Patents

Literature

101results about How to "Implement defect detection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

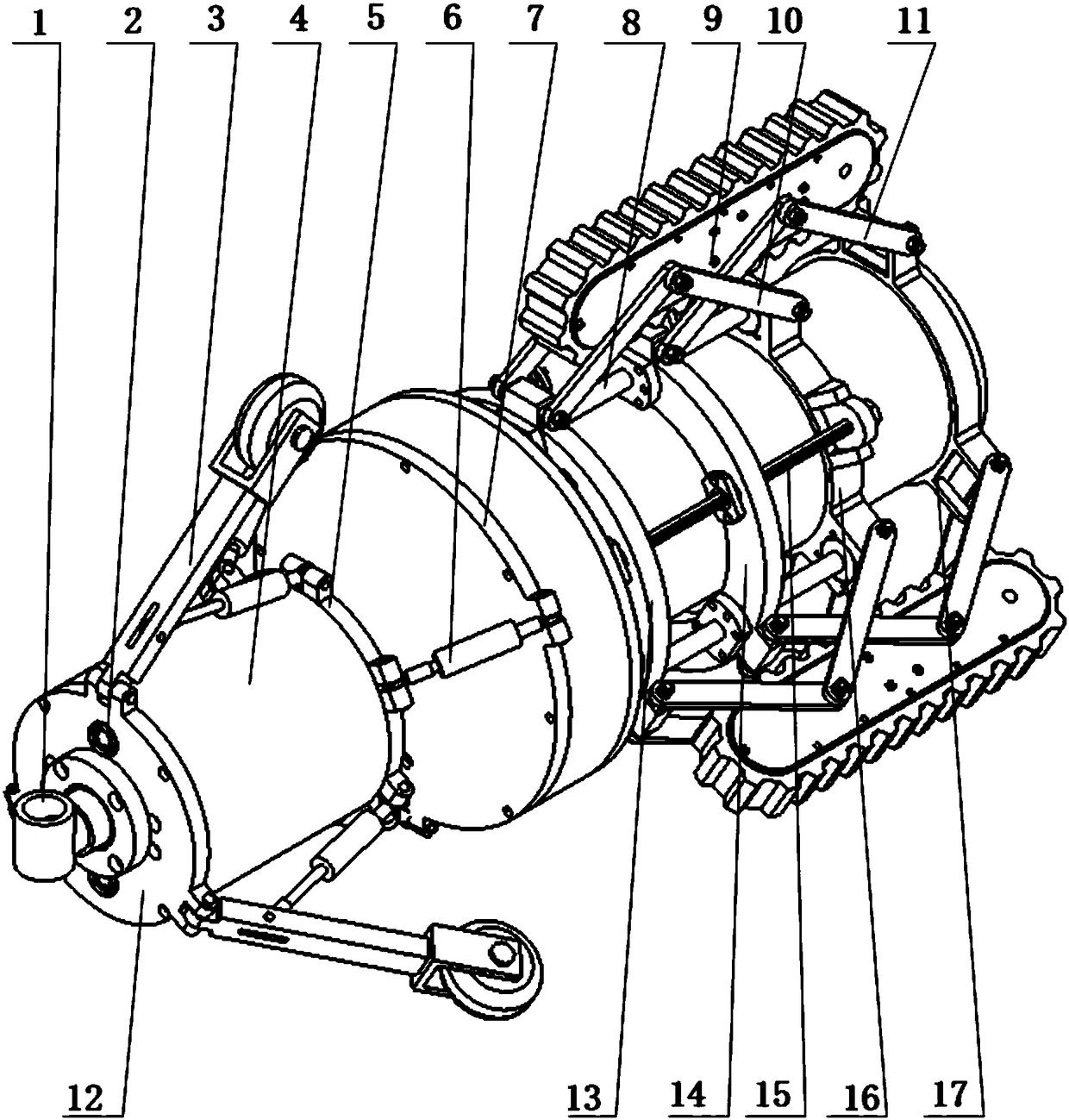

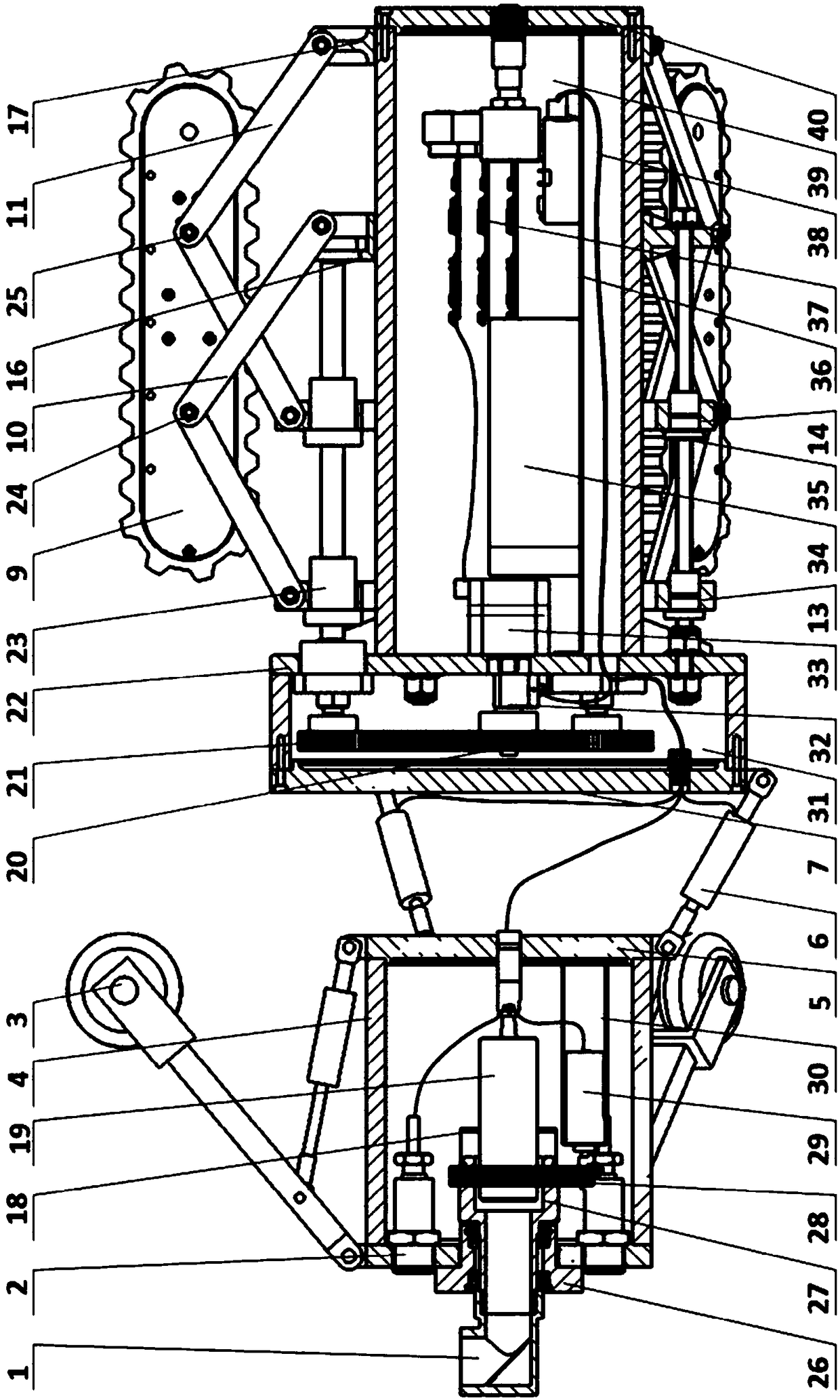

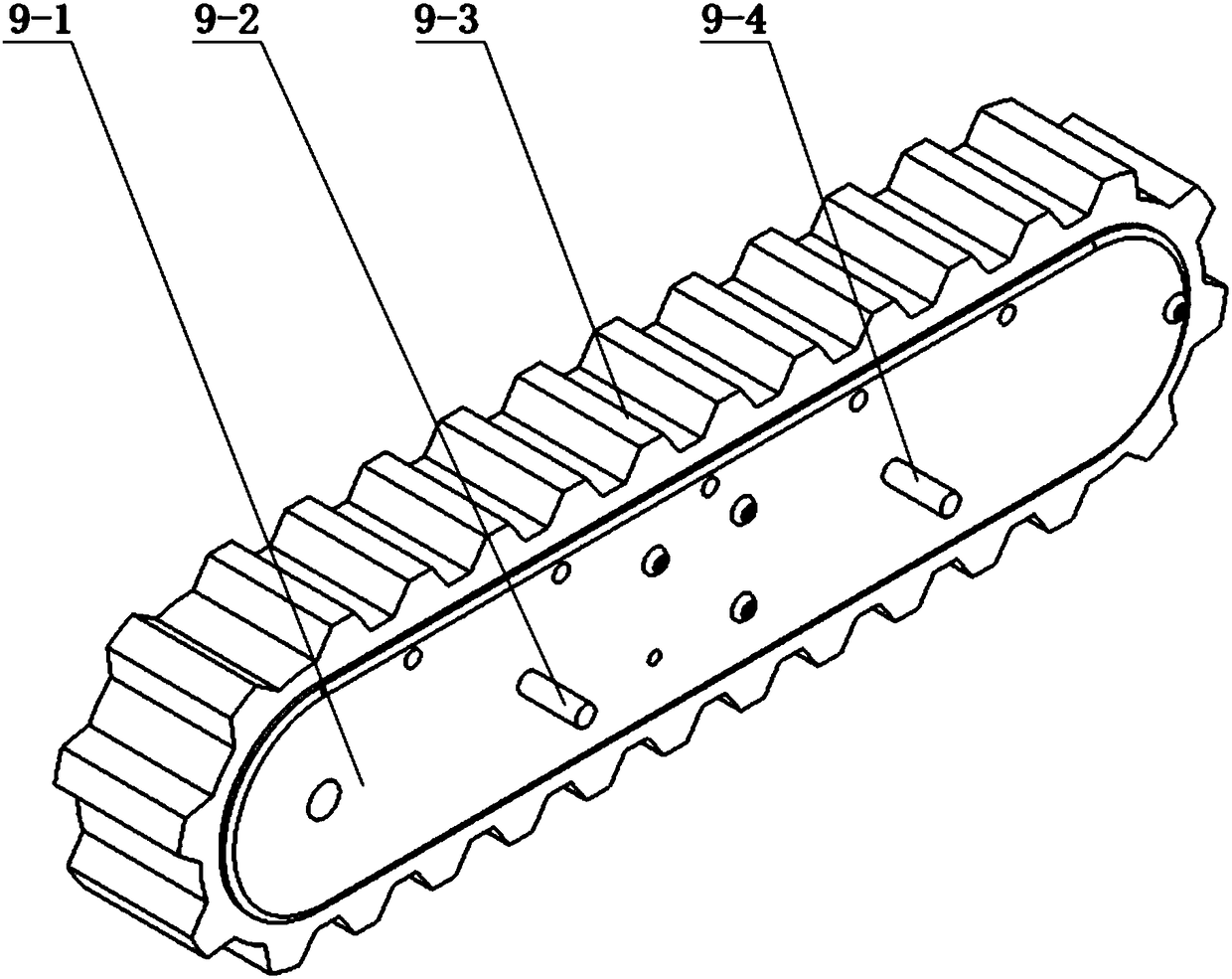

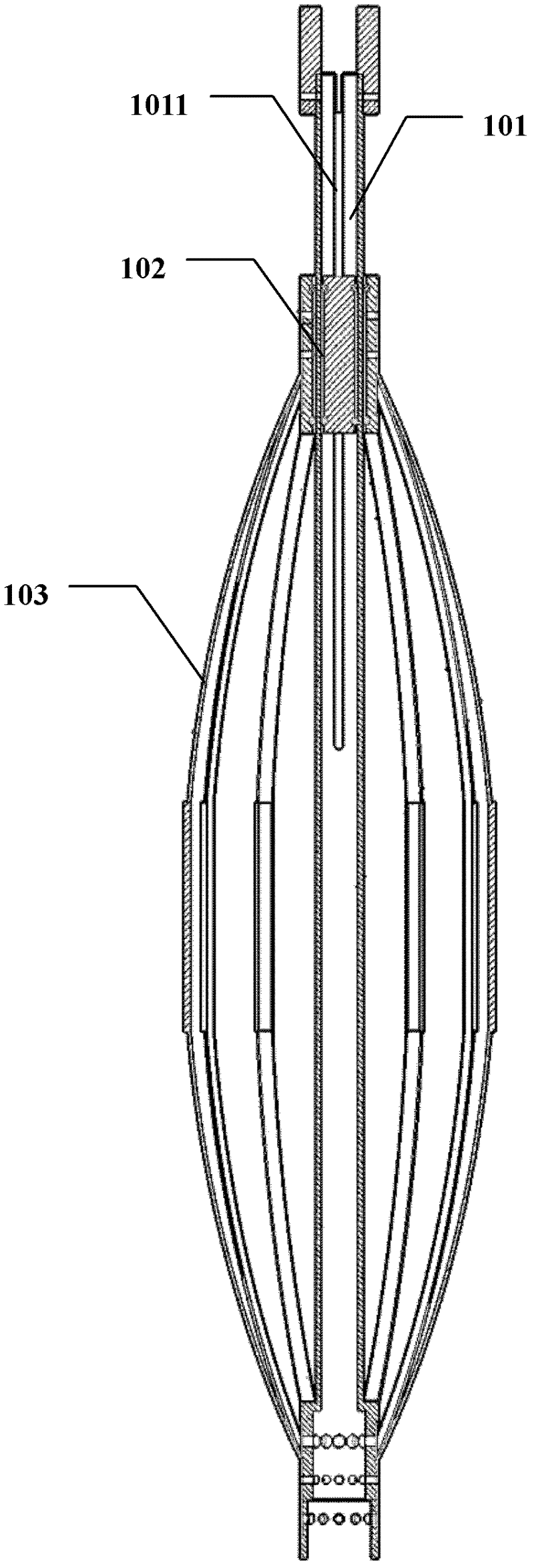

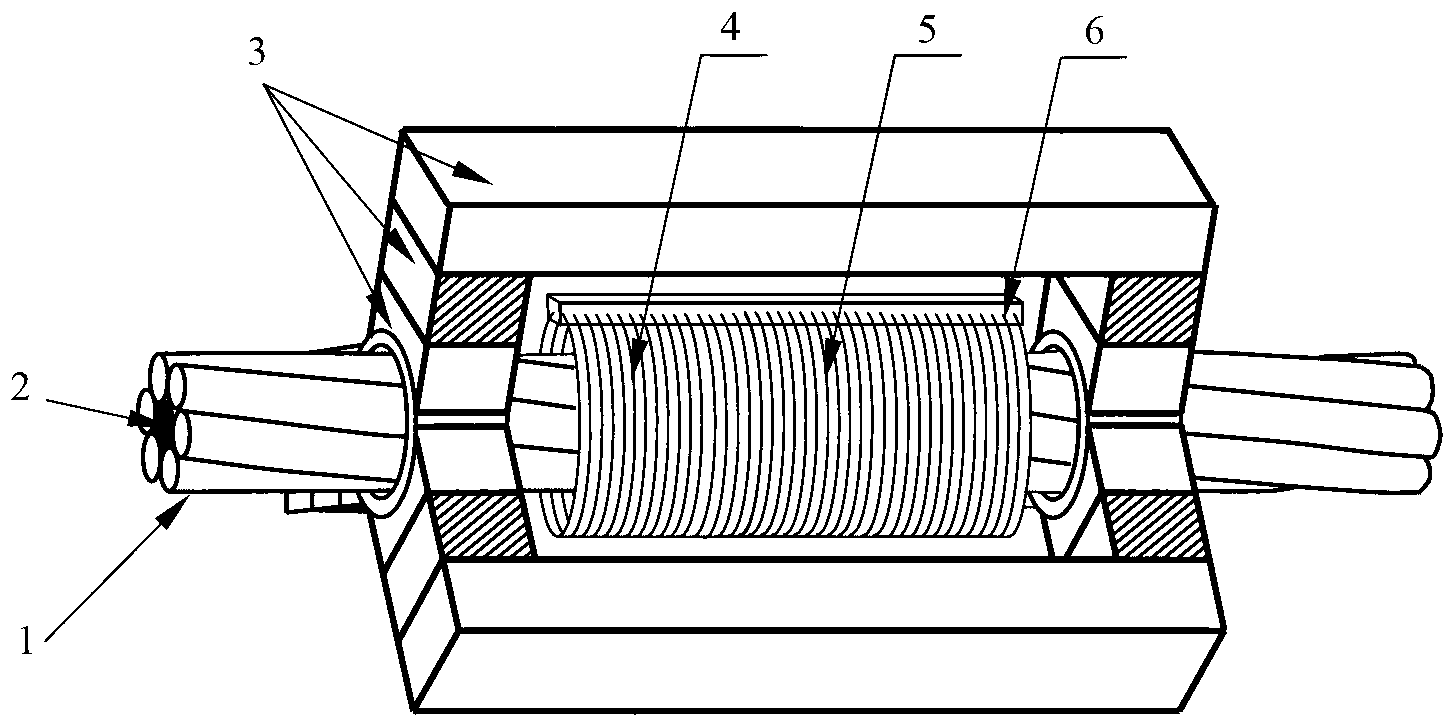

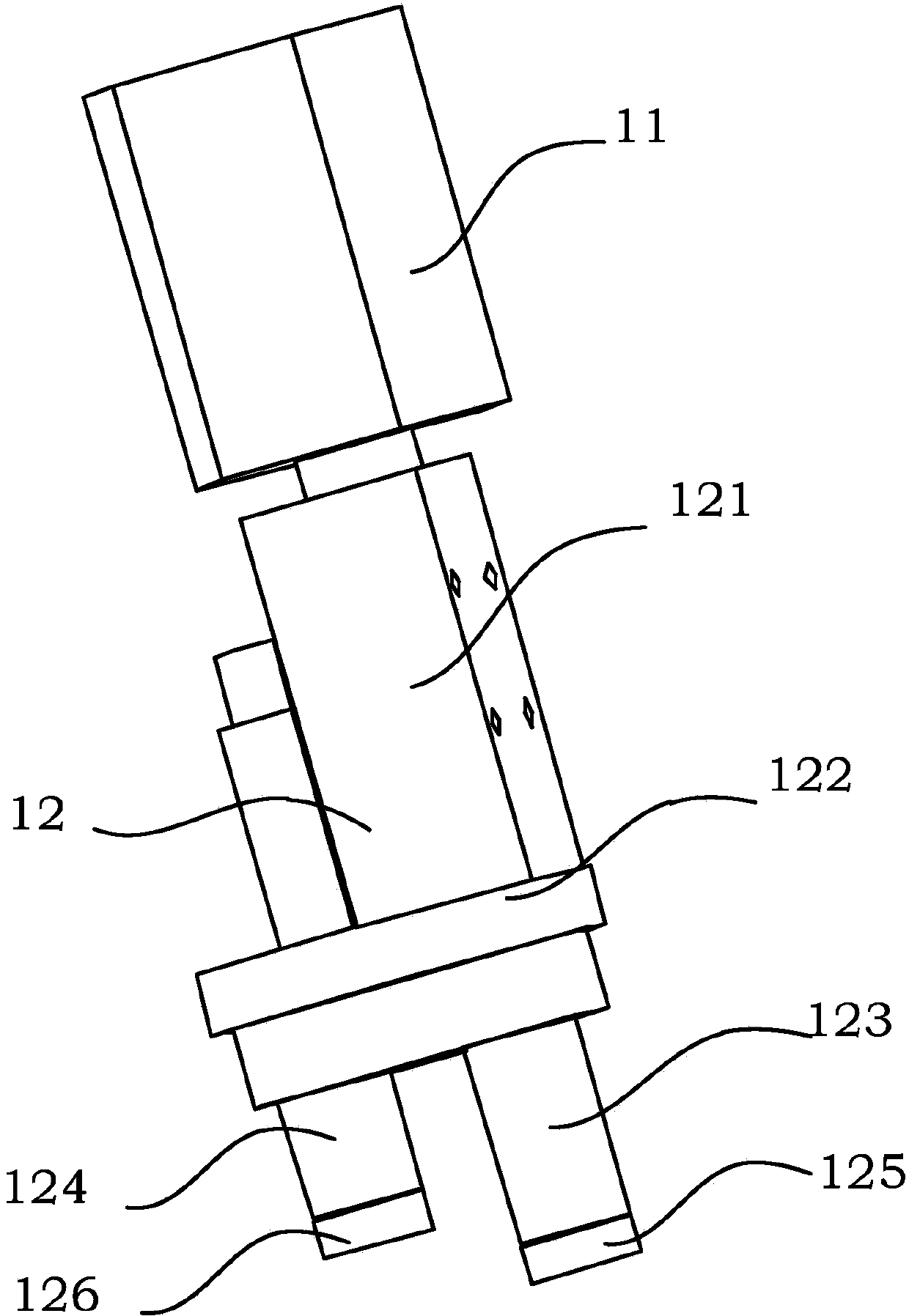

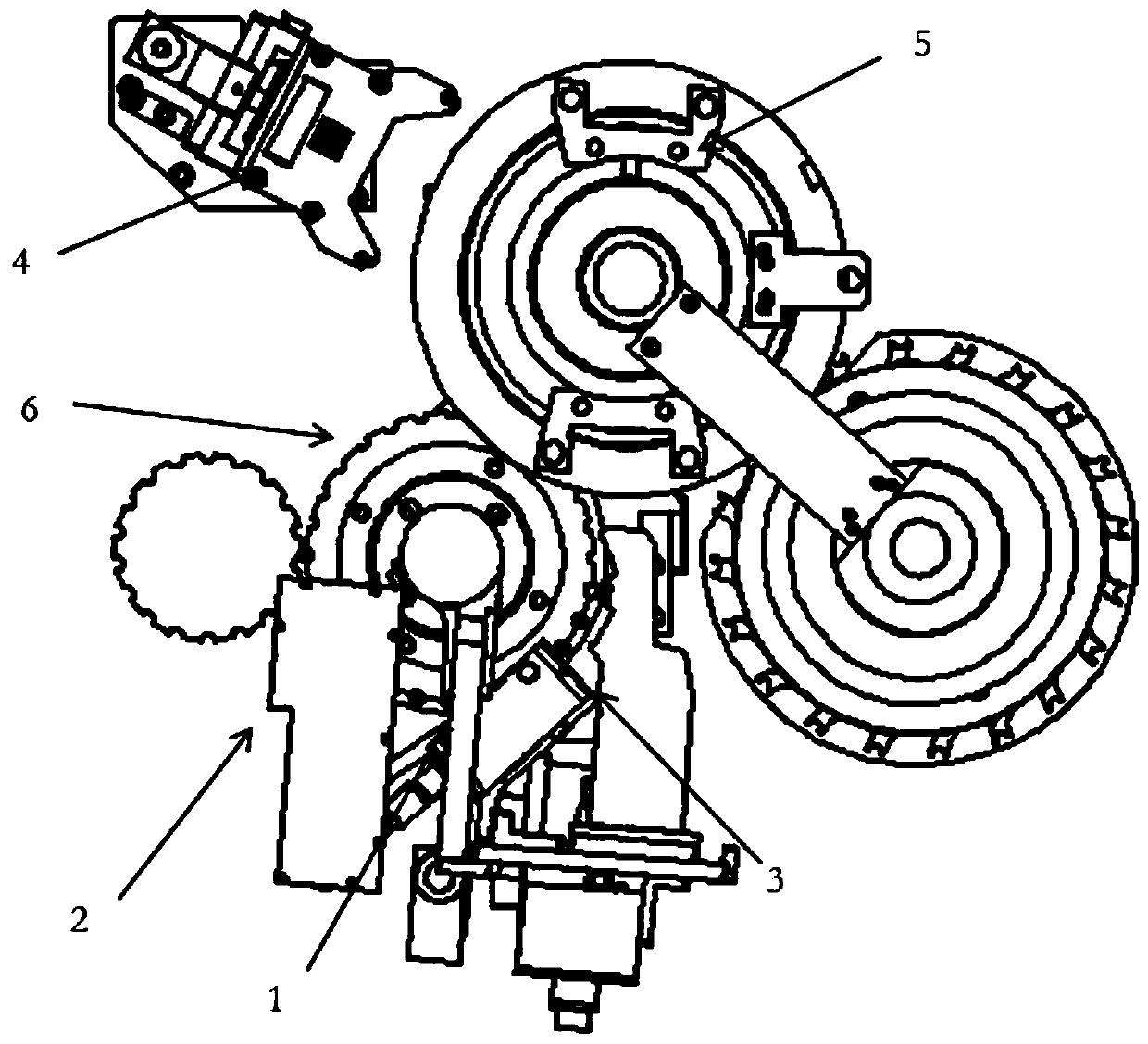

Circumferentially-distributed crawler wheel type pipeline detection robot capable of actively adapting to pipe diameter changes

ActiveCN108488539AImprove the ability to actively adapt to pipe diameterIncrease initiativePigs/molesBall screwElectrical control

The invention discloses a circumferentially-distributed crawler wheel type pipeline detection robot capable of actively adapting to pipe diameter changes. The robot comprises a crawler wheel travelingmechanism and a detection mechanism connected to the front end of the crawler wheel traveling mechanism through a turning mechanism, the crawler wheel traveling mechanism comprises a cylindrical mainbody sleeve, multiple crawler wheels controlled by a crawler driving motor are evenly distributed on the periphery of the cylindrical main body sleeve, the crawler wheels are installed on a ball screw through a pressing adjusting crank sliding block mechanism, and the ball screw is fixed to the outer wall of the cylindrical main body sleeve. The detection mechanism comprises a cylindrical detection barrel, an ultrasonic probe and a wide-angle camera stretch out of a detection barrel