Metal cutter

A cutting knife and metal technology, applied in metal processing equipment, metal processing machinery parts, shearing devices, etc., can solve the problem of high replacement cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The metal cutter of this embodiment is arranged on the rotating shaft 2, and the metal cutting knife includes two blades 1, and a guard 3 is arranged between the blade 1 and the rotating shaft 2, and the guard 3 is used for the blade 1 to encounter more than When the hard material 4 of the hardness is set, the transmission between the blade 1 and the rotating shaft 2 becomes invalid.

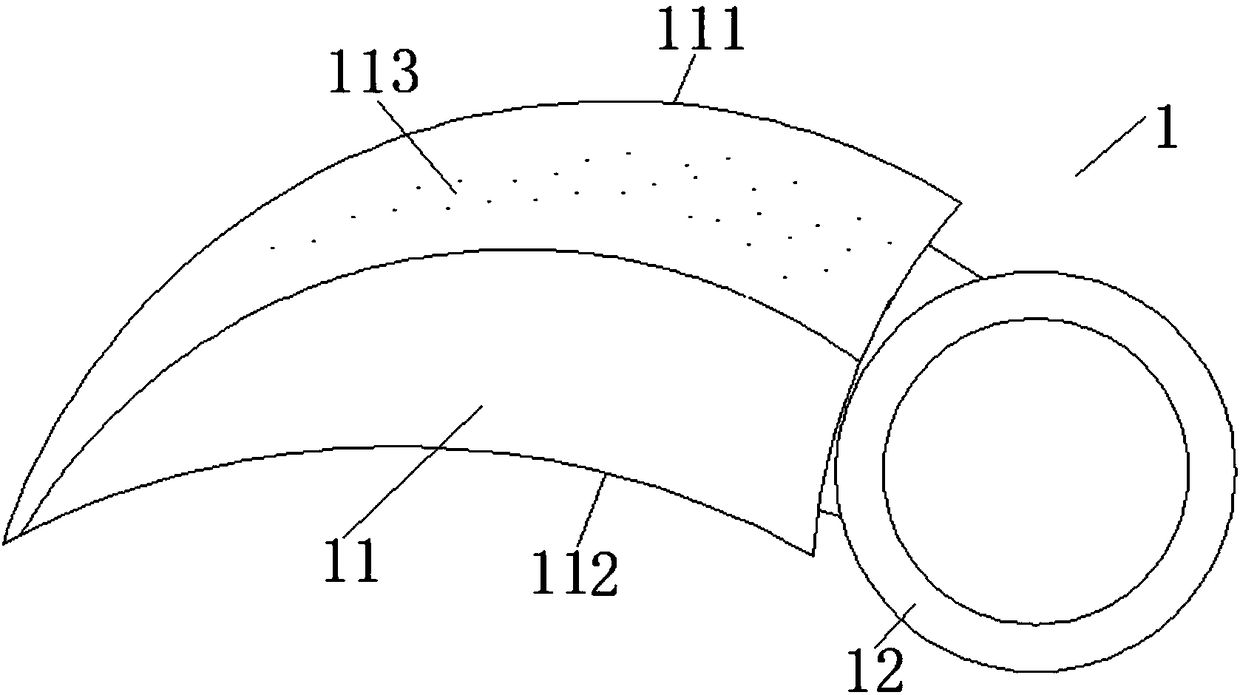

[0028] figure 1 Shown is the blade 1 in this embodiment. The blade 1 includes a blade body 11 and a blade ring 12 integrally formed with the blade body 11 . The blade ring 12 is suitable for being sleeved on the rotating shaft 2 .

