Antiblocking agent masterbatch for plastic film and preparation method of antiblocking agent masterbatch

A technology of plastic film and opening agent, which is applied in the field of opening agent master batch for plastic film and its preparation, can solve the problems of reduced optical performance, poor bonding force, poor quality of plastic film, etc., to ensure transmittance and improve bonding force, reducing the effect of membrane rupture problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

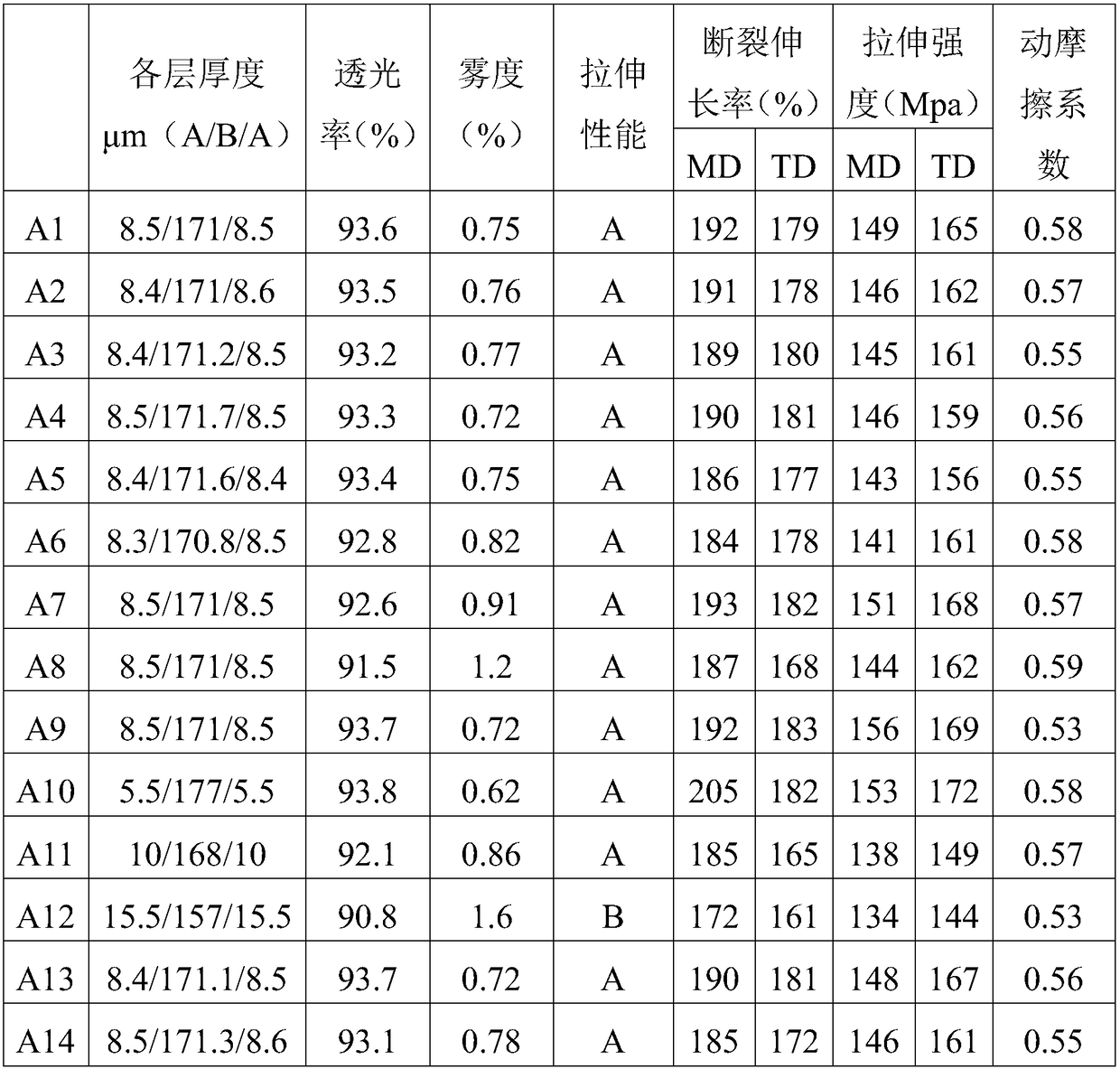

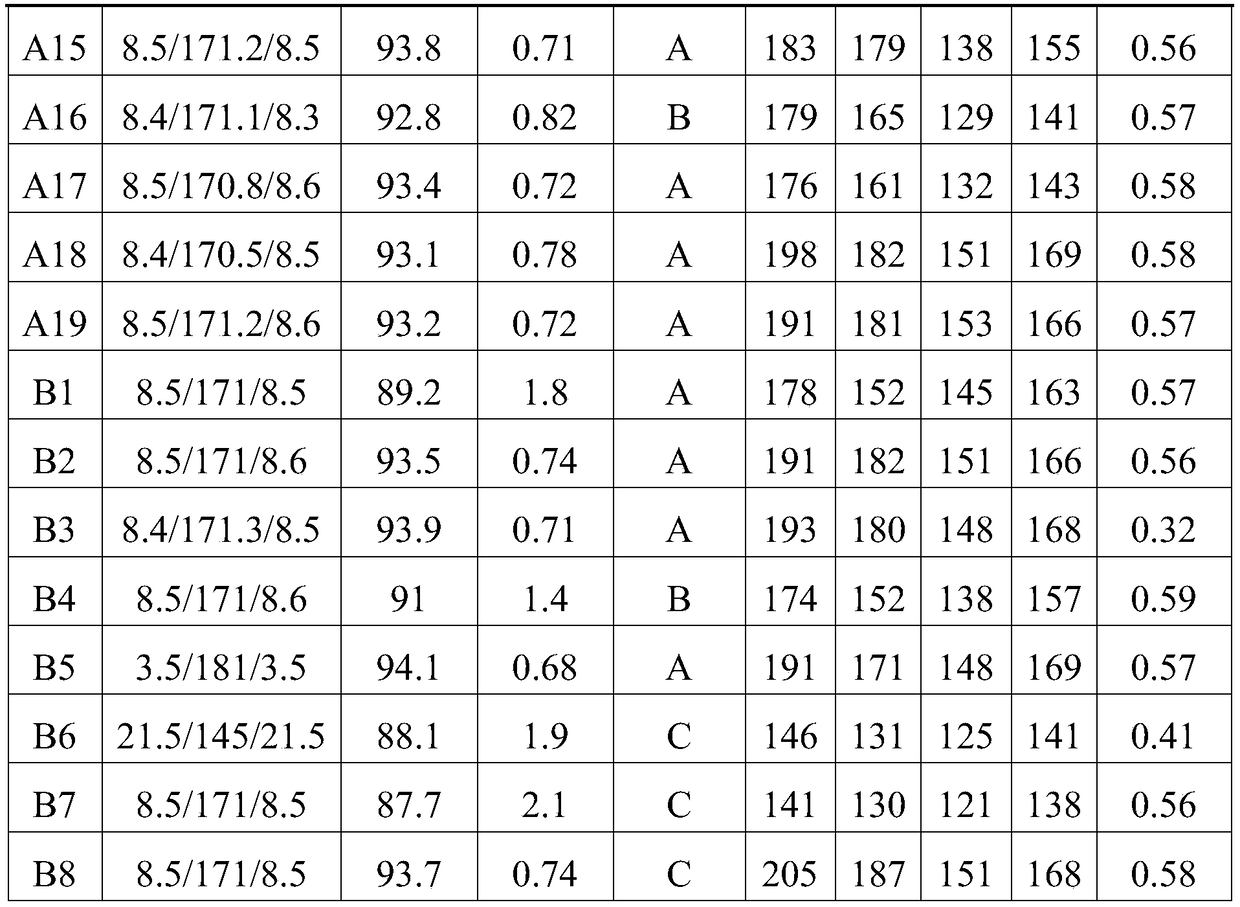

Examples

preparation example Construction

[0027] The preparation method of the modified inorganic particles comprises: ultrasonically dispersing the inorganic particles and the compatibilizer in an organic solvent, recovering the organic solvent, and drying to obtain the inorganic particles coated with the compatibilizer.

[0028] In the present invention, by carrying out surface modification to the inorganic particles, the binding ability between the inorganic particles in the plastic film and the plastic is improved, so that the phenomenon of poor appearance caused by the shedding of the inorganic particles on the surface of the plastic film is reduced; especially The shedding of inorganic particles on the surface of some plastic films occurs during storage and transportation to the terminal, which brings difficulties to the quality inspection and interception of the manufacturer. Often, there is no problem in the detection after the production is completed, but it is only discovered when the terminal is used. series...

