Non-chrome alkali-resistant and solvent-resistant galvanized steel sheet surface treatment liquid and preparation method thereof

A technology of surface treatment liquid and solvent resistance, applied in hot-dip plating process, coating, metal material coating process, etc., can solve the problem of high cost of surface treatment agent, achieve enhanced adhesion, improve corrosion resistance, Improve the effect of alkali resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

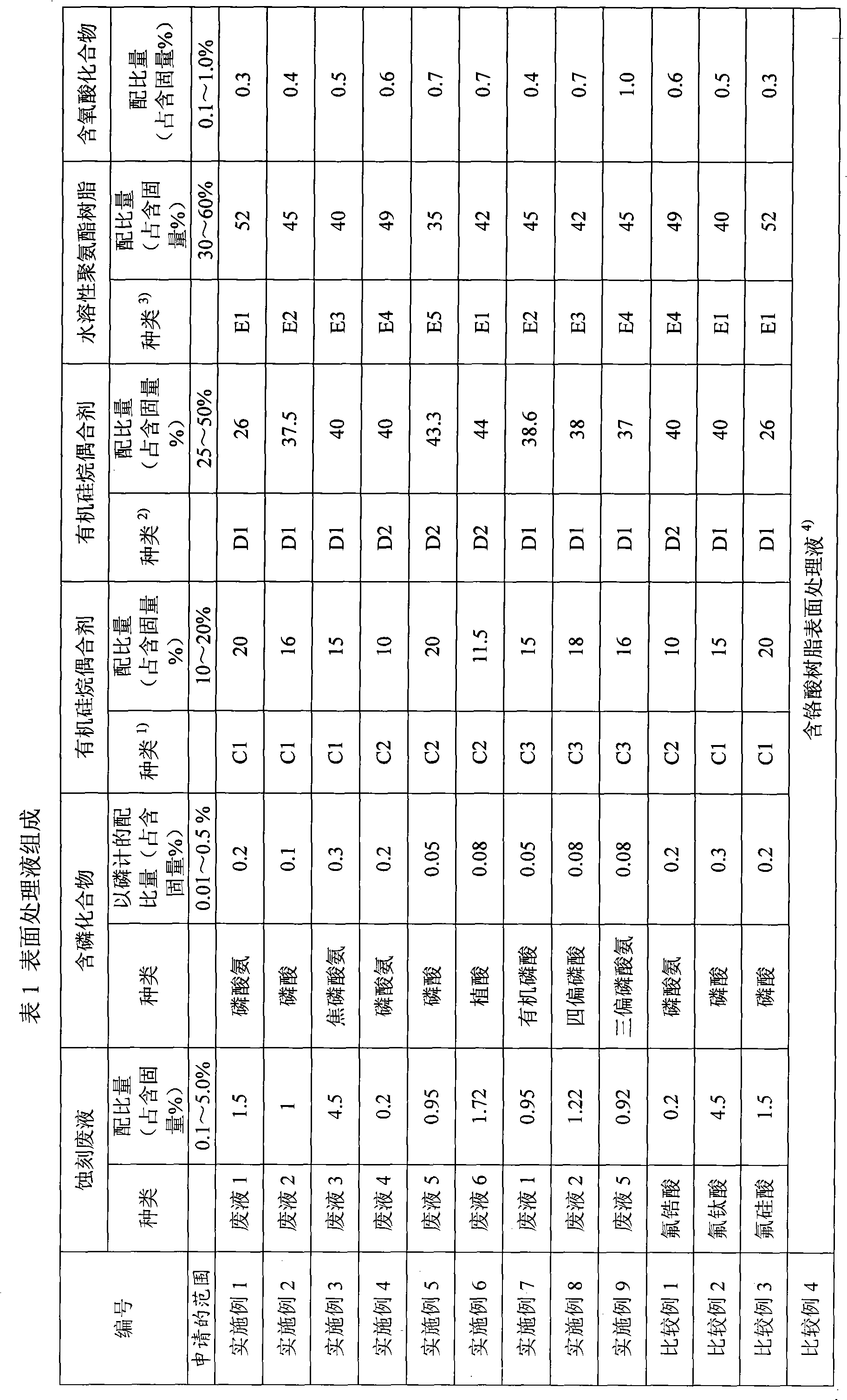

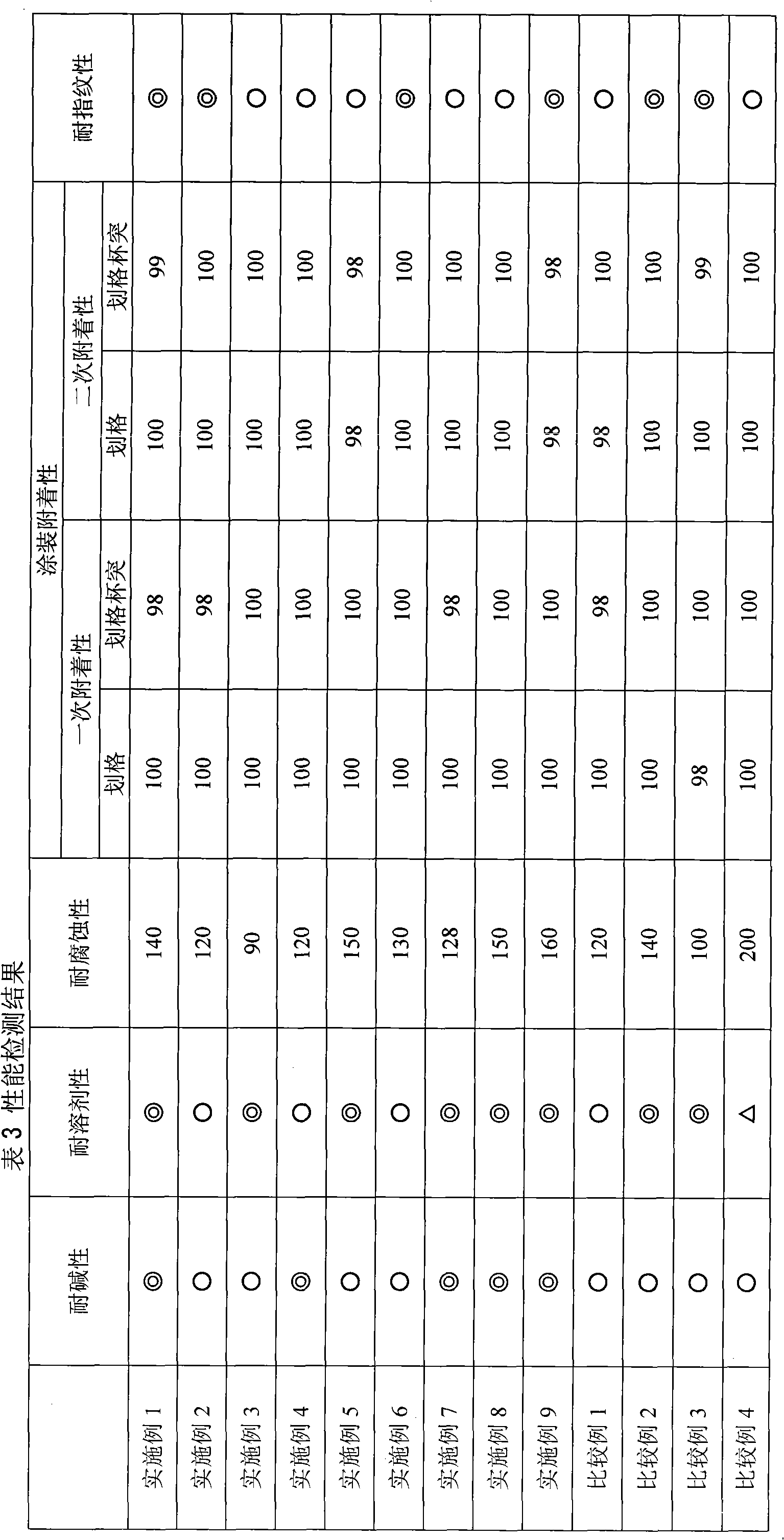

[0045] Embodiment: Embodiment 1~9 of the present invention, comparative example 1~6 implementation situation is as follows:

[0046] The following examples use electro-galvanized, hot-dip galvanized and hot-dip galvanized aluminum alloy steel sheets, but the scope of the present invention is not limited by these specific examples. The galvanized steel sheets used in Examples and Comparative Examples, their surface cleaning methods, surface treatment liquids, and performance tests will be described below.

[0047] 1. Test sample

[0048] Products sold in the market, plate thickness 0.6mm, double-sided electro-galvanized steel plate (EG), galvanized adhesion amount 20g / m 2 ;

[0049] Products sold in the market, plate thickness 0.6mm, hot-dip galvanized steel plate (GI), galvanized adhesion amount 40g / m 2 ;

[0050] Products sold in the market, plate thickness 0.6mm, hot-dip galvanized aluminum alloy steel plate (GF), galvanized adhesion amount 40g / m 2 .

[0051] 2. Cleani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com