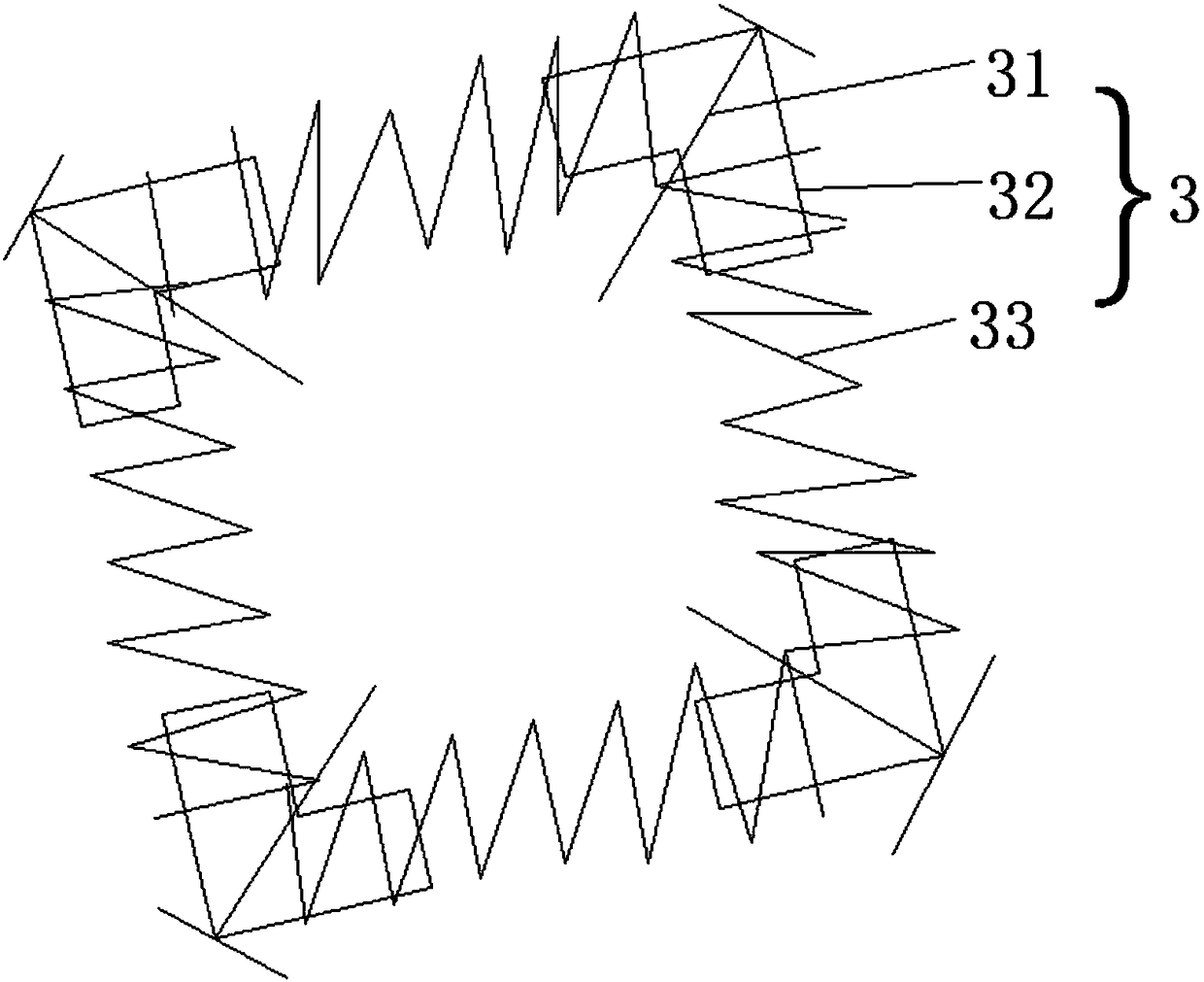

[0029] The protection device 3 includes a fixing part 31 for fixing the knife ring 12. The fixing part 31 radially passes through the knife ring 12 and presses against the rotating shaft 2, and presses against the rotating shaft. When the blade 1 meets a hard material 4 with a hardness greater than the set There is slippage between the fixing member 31 and th...

