Water-based acrylic acid-epoxy-polyurethane dispersoid and alcohol-rubbing-resistant and alkali-resistant coating

A technology of polyurethane dispersion and water-based acrylic, which is applied in the direction of anti-corrosion coatings and coatings, and can solve problems such as high VOC, easy hydrolysis, and increased molecular weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

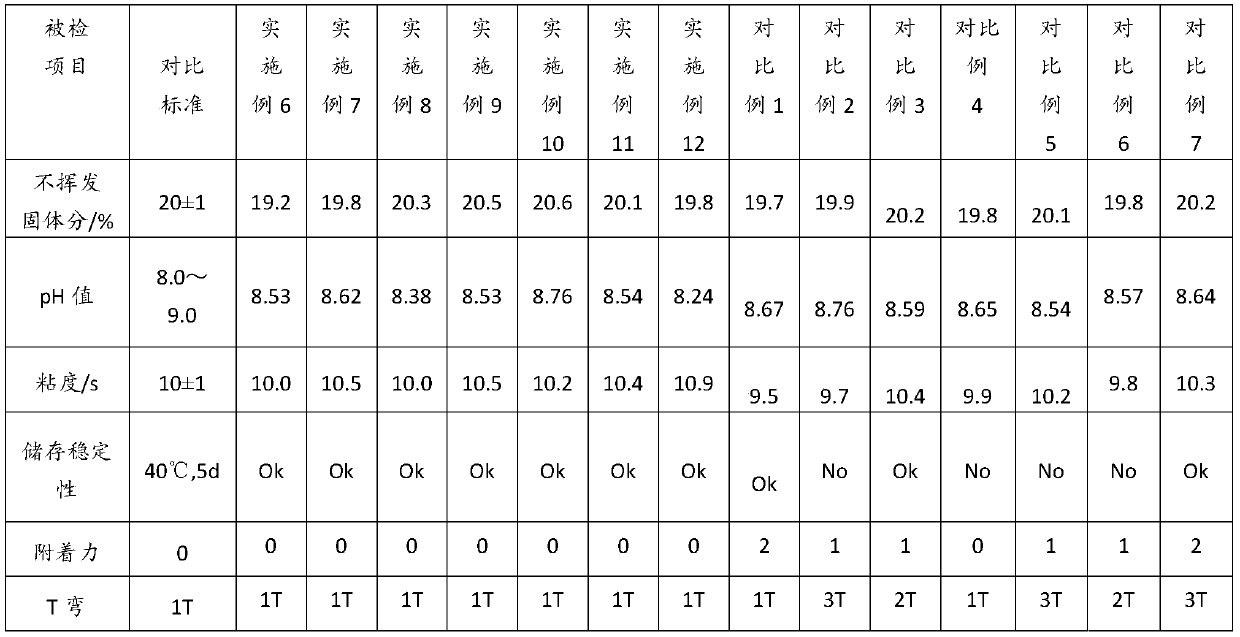

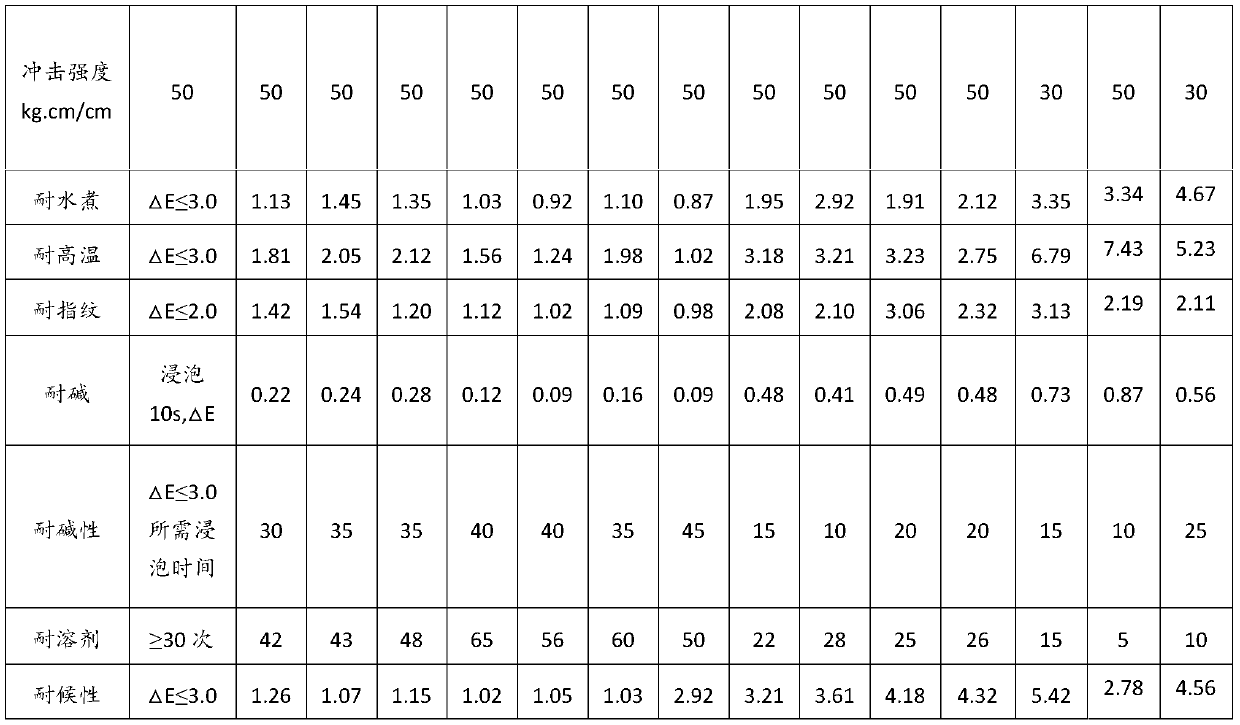

Examples

Embodiment 1

[0137] Synthesis of Epoxy Polyol I

[0138] Add 300g of epoxy resin E44 to a four-necked flask equipped with a reflux condenser, a thermometer and a mechanical stirrer, stir and control the temperature at 100°C, add 70% of the total mass of lactic acid (72g), 0.072g of 2,5 -di-tert-butyl hydroquinone, 0.072g three (nonyl phenyl) phosphite, mix and dissolve; be warming up to 120 ℃, add the catalyst II triphenylphosphine of 0.1% of the gross mass of aforementioned raw material, in The remaining lactic acid was added in 6 times within 120 minutes, and the temperature was raised to 130°C for reaction; during the reaction, samples were taken to test the acid value, and the reaction was carried out until the acid value was basically unchanged, and the epoxy polyol I was obtained by cooling. Wherein, the molar ratio of the epoxy resin to the lactic acid is 1.0:1.2.

Embodiment 2

[0140] Synthesis of Epoxy Polyols II