front end cover of the cylindrical detection barrel, the front end of the ultrasonic probe is provided with anultrasonic reflector, an electrical control system is arranged inside the cylindrical main body sleeve, and the electrical control system is connected with a battery. The circumferentially-distributedcrawler wheel type pipeline detection robot is good in movement controllability, outstanding in climbing and obstacle crossing ability and capable of actively adapting to pipe diameter working conditions.

Owner:XI AN JIAOTONG UNIV

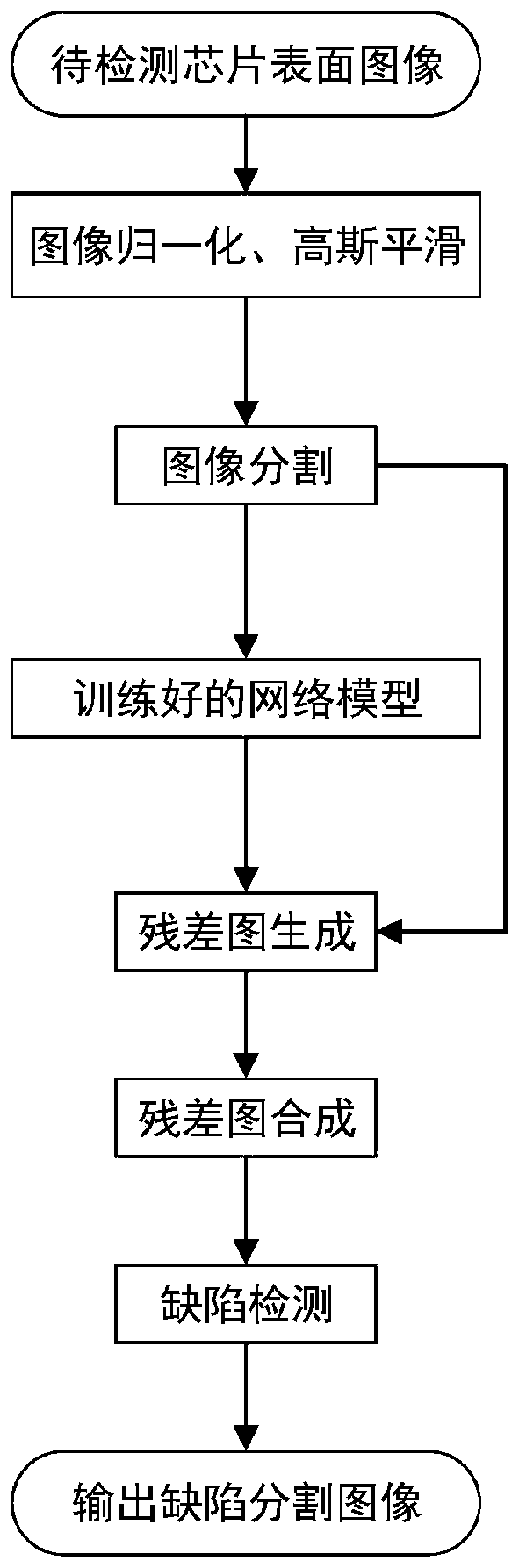

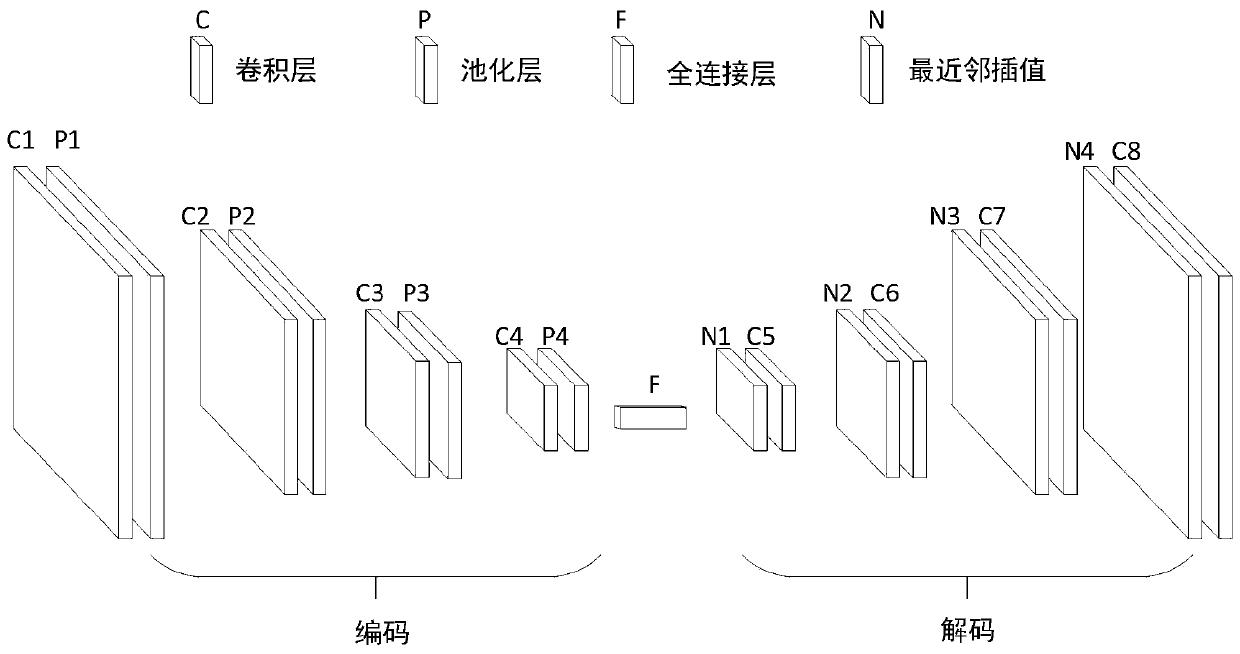

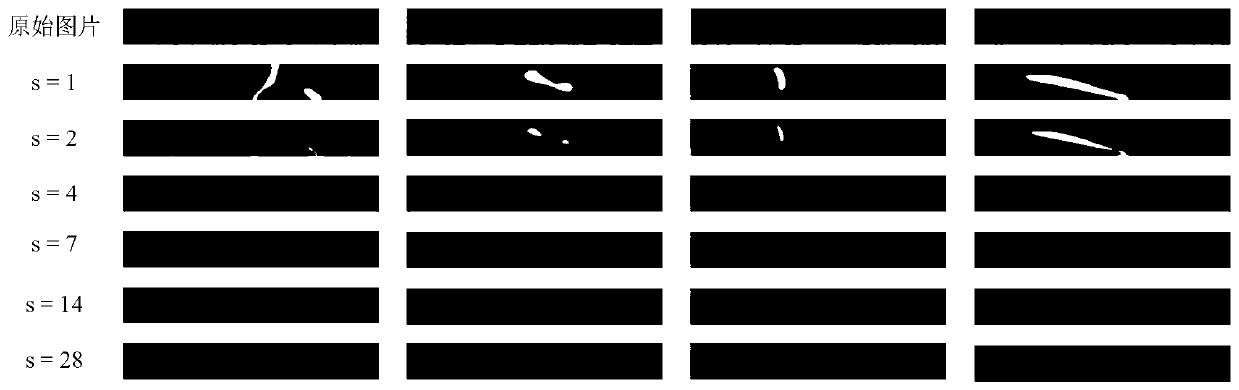

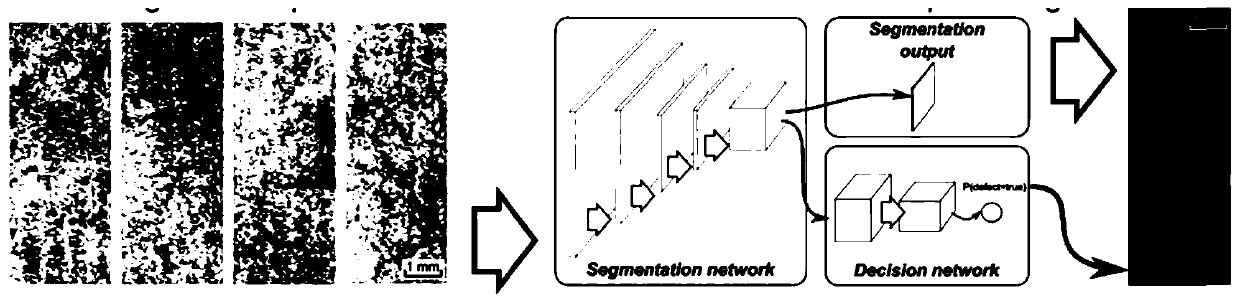

Chip surface defect detection method based on a convolutional denoising auto-encoder

ActiveCN109829903AImplement defect detectionImprove robustnessImage analysisNeural architecturesDenoising auto encoderComputer science

The invention discloses a chip surface defect detection method based on a convolutional de-noising auto-encoder. The method comprises the following steps: 1, constructing defect-free image reconstruction based on the convolutional de-noising auto-encoder; 2, constructing a residual image based on the overlapped area; and 3, performing defect detection based on the residual image. According to themethod, weak defects with the characteristics of low defect and background contrast ratio, small defect and the like can be effectively detected, the robustness is very high, and the chip surface detection precision is improved.

