Four cables and eight petals nickel ore grab

A nickel ore and bucket flap technology, which is applied in the field of nickel ore bulk materials and four-rope and eight-petal nickel ore grab buckets, can solve the problem that the material cannot reach the theoretically calculated tonnage, etc., and achieves improved grasping force, sharp shape and reduced size. The effect of a small area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the technical means, creative features, objectives and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

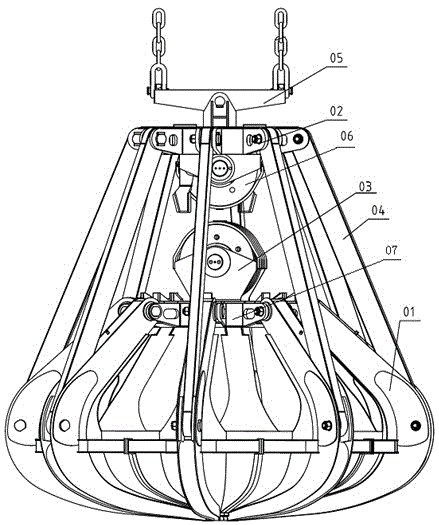

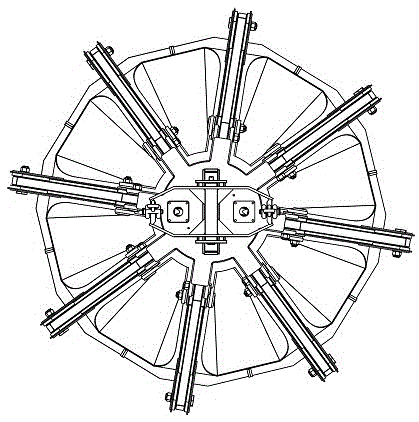

[0019] see figure 1 and 2 , four-cable eight-petal nickel ore grab, including bucket petals 01 connected to the lower end of the strut 04, the upper end of the strut 04 is rotatably connected to the upper bolster 02 through a pin shaft, and the upper bolster 02 is set on the load-bearing cable balance frame 05 On the top, the upper bolster is provided with a fixed pulley block 06; the upper end of the bucket petal 01 is hinged with the lower bolster 07, and the lower bolster is provided with a movable pulley block 03, and the fixed pulley block 06 and the movable pulley block 03 are connected by connecting members. It is a conventional structure and will not be described in detail here.

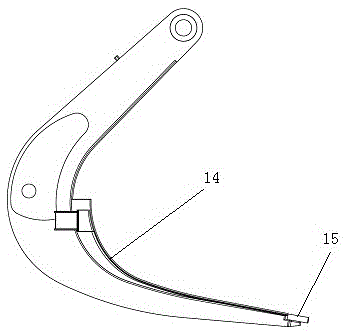

[0020] In the present invention, there are eight buc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com