Preparation method of large high density tungsten alloy counterweight

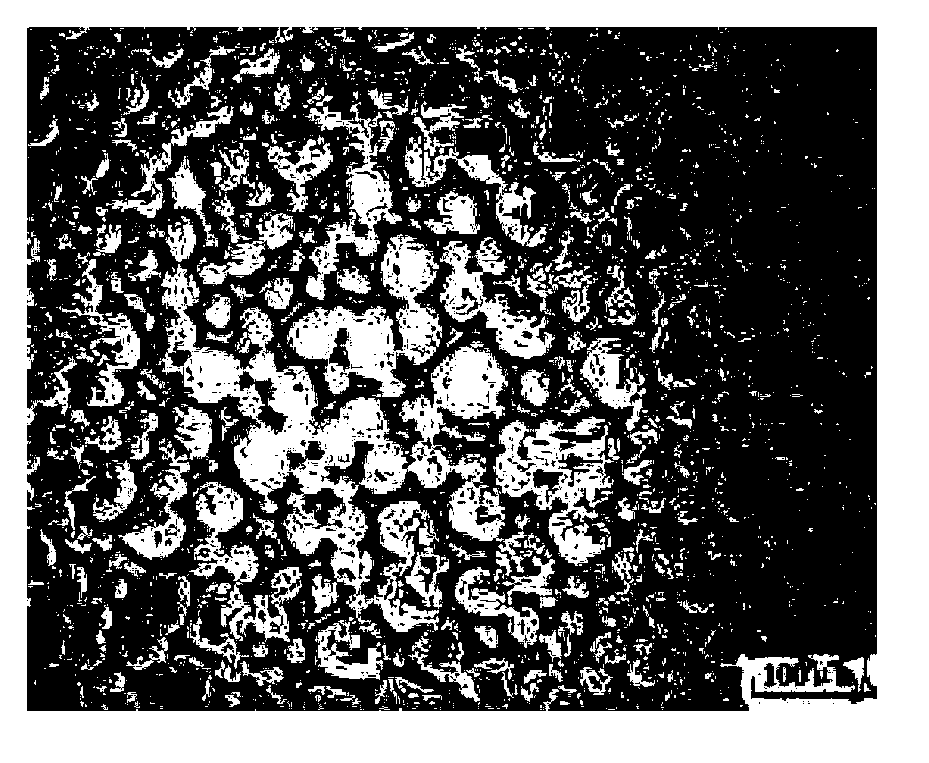

A tungsten alloy and counterweight technology, which is applied in the field of high-density tungsten alloy large-scale counterweight and its preparation, can solve the problems of low uniformity of internal and external density, affect the processing and use of counterweight, and a large number of pores, etc., to achieve low cost and meet density Requirements, organization uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The manufacturing weight is 100Kg cylindrical counterweight, and the density requirement is 17.3g / cm 3 ±0.2g / cm 3 .

