Insulation pull bar and preparation method thereof

A technology for insulating tie rods and fiber fabrics, which is applied to other household appliances, household components, applications, etc., can solve the problems of complex preparation process, unsatisfactory electrical and mechanical properties of products, single fiber fabric, etc., and achieves good interface integration, excellent The effect of electrical insulation properties and mechanical properties, high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

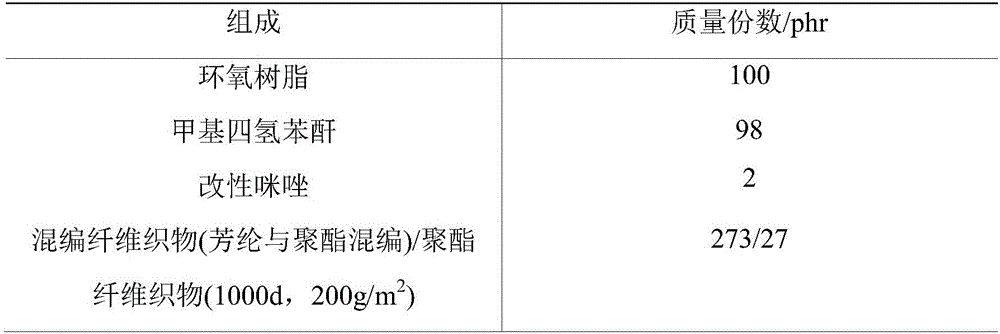

[0030] The formula of insulating rod is as follows:

[0031]

[0032] Insulation rod preparation method:

[0033] 1) Winding of fiber fabric: Wind polyester fiber fabric and mixed fiber fabric on a mandrel coated with release agent, the winding process is similar to a tubular sandwich structure (polyester fiber fabric + mixed fiber fabric +Polyester fiber fabric), the thickness of the polyester fiber single layer is 1mm. After the fiber fabric is wound, it is put into the mold cavity coated with release agent together with the mandrel, and then the two ends of the mold are fixed.

[0034] 2) Vacuum system pretreatment: connect the static mixing equipment, air compressor, vacuum pump, mold, and resin collector with rigid nylon plastic pipes to ensure high vacuum during the entire dipping process. The heating temperature of the mold is 100°C, and the ratio of epoxy resin, methyltetrahydrophthalic anhydride and modified imidazole is 100:98:2. Vacuum dehumidify the fiber fabric at 100℃...

Embodiment 2

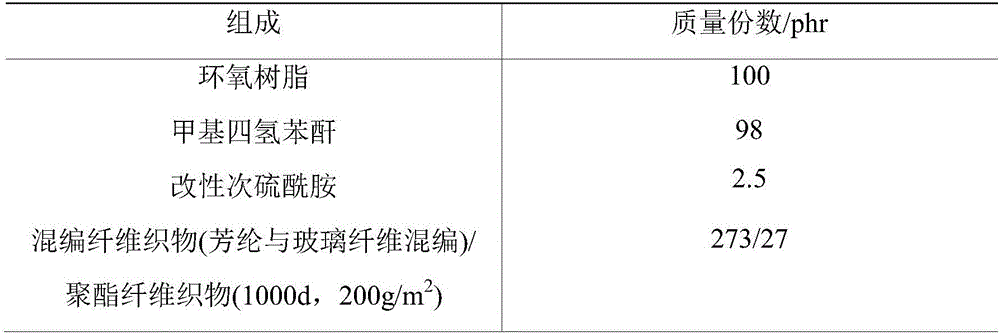

[0040] The formula of insulating rod is as follows:

[0041]

[0042] Insulation rod preparation method:

[0043] 1) Winding of fiber fabric: Wind polyester fiber fabric and mixed fiber fabric on a mandrel coated with release agent, the winding process is similar to a tubular sandwich structure (polyester fiber fabric + mixed fiber fabric +Polyester fiber fabric), the thickness of the polyester fiber single layer is 2mm. After the fiber fabric is wound, it is put into the mold cavity coated with release agent together with the mandrel, and then the two ends of the mold are fixed.

[0044] 2) Vacuum system pretreatment: connect the static mixing equipment, air compressor, vacuum pump, mold, and resin collector with rigid nylon plastic pipes to ensure high vacuum during the entire dipping process. The heating temperature of the mold is 100°C, and the ratio of epoxy resin, methyltetrahydrophthalic anhydride and modified sulfenamide is 100:98:2.5. Vacuum dehumidify the fiber fabric at ...

Embodiment 3

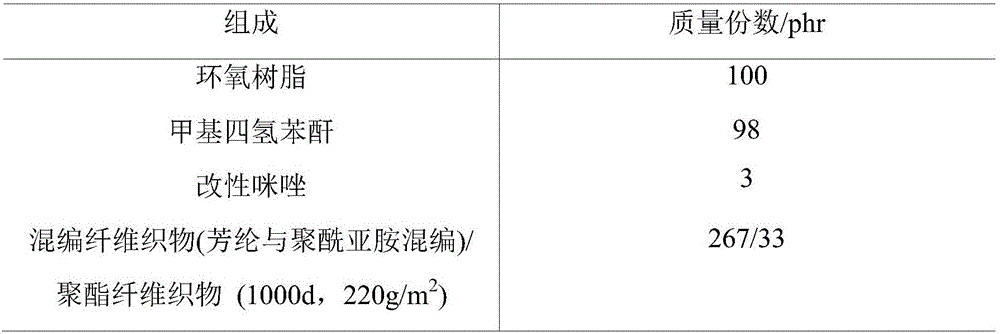

[0050] The formula of insulating rod is as follows:

[0051]

[0052] The manufacturing process of the insulating pull rod:

[0053] 1) Winding of fiber fabric: Wind polyester fiber fabric and mixed fiber fabric on a mandrel coated with release agent, the winding process is similar to a tubular sandwich structure (polyester fiber fabric + mixed fiber fabric +Polyester fiber fabric), the thickness of the polyester fiber single layer is 3mm. After the fiber fabric is wound, it is put into the mold cavity coated with release agent together with the mandrel, and then the two ends of the mold are fixed.

[0054] 2) Vacuum system pretreatment: connect the static mixing equipment, air compressor, vacuum pump, mold, and resin collector with rigid nylon plastic pipes to ensure high vacuum during the entire dipping process. The heating temperature of the mold is 100°C, and the ratio of epoxy resin, methyltetrahydrophthalic anhydride and modified imidazole is 100:98:3. Vacuum dehumidify the f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com