Owner:HEFEI UNIV OF TECH

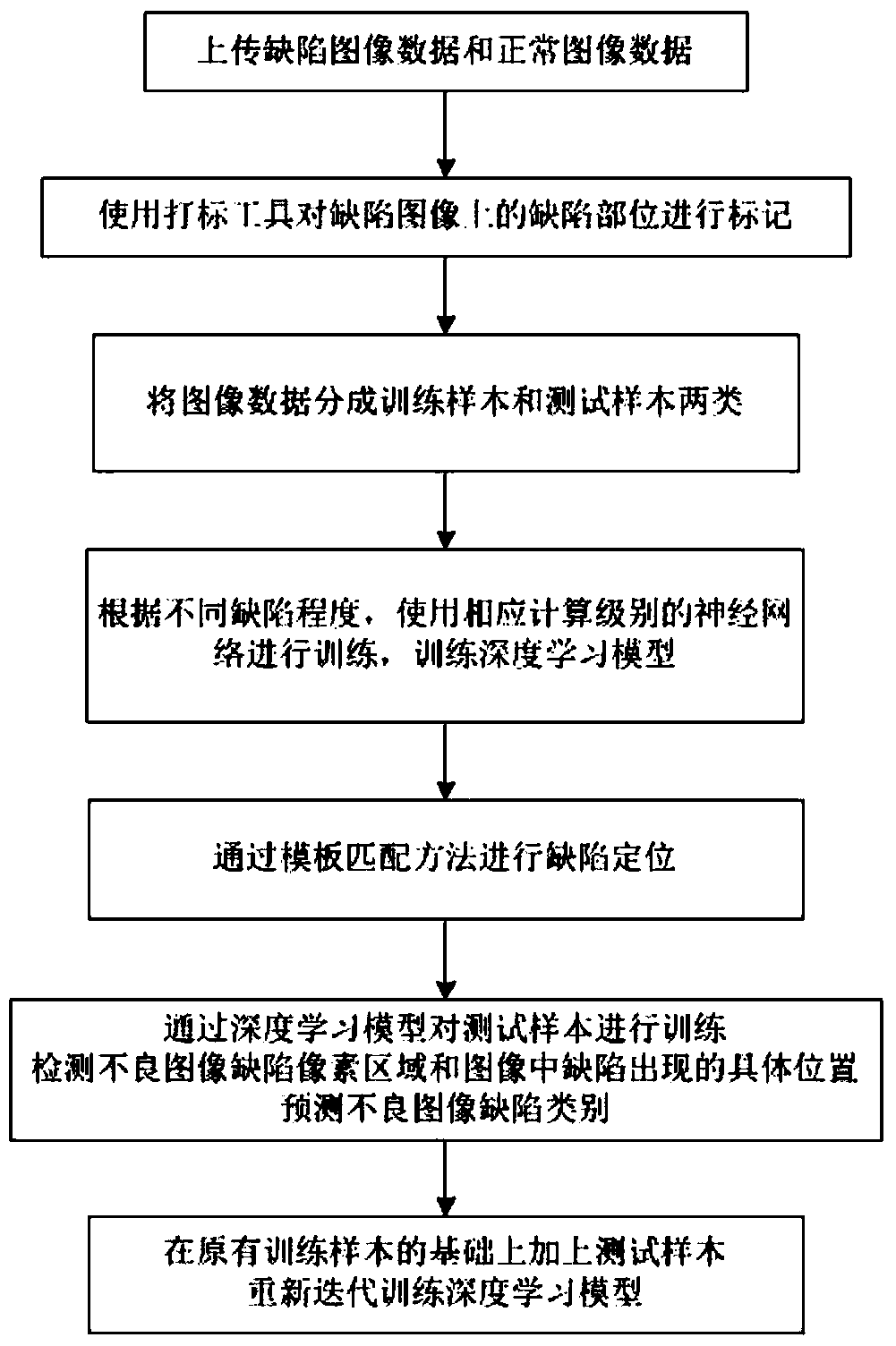

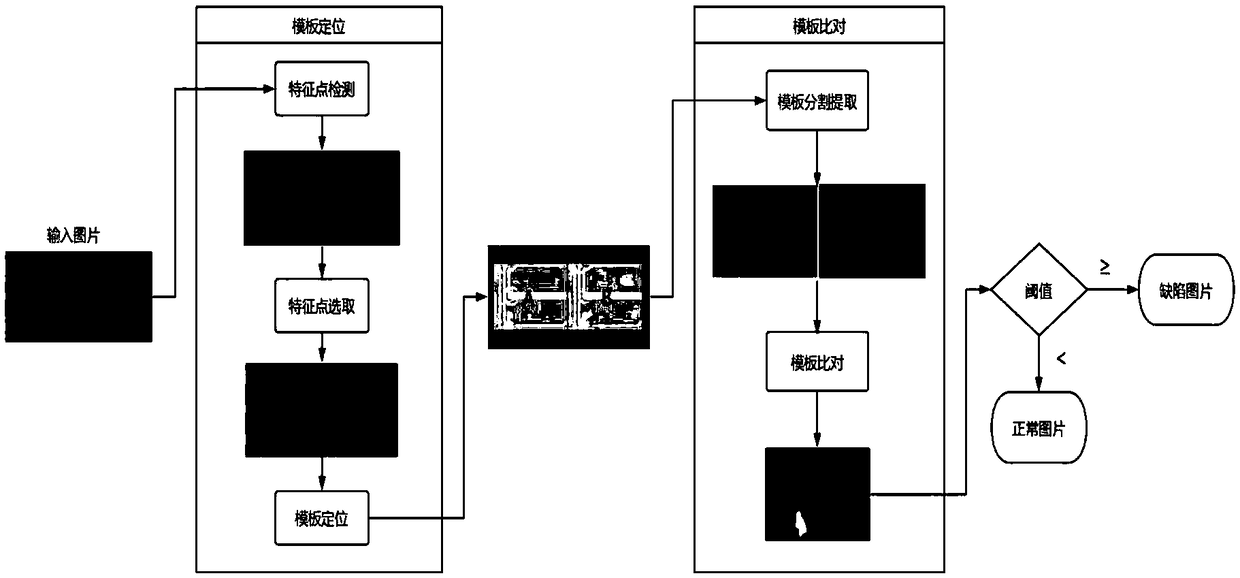

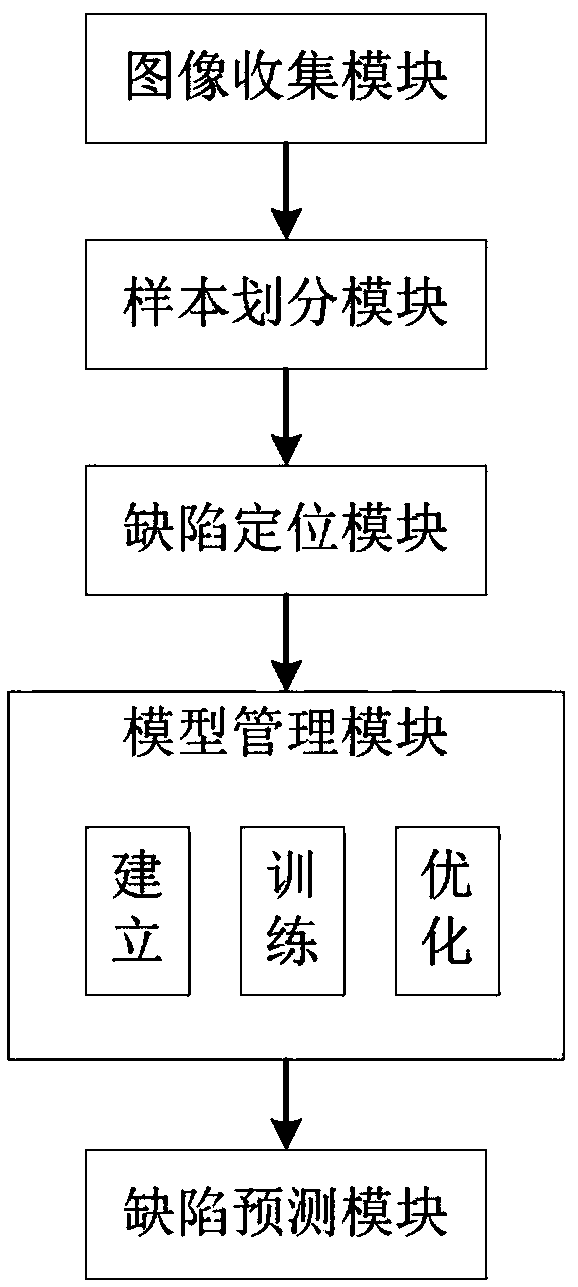

A method and system for detect defects in defective image

InactiveCN109472769AImprove the level of automated detectionImprove detection accuracyImage enhancementImage analysisComputer visionNetwork model

The invention discloses a defect detection method and a system of a defective image. Through a depth learning method, a depth convolution neural network model is constructed to analyze the deep logical relationship between defect factors in the bad image, the defect relationship between parts and parts, and the defect classification between parts and the whole, thereby realizing defect classification. The invention can effectively realize defect position detection and defect class prediction, has high precision and accurate classification, and has better detection effect on small targets. It can optimize the detection accuracy and reduce the missed detection.

Owner:CHENGDU UNION BIG DATA TECH CO LTD

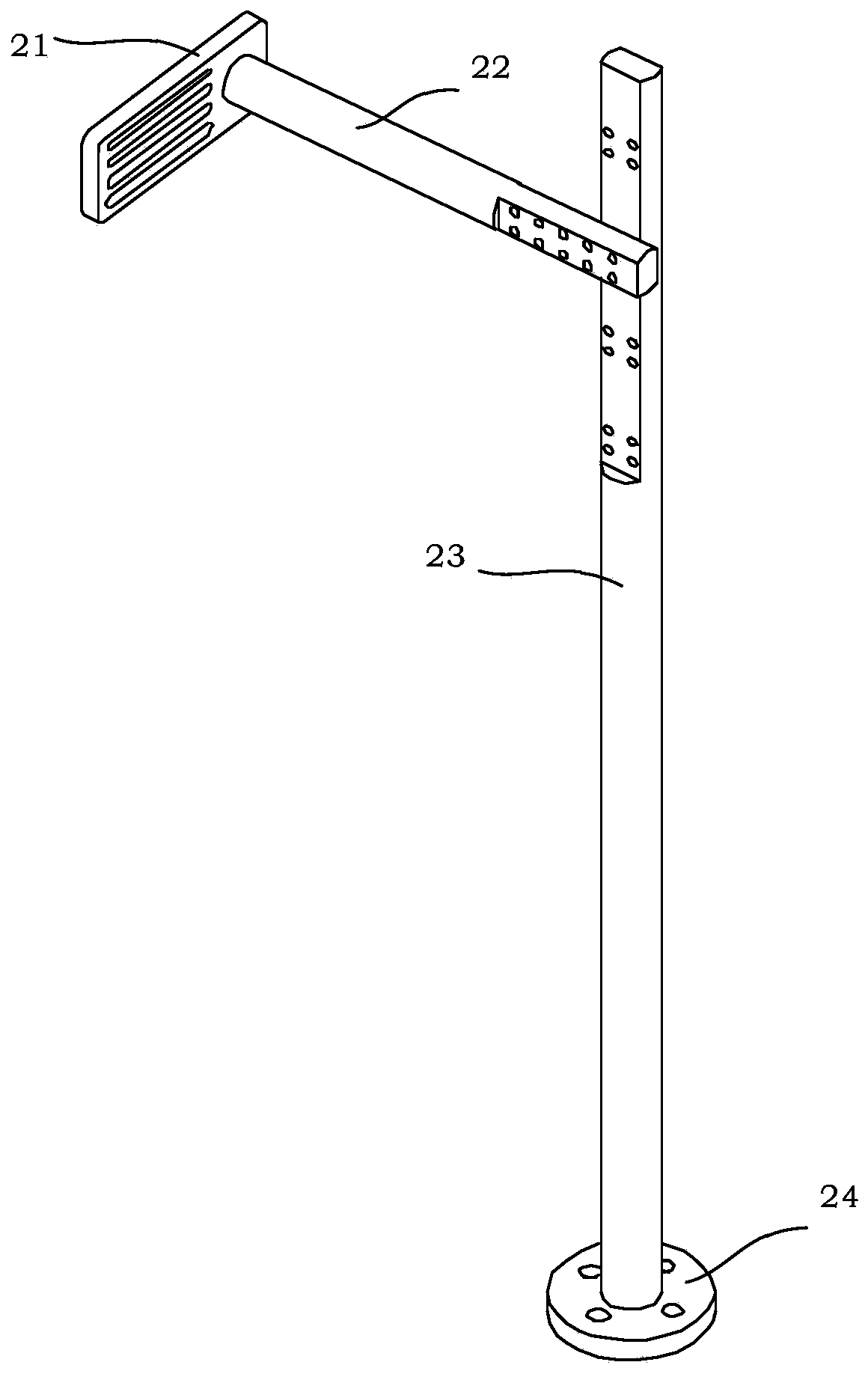

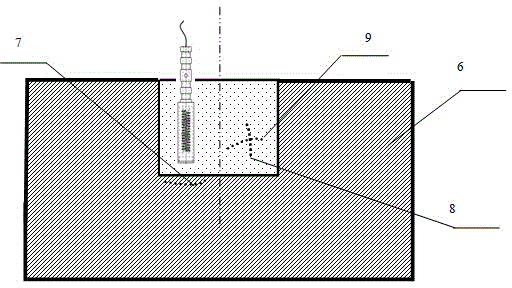

Detection apparatus for defects of inner and outer walls of pipeline based on remote field eddy current testing

ActiveCN102313777AImplement defect detectionMaterial magnetic variablesPhase differenceComputer module

The invention discloses a detection apparatus for defects of inner and outer walls of a pipeline based on remote field eddy current testing. According to the invention, at the part of a mechanical structure, spring leaves are controlled to stretch and fold so as to make a horizontal part at the top of the spring leaves abut the inner wall of the pipeline; the horizontal part at the top of each spring leaf is provided with a magnetoresistor member for receiving remote field eddy current signals which indicate defects of the inner and outer walls of the pipeline in a remote field; a data processing module outputs electric signals to the magnetoresistor members and calculates phase difference with excitation signals provided by an excitation module as reference signals so as to obtain a plurality of sets of data which indicate defects of the inner and outer walls of the pipeline and enable detection of the inner and outer walls of the pipeline to be completed. According to the invention,arc spring leaves are uniformly circumferentially distributed along a main axis, each magnetoresistor member abuts the inner wall of the pipeline, and the circumference of the pipeline are totally occupied by the magnetoresistor members; therefore, detection of circumferential position and minimal defects of a defective pipeline can be realized, defect detection of overall inner and outer walls of a pipeline is achieved, and parameters of the shape and dimension of a defect is obtained.

