Water-stopping sponge rubber material and preparation method thereof, sealing strip and preparation method thereof, and automobile

A sealing strip and sponge rubber technology, which is applied in sealing devices, engine seals, mechanical equipment, etc., can solve the problems of complex glue injection process, high cost, and low production efficiency, and achieve high tensile strength and aging resistance. The effect of reducing the dosage and improving the processing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

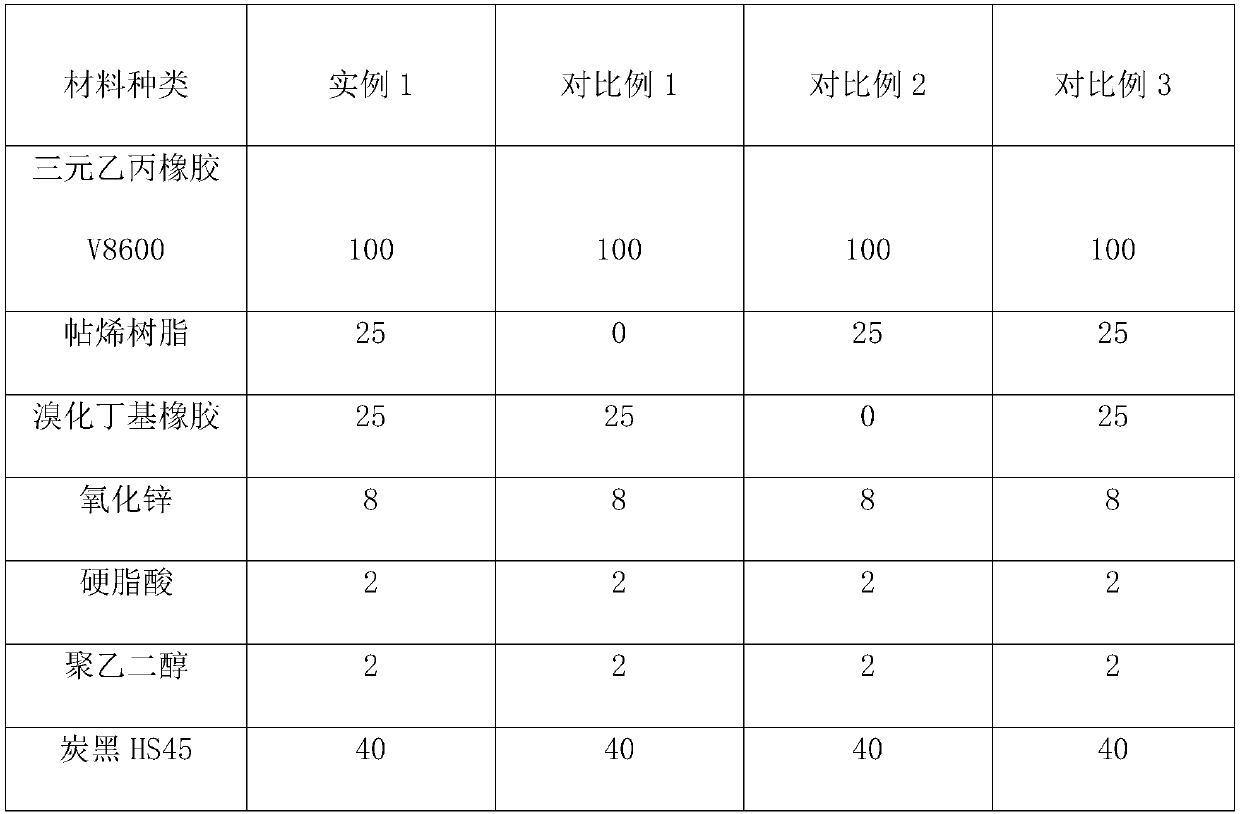

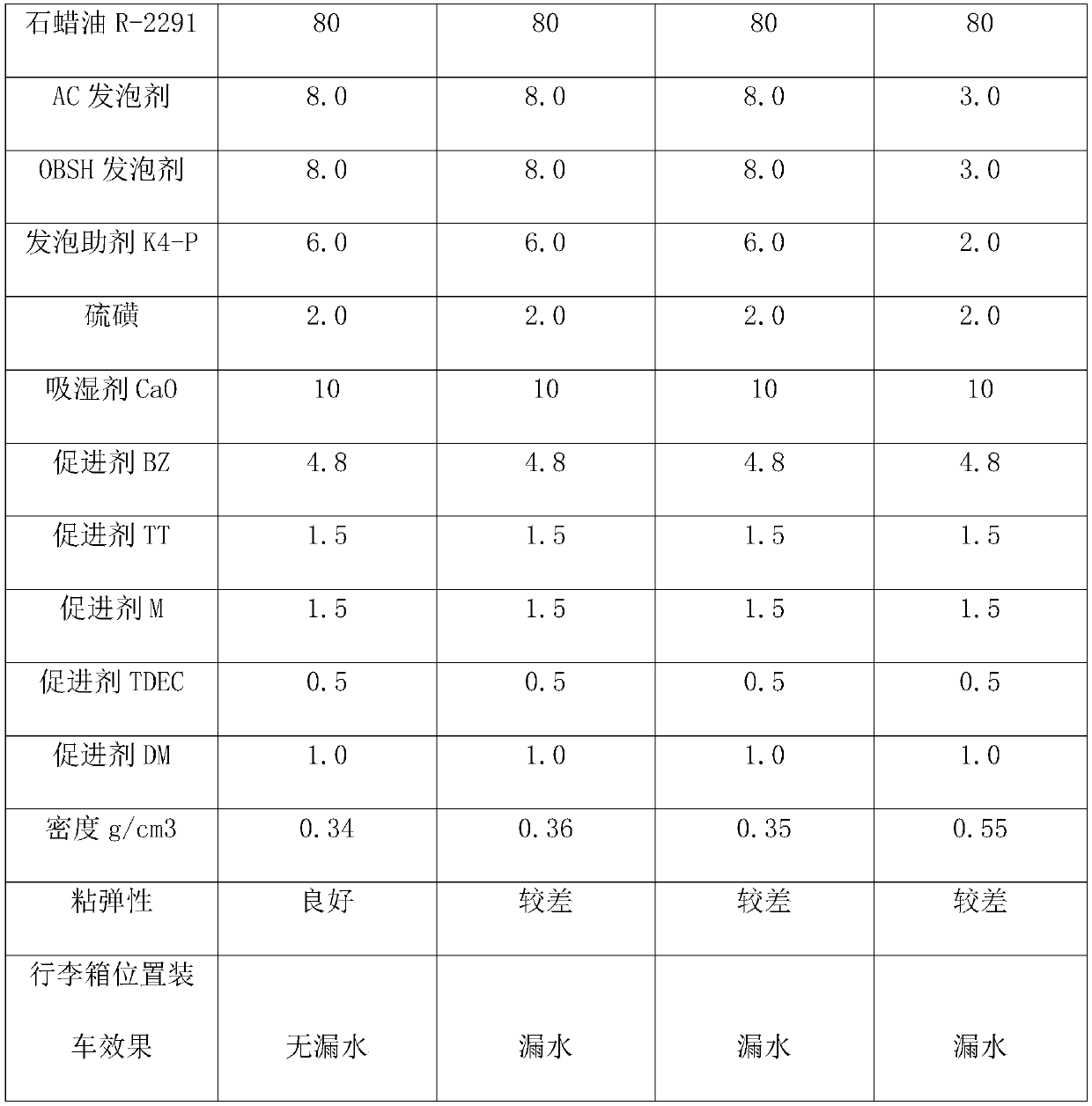

[0044]This embodiment relates to a water-stop sponge compound, which is specifically made of the following components by weight: EPDM rubber V8600: 100 parts, terpene resin: 20-30 parts, brominated butyl rubber: 20-30 parts, zinc oxide: 6-10 parts, stearic acid: 1-3 parts, polyethylene glycol: 1-3 parts, carbon black HS45: 30-50 parts, paraffin oil R-2291: 70-90 parts Parts, OBSH foaming agent: 6-10 parts, AC foaming agent: 6-10 parts, foaming aid K4-P: 5-7 parts, sulfur: 1.5-2.5 parts, hygroscopic agent CaO: 7-12 parts , Accelerator: 6-10 parts.

[0045] Wherein, the above-mentioned accelerator specifically includes the following components: accelerator Bz, accelerator TT, accelerator M, accelerator TDEC, accelerator DM, and a weight ratio of each accelerator component can be, for example: accelerator Bz : 4-5 parts, Accelerator TT: 0.5-1.5 parts, Accelerator M: 0.5-1.5 parts, Accelerator TDEC: 0.3-0.7 parts, Accelerator DM: 0.7-1.3 parts.

[0046] In addition, when the abo...

