Nozzle electron beam welding method

A technology of electron beam welding and nozzles, which is applied in the direction of electron beam welding equipment, welding equipment, metal processing equipment, etc., to achieve the effects of avoiding appearance defects, reducing welding deformation, and high energy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

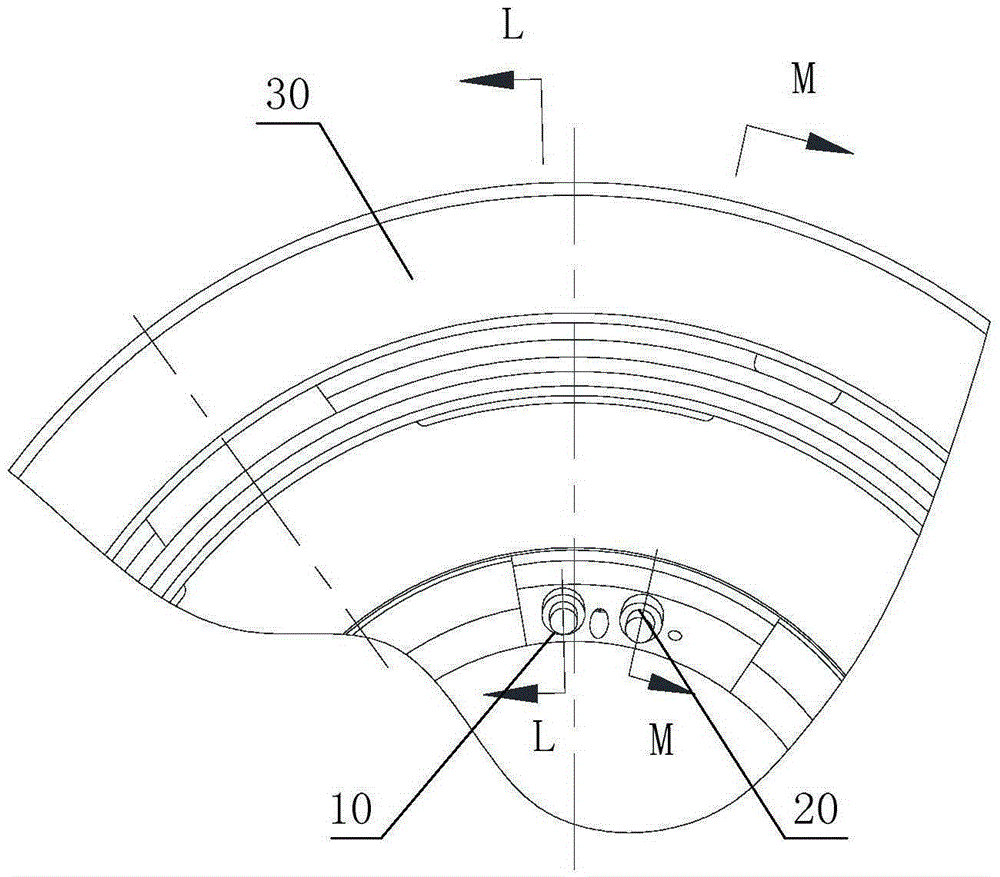

[0043] refer to Figure 6 , a preferred embodiment of the present invention provides a nozzle electron beam welding method, comprising steps:

[0044] Step S100, putting the nozzle to be welded into the casing, and completing the assembly of the nozzle to be welded.

