Polyolefin microporous membrane preparation method and use

A technology of polyolefin microporous membrane and polyolefin, which is applied in the field of polyolefin film, and can solve problems such as difficulty in achieving air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

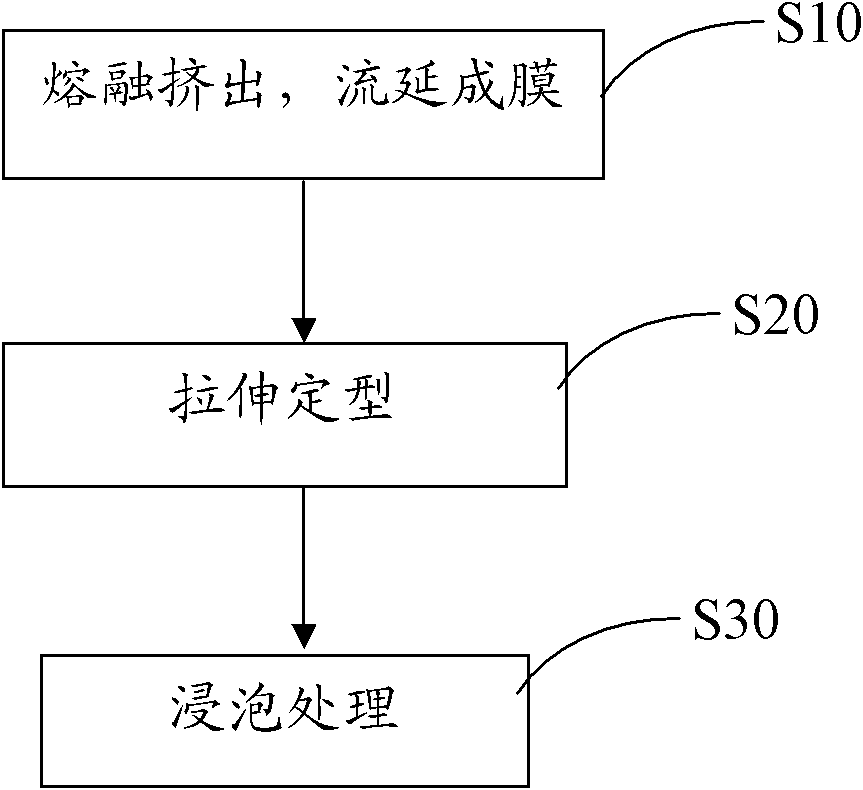

[0022] see figure 1 , showing the flow chart of the polyolefin microporous membrane preparation method of the embodiment of the present invention, including the following steps:

[0023] S01, melt extrusion, cast film formation: polyolefin is melt extruded at 180-260°C, and cast into a film to obtain a polyolefin cast base film;

[0024] S02, stretching and setting: stretching the polyolefin casting base film, and then performing heat setting treatment to obtain a preformed polyolefin microporous film;

[0025] S03, soaking treatment: soak the preformed polyolefin microporous membrane in an organic solvent with a surface tension lower than 30 mN / m, remove the organic solvent after soaking, and obtain the polyolefin microporous membrane.

[0026] In step S01, the polyolefin can be selected from but not limited to polypropylene, polyethylene, polytetramethylpentene or mixtures thereof. The polypropylene used may be homopolypropylene or copolypropylene, among which homopolyprop...