Embodiment 2

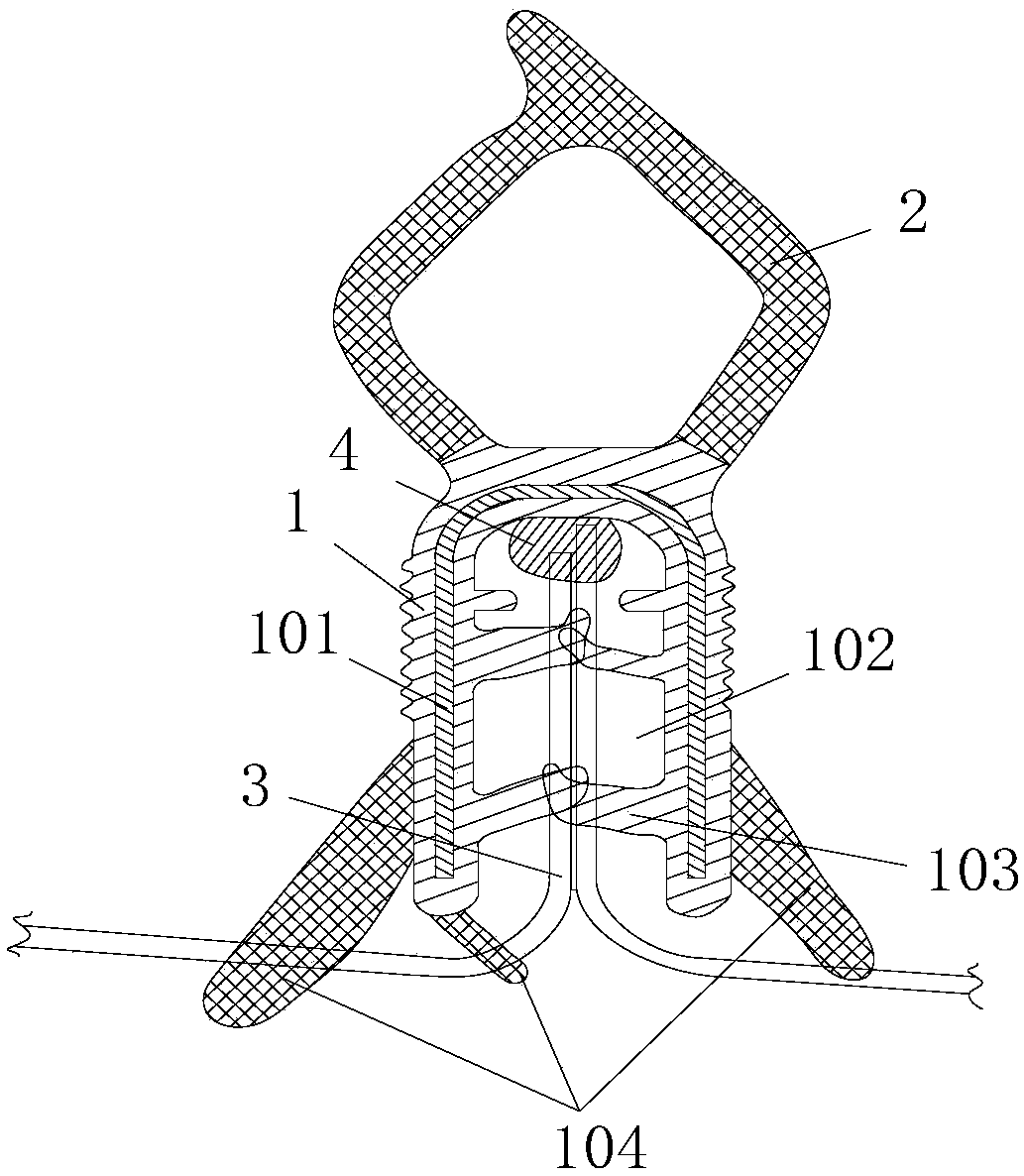

[0057] This embodiment relates to a sealing strip, such as figure 1 As shown in , it includes a mounting part 1 made of compact rubber, a mounting groove 102 opening to one side of the mounting part 1 is formed on the mounting part 1, and a steel belt skeleton 101 is embedded in the mounting part 1, and Relative to the opening end of the installation groove 102 , the other end of the installation part 1 is integrally connected with a sealing part 2 made of sponge glue. In addition, the sealing strip of this embodiment also includes a water stop part 4 integrally connected with the installation part 1 provided at the bottom of the installation groove 102, and the water stop part 4 is specifically made of the water stop sponge rubber material of the first embodiment. become.

[0058] In the sealing strip in this embodiment, the compact glue and sponge glue used to form the installation part 1 and the sealing part 2 can be made of conventional rubber products commonly used in au...

Embodiment 3

[0071] This embodiment relates to a kind of automobile, and it comprises the vehicle body that is molded with the trunk, and is provided with the trunk lid at the mouth of the trunk, and on this body, is installed at least at the mouth of the trunk can be connected with the luggage. The door abuts against the sealing strip as in Embodiment 2.

[0072] By adopting the sealing strip product in the second embodiment, the automobile of this embodiment can improve the water-tight sealability of the automobile such as the trunk position, can improve the quality of use of the automobile, and has good practicability.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com