Embodiment 1

[0061] S1: Modification of inorganic particles

[0062] The silicon dioxide particles and the compatibilizer ABS-g-MAH (grafting rate ≥ 0.5%) are ultrasonically dispersed in acetone, the acetone is recovered and dried to obtain the compatibilizer-coated silicon dioxide particles. Among them, the mass ratio of silica particles, compatibilizer ABS-g-MAH (grafting rate ≥ 0.5%) and acetone is 1:0.07:19;

[0063] S2: Preparation of anti-blocking agent masterbatch

[0064] Add polyethylene terephthalate, modified silica particles and other additives into the twin-screw extruder through weight loss, and make the modified inorganic particles in the carrier resin through shearing and mixing of the screws. Disperse evenly to obtain a molten mixture, pressurize the molten mixture through a melt pump and filter through a filter to obtain a molten product, then pull the molten material into strands, cool it through a water tank, and then continuously pass it through a water eliminator and...

Embodiment 2

[0073] The polyester film that provides as embodiment 1, in the modified treatment of silicon dioxide particle, the mass ratio of silicon dioxide particle, compatibilizer ABS-g-MAH (grafting rate ≥ 0.5%) and acetone is changed to 1:0.07:18, with the rest unchanged, the polyester film was prepared, and the prepared polyester film was recorded as A2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com