Owner:四川庆达实业集团有限公司

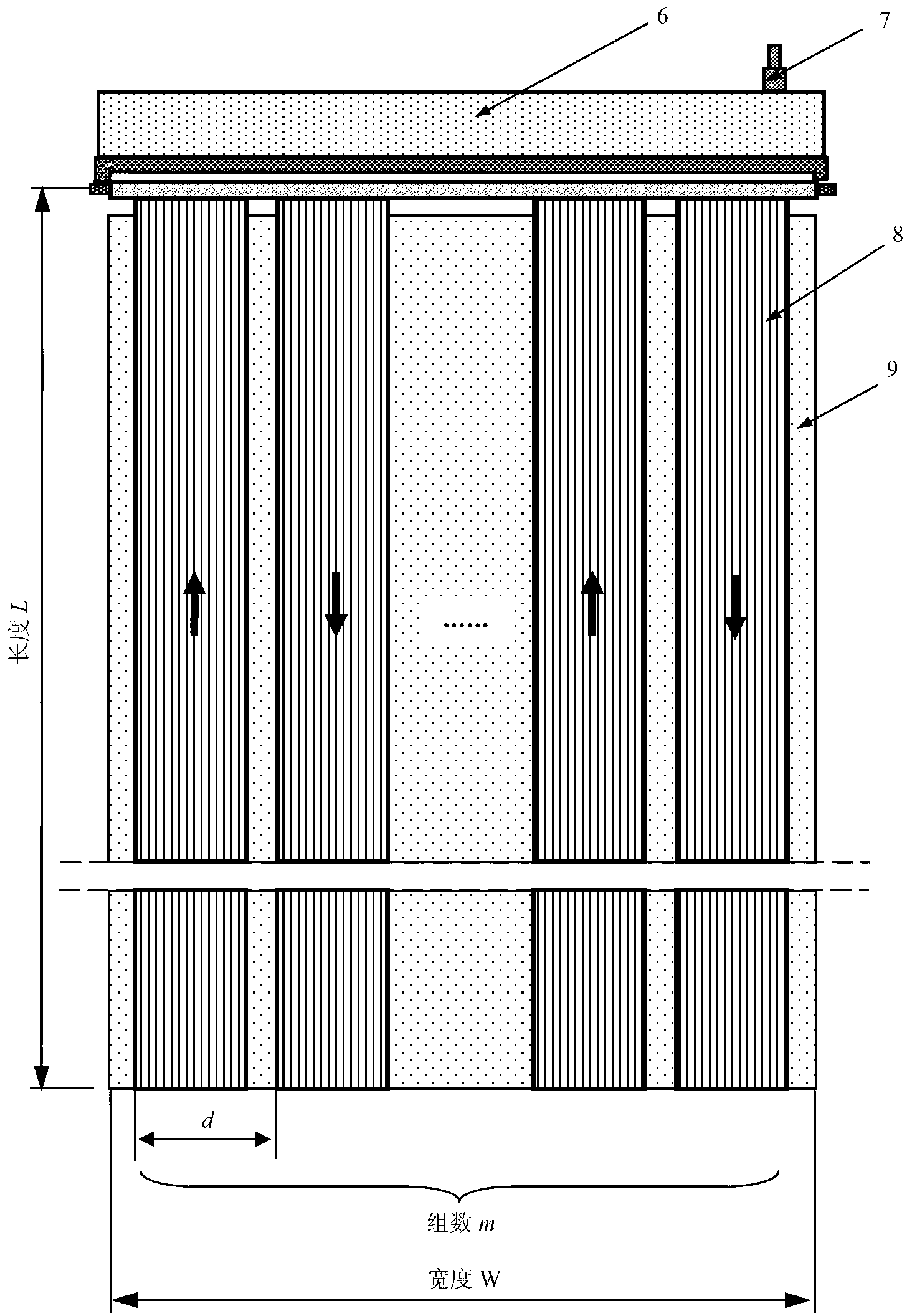

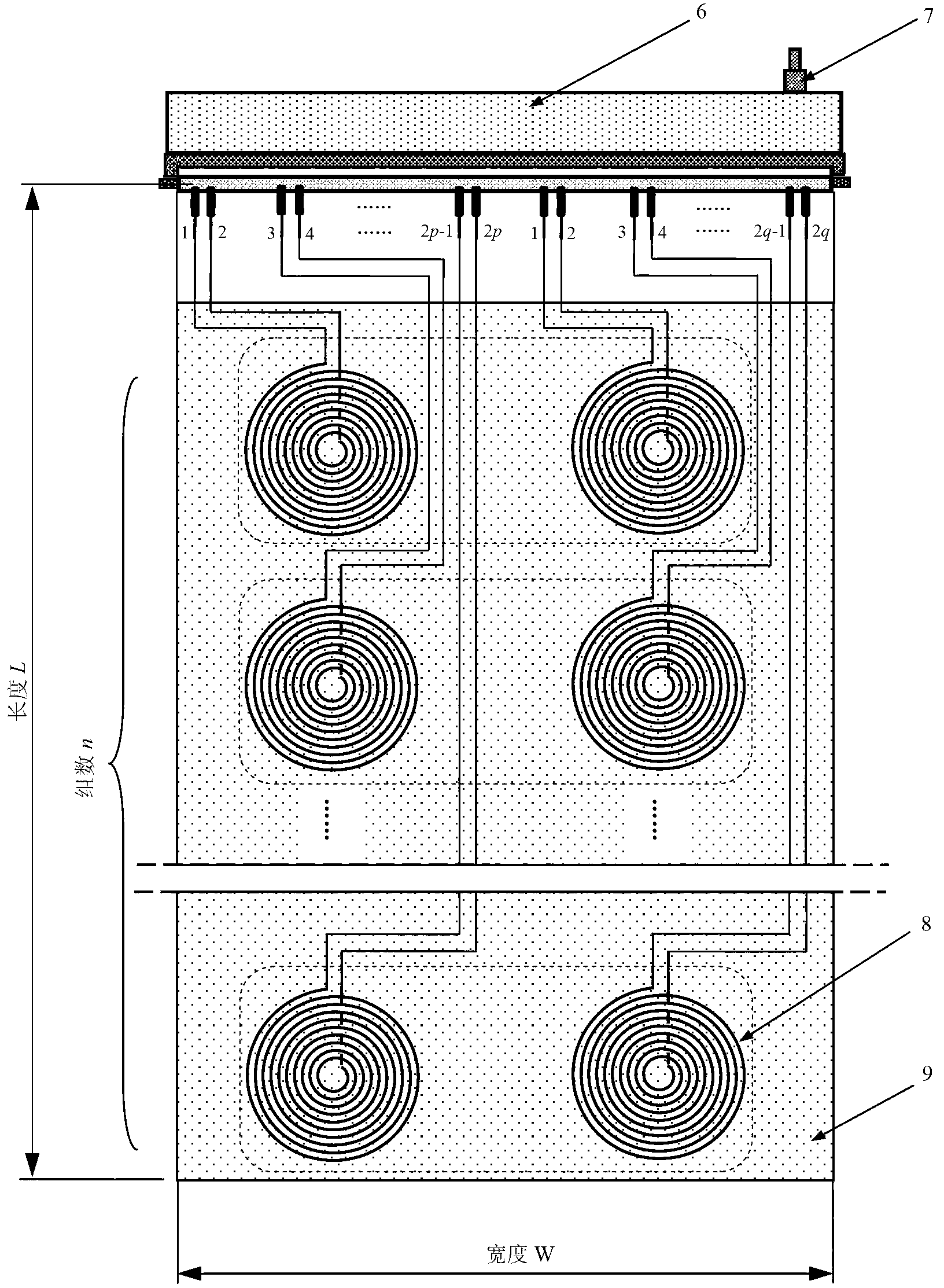

Flexible magnetostriction and eddy integrated sensor for detecting defects of high-voltage transmission line

ActiveCN102841132ARealize full structural defect detectionAchieve axial positioningOptically investigating flaws/contaminationMaterial magnetic variablesEngineeringHigh pressure

The invention relates to a flexible magnetostriction and eddy integrated sensor for detecting defects of a high-voltage transmission line and belongs to the technical field of an electromagnetic acoustic sensor. An outer-layer magnetostriction sensor is printed on a substrate through a flexible printing coil and an inner-layer eddy sensor is printed on the substrate through the flexible printing coil; the flexible printing coil can be coiled into a cylindrical shape and clung to the surface of the high-voltage transmission line so as to form a solenoid coil; after the solenoid coil is clamped and fixed by a connector, the solenoid coil is mounted on a detected transmission line so as to detect the defects; and after the clamped and fixed state is released, the solenoid coil can be detached from the surface of the transmission line. The integrated sensor can be used for stimulating a longitudinal modal ultrasonic guide wave from the transmission line and detecting the defects of the whole structure of the transmission line on the basis of a magnetostriction effect; the integrated sensor also can be used for detecting complex impedance change of a sensor detecting coil due to the defects of the transmission line by utilizing a multi-channel eddy sensor and realizing the peripheral positioning for the defects on the basis of an eddy effect; and meanwhile, the deep positions of the defects in the transmission line can be confirmed on the basis of a surface action of an eddy field.

Owner:BEIJING UNIV OF TECH

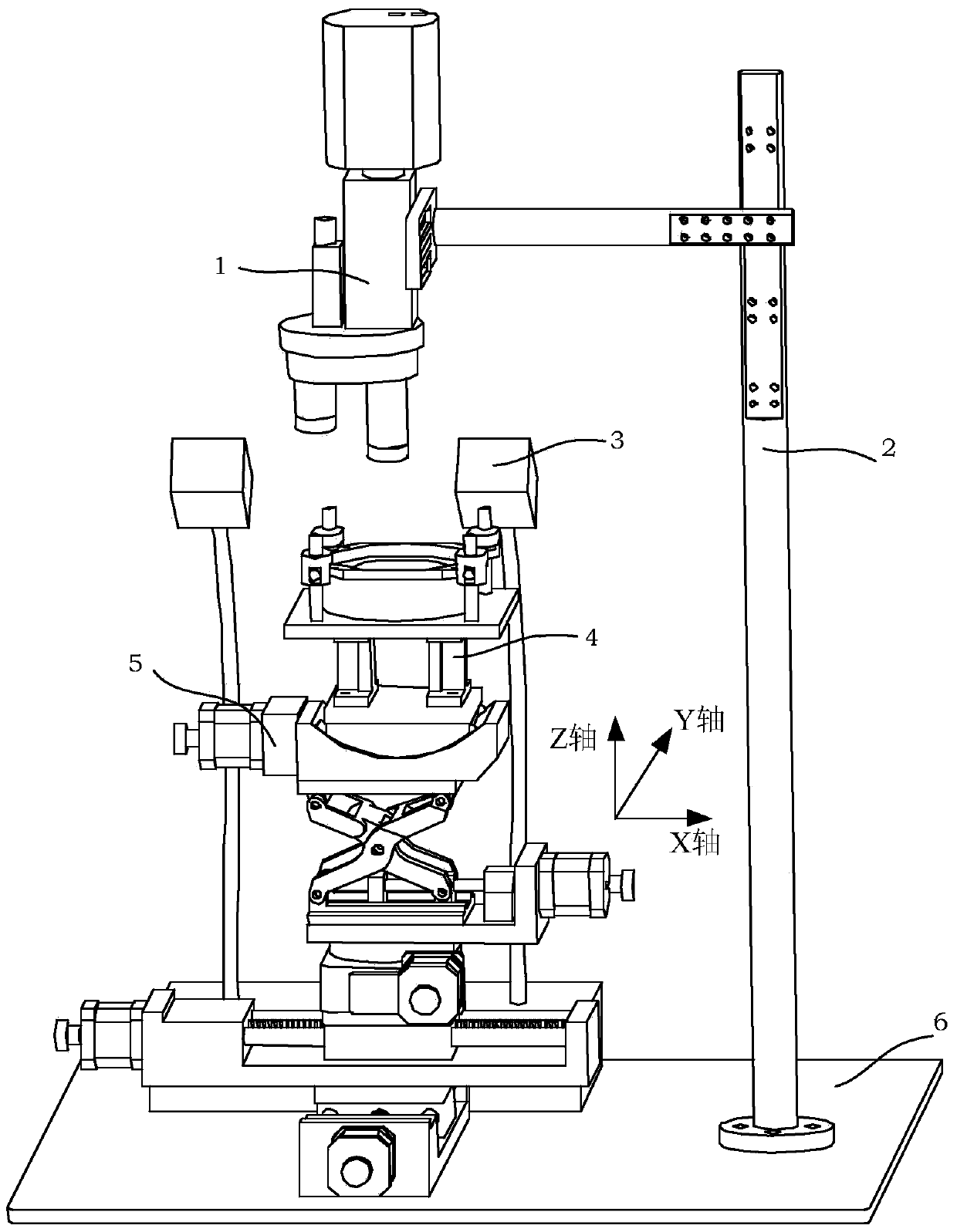

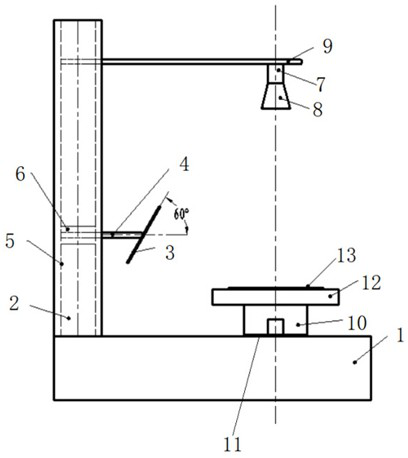

Nondestructive detection device for light path of fiber-optic gyroscope

The invention relates to a nondestructive detection device for a light path of a fiber-optic gyroscope, and belongs to the technical field of fiber-optic gyroscope detection. The device comprises an infrared imaging system, a lens bracket, an illumination system, a fiber-optic gyroscope fixing component, a five-degree-of-freedom displacement device and an optical flat plate, wherein the infrared imaging system is fixedly connected with the lens bracket; the lens bracket is arranged on the optical flat plate; the infrared imaging system is perpendicular to the optical flat plate; the illumination system is arranged on the optical flat plate, and is just opposite to a fiber-optic gyroscope to be detected, which is fixed on the fiber-optic gyroscope fixing component; the fiber-optic gyroscope fixing component is arranged on the five-degree-of-freedom displacement device which is arranged on the optical flat plate.

Owner:BEIJING AEROSPACE TIMES OPTICAL ELECTRONICS TECH

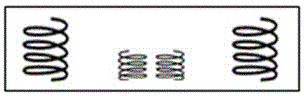

Metal defect eddy current detection device and probe thereof

ActiveCN102879462AAccurately calculate distanceOvercoming the limitations of the skin effectMaterial magnetic variablesMetallic materialsEddy current

The invention discloses a frequency mixing technology-based metal defect eddy current detection device and a probe structure thereof. According to the device, the conventional eddy current technology and low-frequency far field eddy current technology are combined, so that one-time complete detection on metal material defects in a wider range can be realized. According to the device, a high-frequency excitation signal and a low-frequency excitation signal are applied to the probe; the conventional eddy current detection mode is adopted by the high-frequency signal; and the far field eddy current detection mode is adopted by the low-frequency signal. The probe is of a differential structure and consists of two groups of coils; and the two groups of coils are symmetrically arranged in a mirror image manner. Each group of coils consists of a large coil and a small coil of which the axes are away from each other for a certain distance; and the two coils are placed according to a far field principle. A low-frequency sinusoidal signal is conducted through the large coil in the probe; a high-frequency sinusoidal signal is conducted through the small coil; and the small coil is used as a detection coil to receive the high-frequency signal and the low-frequency signal. According to the device, defect information of an upper surface and a lower surface of a plate-shaped metal material or an inner wall and an outer wall of a tubular metal material can be simultaneously and accurately acquired in a large range.

