Manufacturing method and device used for preparing rare earth metal target material through lanthanum thermal reduction

A rare earth metal and manufacturing method technology, applied in metal material coating process, ion implantation plating, coating and other directions, can solve the problems of complex separation of target and mold, inconsistent target density, and only the screen can only be discarded. The effect of reducing metal oxidation links, containing less impurities, and reducing pollution opportunities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

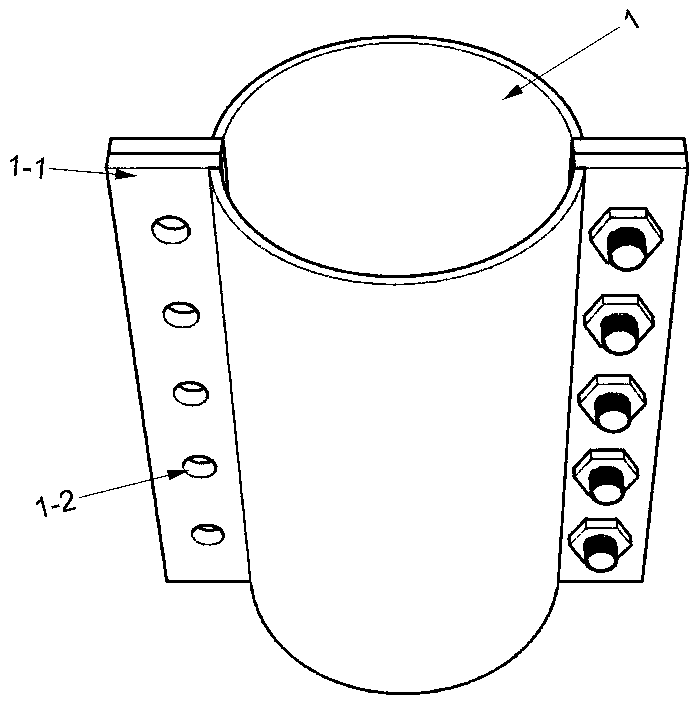

Image

Examples

Embodiment 1

[0025] 1. High-purity rare earth metal oxide ytterbium Yb 2 0 3 / TRE0≥99.999% and high-purity metal lanthanum La 2 0 3 / TRE0≥99.999% debris After mixing evenly in a ratio of 1:1.25 by weight;

[0026] 2. Put it into a stainless steel mold, use 6000×10 5 The pressure of Pa is compressed into a block;

[0027] 3. Put the bulk raw material into the tantalum crucible of the vacuum reduction furnace, and vacuum the vacuum to a degree of 10 -3 Pa, heating at 1200°C for reduction distillation, using crucible 4 to collect metal on the top to obtain rare earth high-purity metal ytterbium embryo body;

[0028] 4. Surface processing the formed rare earth metal blank to obtain a rare earth metal target;

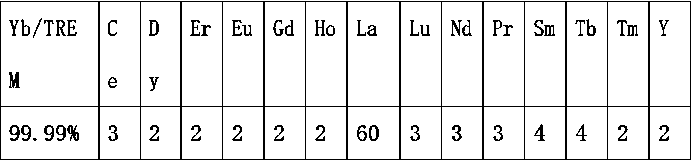

[0029] The detection results of rare earth metal targets prepared by this method are as follows: table unit: ppm

[0030]

[0031]

Embodiment 2

[0033] The preparation method of the rare earth metal Sm target material, the specific steps are as follows:

[0034] 1. High-purity rare earth metal samarium oxide Sm 2 0 3 / TRE0≥99.999% and high-purity metal lanthanum La 2 0 3 After / TRE0≥99.999% debris is mixed evenly at a weight ratio of 1:1.35;

[0035] 2. Put it into a stainless steel mold, use 8000×10 5 The pressure of Pa is pressed into blocks;

[0036] 3. Put the bulk raw material into the molybdenum crucible of the vacuum reduction furnace, and vacuum the vacuum to a degree of 10 -3 Pa, heating at 1280°C for reduction distillation, using a special target mold to collect metals on the top to obtain rare earth high-purity metal samarium embryos;

[0037] 4. Surface processing the formed rare earth metal blank to obtain a rare earth metal target;

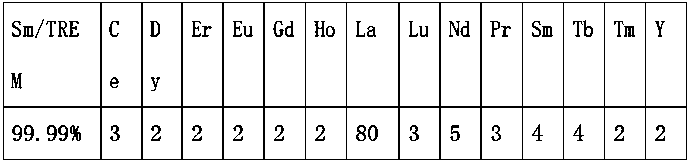

[0038] The detection results of rare earth metal targets prepared by this method are as follows: table unit: ppm

[0039]

[0040]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com