Chromium-free fingerprint-resistant coating solution and preparation method of hot-dip aluminizing zinc plate

A coating liquid, anti-fingerprint technology, used in coatings, anti-corrosion coatings, conductive coatings, etc., can solve the problems of hot-dip aluminum-zinc plate corrosion, aluminum-zinc plate corrosion, etc., and achieve good stability and good heat resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] The preparation method of the chromium-free anti-fingerprint coating liquid of the present invention, at first dissolving phosphate in water, then adding molybdate, after being dissolved, adding nitrite, then adding a pH regulator, adjusting the pH to 7-10 , the present invention adjusts the pH value to 7-10 in order to improve the stability of the coating liquid. Then add colloidal silicon dioxide, and finally add water-based organic resin emulsion, and stir evenly to obtain the product.

[0041] The preparation method of hot-dip aluminum-zinc plate of the present invention comprises the following steps:

[0042] a. The hot-dip galvanized sheet substrate can be prepared by conventional methods;

[0043] B, roll coating or spray coating liquid on the hot-dip galvanized sheet substrate prepared in step a; the coating liquid is the chrome-free anti-fingerprint coating liquid described in any one of claims 1 to 8;

[0044] c. curing the substrate coated with the coating ...

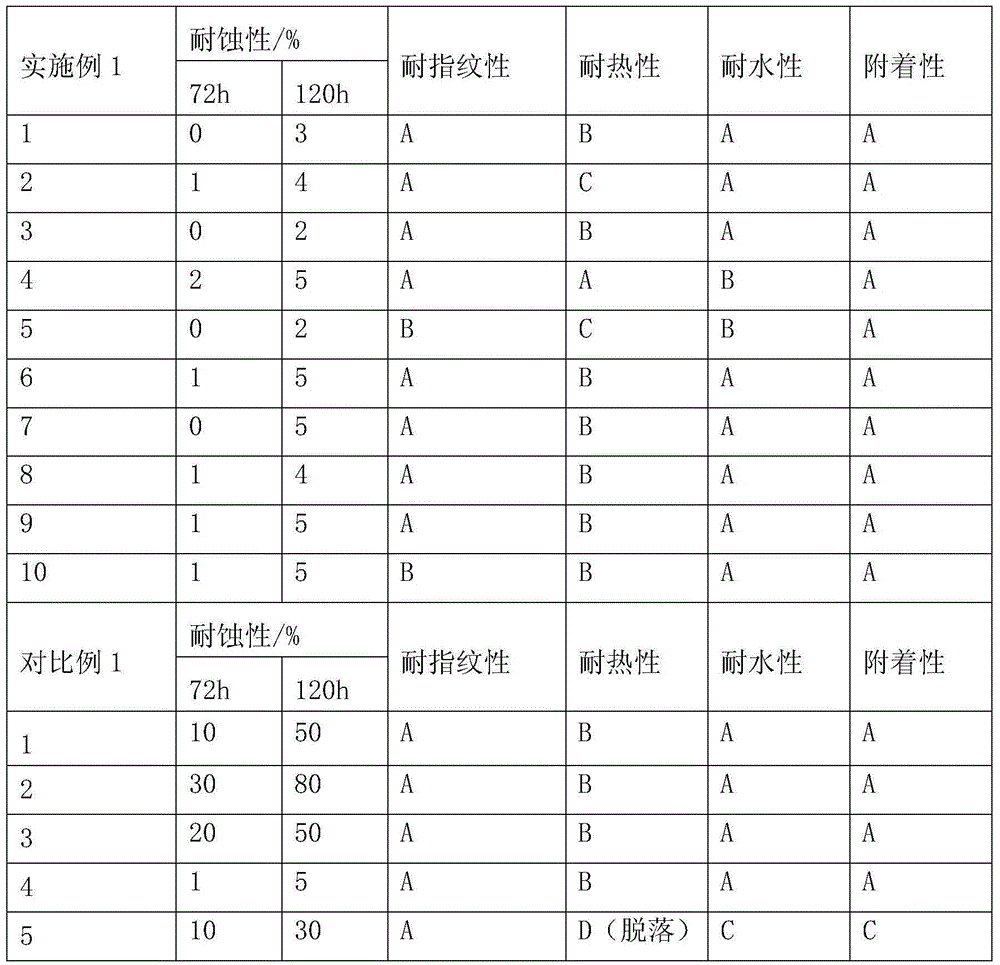

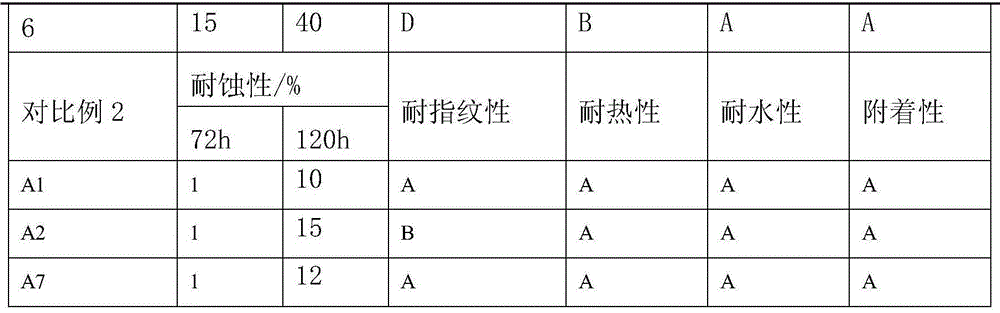

Embodiment 1

[0049] 1. Preparation of chrome-free anti-fingerprint coating solution and heat transfer aluminum-zinc plate

[0050] 1. Preparation of chrome-free anti-fingerprint coating solution:

[0051] First, weigh each component according to the content of each component of the chromium-free fingerprint-resistant coating solution in Table 1, first dissolve the phosphate in water, then add molybdate, after dissolving, add nitrite, and then add pH adjuster , adjust the pH to 7-10, then add colloidal silicon dioxide, and finally add water-based organic resin emulsion, and stir evenly to obtain the chrome-free anti-fingerprint coating liquid prepared by the present invention.

[0052] 2. Preparation of hot-dip galvanized sheet:

[0053] It mainly includes the following steps:

[0054] a, prepare the hot-dip galvanized sheet substrate by conventional methods;

[0055] B, roll coating or spray coating liquid on the hot-dip galvanized sheet substrate prepared in step a; the coating liquid ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com