Ultrahigh-elasticity extensible towel and manufacturing method thereof

A manufacturing method and ultra-high elastic technology, applied in textiles, papermaking, fabrics, textiles, etc., can solve the problems of easy stickiness, mildew, residual cotton fiber hairiness, faded fiber hairiness, etc., to achieve softness, fatigue resistance, and enhanced cleaning. , the effect of large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

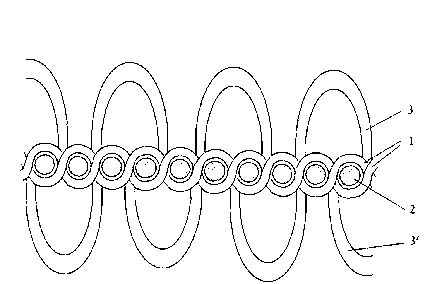

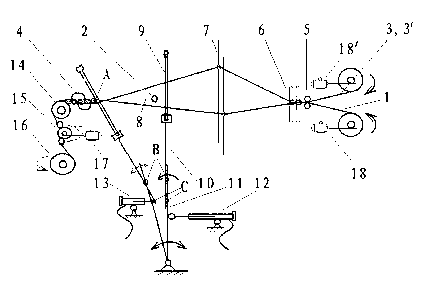

[0021] figure 1 Shown is a schematic cross-sectional view of the ultra-high elastic stretchable towel provided by the present invention. Such as figure 1 As shown, the ultra-high elastic stretchable towel provided by the present invention includes ground warp 1, ground weft 2 and pile warp 3, 3'. Ground warp 1 is covered yarn of "polyester low elastic yarn / ultra-high elastic thick denier spandex yarn". "Polyester low-elasticity yarn / ultra-high-elasticity coarse-denier spandex yarn" uses (140-210) D / (8-12) f ultra-high-elasticity spandex yarn as the inner core, and the polyester low-elasticity yarn is networked through overfeeding Wrap the inner core to achieve the longitudinal stretch and high elasticity of the ground warp 1. Ground weft 2 is polyester low elastic yarn. Ground longitude 1 and ground latitude 2 are interwoven in a plain weave to form a ground weave. Tile warps 3, 3' and ground weft 2 are interwoven in a twill weave to form a terry weave so as to form a ter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com