Owner:ZHEJIANG UNIV

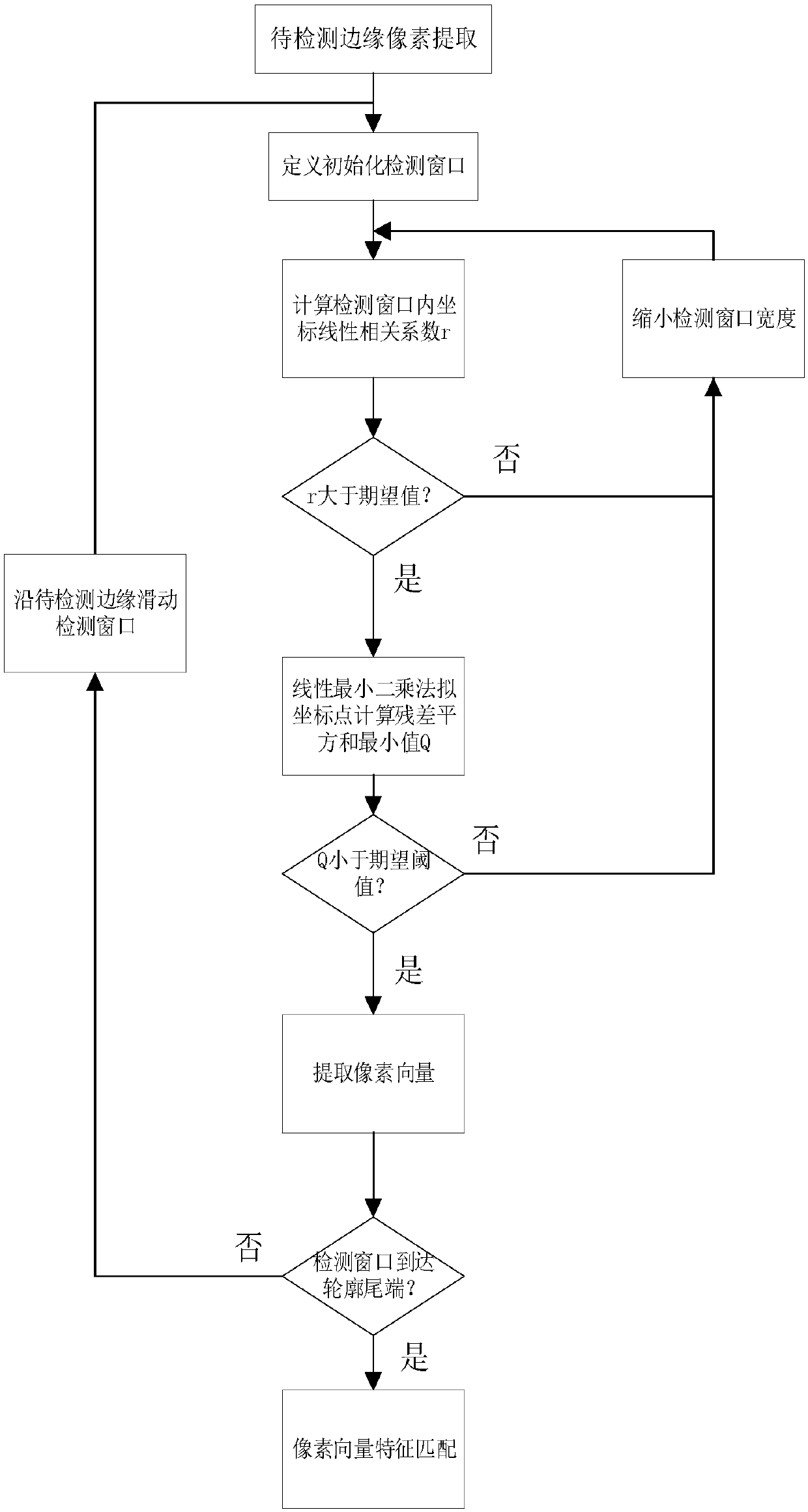

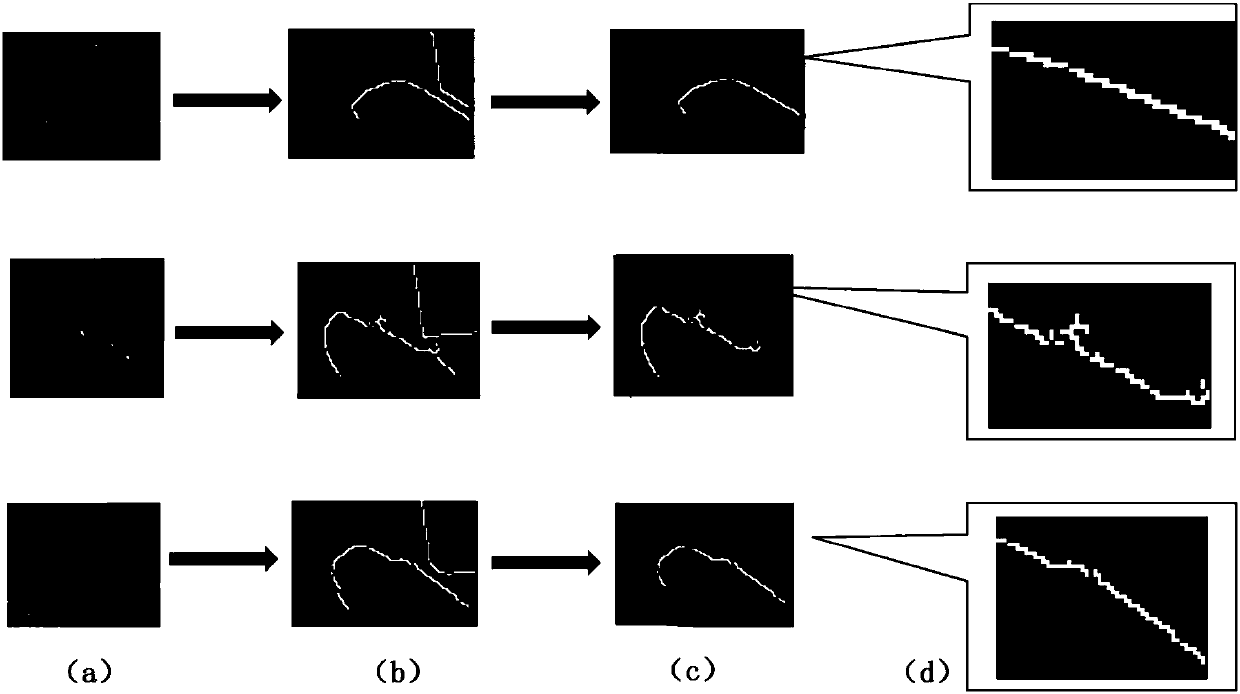

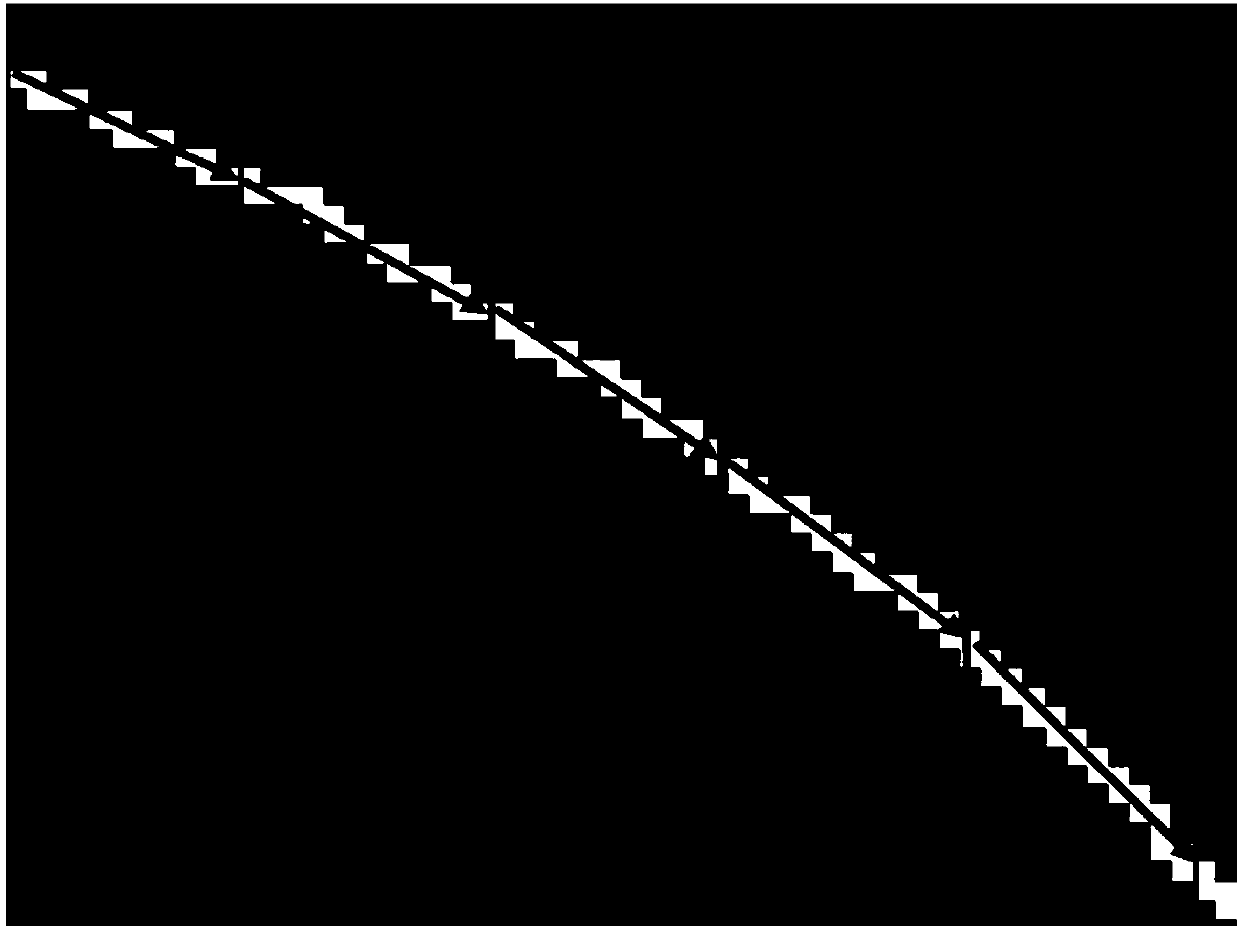

Industrial part defect detection algorithm based on pixel vector invariant relation characteristic

ActiveCN108447070AAchieving feature registration of defectsImplement defect detectionImage analysisCharacter and pattern recognitionAlgorithmEuclidean vector

The invention relates to an industrial part defect detection algorithm based on a pixel vector invariant relation characteristic. The algorithm comprises the following steps that 1) contour extractionis carried out on a counter to be detected and local texture, and edge pixels to be detected are obtained; 2) the width of a detection window is defined, and is optimized according to a defined pixellinearity relation decision function, an inter-pixel direction vector is extracted from the window, the detection window is slid along the detection edge in a preset step length, and pixel vectors are extracted from all edges to be detected; and 3) an invariant relation characteristic of the pixel vectors of the edges to be detected is calculated, the invariant relation characteristic is comparedwith an inter-pixel invariant relation characteristic of a standard part, and whether the part has a defect is determined. The edge pixel vector is constructed by utilizing the difference in the local position relation of the contour pixels, difference matching is carried out by using invariance information between vector directions or vector module values, and defect detection is realized.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

Cigarette appearance online detection method and device

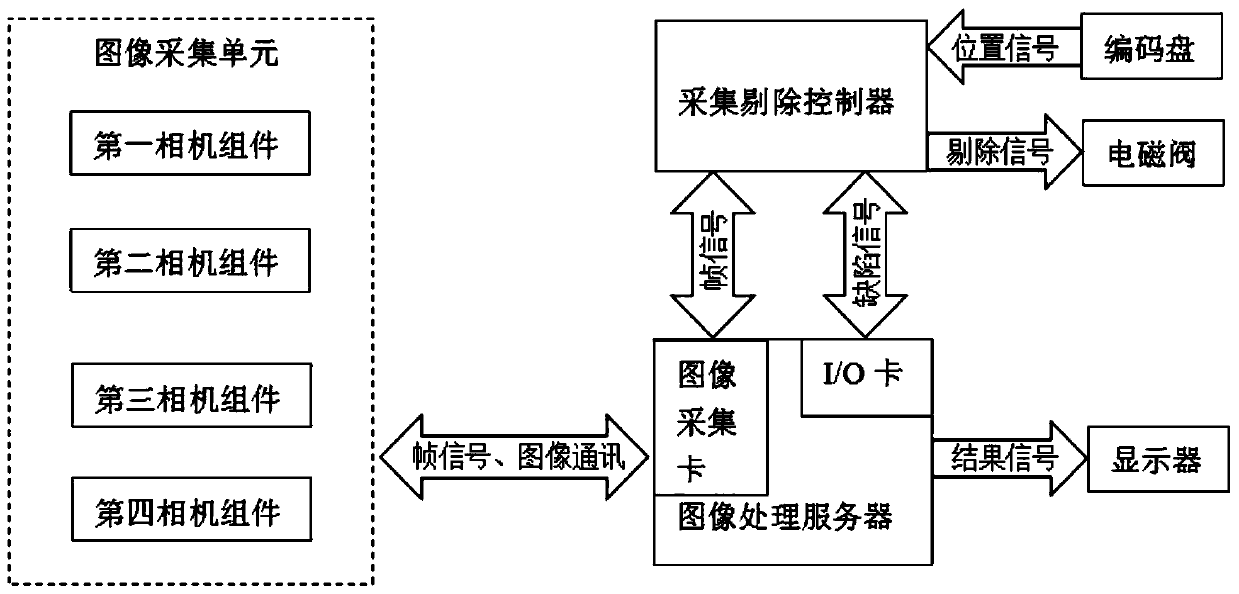

ActiveCN111189837AGuaranteed to feel consistentRealize multi-index appearance defect detectionOptically investigating flaws/contaminationMedicineEngineering

The invention relates to cigarette appearance detection, in particular to a cigarette appearance online detection method and device. The method comprises the following steps of: S1, respectively collecting a three-dimensional information image of a cigarette holder end surface cavity, a cigarette holder end surface appearance image and a cigarette circumferential surface appearance image at corresponding positions of a cigarette making machine; S2, transmitting the collected images to an image processor to be processed as follows in the specification; and S3, judging the product as a good product or bad product after the images in step 2 are processed by the image processor, and when the product is judged as a bad product, sending a signal to a rejecting controller by the image processor to enable the rejecting controller to act, thus rejecting the bad cigarette. A deep learning model used in the invention can accurately classify defects, and can provide information for manufacturers to eliminate mechanical faults and improve production schemes.

Owner:BEIJING FOCUSIGHT TECH

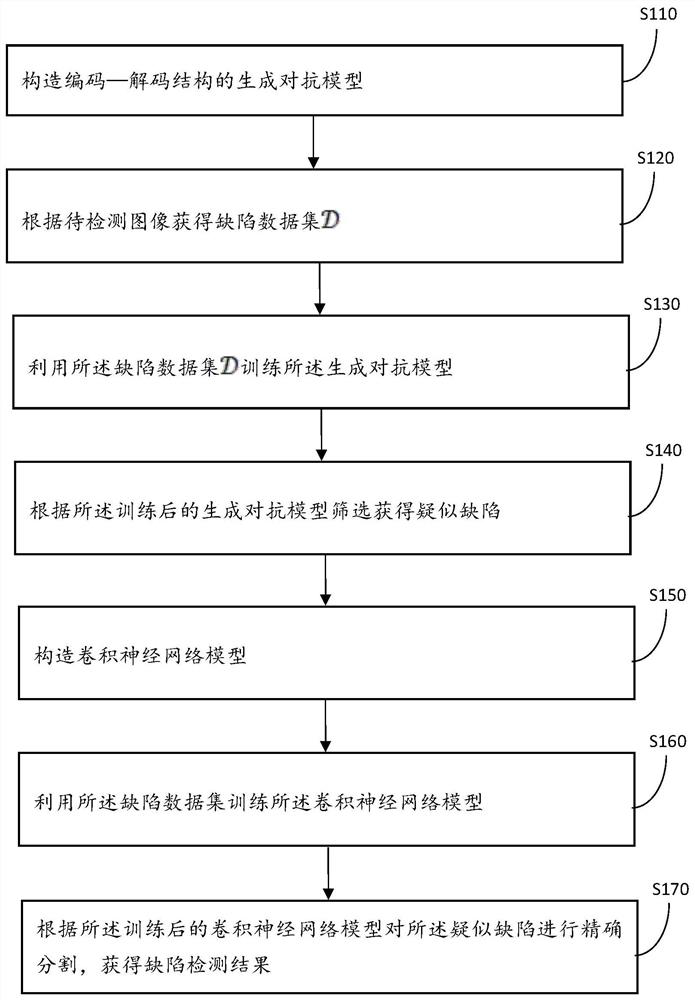

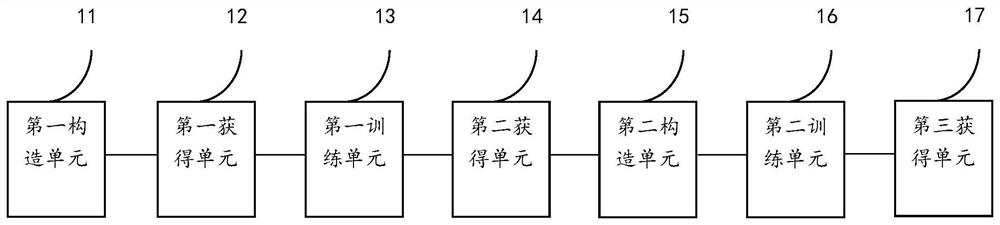

Composite material component defect detection method and device based on generative adversarial learning

ActiveCN111833300ADefect realizationImplement defect detectionImage enhancementImage analysisData setCoding decoding

The invention provides a composite material component defect detection method and device based on generative adversarial learning, and relates to the field of composite material component defect detection, and the method comprises the steps: constructing a generative adversarial model of a coding-decoding structure; obtaining a defect data set according to a to-be-detected image, and training thegenerative adversarial model by using the defect data set; screening according to the trained generative adversarial model to obtain suspected defects; constructing a convolutional neural network model; training the convolutional neural network model by using the defect data set; and accurately segmenting the suspected defect according to the trained convolutional neural network model to obtain adefect detection result. The technical problems that in the prior art, due to the fact that the number of defect samples in a constructed data set is small and categories are seriously unbalanced, a network is difficult to converge, and the omission ratio is high are solved. The technical effects of accurately detecting the defects of the composite material component and greatly reducing the omission factor are achieved.

