Polarizer protection film, polarizing plate and image display

A technology for polarizers and protective films, applied in polarizing elements, optics, instruments, etc., can solve the problems of lowering heat resistance, polarization degree or color tone polarizing plate performance, resin coloring and yellowing, etc., to achieve excellent ultraviolet absorption capacity, Effect of coloring and less foaming, excellent optical clarity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0165]Hereinafter, although an Example demonstrates this invention concretely, this invention is not limited to these Examples. In addition, unless otherwise specified, the percentage in an Example and a comparative example is a basis of weight. Evaluation is performed in the following manner.

[0166]

[0167] The weight-average molecular weight of the polymer was determined in terms of polystyrene by GPC (gel permeation chromatography) (GPC system manufactured by Tosoh Co., Ltd.). Chloroform was used as a developing solution.

[0168]

[0169] The thermal analysis of the resin was carried out using a DSC (differential scanning calorimeter) (manufactured by Rigaku Co., Ltd., device name: DSC-8230). In addition, glass transition temperature (Tg) was calculated|required by the midpoint method based on ASTM-D-3418.

[0170]

[0171] First, based on the weight loss that occurs when all the hydroxyl groups are dealcoholated in the form of methanol from the polymer compos...

reference example 1

[0202] [Reference Example 1]: Manufacture of polarizing plate

[0203] A polyvinyl alcohol film having a thickness of 80 μm was dyed in a 5% by weight (weight ratio: iodine / potassium iodide=1 / 10) iodine aqueous solution. Next, the polyvinyl alcohol film was immersed in an aqueous solution containing 3% by weight of boric acid and 2% by weight of potassium iodide, and further stretched to 5.5 times in an aqueous solution containing 4% by weight of boric acid and 3% by weight of potassium iodide. , dipped in a 5% by weight potassium iodide aqueous solution. Thereafter, it was dried in an oven at 40° C. for 3 minutes to obtain a polarizing plate with a thickness of 30 μm.

reference example 2

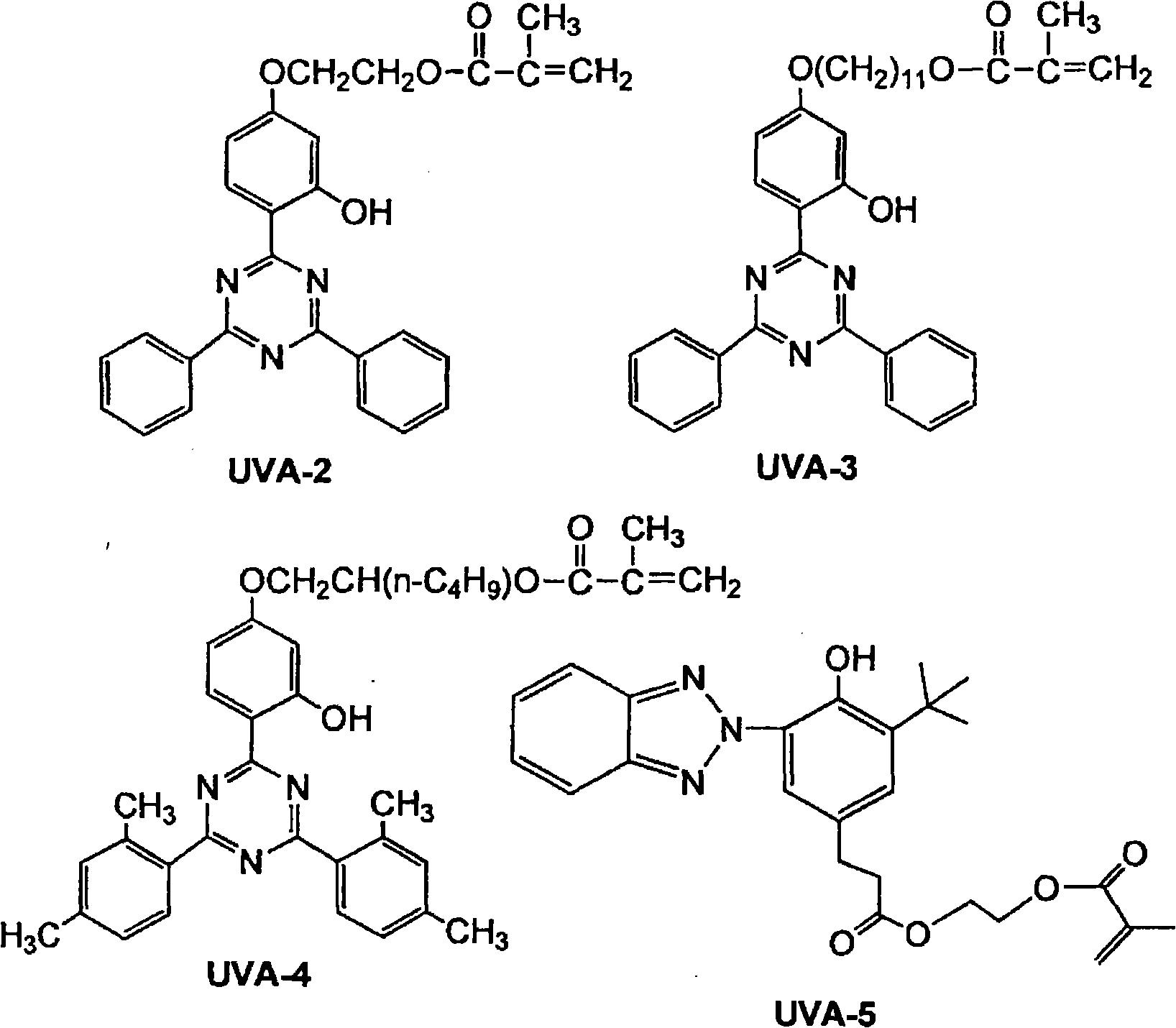

[0204] [Reference Example 2]: Production of acrylic resin containing a lactone ring (Using UV-absorbing monomer)

[0205] In a 30L reaction kettle equipped with a stirring device, a temperature sensor, a condenser tube, and a nitrogen introduction tube, 7000g of methyl methacrylate (MMA), 1000g of 2-[2'-hydroxyl-5'-(methacryloyl Oxyethyl) phenyl] benzotriazole, 2000g of 2-(hydroxymethyl) methyl acrylate (MHMA), 10000g of toluene, nitrogen gas was introduced therein, and the temperature was raised to 105°C, and reflux was carried out, and then Add 10.0 g of tert-amyl peroxyisononanoate (manufactured by Arkema Yoshitomi, trade name: Lupasol 570) as an initiator, and at the same time, dropwise add a solution containing 20.0 g of the initiator and 100 g of toluene for 4 hours, while refluxing Solution polymerization was carried out at low temperature (about 105-110° C.), followed by aging for 4 hours.

[0206] Add 10 g of octadecyl phosphate / dioctadecyl phosphate mixture (manufac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com