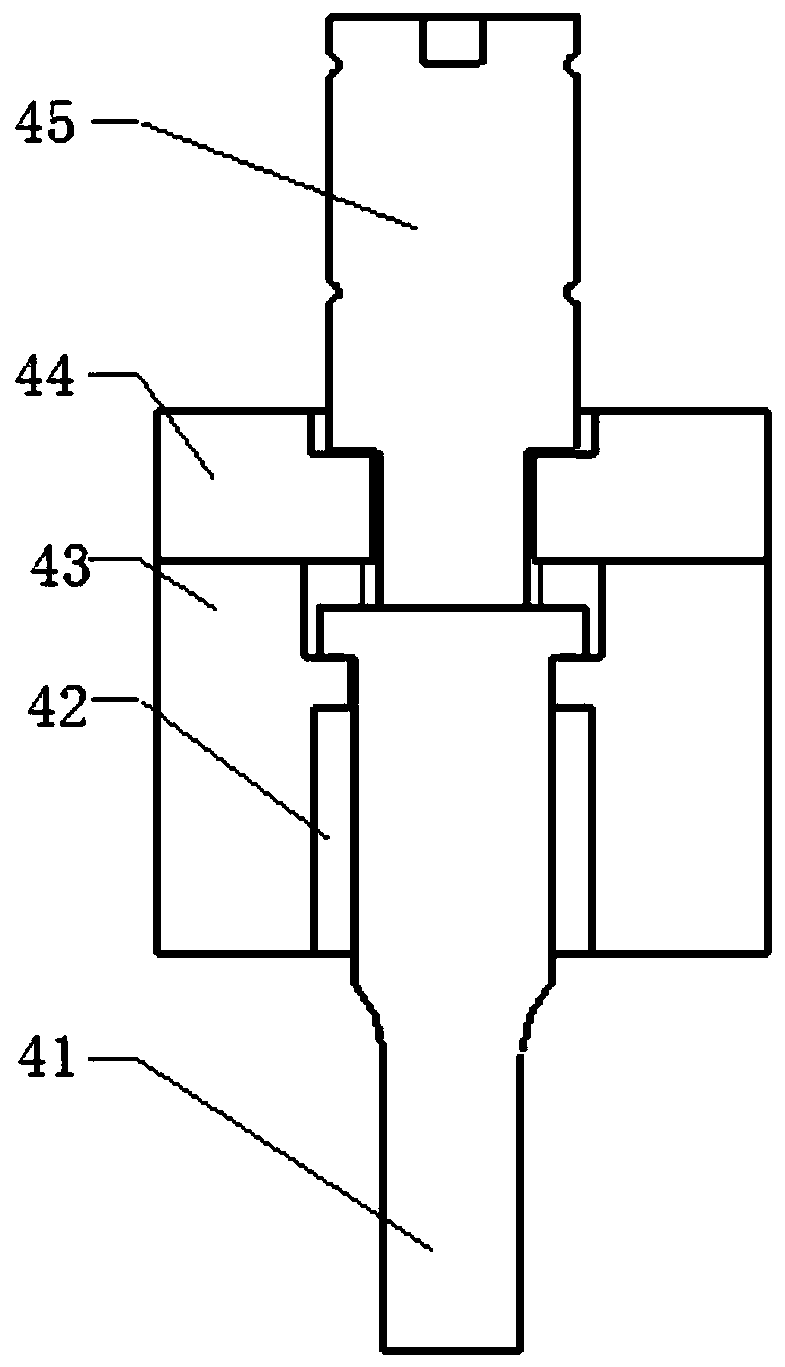

[0021] This floating waste knife mechanism of the present invention, as figure 2 , 3 As shown, it is arranged on the upper mold of the trimming mold. The floating waste knife mechanism includes a floating waste knife 41 that can move up and down relative to the waste knife 3 of the lower mold below. The mold scrap knife 41 acts as a pressure cylinder 45 which separates the panel product from the scrap here.

[0022] In the present invention, if figure 2 , 3 As shown in , the floating waste knife 41 is fixedly connected to the upper mold through the fixed seat 43 , and the inner side of the fixed seat 43 is provided with a limit card platform for clamping the floating waste knife 41 . The upper end of the floating waste knife 41 is provided with a corresponding locking convex edge that is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com