Owner:XIDIAN UNIV

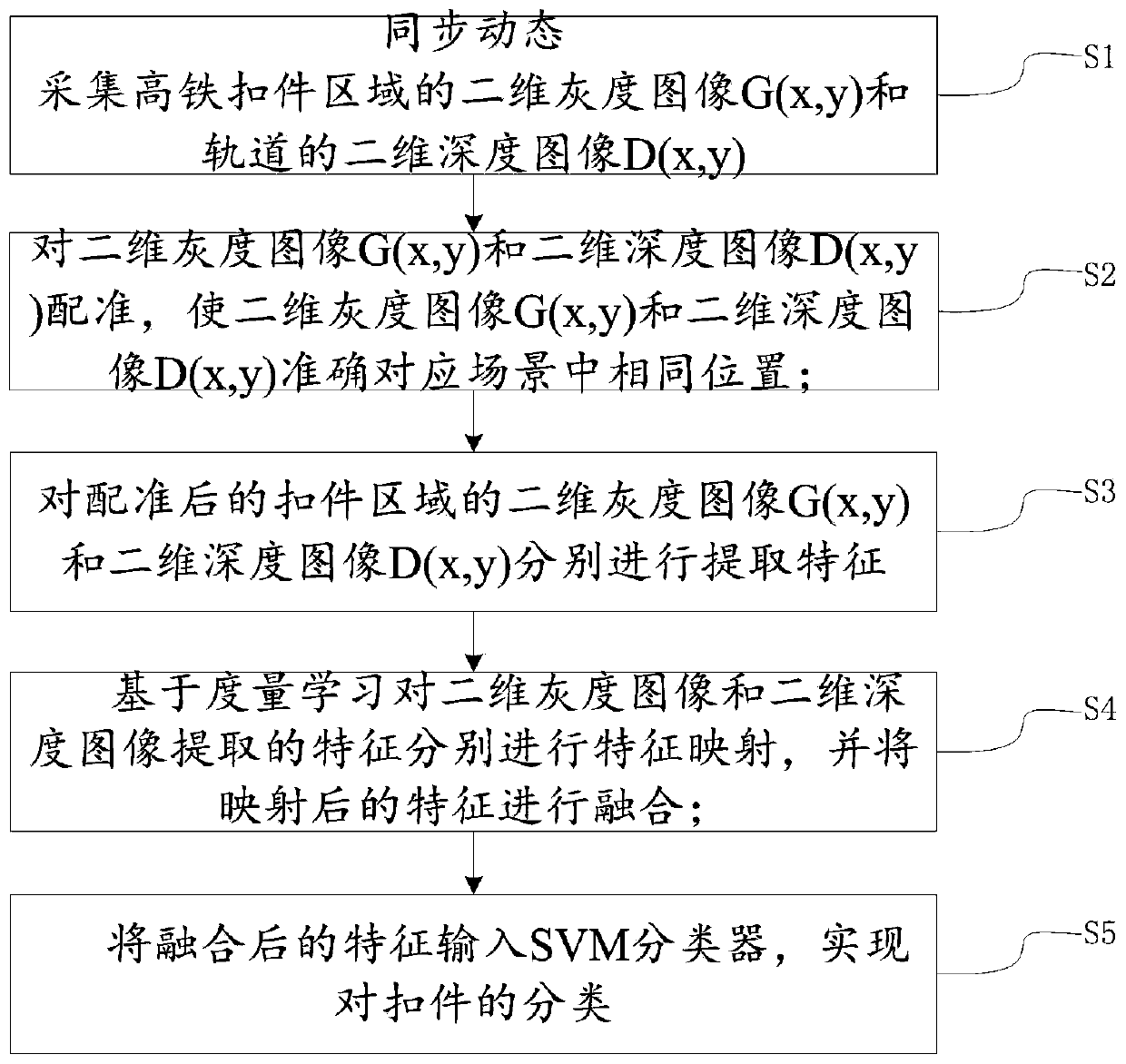

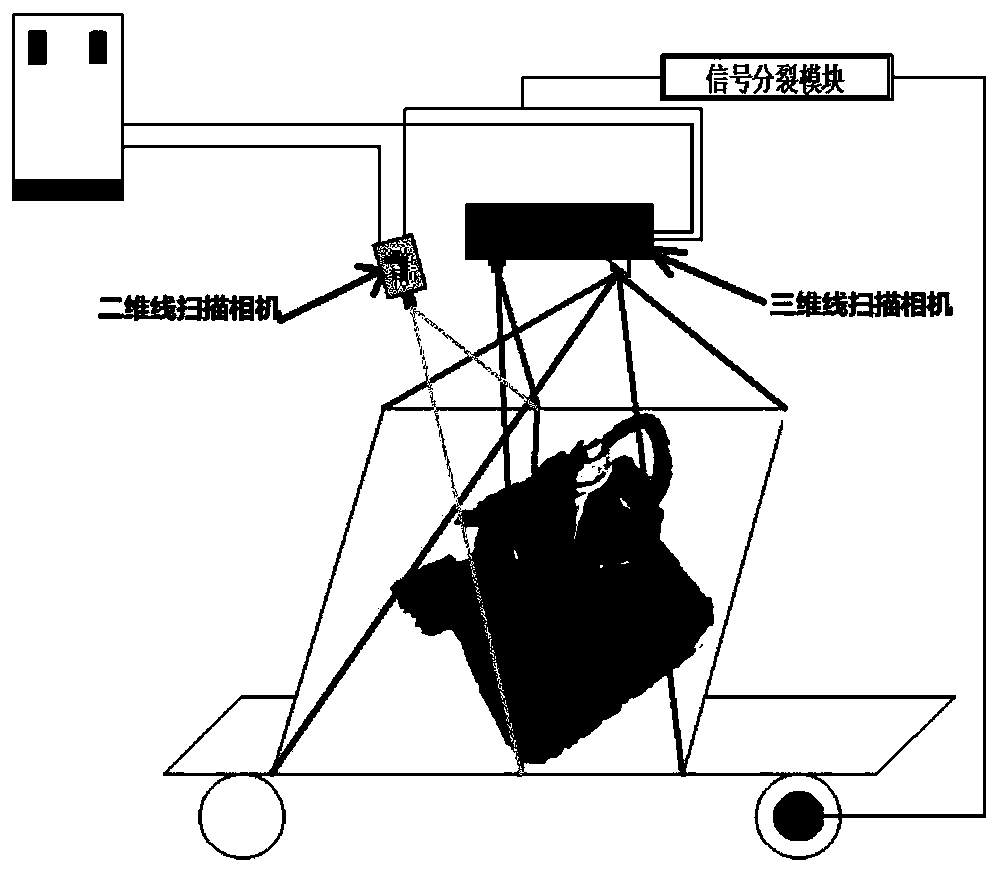

High-speed rail fastener defect identification method based on heterogeneous image fusion

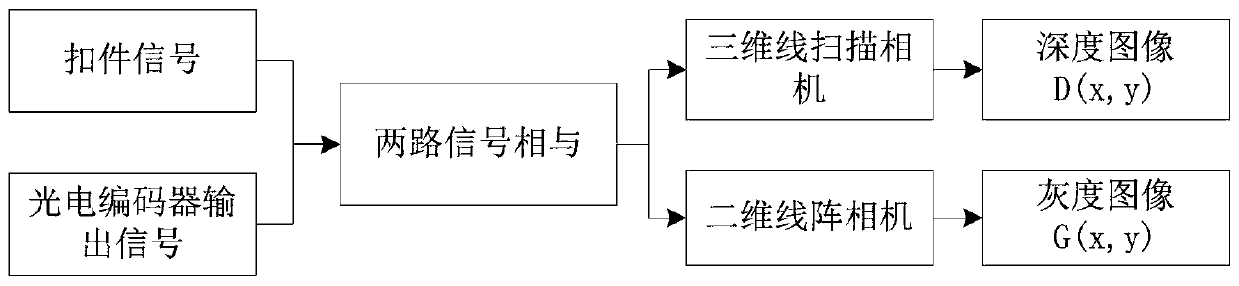

ActiveCN111476767AImprove defect detection rateImplement defect detectionImage enhancementImage analysisImage extractionMachine vision

The invention relates to a high-speed rail fastener defect identification method based on heterogeneous image fusion, and belongs to the technical field of machine vision detection. The method comprises the following steps: S1, synchronously and dynamically acquiring a two-dimensional gray image G(x, y) of a high-speed rail fastener area and a two-dimensional depth image D(x, y) of a rail; S2, registering the two-dimensional grayscale image G(x, y) and the two-dimensional depth image D(x, y) to enable the two-dimensional grayscale image G(x, y) and the two-dimensional depth image D(x, y) to accurately correspond to the same position in the scene; S3, respectively carrying out feature extraction on the two-dimensional grayscale image G(x, y) and the two-dimensional depth image D(x, y) of the fastener area after registration; S4, performing feature mapping on features extracted from the two-dimensional grayscale image G(x, y) and the two-dimensional depth image based on metric learning,and fusing the mapped features; S5, inputting the fused features into an SVM classifier to realize classification of the fasteners. According to the invention, the defect detection rate of the fastener is improved, the omission ratio of the defective fastener is lower, the practicability is strong, and the method is worth popularizing.

Owner:NANCHANG INST OF TECH

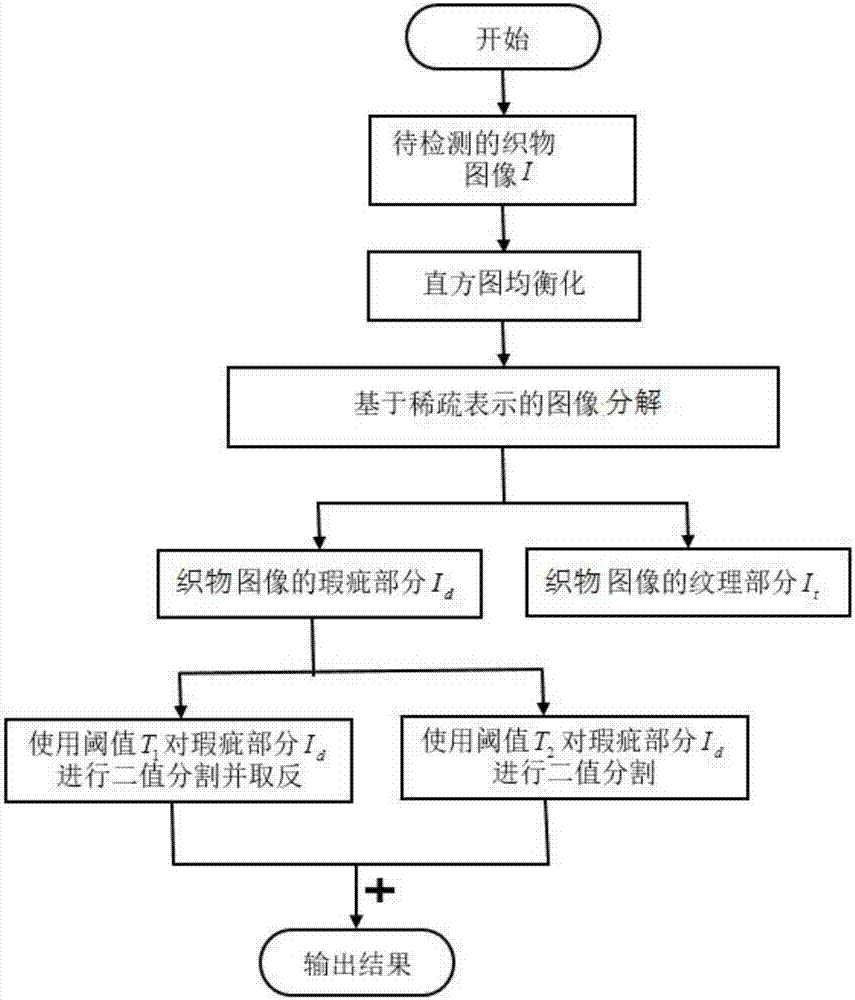

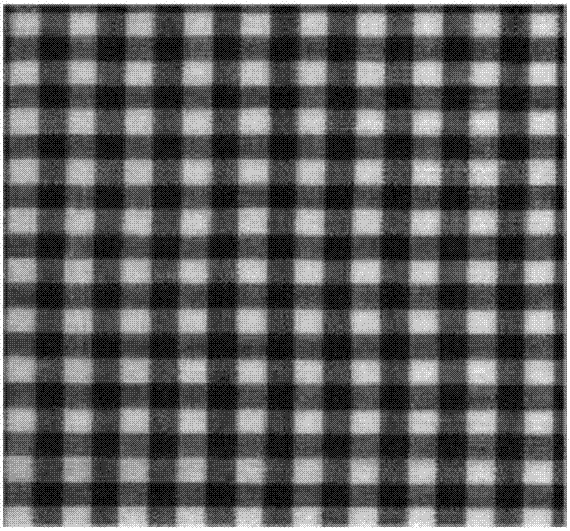

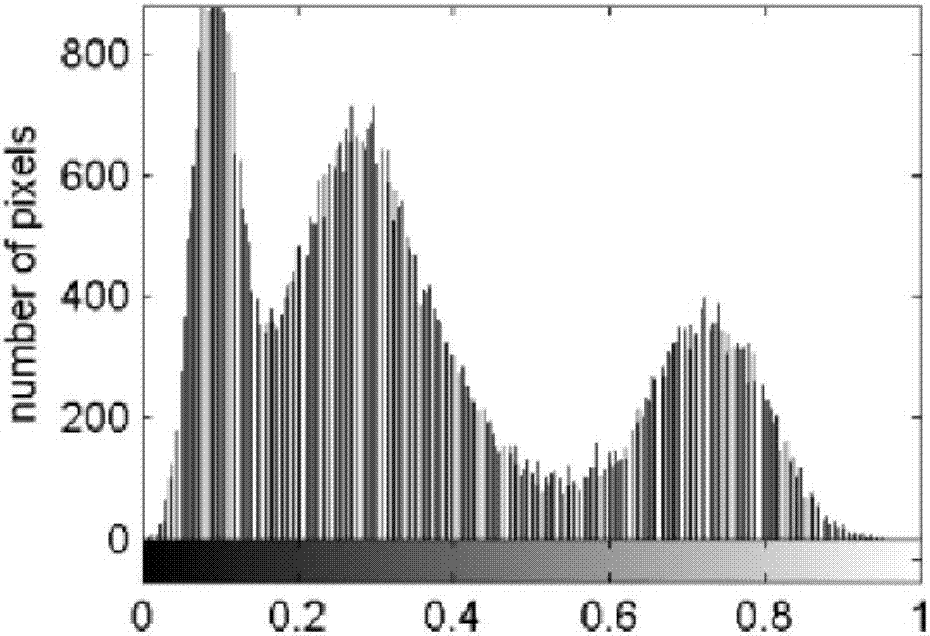

Fabric defect detection method based on image decomposition algorithm with sparse representation

InactiveCN107085844AGood segmentation resultImplement defect detectionImage enhancementImage analysisImage segmentationDecomposition

The invention provides a fabric defect detection method based on an image decomposition algorithm with sparse representation. The method comprises the steps that step 1 a number of fabric images are collected; 2 the preprocessing of histogram equalization is carried out on the fabric images; 3 the fabric images after the step 2 are modeled based on sparse representation and are decomposed into a texture part and a defective part; and 4 a superposition binarization method is used to carry out image segmentation on the defective part to acquire a binarization image detection result. The fabric defect detection method based on the image decomposition algorithm with sparse representation can efficiently decompose and clearly display the defective part contained in the fabric images with complex background textures, and has the advantages of high detection rate and high versatility. The disadvantages of manual detection are reduced. The detection need of a variety of fabrics in an industrial production process is met.

