Laser spiral perforating device and device adopting eddying effect for assisting in heating

A technology of auxiliary heating and eddy current effect, which is applied in the direction of laser welding equipment, metal processing equipment, welding equipment, etc., can solve the problems of poor roundness and taper, recast layer thickness, poor taper and roundness, etc., and achieve reduction Effect of microcracks and pits, weakening of hardening tendency, and increased removal amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In order to better illustrate the implementation details of the present invention, the technical solutions of the present invention will be further described below in conjunction with the accompanying drawings.

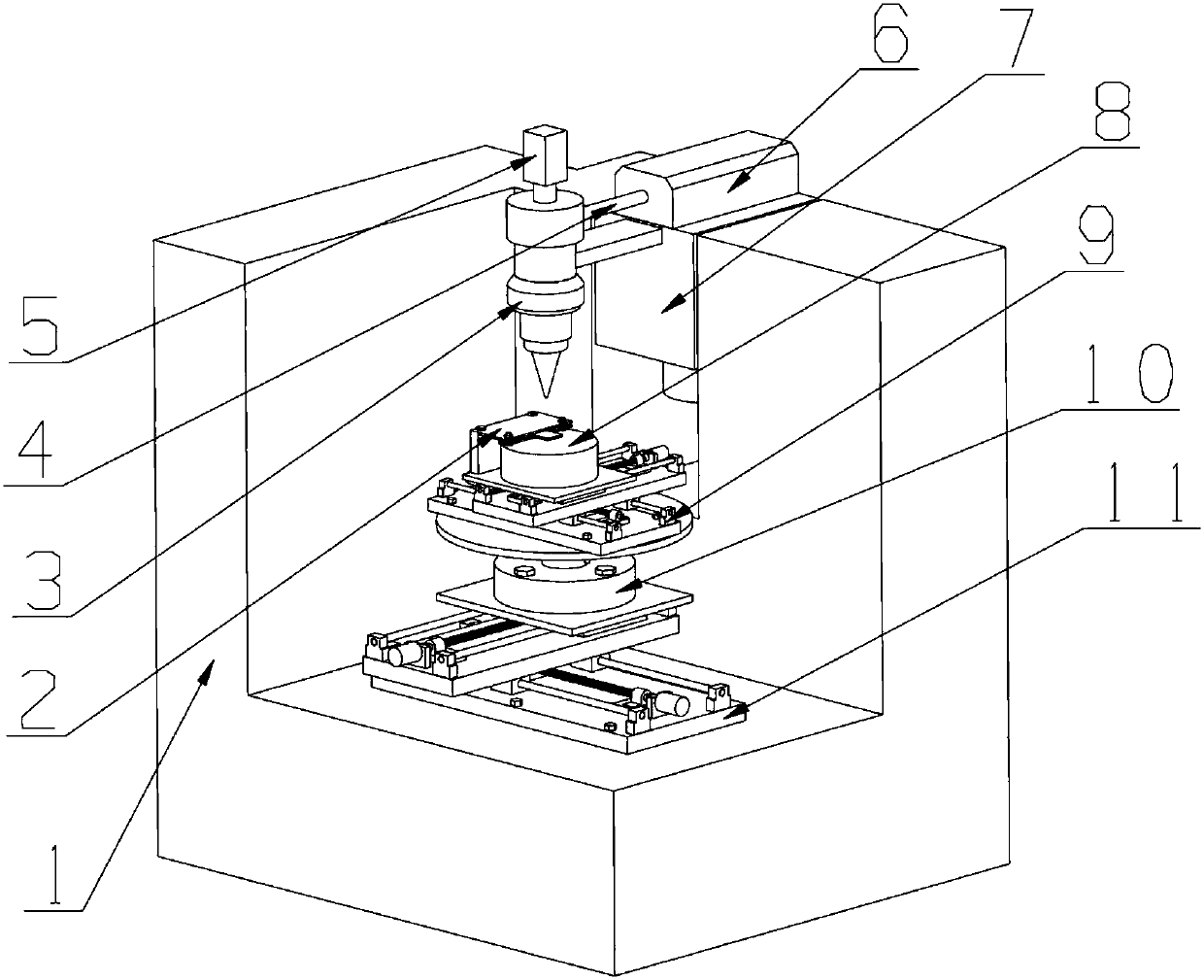

[0043] combined with figure 1 , a laser spiral drilling device for auxiliary heating by eddy current effect, characterized in that it includes a power supply box 1, a workpiece fixture 2, a laser head 3, a light guide tube 4, a CCD camera 5, a laser 6, a z-direction moving mechanism 7, an eddy current Generating device 8, first x-y mobile platform 9, rotating platform device 10, second x-y mobile platform 11;

