Conveniently folding window curtain

A curtain and curtain body technology, applied in the field of curtains, can solve problems such as strength reduction, light transmission, and many appearance defects, and achieve the effects of low loss of defective products, easy jacquard, and reduced appearance defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

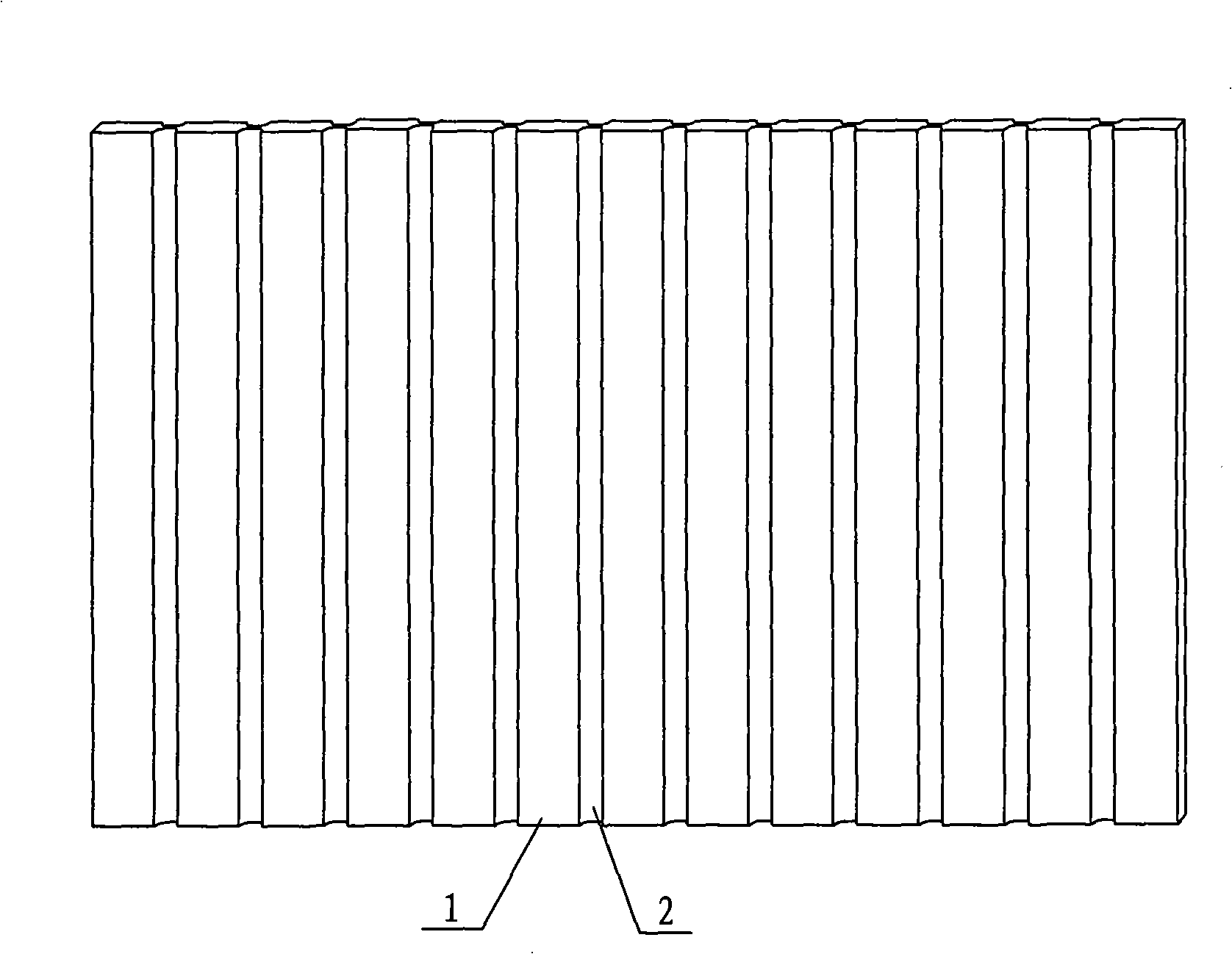

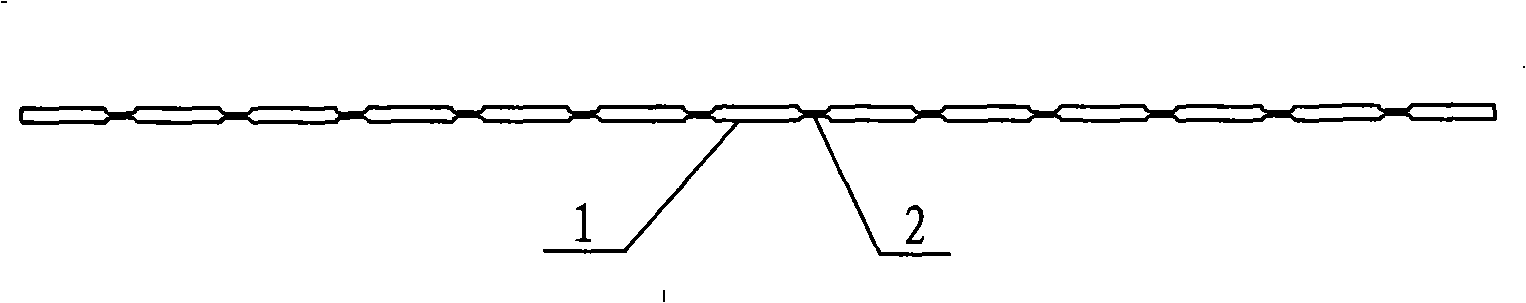

[0043] See figure 1 with figure 2 The curtain of the present invention is easy to fold, including a curtain body. The curtain body is composed of a plurality of thick fabric sections 1 and thin fabric sections 2 spaced apart from each other. The curtain of the present invention can be folded horizontally. When folded, the two adjacent thick The fabric section is folded along the thin fabric section between the two. The thickness of the thick fabric section is greater than the thickness of the thin fabric section, and the thin fabric section is slightly softer for folding.

