Novel arc-shaped reciprocating saw

A reciprocating saw and arc technology, which is applied to metal sawing equipment, sawing machine tools, metal processing equipment, etc., can solve the problems of electric reciprocating saw baffle breakage, discontinuous reciprocating saw handle, and reduced punching knife life. , to achieve the effect of improving cutting efficiency, improving vibration and increasing sawing depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

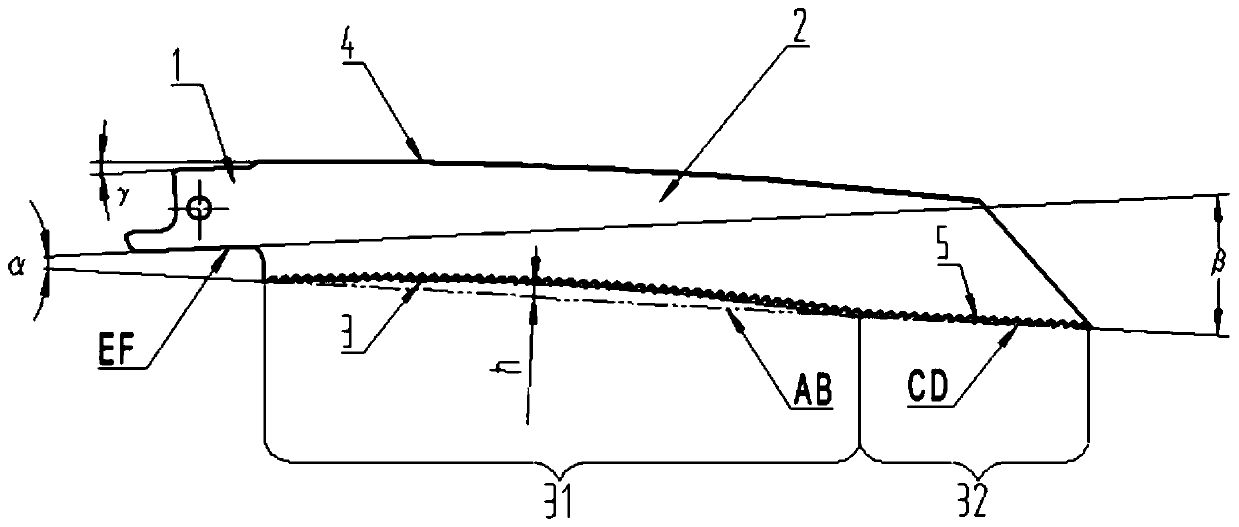

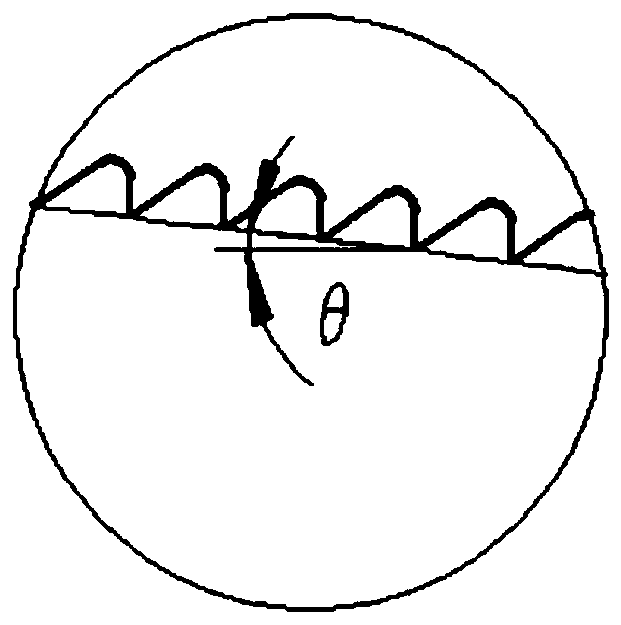

[0034] Such as Figure 1-2 As shown, the present invention provides a novel arc-shaped reciprocating saw, including a saw body 2 and a handle 1 for connecting with an electric reciprocating saw clamping device; the cutting edge 3 of the saw body 2 is provided with a row of saw teeth 5 ; The cutting edge 3 includes an arc-shaped curved portion 31, and the back edge 4 of the saw body 2 is arc-shaped.

[0035] Further, the cutting edge 3 also includes at least a section of straight line section 32 .

[0036] Further, the cutting edge 3 includes an arc-shaped curve portion 31 and a straight-line portion 32 , and the arc-shaped curve portion 31 is close to the handle 1 .

[0037] Further, the cutting edge 3 includes an arc-shaped curved portion 31 and two straight-line portions 32 , and the arc-shaped curved portion 31 is located between the two straight-line portions 32 .

[0038] Further, the length AB of the line segment between the two ends of the arc-shaped curve part 31 is ...

Embodiment 2

[0045] The difference between this embodiment and Embodiment 1 is that the cutting edge 3 is an arc curve 31 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com