Owner:XI'AN POLYTECHNIC UNIVERSITY

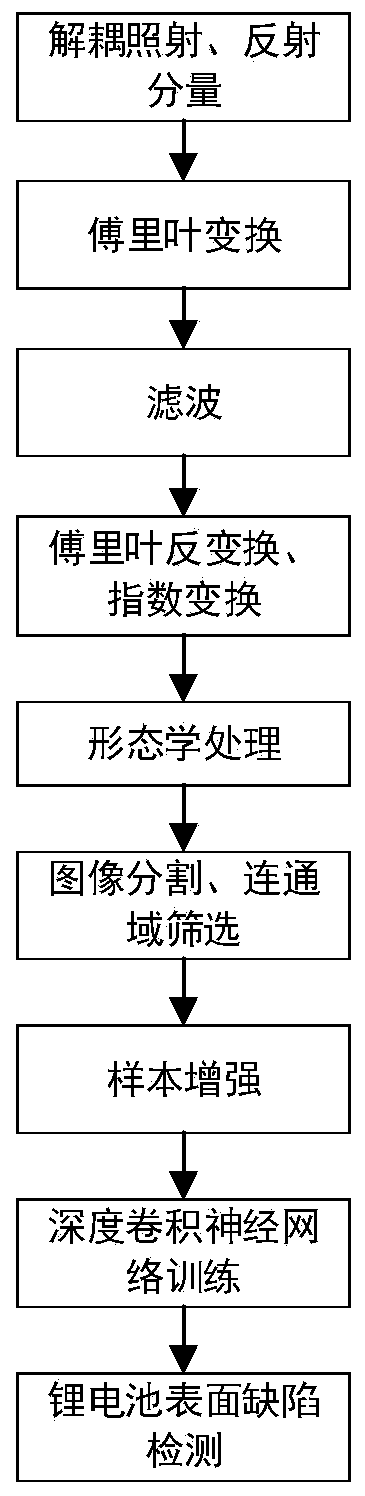

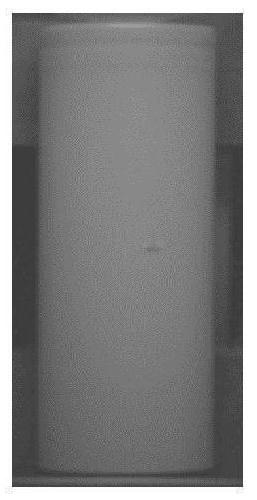

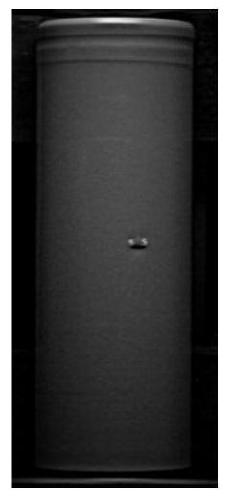

New energy lithium battery surface defect detection method based on adaptive deep learning

ActiveCN111105405AAccurate defect locationNo need for manual labelingImage enhancementImage analysisImage segmentationSample image

The invention discloses a new energy lithium battery surface defect detection method based on adaptive deep learning. The method comprises the following steps: carrying out nonlinear mapping on a lithium battery surface grayscale image; transforming the decoupled irradiation component and reflection component to a frequency domain; performing filtering, inverse Fourier transform and exponential transform on the frequency domain data to obtain a reconstructed lithium battery image; based on morphological processing and background differencing, enhancing gray scale response at the defect; carrying out image segmentation and connected domain analysis and screening processing, and taking a result as a labeled image; designing an operator to simulate illumination details, and carrying out sample enhancement operation on the surface grayscale image of the lithium battery; training a deep convolutional neural network based on the enhanced sample image set and the labeled image; and achievinglithium battery surface defect detection based on the trained network. By utilizing the method, the detection efficiency can be improved and the false detection rate can be reduced in a lithium battery surface defect detection scene.

Owner:芜湖楚睿智能科技有限公司

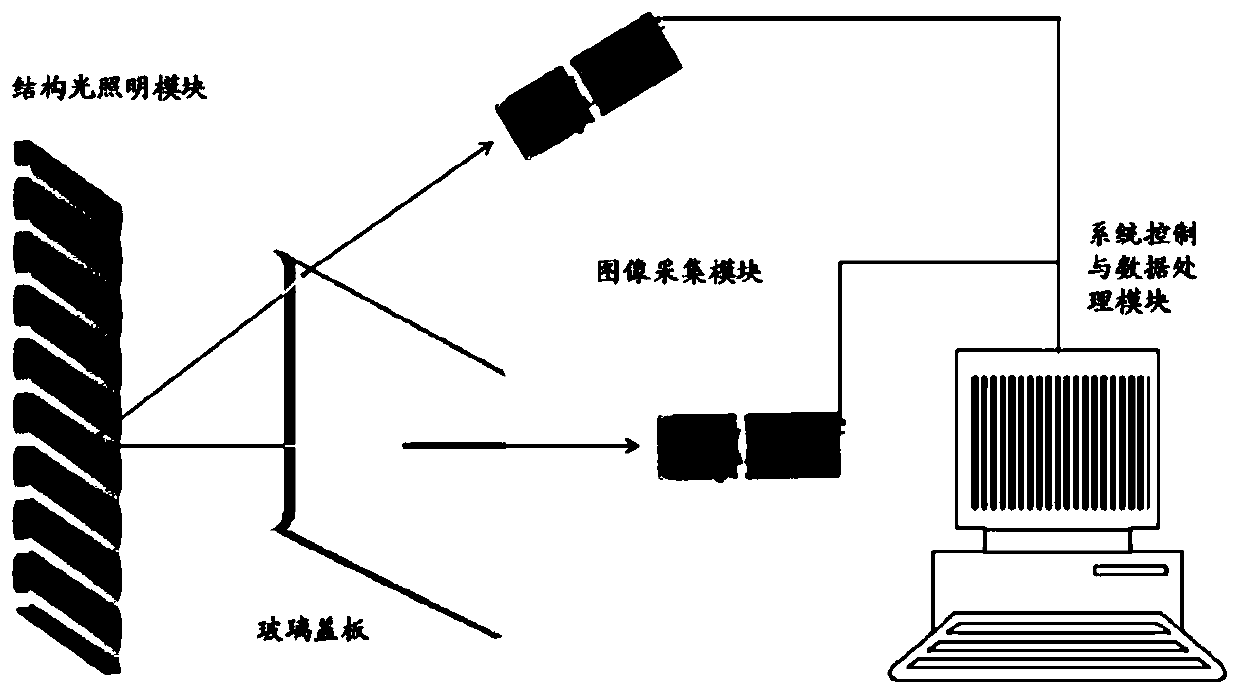

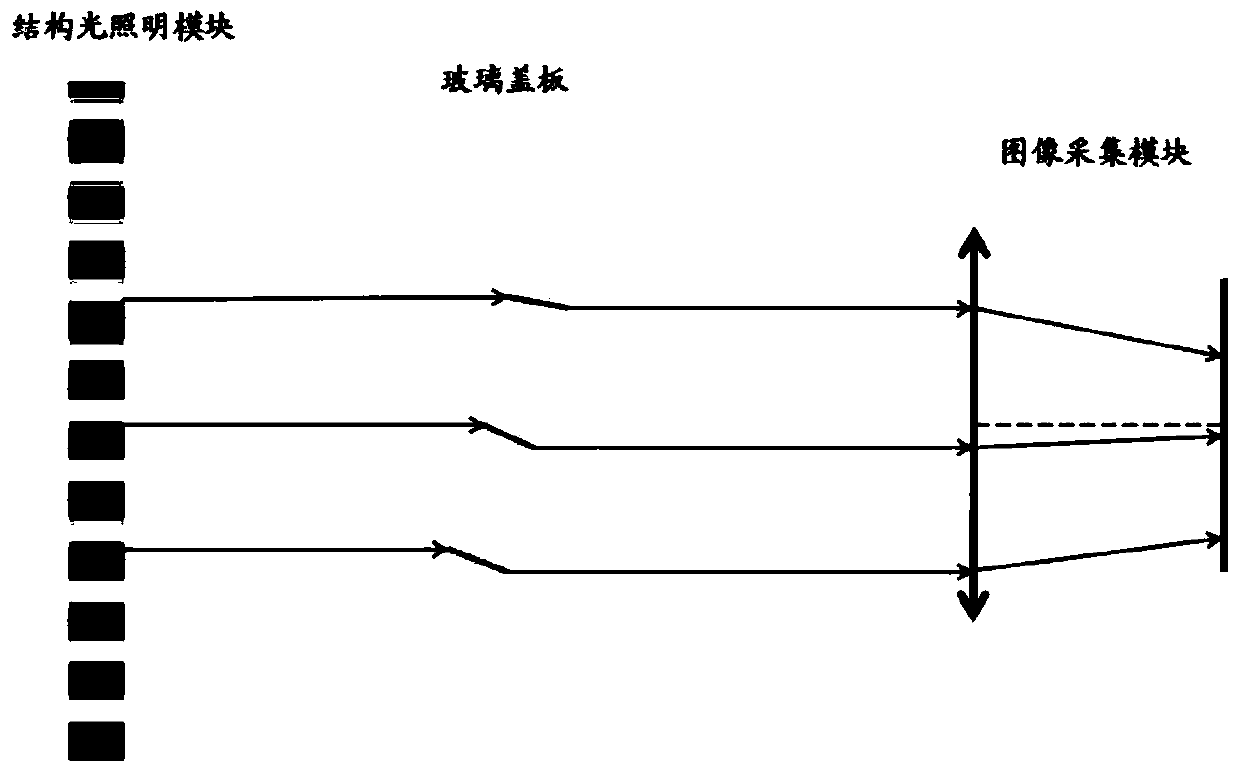

Defect detection method based on transmission structured light

InactiveCN110057841ARealize detectionFewer image acquisition timesMaterial analysis by optical meansSignal-to-noise ratio (imaging)Glass cover

The invention discloses a defect detection method based on transmission structured light, and is used for detecting the defects of a detected object with high transmissivity. The method comprises thefollowing steps that: firstly, generating stripe structured light, projecting the stripe structured light to the surface of the detected object, and after the stripe structured light is transmitted through the detected object, generating deformed stripe structured light; collecting the deformed stripe structured light, and utilizing a modulation degree technology to convert a collected light intensity graph into a modulation degree graph; and combining with a subsequent algorithm to obtain the surface defect information of the detected object. The method is especially suitable for the defect detection of a large-size large-curvature glass cover plate. Compared with a reflection system, a transmission system which is put forward by the invention eliminates the influence of parasitic stripes, improves the stripe contrast ratio of a collected image, improves the signal-to-noise ratio of an original image and improves a measurement result. In a whole detection process, a complex calibration process is not required, the height information of the object does not need to be subjected to integral reconstruction, errors brought by an integral algorithm are avoided, and the method has the characteristics of being quick, easy in operation, simple and practical.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

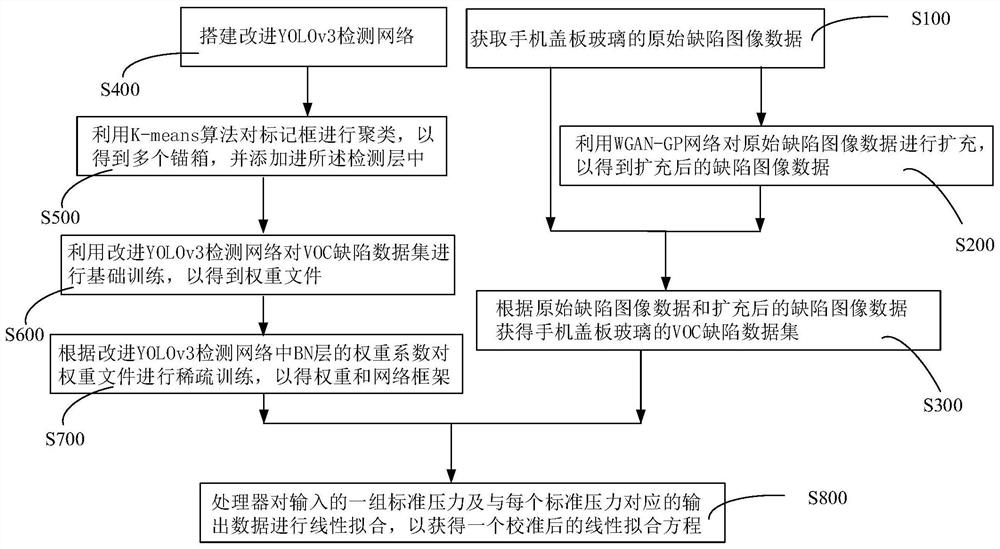

Mobile phone glass defect detection method and device, computer equipment and storage medium

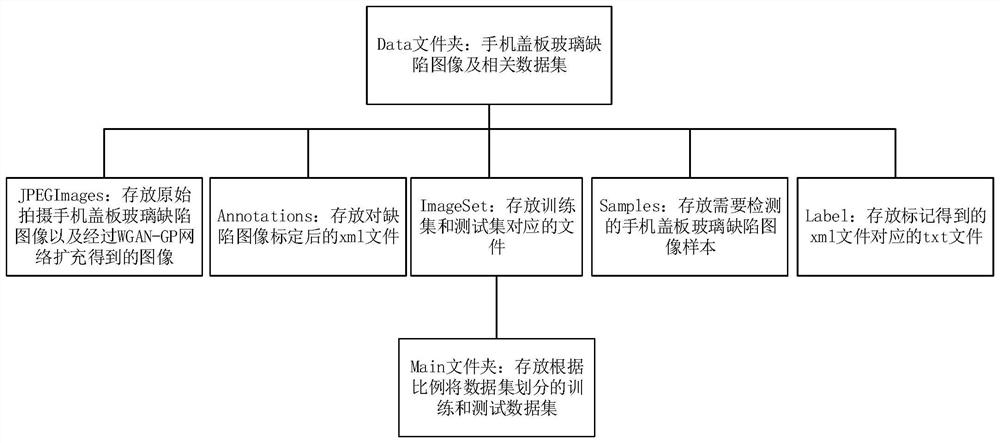

PendingCN112614125AImplement defect detectionImprove accuracyImage analysisCharacter and pattern recognitionData setAlgorithm

The invention relates to a mobile phone glass defect detection method and device, computer equipment and a storage medium. The mobile phone glass defect detection method comprises the following steps: acquiring original defect image data of mobile phone cover plate glass; expanding the original defect image data by using a WGAN-GP network to obtain expanded defect image data; obtaining a VOC defect data set of the mobile phone cover plate glass; building an improved YOLOv3 detection network; clustering the mark box by using a K-means algorithm to obtain a plurality of anchor boxes, and adding the anchor boxes into a detection layer; performing basic training on the VOC defect data set by using an improved YOLOv3 detection network to obtain a weight file; performing sparse training on the weight file according to the weight coefficient of the BN layer in the improved YOLOv3 detection network to obtain a weight and a network framework; and testing the detection data set for the weight and the network framework to obtain category information, position information and confidence information of the detection target. The method has high defect detection efficiency and high defect detection precision at the same time.

Owner:HUNAN UNIV OF SCI & TECH

Combined overhead conductor defect detection method

ActiveCN103837493AImplement defect detectionEfficient detectionMaterial analysis by optical meansMaterial analysis by transmitting radiationSoft x rayDigital imaging

The invention discloses a combined overhead conductor defect detection method. The method comprises the following steps: acquiring a thermal infrared image, namely observing an overhead conductor at the same observation point by utilizing a thermal infrared imager; performing laser radar plotting, namely plotting the overhead conductor by utilizing laser radar plotting equipment, and acquiring plotting data and a plotting image; determining coordinates of the defect positions of the conductor, namely comparing the thermal infrared image with the plotting image, and determining corresponding global position system (GPS) position coordinates of temperature abnormality points on the overhead conductor in the thermal infrared image on the plotting image; and performing X-ray digital imaging detection. A combined detection method of the thermal infrared imaging technology, laser radar plotting technology and X-ray digital detection technology is utilized, so that defect detection of the overhead conductor is realized. Compared with a traditional detection method, the method has the advantages that the defects of the overhead conductor can be effectively detected, and the defects are judged and evaluated.