Embodiment 2

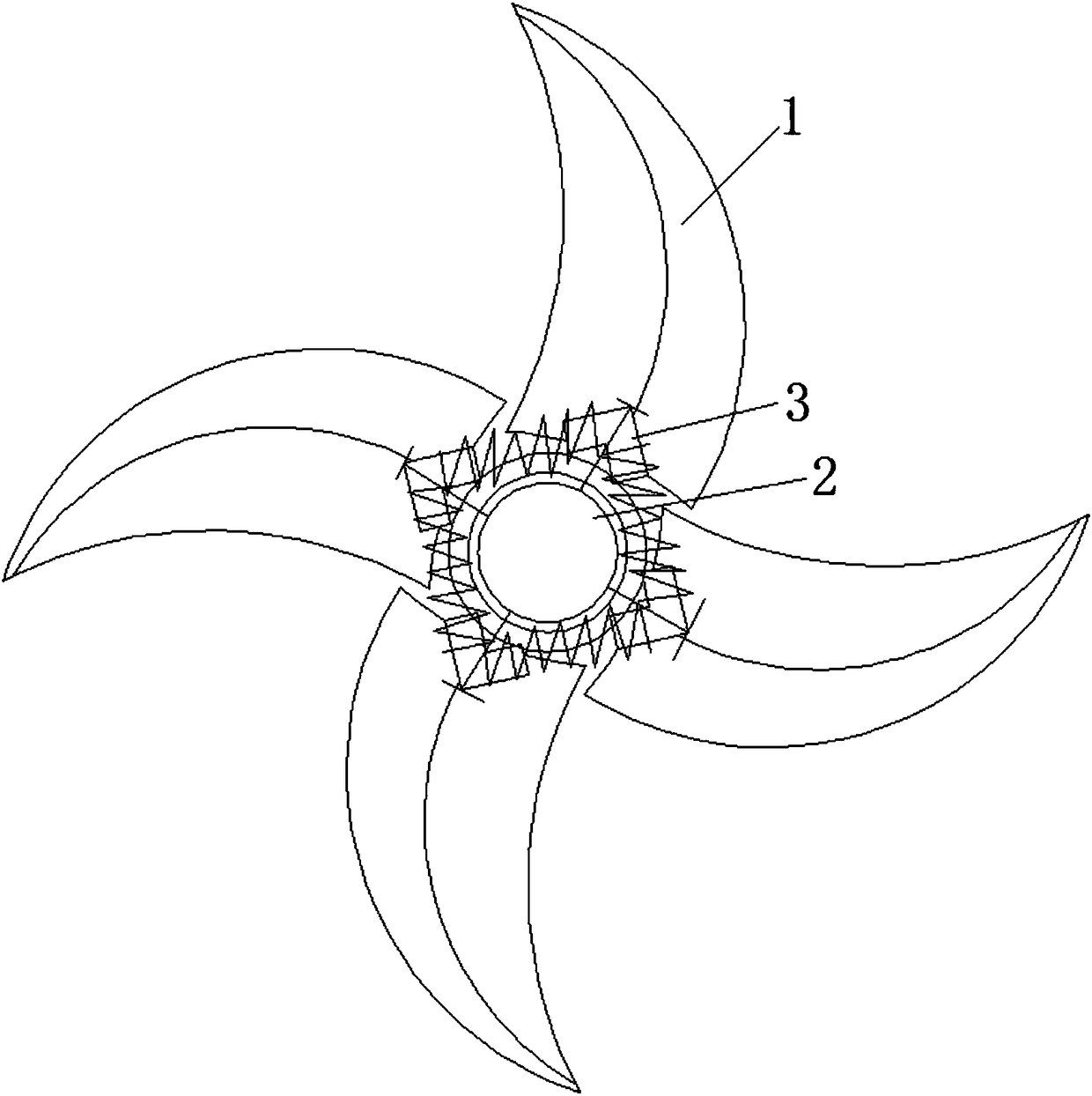

[0031] image 3 Shown is the metal cutter of this embodiment, which is arranged on the rotating shaft 2. The metal cutting knife includes 4 blades 1. In this embodiment, the blades 1 are uniformly arranged around the rotating shaft 2. Between the blades 1 and the rotating shaft 2, there is a The protection device 3 is used to make the transmission between the blade 1 and the rotating shaft 2 ineffective when the blade 1 encounters a hard material 4 with a hardness greater than a set hardness during cutting.

[0032] figure 1 Shown is the blade 1 in this embodiment. The blade 1 includes a blade body 11 and a blade ring 12 integrally formed with the blade body 11 . The blade ring 12 is suitable for being sleeved on the rotating shaft 2 .

[0033] The protective device 3 includes a fixing part 31 for fixing the knife ring 12, a transmission part 32 fixedly arranged on the blade 1, and an elastic conductive part 33. The fixing part 31 radially passes through the knife ring 12 and...

Embodiment 3

[0036] Figure 4 Shown is the metal cutter in this embodiment, the metal cutter includes several blades 1, the number of blades in this embodiment is 4, but not limited to this number, it can also be 3 or 5, the blade 1 and the rotating shaft 2 is provided with a protective device 3, the protective device 3 transmits the force of the rotating shaft 2 to the blade 1, and makes the transmission between the blade 1 and the rotating shaft 2 invalid when the blade 1 cuts hard material 4 with a hardness greater than the set hardness. The blade 1 includes a cutter body 11 and a cutter ring 12 integrally formed with the cutter body 11 , and the cutter ring 12 is suitable for being sleeved on the rotating shaft 2 . The protection device 3 includes a fixing part 31 for fixing the knife ring 12. The fixing part 31 radially passes through the knife ring 12 and presses the rotating shaft 2 against the inner wall of the knife ring. When the blade 1 meets the hard material 4, the fixing part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com