Method for rapidly forming amine group on surface of material, medical material with surface loaded with high-density amine group and application of medical material

An amine-based, rapid technology, applied in medical science, surgery, coating, etc., can solve problems such as complex methods, unfavorable industrial application, long production cycle, etc., achieve short reaction time, simple and easy preparation method, meet the requirements of amine-based Effect of Density Requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

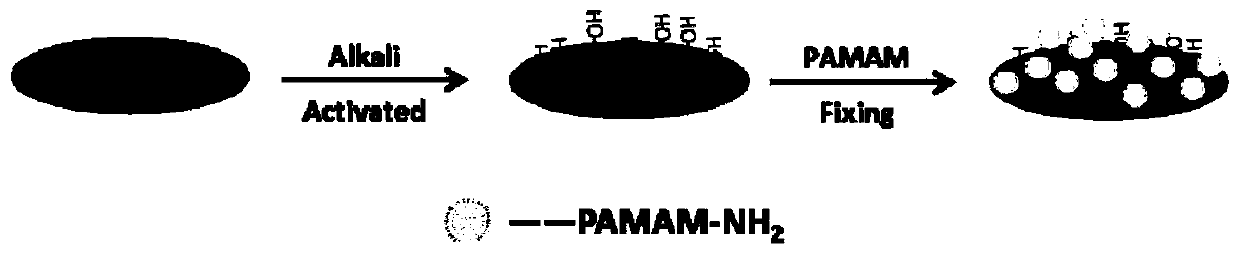

[0041] This embodiment provides a method for rapidly forming amine groups on the surface of a material, which includes the following steps:

[0042] After polishing and cleaning the titanium sheet, soak it in 1mol / L potassium hydroxide solution, keep it at 70℃ for 10h, then use RO water ultrasonic cleaning twice, keep it at 70℃ for 10h, and then put the material in Dry at 50℃ for later use.

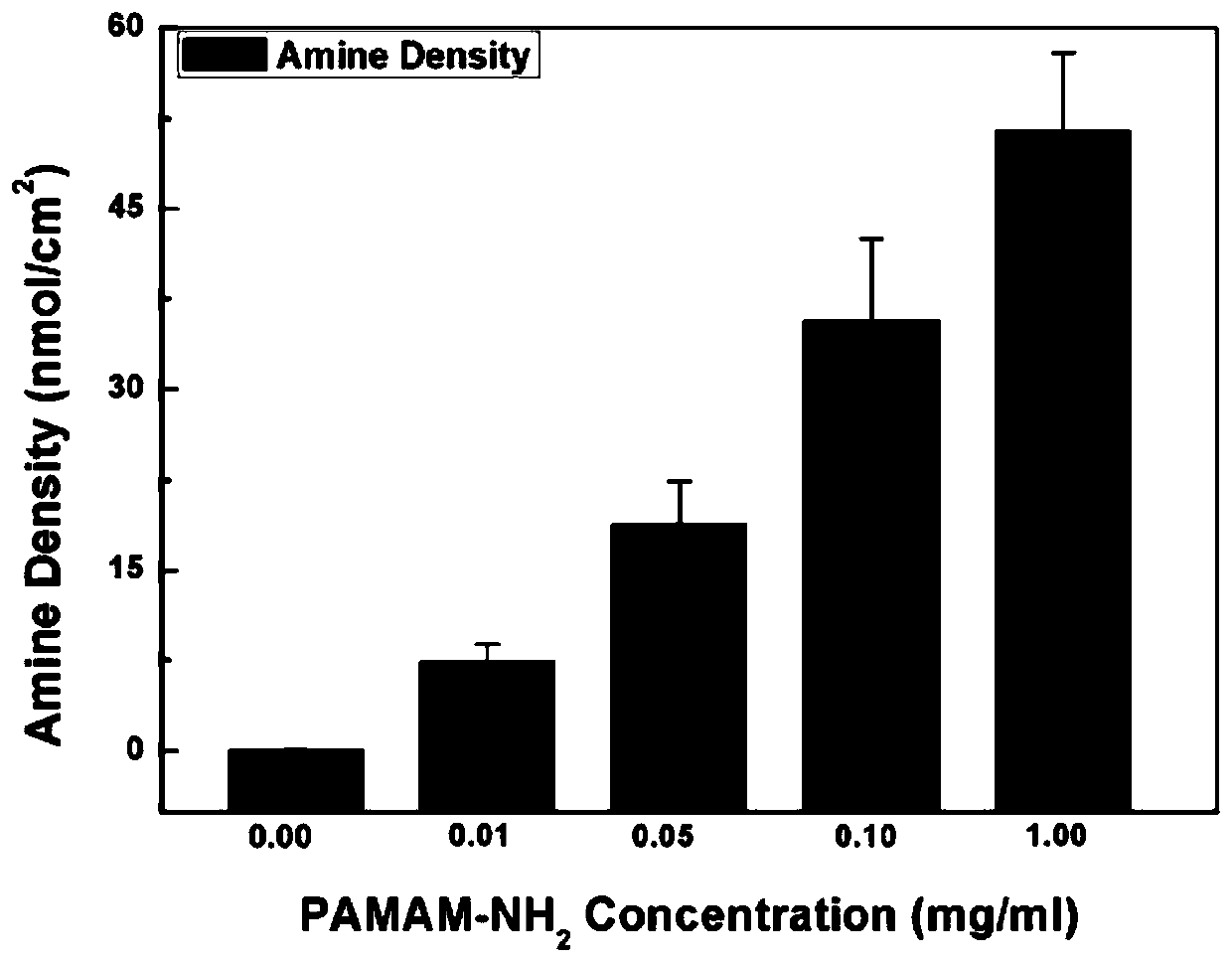

[0043] The alkali-activated material and PAMAM-NH at a concentration of 0.01 mg / mL 2 The solution (molecular weight is about 6900) was reacted for 5 minutes at a temperature of 3°C, and then washed with RO for 3 times, and the ear ball was blown dry for use.

Embodiment 2

[0045] This embodiment provides a method for rapidly forming amine groups on the surface of a material, which includes the following steps:

[0046] After polishing and cleaning the titanium sheet, soak it in a 5mol / L sodium hydroxide solution, keep it at 90℃ for 14h, then use RO water ultrasonic cleaning 4 times, keep it at 90℃ for 14h, and then put the material in Dry at 50℃ for later use.

[0047] The alkali-activated material and PAMAM-NH at a concentration of 1 mg / mL 2 The solution (molecular weight is about 14300) was reacted at 10°C for 24h, then washed with RO 3 times, and the ear ball was blown dry for use.

Embodiment 3

[0049] This embodiment provides a method for rapidly forming amine groups on the surface of a material, which includes the following steps:

[0050] After polishing and cleaning the titanium sheet, soak it in a 3mol / L sodium hydroxide solution, keep it at 80℃ for 12h, then use RO water ultrasonic cleaning 4 times, keep it at 80℃ for 12h, then put the material in Dry at 50℃ for later use.

[0051] The alkali-activated material and PAMAM-NH at a concentration of 0.1 mg / mL 2 The solution (molecular weight is about 6909) was reacted for 30 minutes at a temperature of 5°C, and then washed with RO for 3 times, and the ear ball was blown dry for use.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com