[0141] Add 300g of epoxy resin E44 to a four-necked flask equipped with a reflux condenser, a thermometer and a mechanical stirrer, stir and control the temperature at 100°C, add 70% of the total mass of lactic acid (84g), 0.084g of 2,5 -di-tert-butyl hydroquinone, 0.084g three (nonyl phenyl) phosphite, mix and dissolve; be warming up to 110 ℃, add the catalyst II triphenylphosphine of 0.1% of the gross mass of aforementioned raw material, in The remaining lactic acid was added in 6 times within 120 minutes, and the temperature was raised to 150°C for reaction; during the reaction, samples were taken to test the acid value, and the reaction was carried out until the acid value was basically unchanged, and the epoxy polyol II was obtained by cooling. Wherein, the molar ratio of the epoxy resin to the lactic acid is 1.0:1.4.

Embodiment 3

[0143] Synthesis of Epoxy Polyols III

[0144] Add 300g of epoxy resin E44 to a four-necked flask equipped with a reflux condenser, a thermometer and a mechanical stirrer, stir and control the temperature at 100°C, add 70% of the total mass of lactic acid (120g), 0.12g of 2,5 -di-tert-butyl hydroquinone, 0.12g three (nonyl substituted phenyl) phosphite, mix and dissolve; be warming up to 120 ℃, add the catalyst II triphenylphosphine of 0.1% of the gross mass of aforementioned raw material, in The remaining lactic acid was added in 6 times within 120 minutes, and the temperature was raised to 140°C for reaction; during the reaction, samples were taken to test the acid value, and the reaction was carried out until the acid value was basically unchanged, and the epoxy polyol III was obtained by cooling. Wherein, the molar ratio of the epoxy resin to the lactic acid is 1.0:2.0.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com