Ultrathin prepreg and preparation method thereof

A prepreg, ultra-thin technology, applied in the field of ultra-thin prepreg and its preparation, achieves the effects of good mechanical properties, low production cost and good appearance quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

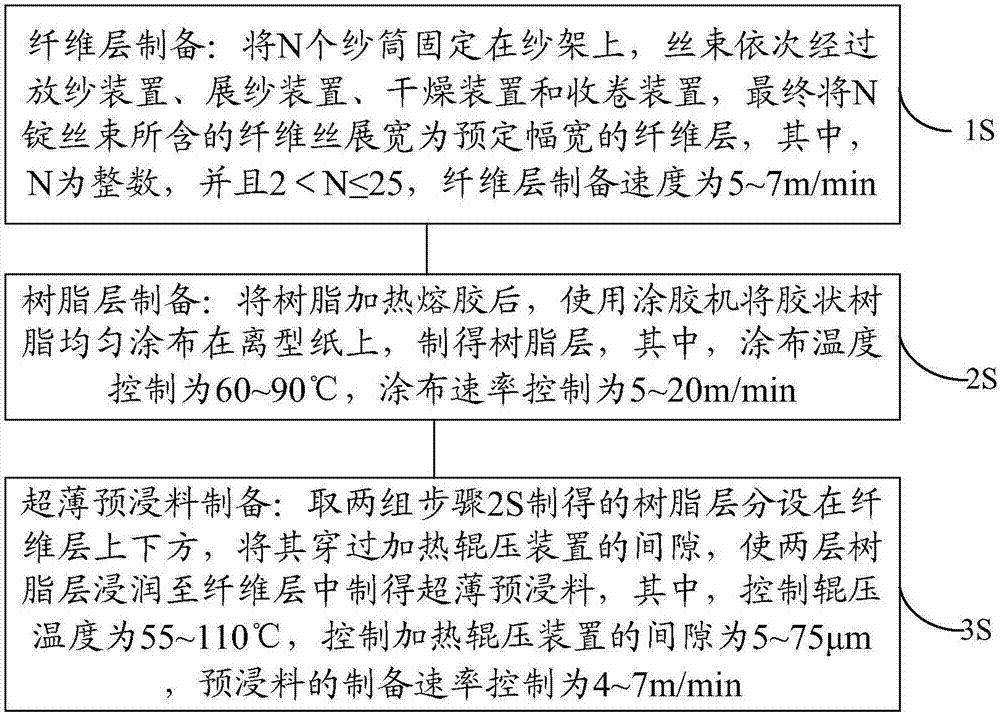

[0070] 1S fiber layer preparation: fix 25 spindles of carbon fiber bobbins with the brand name T700SC-12K on the creel, and the tow passes through the yarn unwinding device, yarn spreading device, drying device and winding device in turn, and finally the 25 spindles of tow The fiber filament stretching width is a fiber layer with a width of 500mm, wherein the fiber layer preparation speed is 5m / min;

[0071] 2S resin layer preparation: After heating and melting the epoxy resin, use a glue applicator to evenly coat the gel-like resin on the release paper to obtain a resin layer. The coating temperature is controlled at 70°C and the coating rate is controlled 10m / min;

[0072] Preparation of 3S ultra-thin prepreg: Take two sets of resin layers prepared in step 2S and place them on the upper and lower layers of the fiber layer, pass them through the gap of the heating roller press device, and soak the two layers of resin layers into the fiber layer to obtain an ultra-thin prepreg...

Embodiment 2

[0075] 1S fiber layer preparation: 19 spindles of carbon fiber bobbins with the brand name T700SC-12K are fixed on the creel, and the tow passes through the yarn unwinding device, yarn spreading device, drying device and winding device in sequence. Among them, the yarn unwinding tension of the bobbin It is 8N, and finally the fiber filaments contained in the 19 spindle tows are combined into a fiber layer with a width of 500mm, and the fiber layer is laid on kraft paper for winding;

[0076] In addition, in the ultrasonic spreading device, the frequency of the ultrasonic generator is 100MHz, the medium in the ultrasonic tank is industrial-grade pure water, the unwinding tension of the kraft paper is 30N, the winding tension of the fiber layer is 130N, and the fiber layer preparation speed is 6m / min ;

[0077] 2S resin layer preparation: After heating and melting the epoxy resin, use a glue applicator to evenly coat the gel-like resin on the release paper to obtain a resin laye...

Embodiment 3

[0082] 1S fiber layer preparation: fix 14 spindles of carbon fiber bobbin T700SC-12K on the creel, and the tow passes through the yarn unwinding device, yarn spreading device, drying device and winding device in sequence, among which, the yarn unwinding tension of the bobbin It is 15N, and finally the fiber filaments contained in the 14 spindle tows are combined into a fiber layer with a width of 500mm, and the fiber layer is laid on kraft paper for winding;

[0083] In addition, in the ultrasonic spreading device, the frequency of the ultrasonic generator is 100MHz, the medium in the ultrasonic tank is industrial-grade pure water, the unwinding tension of the kraft paper is 30N, the winding tension of the fiber layer is 150N, and the fiber layer preparation speed is 7m / min ;

[0084] 2S resin layer preparation: After heating and melting the epoxy resin, use a glue applicator to evenly coat the gel-like resin on the release paper to prepare a resin layer. The coating temperatu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tension | aaaaa | aaaaa |

| winding tension | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com