Method for adding catalyst in industrial production of optical film-grade polyester chips

A polyester chip and catalyst technology, applied in the field of polyester production, can solve the problems of long residence time in the prepolymerization tank, affecting optical properties such as slice transparency, and uneven gas-liquid phase mixing, etc., to achieve better optical properties and stable color , color and transparent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~9

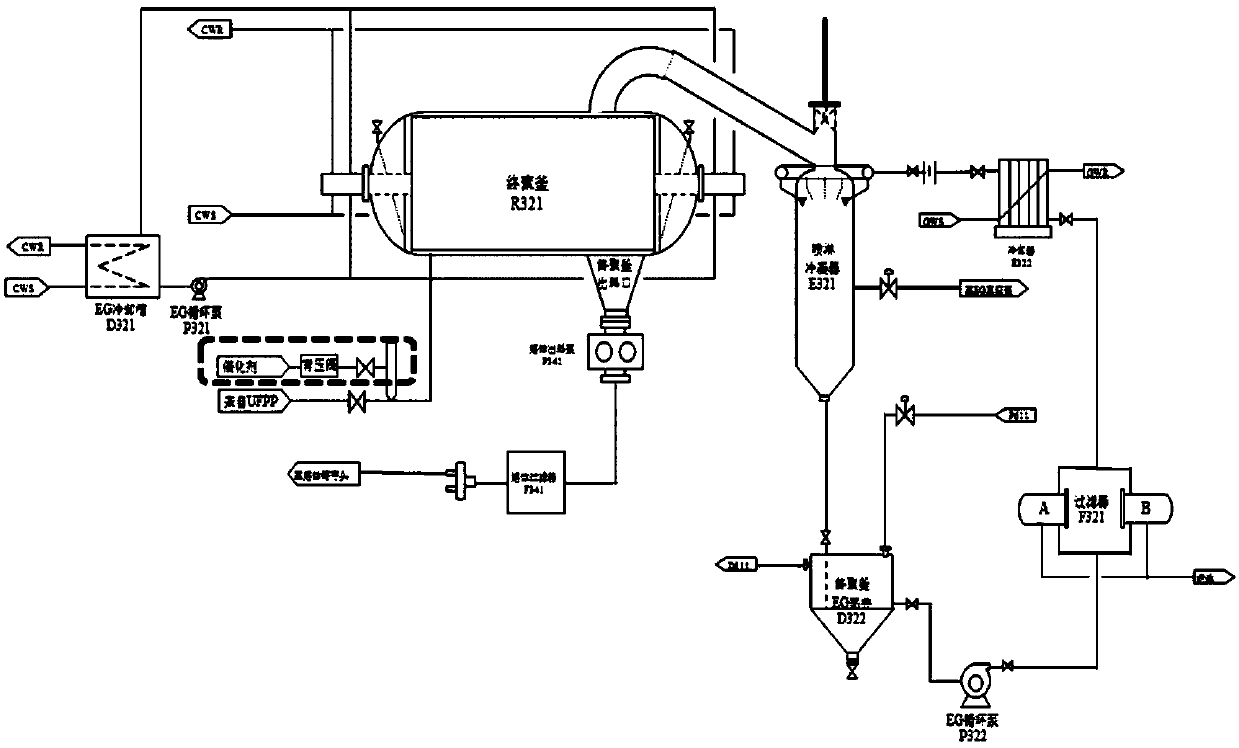

[0031] A method for adding a catalyst in the industrial production of optical film grade polyester chips, the specific steps are as follows:

[0032] (1) 50Kg of titanium-based catalyst with a titanium content of 0.4% and 1250L of ethylene glycol are configured into a solution, and a certain amount of chromaticity agent, optical brightener, and thermal stabilizer are stirred evenly;

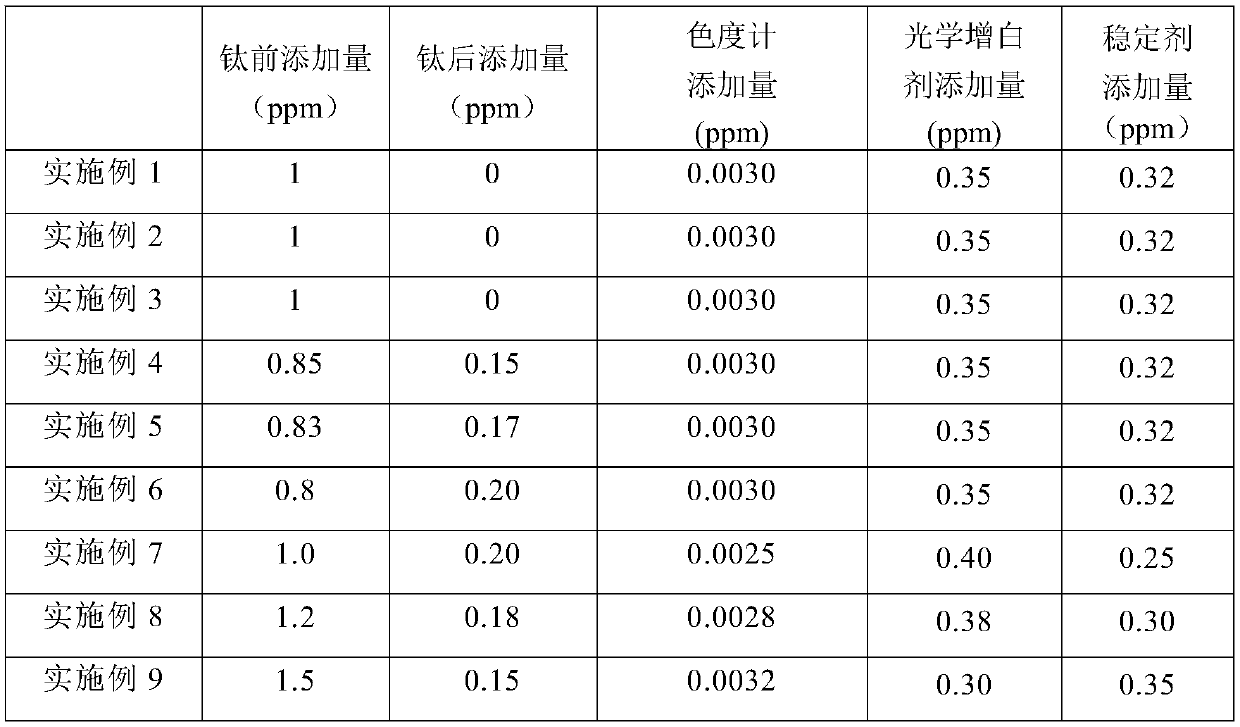

[0033] (2) Inject the mixed solvent into the feed line of the final polymerization tank through a syringe, in the final polymerization tank with an absolute pressure of 10-800Pa, a temperature of 270-300°C, and a reaction residence time of 1.8-2.5h. reaction. The amount of titanium added before the reaction material is 0.8-1.5ppm, the amount of titanium added after is 0.15-0.20ppm, the amount of colorimeter added is 0.0025-0.0032ppm, and the amount of whitening agent added is 0.30-0.40ppm , The amount of heat stabilizer added is 0.25-0.35ppm, based on the theoretical amount of polyester.

[003...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com