Flexible magnetostriction and eddy integrated sensor for detecting defects of high-voltage transmission line

A high-voltage transmission line and defect detection technology, which is applied in the direction of optical testing of defects/defects, material magnetic variables, etc., can solve problems such as inconvenient installation, high quality, complex sensor structure, etc., and achieve the effect of light structure and easy disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

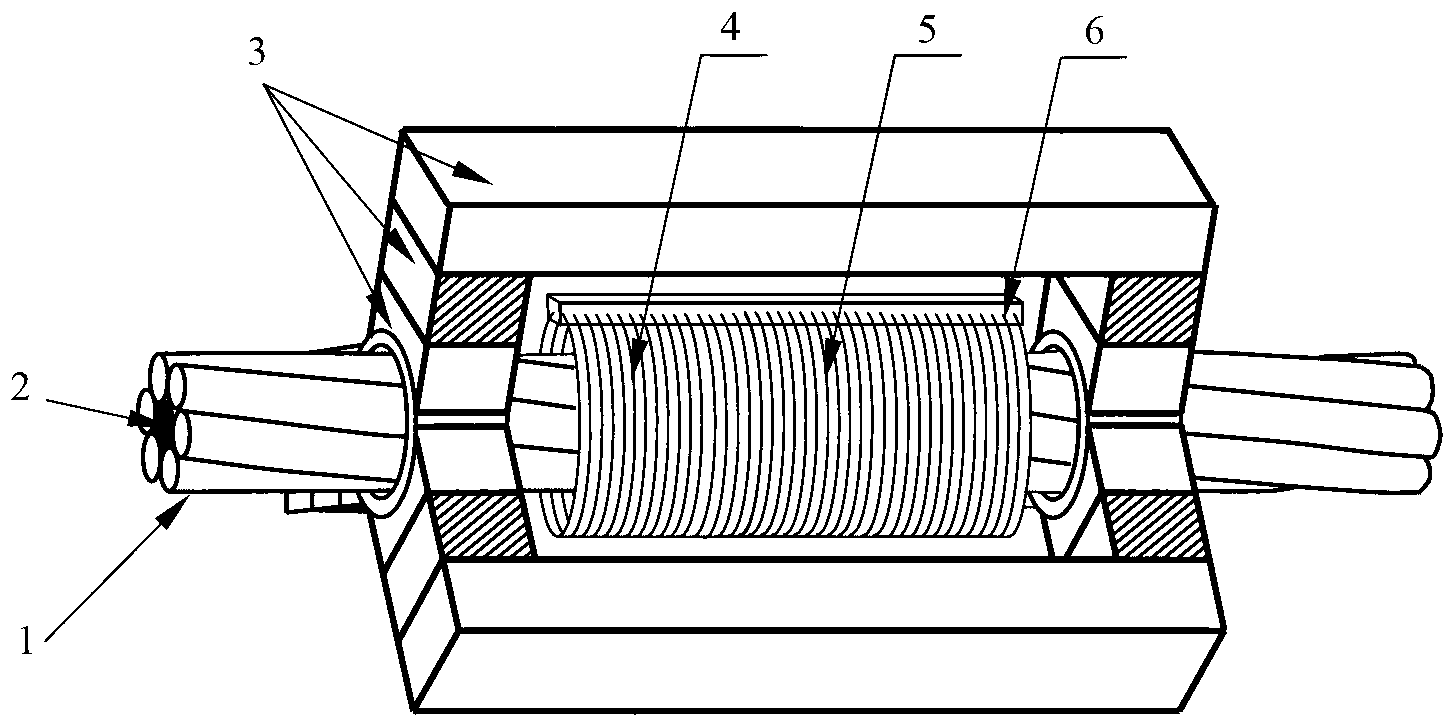

