Small satellite formation design method for realizing space debris racemization by utilizing eddy current effect

A space debris and satellite formation technology, applied in the aerospace field, can solve the problems of long racemization time, poor racemization effect, and limited size requirements of debris, and achieve the effect of accelerating racemization and enhancing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention is described in further detail below in conjunction with accompanying drawing:

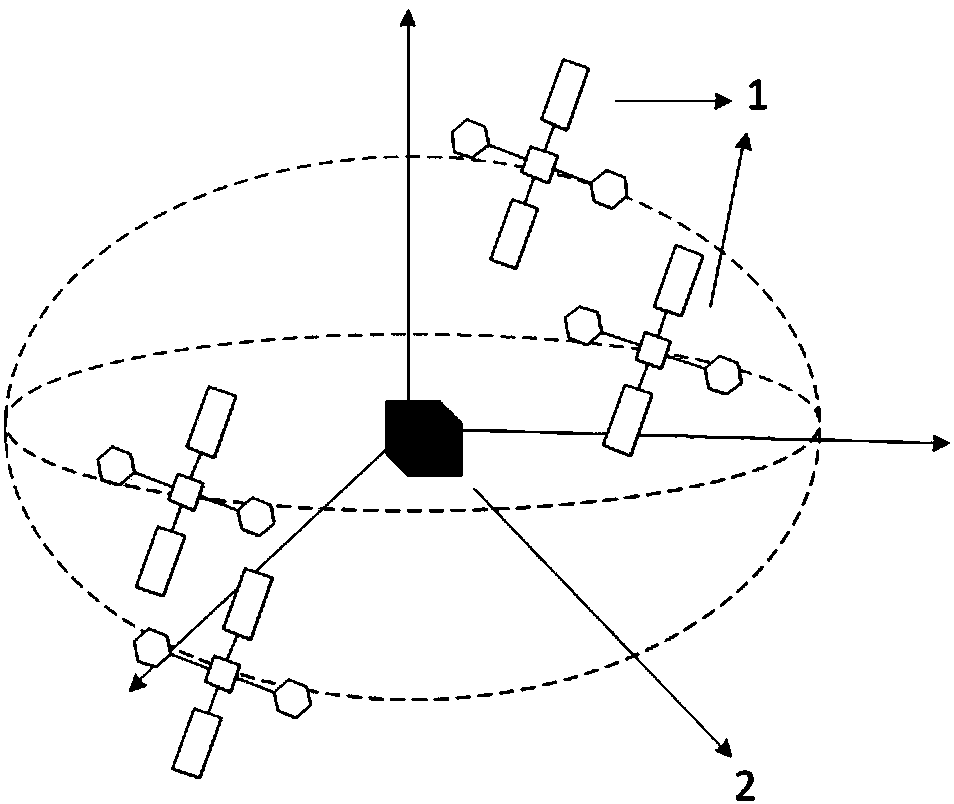

[0033] see figure 1 , figure 1 It is a schematic diagram of the small satellite formation design proposed by the present invention to realize the derotation of space debris, wherein the center is the space debris 2 that needs to be derotated, and the released four small satellites 1 include two in-plane and two out-of-plane. Use four small satellites carrying energized solenoid coils and solar sails for formation, and the two small satellites in the plane can change their positions in the formation, and there are two states, one is to ensure that the energized spiral coil is facing the debris rolling x The second is to ensure that the energized solenoid coil is facing the y-axis direction of the debris rolling; the two small satellites in the plane always ensure that the energizing solenoid coil is facing the z-axis direction of the debris rolling.

[0034] The prese...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com