Metal protective coating and hot galvanizing metal material and hot dip aluminum-zinc metal material

A metal protective coating and hot-dip galvanizing technology, which is applied in the direction of anti-corrosion coatings, polyester coatings, metal layered products, etc., can solve the problems of poor corrosion resistance, water resistance, heat resistance and fingerprint resistance of the protective film, and achieve Excellent heat resistance and excellent fingerprint resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

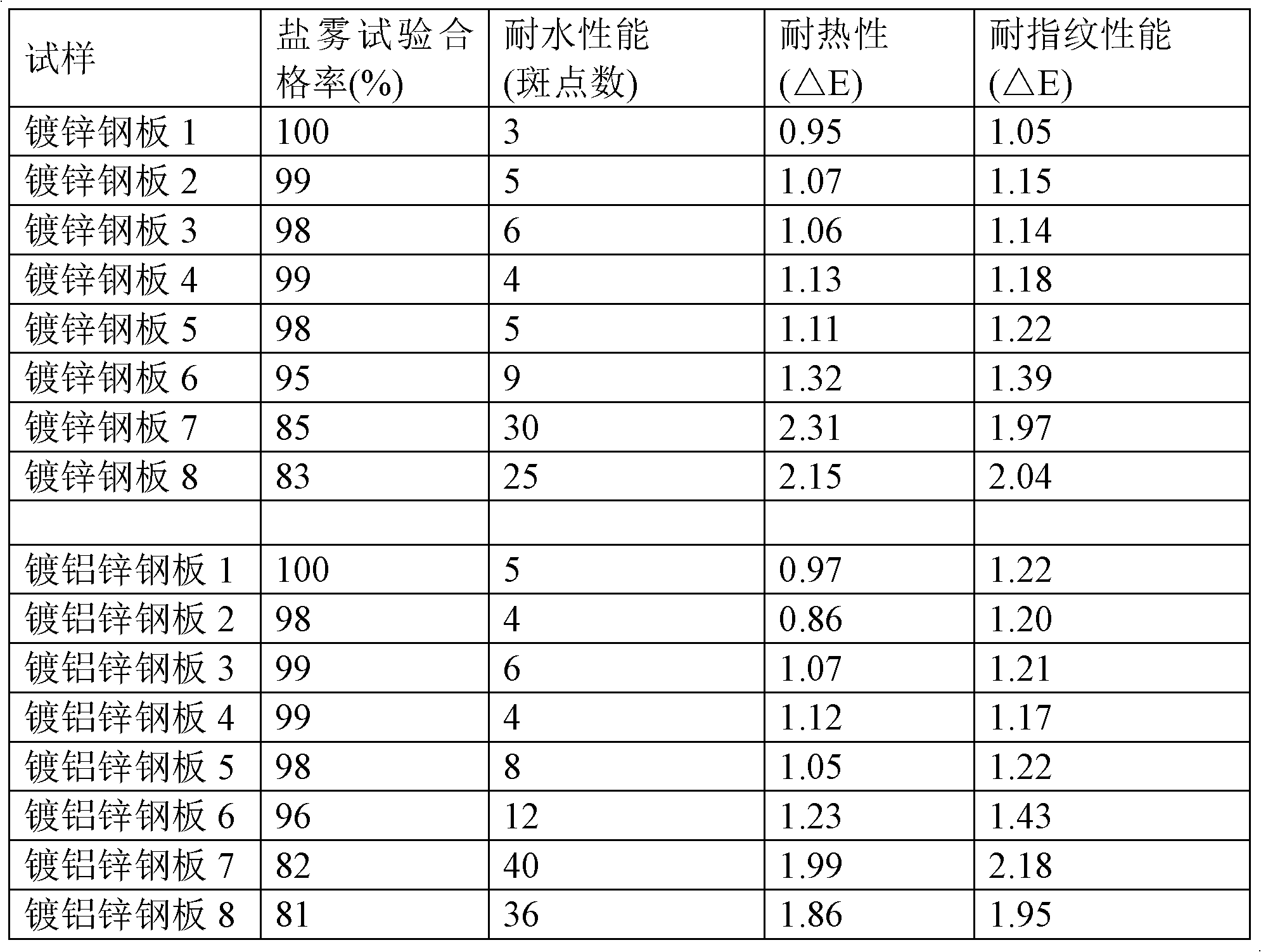

Examples

Embodiment 1

[0040] 1 part by weight of water-soluble silicate (Na 2 SiO 3 ), 0.6 parts by weight of accelerator (thiourea), 1.6 parts by weight of silane coupling agent (the first silane derivative (2-(3,4-epoxycyclohexyl) ethyltrimethoxysilane, purchased from Hubei Debang Fine Chemical Co., Ltd.) and the second silane derivative (γ-aminopropyltriethoxysilane, purchased from Hubei Debang Fine Chemical Co., Ltd.) obtained by mixing at a weight ratio of 1:0.25), 0.72 parts by weight of oxidation Silicon filler (nano silica powder, purchased from U.S. GE company, RNS-E, average particle size 20nm), 2.4 parts by weight (in solid terms) of water-soluble film-forming resin (water-soluble silicon acrylic film-forming resin (Qingdao Xingguo Paint company TC-05 silicone acrylic emulsion, the solid content is 48% by weight)) and 28 parts by weight of water, mixed until uniform at a stirring speed of 1500 rpm, to obtain the metal protective coating of this embodiment.

Embodiment 2

[0042] With 1 weight part of water-soluble silicate (K 2 SiO 3 ), 0.5 parts by weight of accelerator (urea), 1.4 parts by weight of silane coupling agent (the first silane derivative (2-(3,4-epoxycyclohexyl) ethyl triethoxysilane, purchased from Hubei Debang Fine Chemical Co., Ltd.) and the second silane derivative (γ-glycidyl etheroxypropyl trimethoxysilane, purchased from Hubei Debang Fine Chemical Co., Ltd.) in a weight ratio of 1:0.4 to obtain), 0.6 parts by weight Silica filler (nano silicon dioxide, available from U.S. GE company, RNS-E, average particle size 20nm), 2.1 parts by weight (in solid terms) of water-soluble film-forming resin (water-soluble acrylic film-forming resin (available from Acrylic resin (A-3418) of Guangzhou Oupeng Chemical Co., Ltd. and 25 parts by weight of water were mixed until uniform at a stirring speed of 1500 rpm to obtain the metal protective coating of this embodiment.

Embodiment 3

[0044] 1 part by weight of water-soluble silicate (Na 2 SiO 3 ), 0.7 parts by weight of accelerator (thiourea and urea are obtained by mixing in a weight ratio of 1:1), 1.8 parts by weight of silane coupling agent (the first silane derivative (2-(3,4-epoxycyclohexyl ) Propyltrimethoxysilane, purchased from Hubei Debang Fine Chemical Co., Ltd.) and the second silane derivative (γ-glycidyl etheroxypropyl trimethoxysilane, purchased from Hubei Debang Fine Chemical Co., Ltd.) by weight Ratio 1: 0.1 mixed to obtain), 0.85 parts by weight of silica filler (30% by weight of colloidal silica, usage in solids), 2.7 parts by weight (in solids) of water-soluble film-forming resin (water-soluble polyurethane film-forming Resin (purchased from Fujian Jinjiang Jianhua Company, brand 812 polyurethane resin)) and 40 parts by weight of water were mixed until uniform at a stirring speed of 1500 rpm to obtain the metal protective coating of this embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com