Embodiment 1

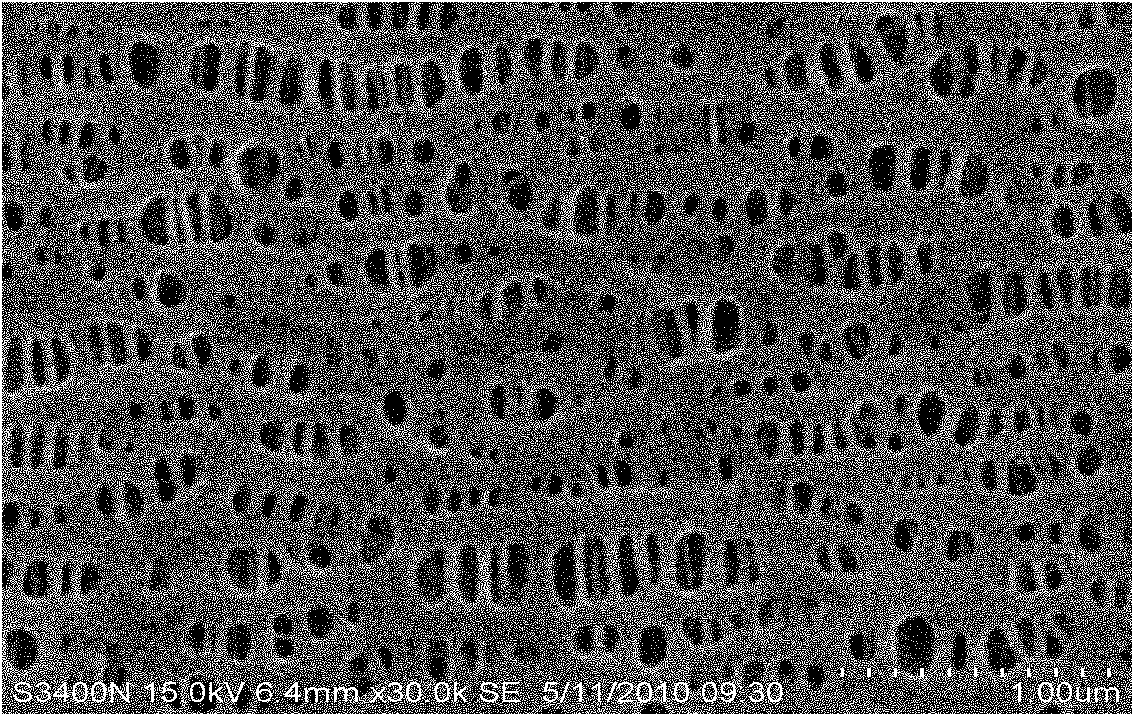

[0035] A homopolypropylene single-screw extruder with a melt index of 3.0 g / 10 min was used to extrude and cast a thick film, the extrusion temperature was 180° C., the temperature of the casting roll was 30° C., and the thickness of the tape-cast thick film was 40 microns. Then heat treatment at 110° C. for 10 hours in an oven. The cold drawing temperature is normal temperature, the cold drawing ratio is 20%, the hot drawing temperature is 110°C, and the hot drawing ratio is 120%. Carry out heat setting treatment again, heat setting temperature 110 ℃, heat setting time 20s. Then soak the film online in acetone for 5 minutes, leave the soaking solution, and dry the film at room temperature to obtain the final PP microporous film.

Embodiment 2

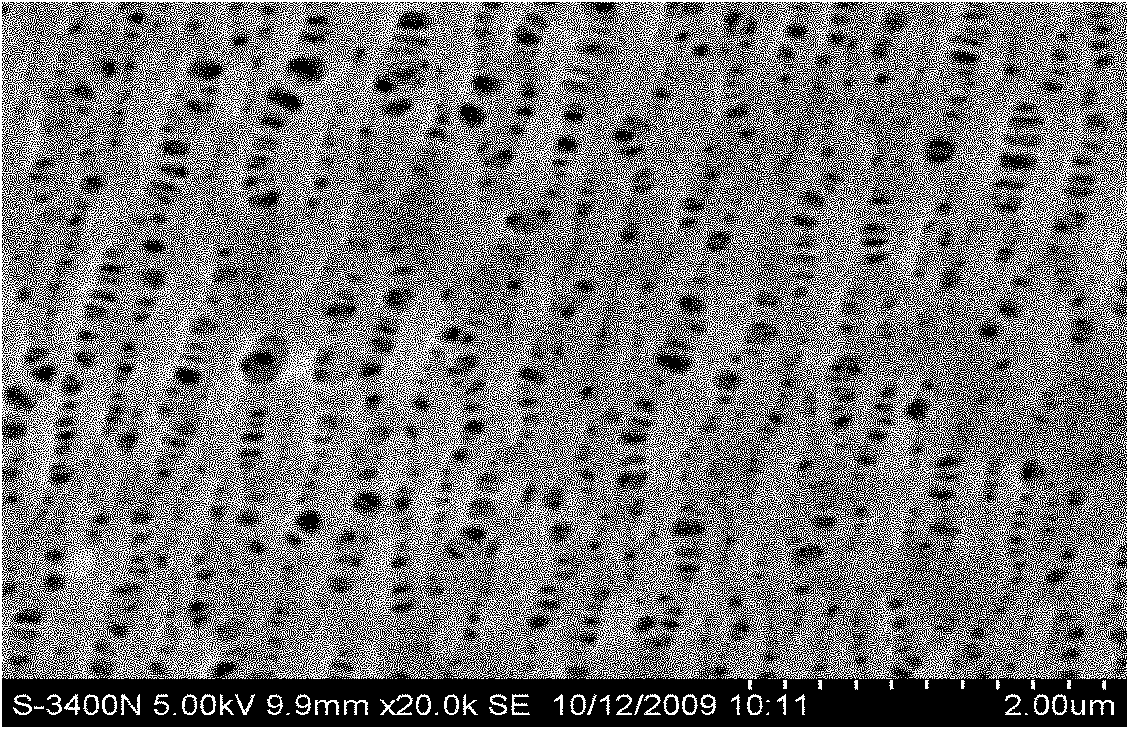

[0037] A homopolypropylene single-screw extruder with a melt index of 2.6 g / 10 min was used to extrude and cast a thick film, the extrusion temperature was 200° C., the temperature of the casting roll was 60° C., and the thickness of the tape-cast thick film was 40 microns. Then heat treatment in an oven at 150°C for 10 hours. The cold drawing temperature is normal temperature, the cold drawing ratio is 20%, the hot drawing temperature is 150°C, and the hot drawing ratio is 120%. Carry out heat setting treatment again, heat setting temperature 150 ℃, heat setting time 180s. Then soak the film online in acetone for 5 minutes, leave the soaking solution, and dry the film at 60°C to obtain the final PP microporous membrane.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

| Boiling point | aaaaa | aaaaa |

| Surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com