Surface treating agent for metallic materials, method for surface treating metallic materials using the surface treating agent, and surface treated metallic materials

A technology for surface treatment agents and metal materials, applied in metal material coating technology, anti-corrosion coatings, coatings, etc., can solve the problems of poor conductivity, spot weldability, coloring, increased viscosity, conductivity and fingerprint resistance Insufficient and other problems, to achieve excellent liquid stability, excellent heat resistance and electrical conductivity, excellent corrosion resistance and acid resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0128] The preparation method of the surface treatment agent for metal materials of the present invention is not particularly limited. For example, it can be produced by sufficiently mixing the compound (A), the metal alkoxide (B), the compound (C), the organic compound (D), other additives, and water using a mixer such as a mixing mixer.

[0129]

[0130] The surface treatment method using the surface treatment agent for metal materials of the present invention is not particularly limited, and the preferred treatment method is: coating the above-mentioned surface treatment agent for metal materials on the surface of the metal material and drying it, The amount of film formed is 10~3000mg / m 2 of the membrane.

[0131] Hereinafter, this surface treatment method will be described.

[0132] Before applying the treatment agent, the metal material may be pretreated to remove oil and dirt on the surface of the metal material as needed. Metal materials are often coated with anti...

Embodiment

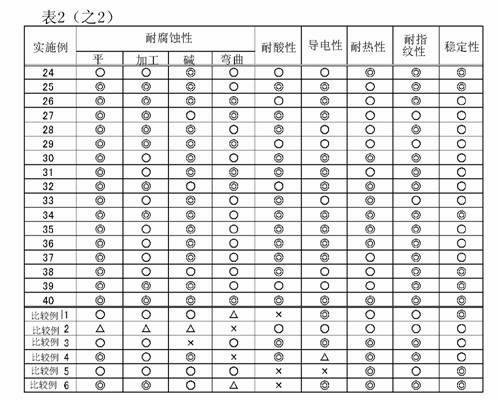

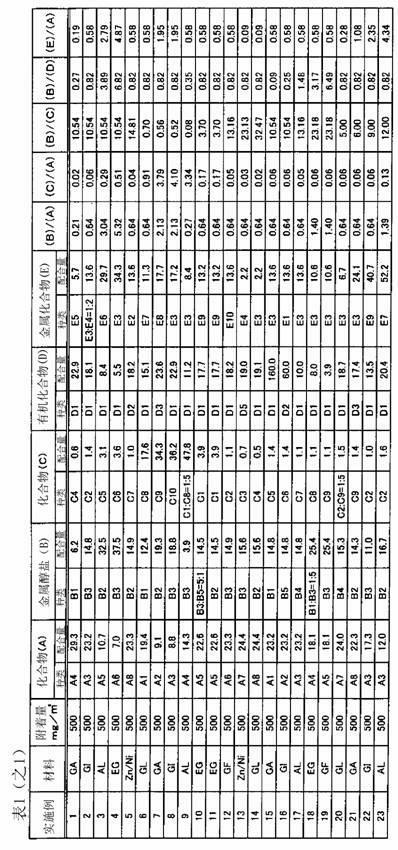

[0148] The following examples and comparative examples of the present invention are given to describe the present invention in detail, but the present invention is not limited by them. Preparation of test panels, Examples and Comparative Examples, and a coating method of a surface treatment agent for metal materials will be described below.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com