Nonplanar microneedle array and manufacturing method thereof

A micro-needle array and plane technology, applied in the field of medical cosmetic devices and micro-needles for medical injection, can solve the problems of complex manufacturing process and height limitation, and achieve the effects of good needle tip quality, reduced manufacturing cost and easy realization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

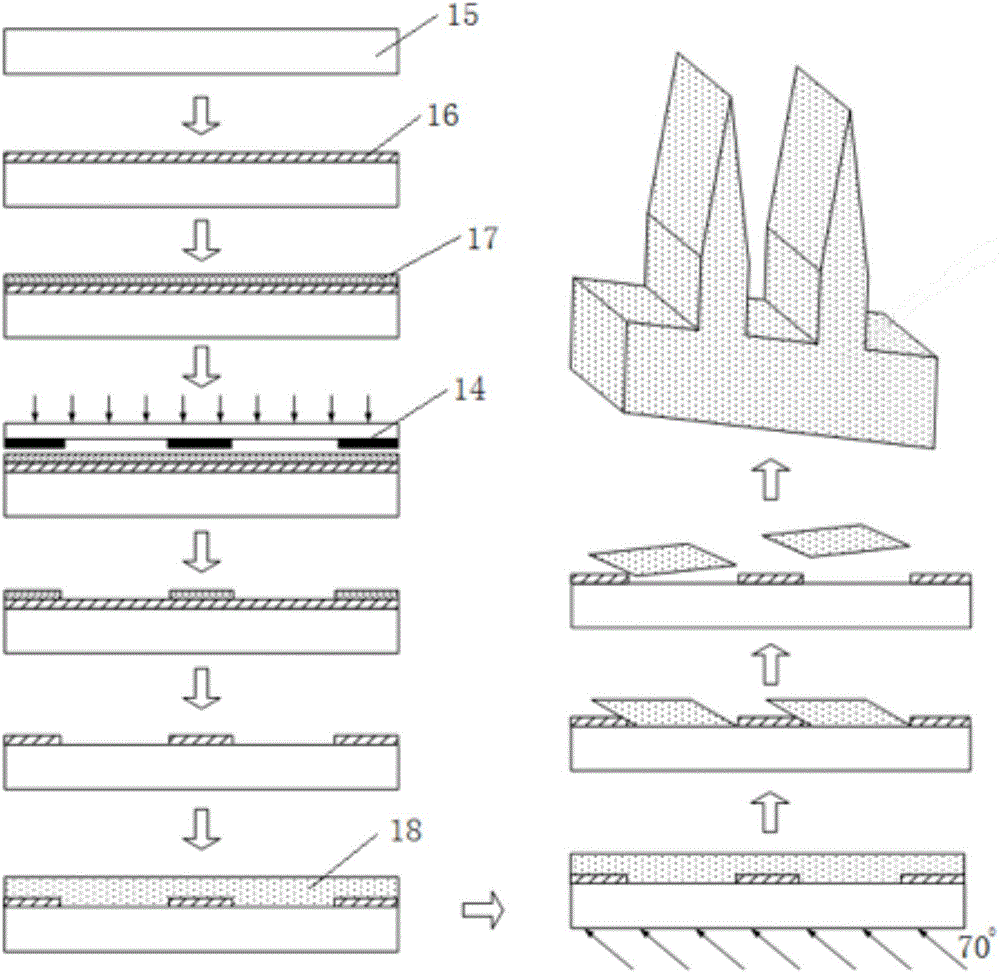

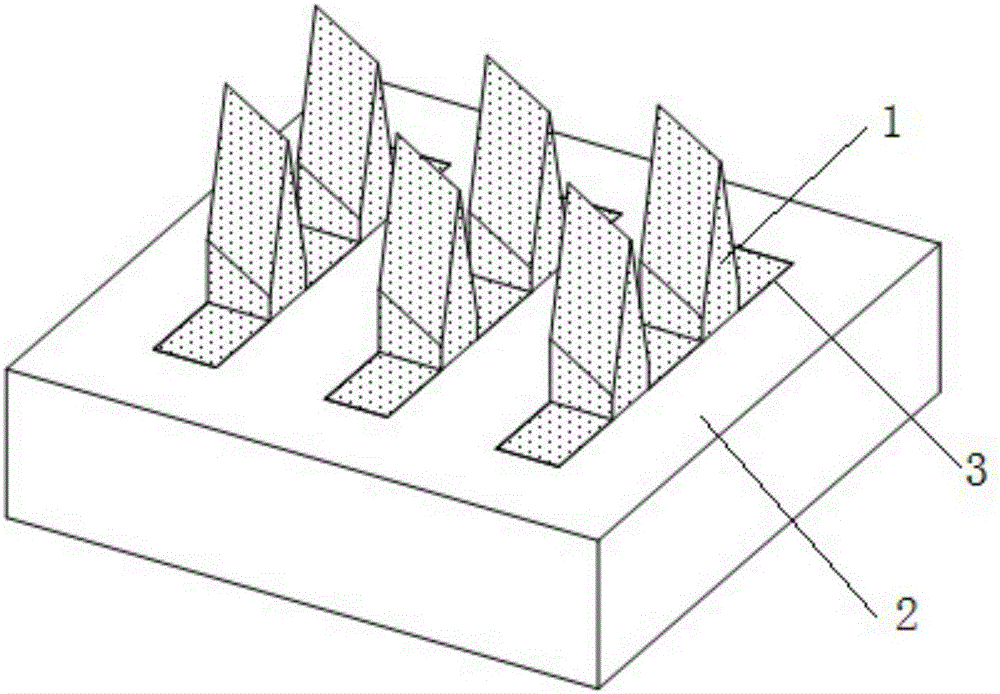

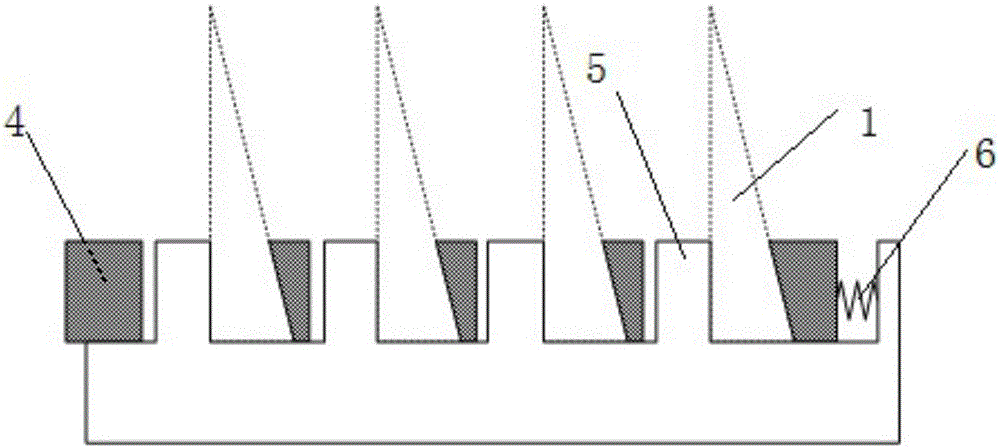

[0057] A different-plane microneedle array, including coplanar microneedles 1 and a substrate 2, coplanar microneedles 1 including one or more needlepoints and a base connecting the needlepoints, the needlepoints and bases are in the same plane, and more than two coplanar microneedles The needle 1 is assembled on the substrate 2, and an elastic cushion block 19 is arranged between the microneedles 1 on the same plane.

[0058] The elastic cushion block 19 has the following functions: 1. It can isolate and control the distance between microneedles 1 on the same plane; The degree of deformation of the elastic buffer block 19 can further control the length of the microneedle body protruding from the elastic buffer block 19 to adjust the depth of penetration into the skin.

[0059] The present invention intends to integrate the advantages of coplanar microneedles and non-planar microneedles, and combine the advantages of low-cost polymer microneedle technology.

[0060] The copla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com