Machining process of wind power bearing sealing rubber strip

A technology of bearing sealing and processing technology, which is applied in the field of vulcanization molding processing technology, can solve the problems that the density of the rubber strip cannot meet the requirements, cannot fully meet the product use requirements, and poor quality stability, so as to meet the requirements of density, compression performance and Improve wear resistance, meet the effect of uniformity and consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

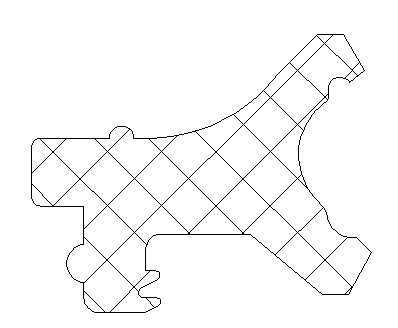

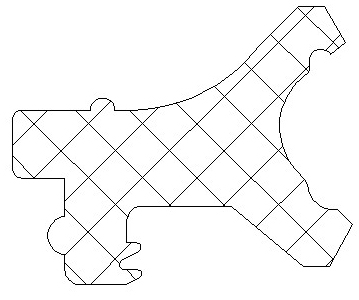

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

[0024] A processing technology for wind power bearing sealing strips, the material is oil-resistant and weather-resistant rubber, the hardness of the rubber is 70~75°Shore A, the process steps are as follows:

[0025] a. Filter the mixed rubber material with a filter to ensure that the rubber material is free of impurities;

[0026] b. Preform the rubber material with the mouth of the extruder to ensure the size of the rubber material so as to meet its weight requirements;

[0027] c. Preheat the preformed mixed rubber to increase its fluidity;

[0028] d. Draw the preformed rubber to each cavity with a jig and place it neatly;

[0029] e. Close the mold and start vulcanization molding;

[0030] f. Trim the vulcanized and formed product, remove the burr to make a wind power bearing sealing strip that meets the assembly requirements.

[003...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com