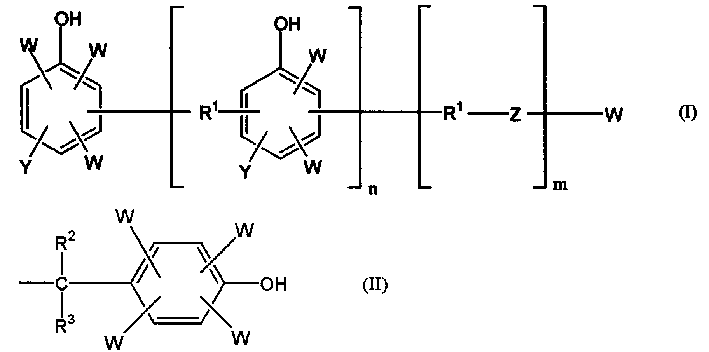

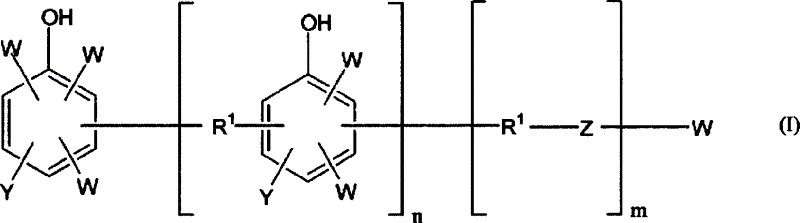

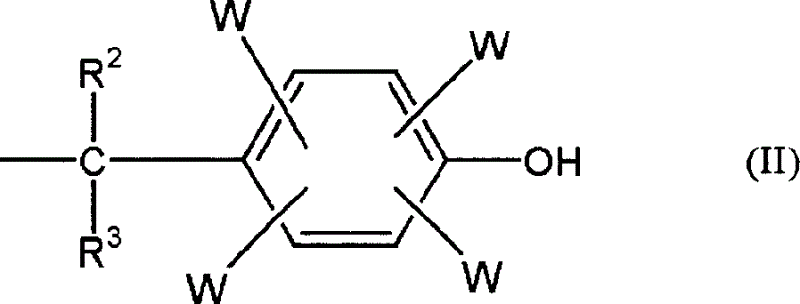

Surface treatment agent for metal, process for surface treatment of metallic substances and surface-treated metallic substances

A technology of metal surface treatment and metal materials, applied in the direction of metal material coating process, device for coating liquid on the surface, anti-corrosion coating, etc., can solve fingerprint resistance, scratch resistance and insufficient lubricity, corrosion resistance Insufficient corrosion resistance, inability to obtain corrosion-resistant metal surface treatment agents, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0072] Hereinafter, the present invention will be described using examples and comparative examples, but this example is merely an example, and the present invention is not limited thereto. The evaluation methods of the processed plate samples produced in Examples and Comparative Examples are as follows.

[0073] 1. Metal material to be processed

[0074] A: Galvanized steel sheet (thickness: 0.8mm)

[0075] B: hot-dip galvanized steel sheet (thickness: 0.8mm)

[0076] C: 55% Al-Zn electroplated steel plate (thickness: 0.5mm)

[0077] 2. Treatment liquid

[0078] (1) Treatment liquid components

[0079] The water-soluble resin or aqueous emulsion resin (A) used will be described below.

[0080] a1: Cationic modified epoxy resin (Adeka Resin EPEC-0436 manufactured by Asahi Denka Co., Ltd.)

[0081] a2. Nonionic water-soluble polyester resin (manufactured by Huo Chemical Industry Co., Ltd., FR-627)

[0082] a3: Cationic polyurethane resin (Adeka Bota HUX-670, manufactured...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com