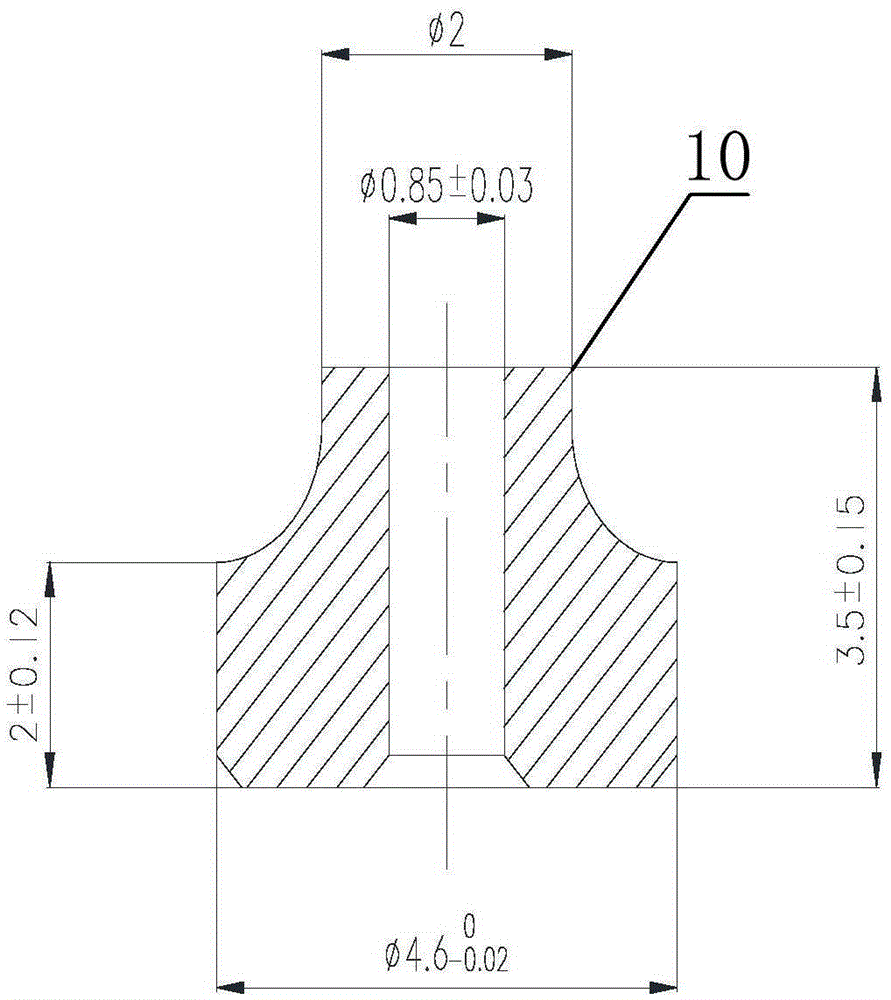

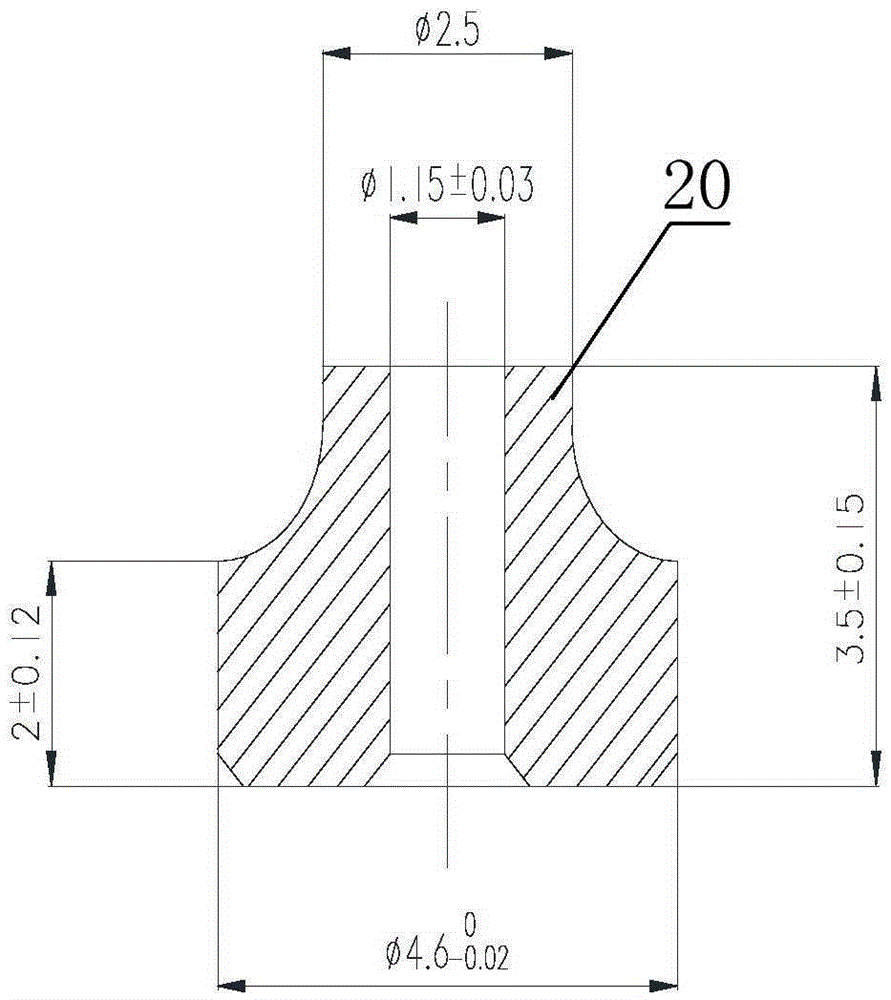

[0045] Since the size of the nozzle to be welded is too small, and the fit with the bottom hole of the casing is an interference fit, a conduit with a diameter of φ4mm is used as an auxiliary tooling, and the boss at the front end of the nozzle is inserted into the conduit hole, and then Align the bottom of the nozzle to be welded with the bottom hole of the casing, tap the conduit lightly, and put the nozzle to be welded into t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com