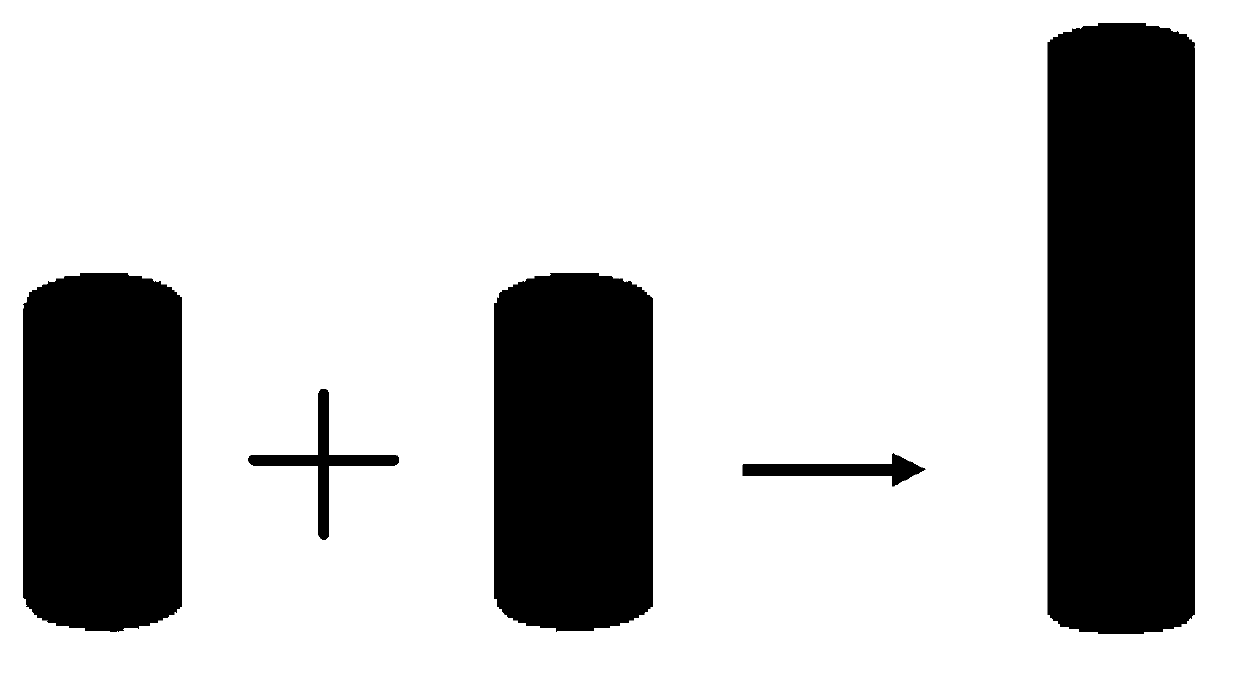

[0024] Step 1: The cylindrical counterweight can be divided into two small counterweights of 50Kg for preparation;

[0025] Step 2: The components and their contents in terms of mass percentage are: tungsten W: 91%, nickel Ni: 6.3%, iron Fe: 2.7%. According to the mass percentage of the above-mentioned powder raw materials, the average particle size of tungsten powder is 2.5μm~3.5μm, and the purity is ≥99%; the average particle diameter of nickel powder is about 1μm~3μm, and the purity is ≥99.8%; the average particle diameter of iron powder is about 1μm~3μm , purity ≥ 99.5%; mix in a mechanical mixer for 12 hours.

[0026] Step 3: Put the mixed raw material powder into a soft rubber mold, seal the rubber plug, and put it into a wet-jacket cold isostatic press for pressing with a pressing force of 200MPa and hold the pressure for 3s.

[0027] Step 4: ...

Embodiment 2

[0030] The manufacturing weight is 150Kg cylindrical counterweight, and the density requirement is 17.6g / cm 3 ±0.2g / cm 3 .

[0031] Step 1 The cylindrical counterweight can be divided into three small counterweights of 50Kg for preparation;

[0032] The components and their content in step 2 by mass percentage are: tungsten W: 93%, nickel Ni: 5%, iron Fe: 2%. According to the mass percentage of the above-mentioned powder raw materials, the average particle size of tungsten powder is 2.5μm~3.5μm, and the purity is ≥99%; the average particle diameter of nickel powder is about 1μm~3μm, and the purity is ≥99.8%; the average particle diameter of iron powder is about 1μm~3μm , purity ≥ 99.5%; mix in a mechanical mixer for 12 hours.

[0033] Step 3: Put the mixed raw material powder into a soft rubber mold, seal the rubber plug, and put it into a wet-jacket cold isostatic press for pressing with a pressing force of 200MPa and hold the pressure for 3s.

[0034] Step 4: Put the pre...

Embodiment 3

[0037] The manufacturing weight is 300Kg cylindrical counterweight, and the density requirement is 18.0±0.2g / cm 3 .

[0038] Step 1 The cylindrical counterweight can be divided into six small counterweights of 50Kg for preparation;

[0039]The components and their contents in step 2 by mass percentage are: tungsten W: 95%, nickel Ni: 3%, iron Fe: 2%. According to the mass percentage of the above-mentioned powder raw materials, the average particle size of tungsten powder is 2.5μm~3.5μm, and the purity is ≥99%; the average particle diameter of nickel powder is about 1μm~3μm, and the purity is ≥99.8%; the average particle diameter of iron powder is about 1μm~3μm , purity ≥ 99.5%; mix in a mechanical mixer for 12 hours.

[0040] Step 3: Put the mixed raw material powder into a soft rubber mold, seal the rubber plug, and put it into a wet-jacket cold isostatic press for pressing with a pressing force of 200MPa and hold the pressure for 3s.

[0041] Step 4: Put the pressed blank...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com