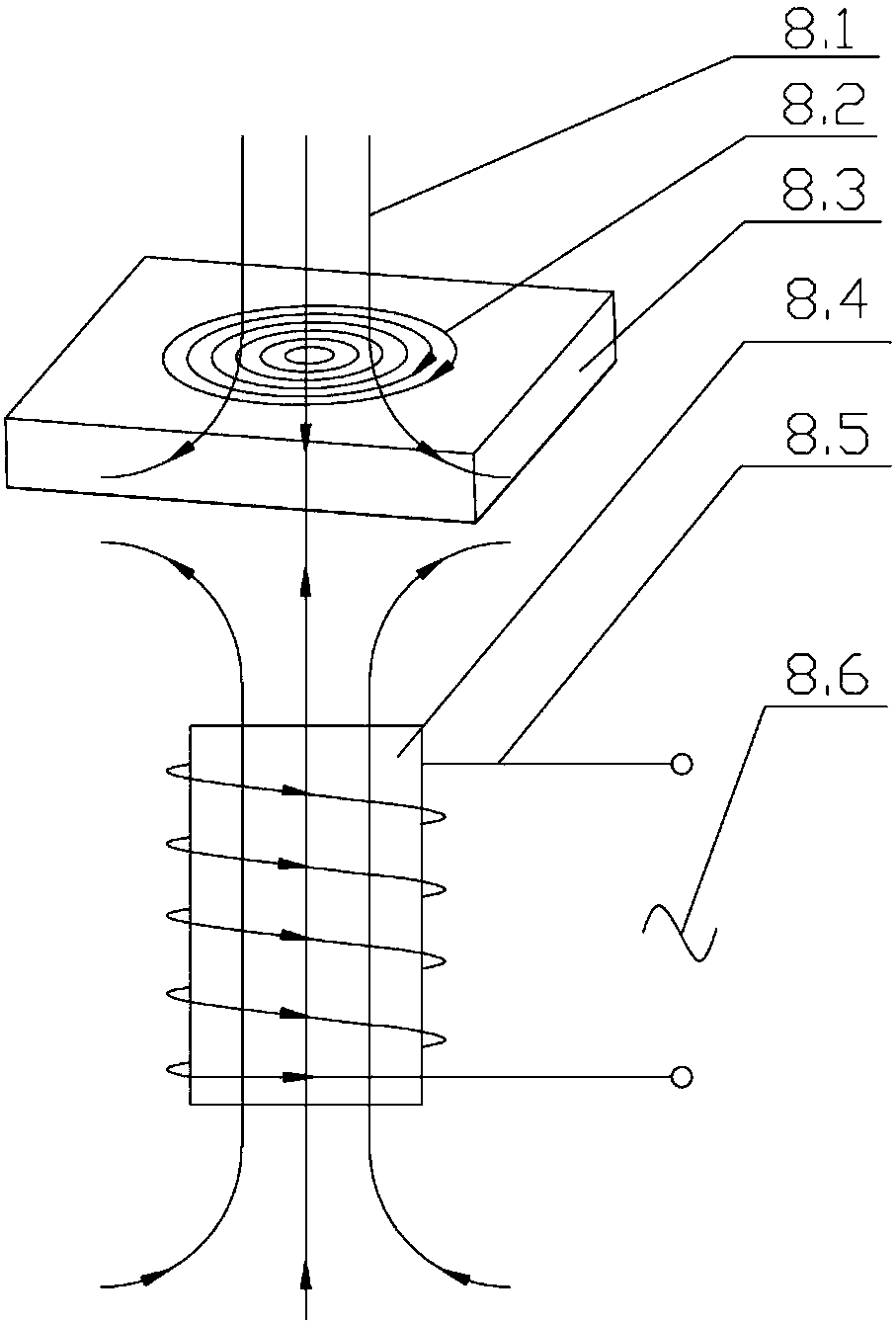

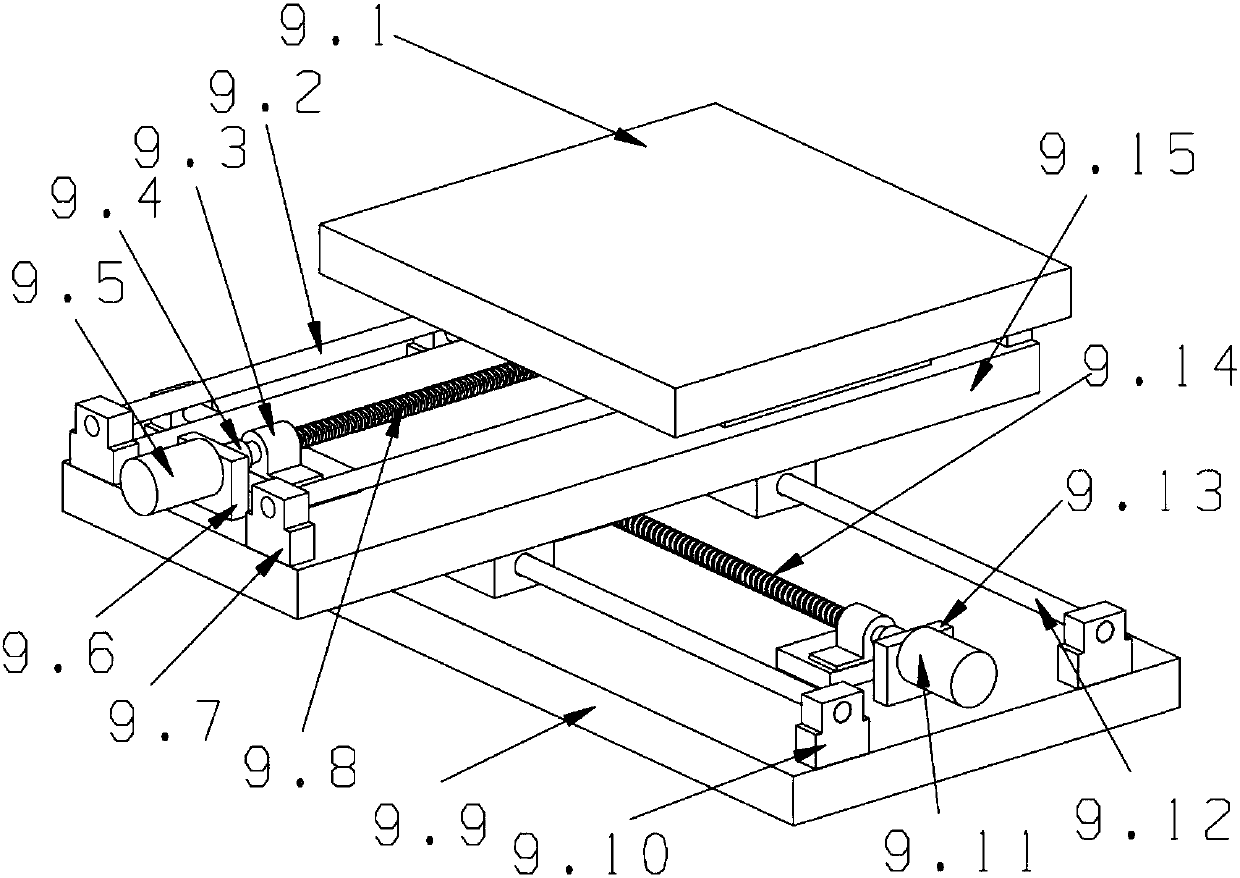

[0044] The power box 1 is installed on the left side of the machine tool base, the second x-y mobile platform 11 is above the base of the machine tool, the rotary platform device 10 is installed on the second x-y mobile platform 11, and the first x-y mobile platform is installed on the rotary platform device 10 Platform 9, install eddy current generatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com