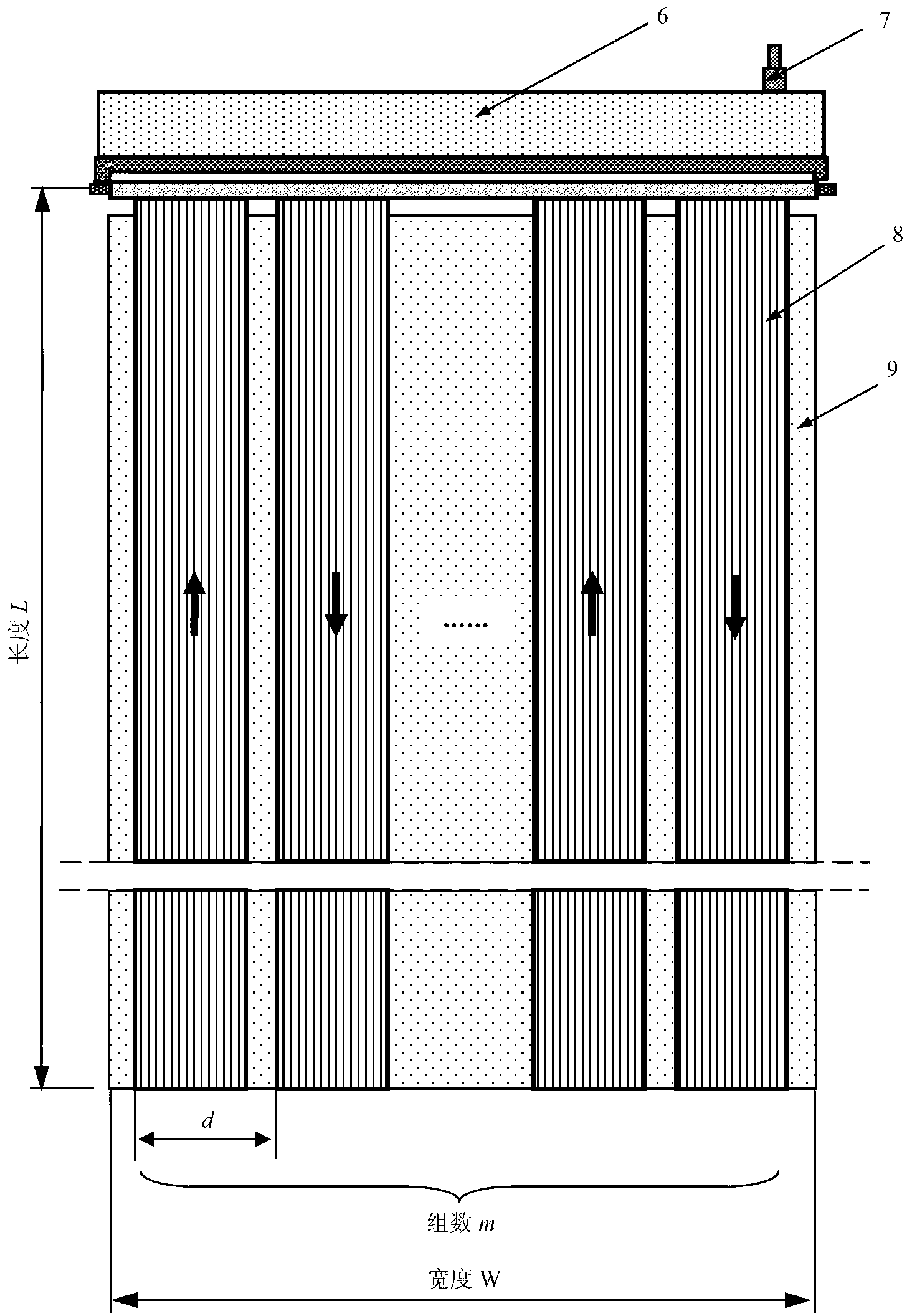

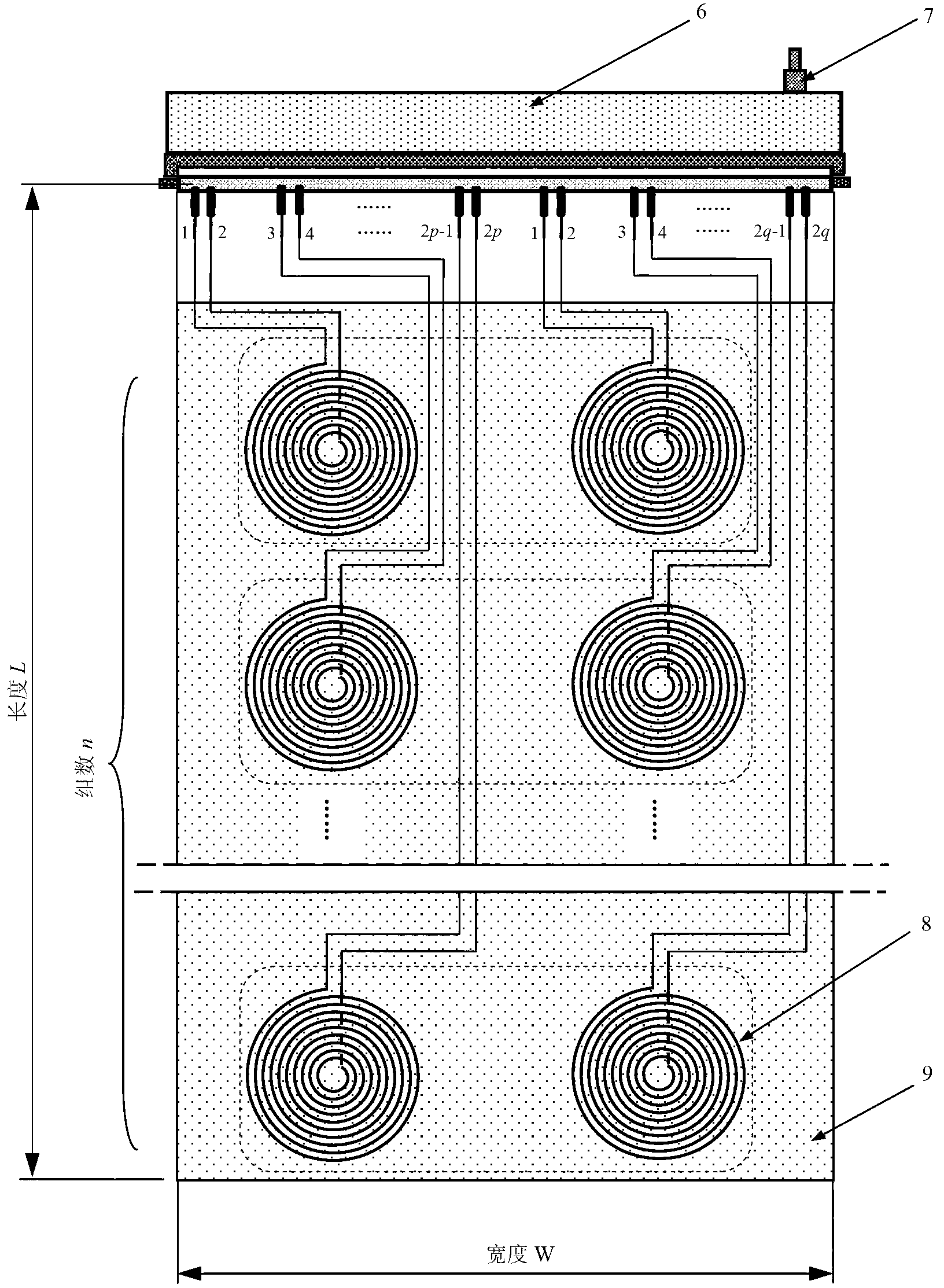

[0023] The flexible magnetostrictive and eddy current integrated sensor for defect detection of high-voltage transmission lines consists of a bias magnetic circuit 3 and an outer flexible printed coil 4 ( figure 2 ), the inner flexible printed coil 5 ( image 3 ) and connector 6 and other components. The object to be tested is a high-voltage transmission line, including an aluminum stranded wire 1 on the outer layer of the transmission line and a steel core 2 on the inner layer of the transmission line. The flexible printed coil is composed of copper wires 8 and a substrate 9 , and the connecting parts of the flexible printed coil include connectors 6 and BNC connectors 7 . The length of the double-layer flexible printed coil is greater than the circumference of the transmission line under test. After crimping, it is fixed on the surface of the transmission line through the connector 6. The installation diagram is as follows: figure 1 shown. The flexible integrated sensor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com