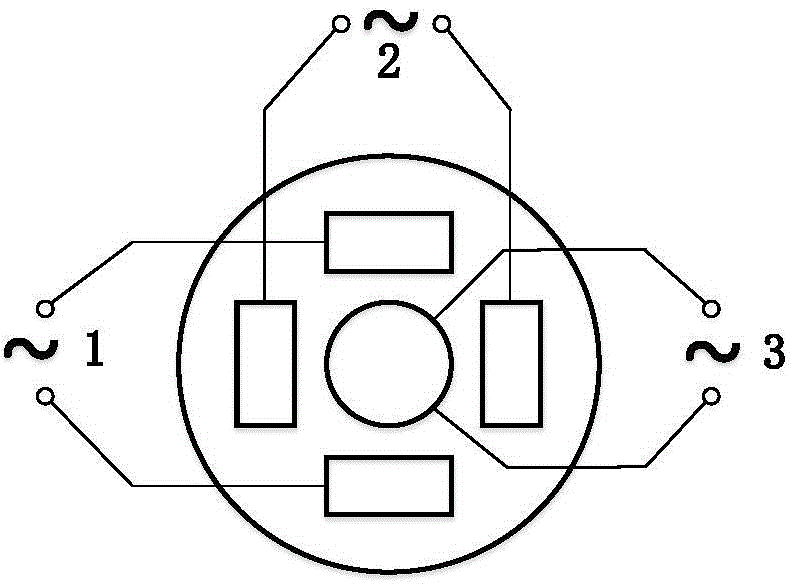

Orthogonal rotation exciting field eddy current transducer

An eddy current sensor and sensor technology, which is applied in the direction of material magnetic variables, can solve the problem of only selective detection, etc., and achieve the effects of reducing the occurrence of defect missed detection, high sensitivity, and meeting the detection requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

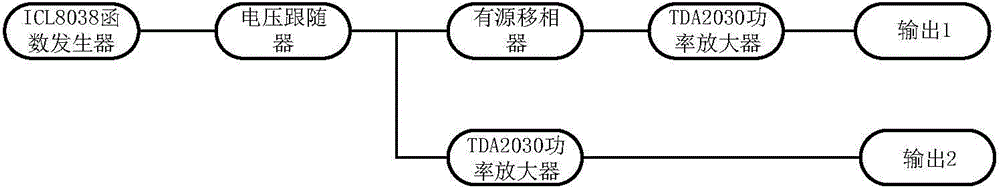

Method used

Image

Examples

Embodiment Construction

[0026] In order to better illustrate the purpose and advantages of the present invention, the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0027] In the embodiment, an aluminum-based alloy plate is selected, and crack-like defects with a size of (width × length × depth) 0.15 mm × 20 mm × 1 mm are processed on it by electric spark etching, and they are arranged at different angles, such as Figure 5 As shown, the purpose of setting defects in this way is to examine the detection ability of the sensor for defects in different orientations.

[0028] Move the sensor along the length of the specimen, and a sudden change in the signal amplitude can be observed at the defect position, such as Image 6 , Figure 7 , the signal is further processed through a low-pass filter, etc., and the defect signal can be clearly extracted. from Image 6 , Figure 7 It can be found that for the new structure sensor, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com