Impact resistance high wearing-proof conveyer belt

A high wear-resistant, conveyor belt technology, applied in the field of conveyor belts, can solve the problems of downtime loss maintenance costs, poor elasticity of covering rubber, short service life, etc., and achieve environmental protection and resources, poor wear performance, and use long life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

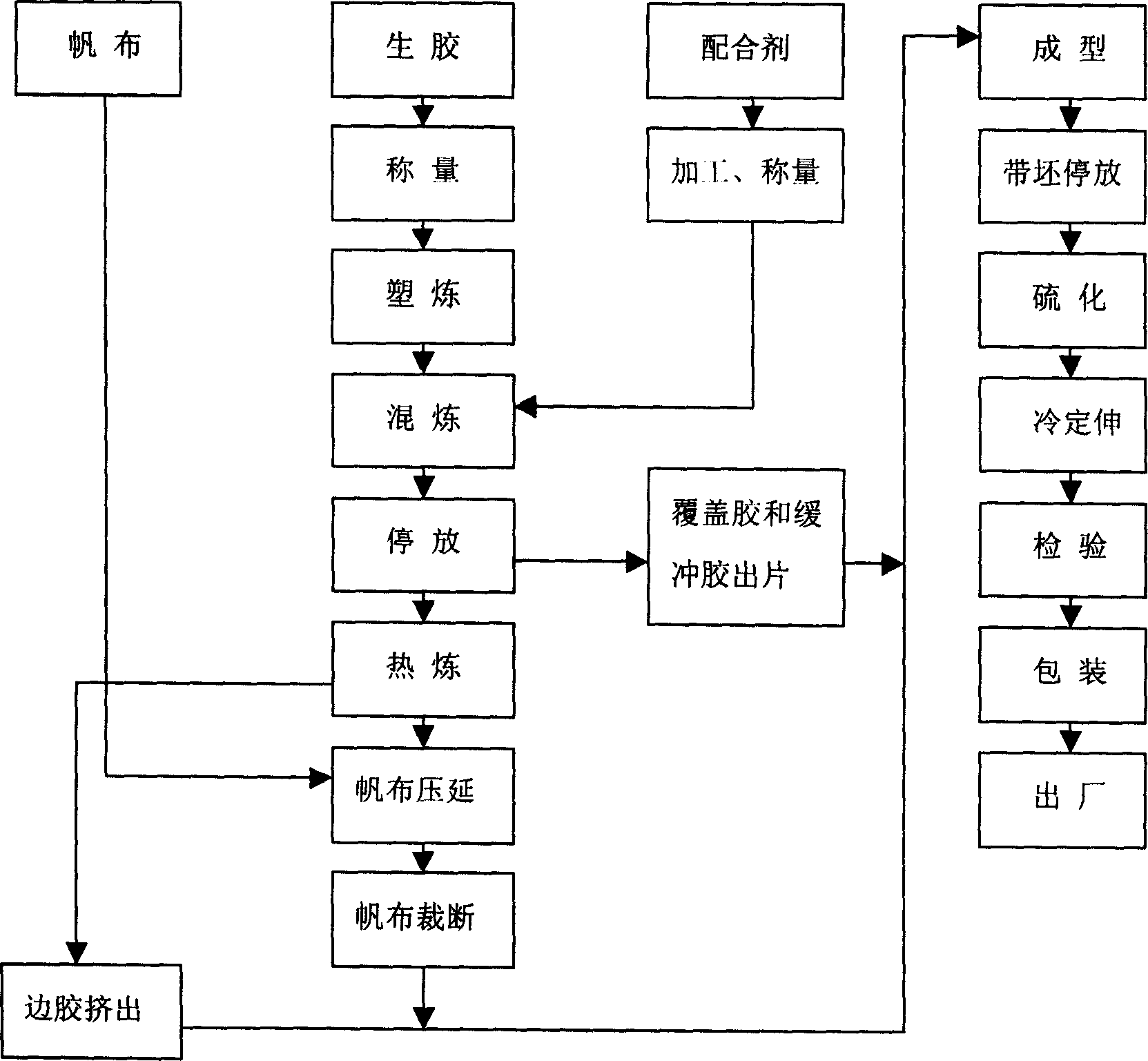

Method used

Image

Examples

Embodiment 1

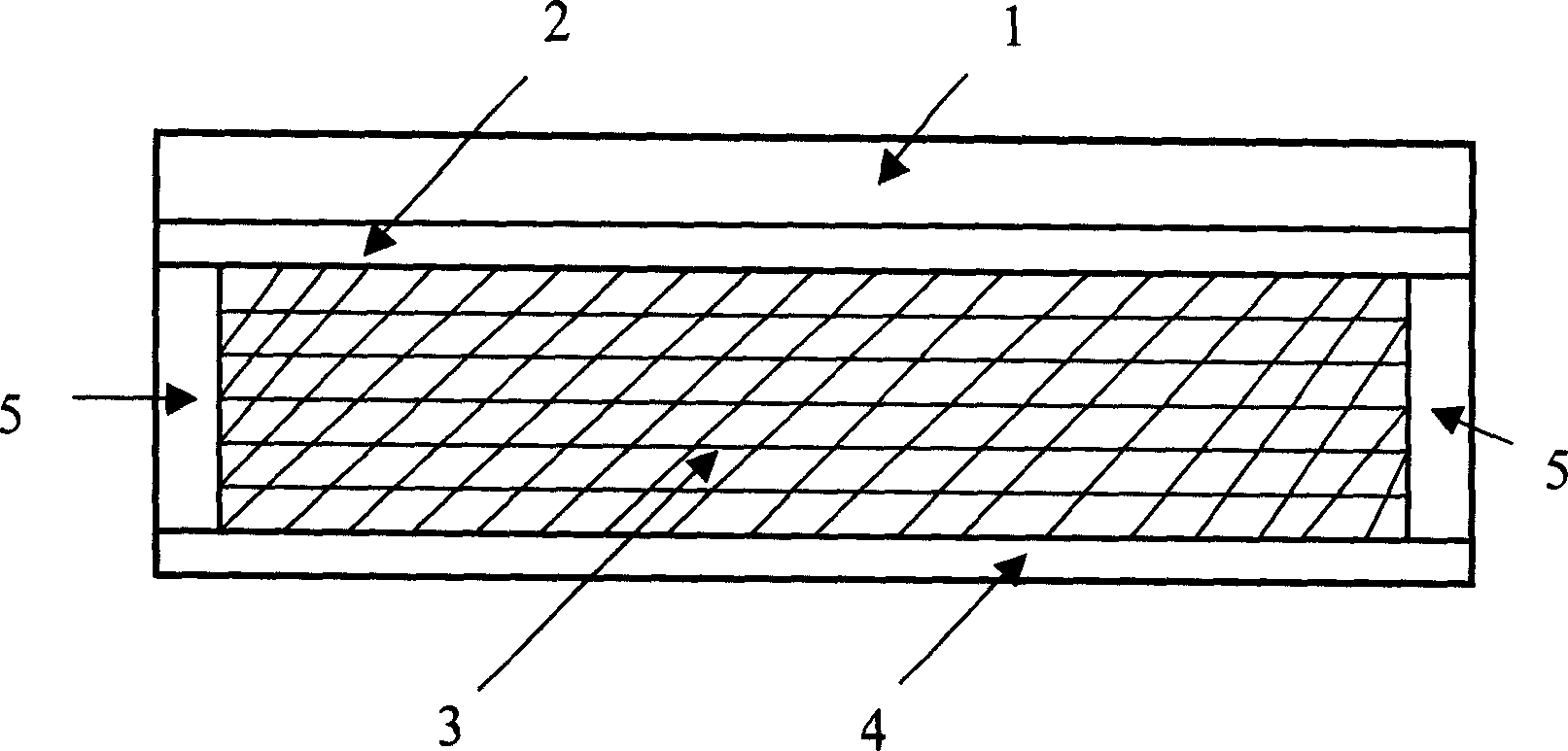

[0015] Embodiment one: the structure of conveyor belt of the present invention is as figure 2 As shown, it is composed of an upper cover rubber 1, a buffer rubber 2, a belt core 3, a lower cover rubber 4 and an edge rubber 5. To achieve the dual effects of impact resistance and high wear resistance, the production of covering rubber is the key. The covering rubber preparation material of this embodiment comprises the following components and weight content: 70 parts of natural rubber, 30 parts of synthetic rubber, 1.8 parts of sulfur, 5 parts of zinc oxide, 2.5 parts of stearic acid, 1.8 parts of accelerator, 55 parts of reinforcing agent parts, 11.5 parts of softening agent, 3 parts of anti-aging agent, add up to 180.6 parts.

[0016] In terms of rubber materials, natural rubber has good elasticity, strength, adhesion, and process performance, but its wear performance is slightly worse, and its impact elasticity is not as good as that of butadiene rubber. Butadiene rubber ...

Embodiment 2

[0037] Embodiment 2: The production process is basically the same as in Embodiment 1. The material components of the covering rubber are adjusted appropriately, and the following formula is adopted: 75 parts of natural rubber, 35 parts of synthetic rubber, 2 parts of sulfur, 5 parts of zinc oxide, stearin 3 parts of acid, 2 parts of accelerator, 60 parts of reinforcing agent, 13 parts of softener, 4 parts of anti-aging agent, 199 parts in total.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tear strength | aaaaa | aaaaa |

| Tear strength | aaaaa | aaaaa |

| Absorbance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com