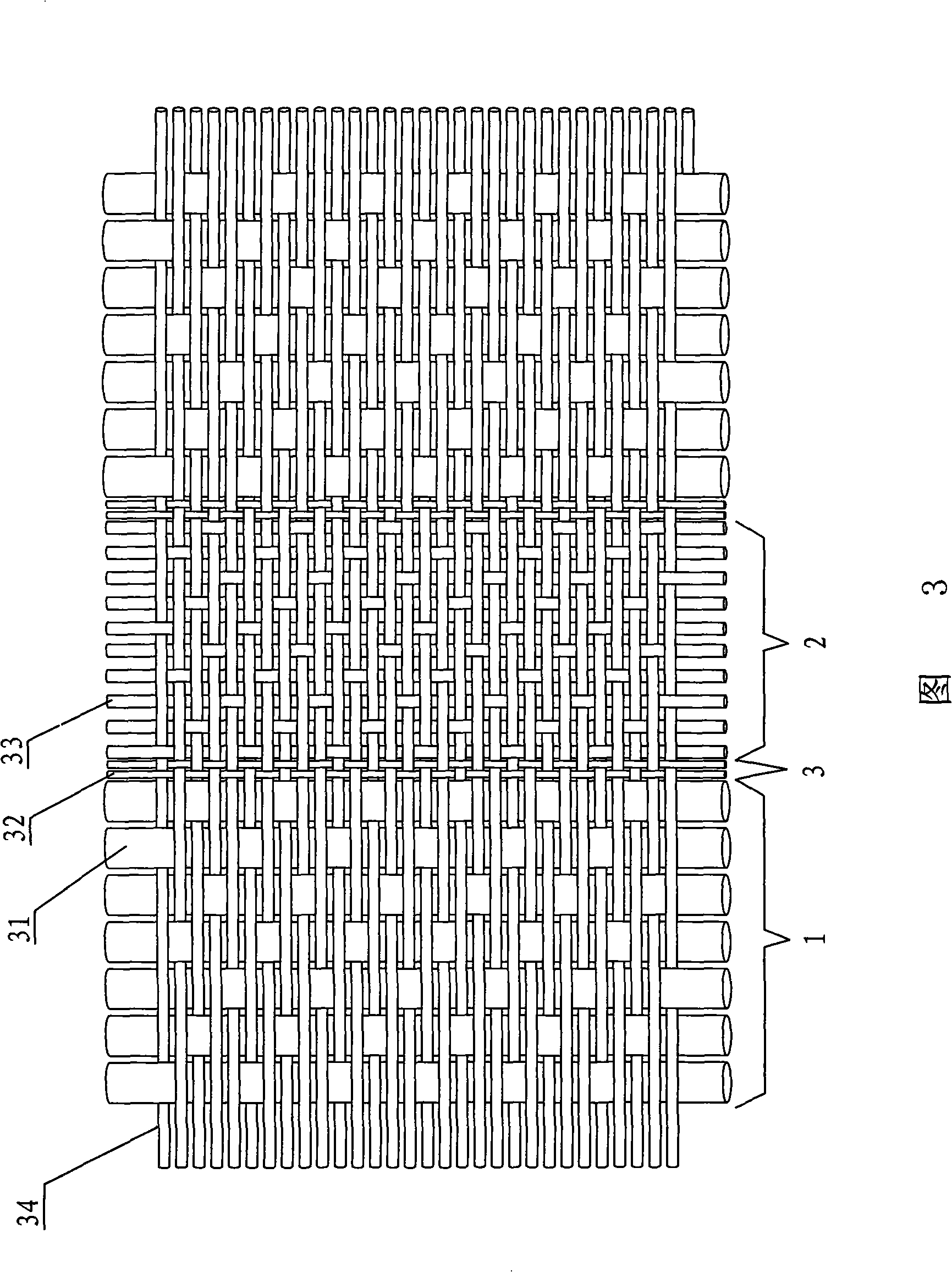

[0044] Referring to FIG. 3, it can be seen that a seam weave 3 is provided at the junction of the thick fabric section 1 and the thin fabric section 2.

[0045] The linear density of the warp yarn 34 used for weaving the curtain body is 11.1 tex; the linear density of the weft yarn 31 used for weaving the thick fabric section 1 is 222 tex; the weft used for weaving the thin fabric section 2 The linear density...

Embodiment 2

[0060] When weaving, the curtain body adopts the warp yarn with a linear density of 16.7 tex as a whole, and the density of the warp yarn is 550 (pieces / 10cm).

[0061] (1) Weaving the weft yarn with a linear density of 222 tex and the curtain body warp yarn to form a thick fabric section with a width of 6.5 cm;

[0062] (2) Weaving with two weft yarns with a linear density of 8.3 tex and curtain body warp yarns to form a first seam weave, the width of the first seam weave is 0.1 cm;

[0063] (3) Weaving the weft yarn with a linear density of 8.3 tex to form a thin fabric section with a width of 0.5 cm;

[0064] (4) Weaving with two weft yarns with a linear density of 8.3 tex and curtain body warp yarns to form a second seam weave, the width of the second seam weave is 0.1 cm;

[0065] (5) Repeat steps (1) to (4) until a predetermined length of fabric is obtained;

[0066] (6) After the fabric is dyed and surface treated, the weft skew correction and setting are performed at 220°C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com