Owner:YUN NAN ELECTRIC TEST & RES INST GRP CO LTD ELECTRIC INST +1

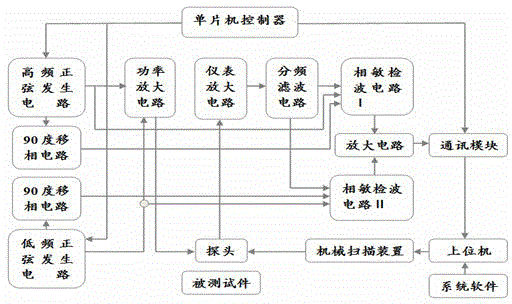

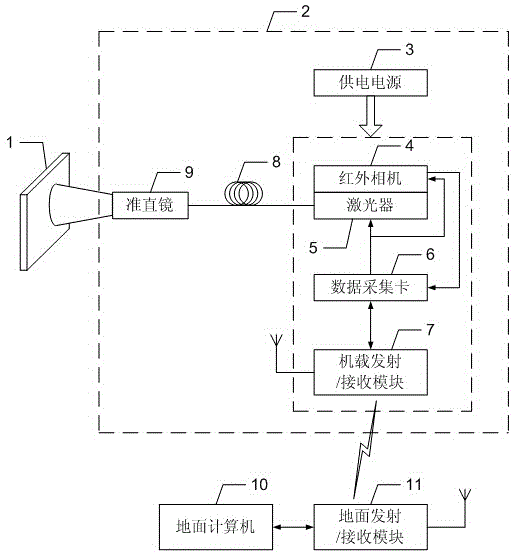

Active infrared nondestructive test unmanned plane system

InactiveCN105486716AEnsure stable operationImprove detection efficiency and accuracyMaterial flaws investigationTest objectPhase locking

The invention discloses an active infrared nondestructive test unmanned plane system and belongs to the field of a nondestructive test on a large complex member such as an aerospace structural component. The system solves the problem that the aerospace structural component has a large volume and a complex structure so that manual climbing checking efficiency is low and potential safety hazard exists. The system comprises an unmanned plane main body, an unmanned plane mounted monitoring module is arranged on the unmanned plane main body, a ground-based computer transmits a position instruction in a wireless way to control the unmanned plane main body so that the unmanned plane main body is moved to a certain position on the outer surface of a tested object, a data acquisition card controls a modulating signal and power of a laser according to an acquisition instruction, light beams transmitted through the laser go through optical fibers, are collimated through a collimating lens and irradiate the outer surface of the tested object, an infrared camera acquires an image sequence and the ground-based computer carries out phase locking operation on the acquired image sequence and a reference signal so that a thermal radiation signal amplitude image and a phase image of the tested object are obtained and defect types and positions are obtained.

Owner:HARBIN INST OF TECH

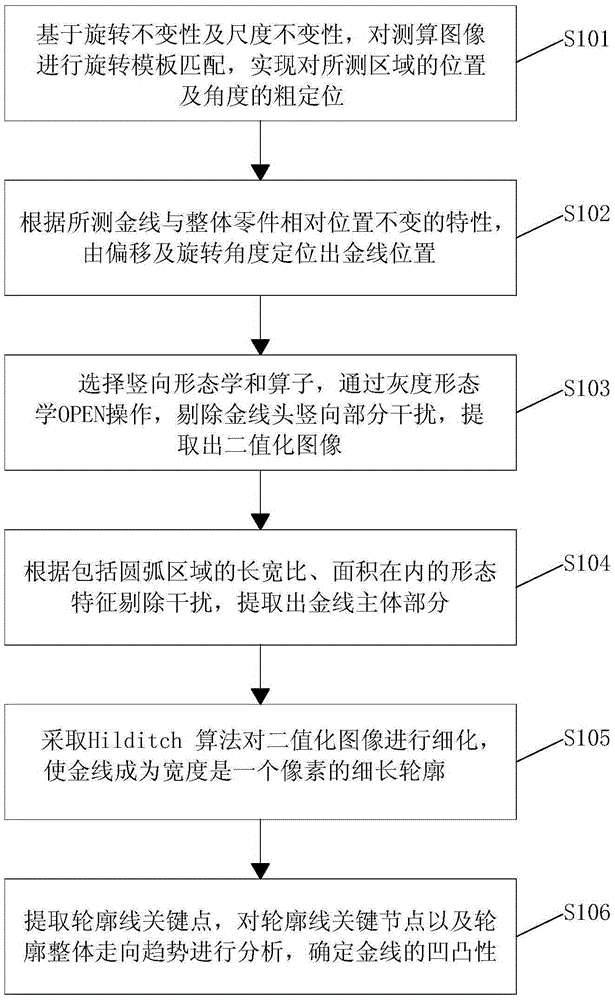

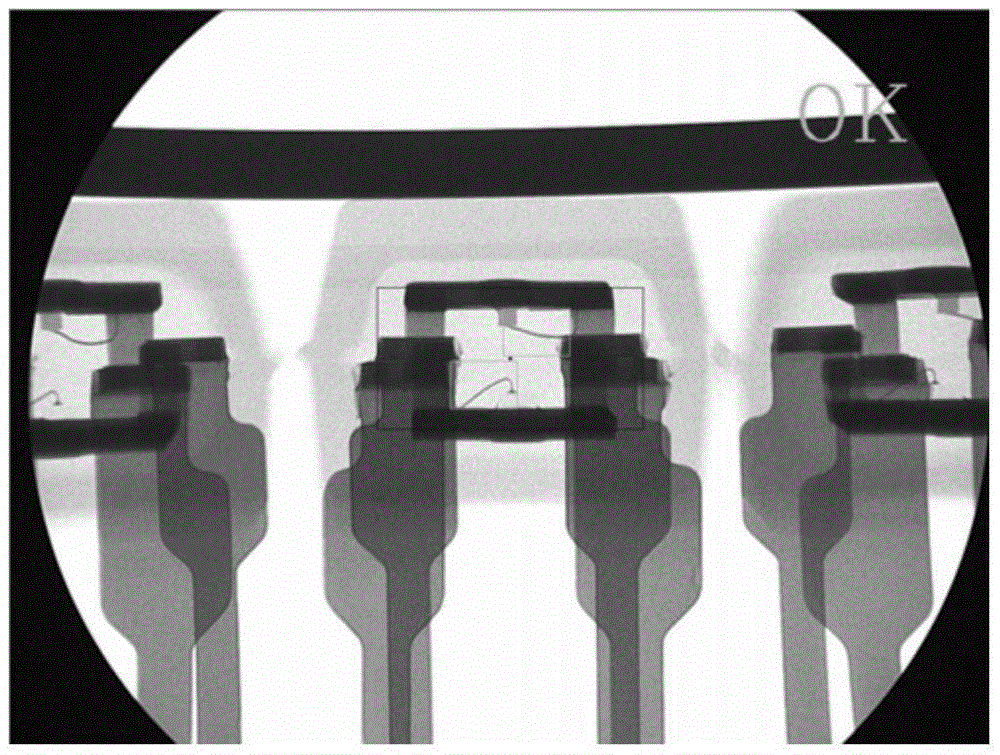

IC component defect detection method based on X-Ray image

ActiveCN105389802AImplement defect detectionImprove efficiencyImage enhancementImage analysisTemplate matchingCrucial point

The invention discloses an IC component defect detection method based on an X-Ray image. The IC component defect detection method comprises the steps of: carrying out rotational template matching on a measured image, and achieving coarse positioning of a position and an angle of a measured region; positioning a position of a gold wire via a deviation and rotation angle according to the characteristic that the relative position of the gold wire and an overall component is unchanged; eliminating vertical part interference of the gold wire head through gray morphological OPEN operation, and extracting a binary image; eliminating interference according to morphological characteristics, and extracting the main body part of the gold wire; adopting a Hilditch algorithm for refining the binary image, so that the gold wire becomes an elongated contour with the width being a pixel; and determining concavity and convexity of the gold wire through extracting key points of the contour line and analyzing tendency of key points of the contour line and the overall contour, and judging the defect condition of the IC component. The IC component defect detection method achieves defect detection of the IC component quickly and reliably, and has high adaptability.

Owner:WUXI UNICOMP TECH

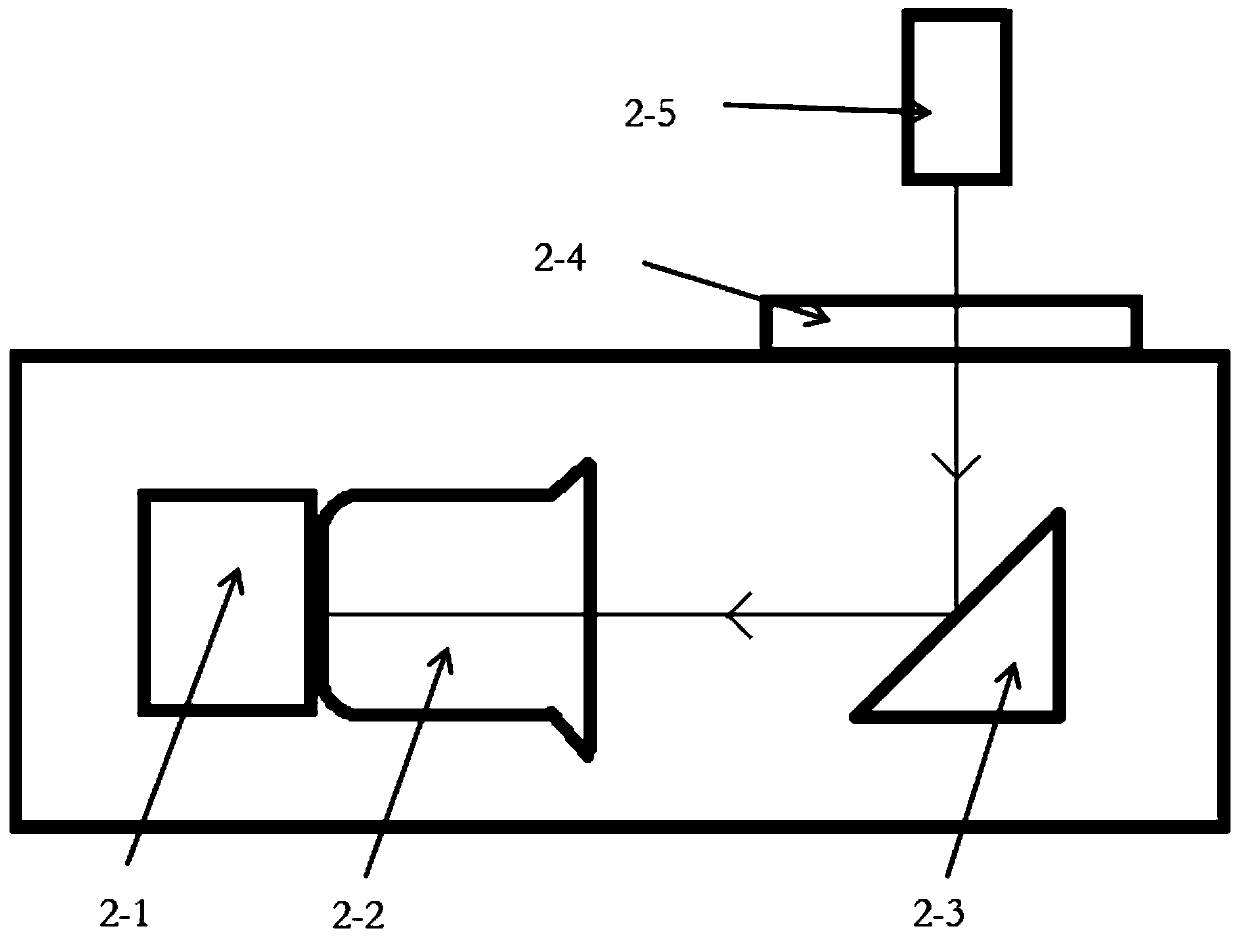

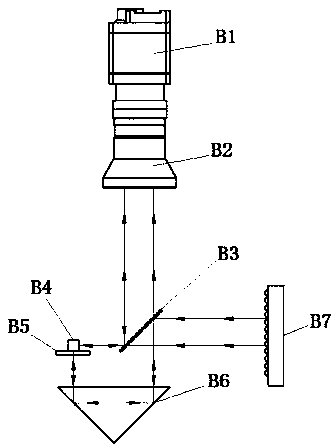

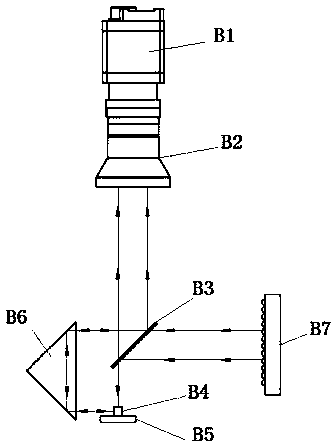

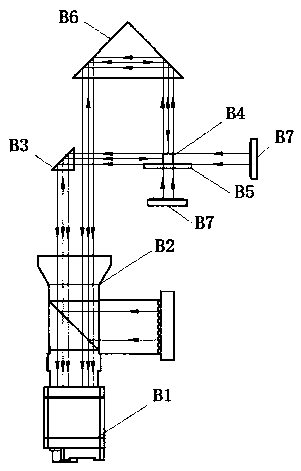

New device and method for simultaneous quasi-aplanatic imaging confocal detection of adjacent surfaces of semiconductor crystal grains

PendingCN111089840AAdjustable optical path differenceCompact structureOptically investigating flaws/contaminationOptical axisImaging lens

The invention discloses a new method for simultaneous quasi-aplanatic imaging confocal detection of adjacent surfaces of semiconductor crystal grains. A detection device comprises a camera, a telecentric imaging lens, a semi-transparent and semi-reflective image combiner, the semiconductor crystal grains and a transparent object stage for bearing the semiconductor crystal grains which are sequentially arranged in a direction of a light path; a first right-angle transferring prism and a second right-angle transferring prism are respectively arranged on the light path between the semiconductor crystal grains and the semi-transparent and semi-reflective image combiner, the second right-angle transferring prism is positioned at a first side part of the optical axis of the telecentric imaging lens, the two right-angle surfaces of the two right-angle transferring prisms are respectively vertical to the light path, at least two surfaces of the semiconductor crystal grains are respectively imaged at different area positions on a sensor surface of the camera through the right-angle transferring prisms and the semi-transparent and semi-reflective image combiner by double light paths, and thedistance delta between the double images of the adjacent surfaces is adjustable.

Owner:QUANZHOU NORMAL UNIV

Multicasting network system and method for detecting link fault of multicasting network

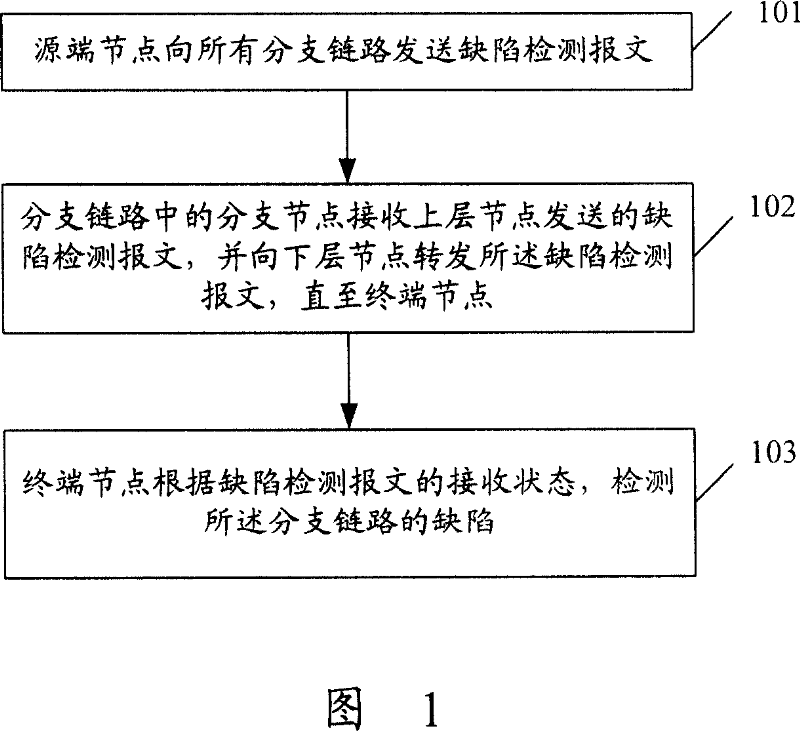

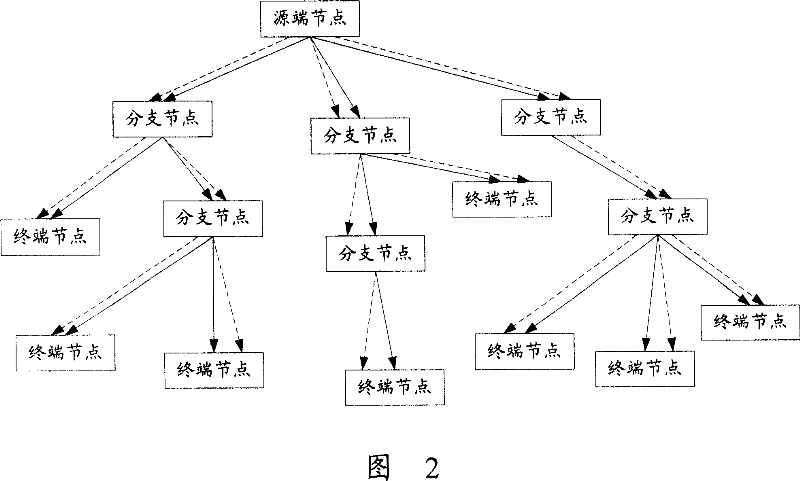

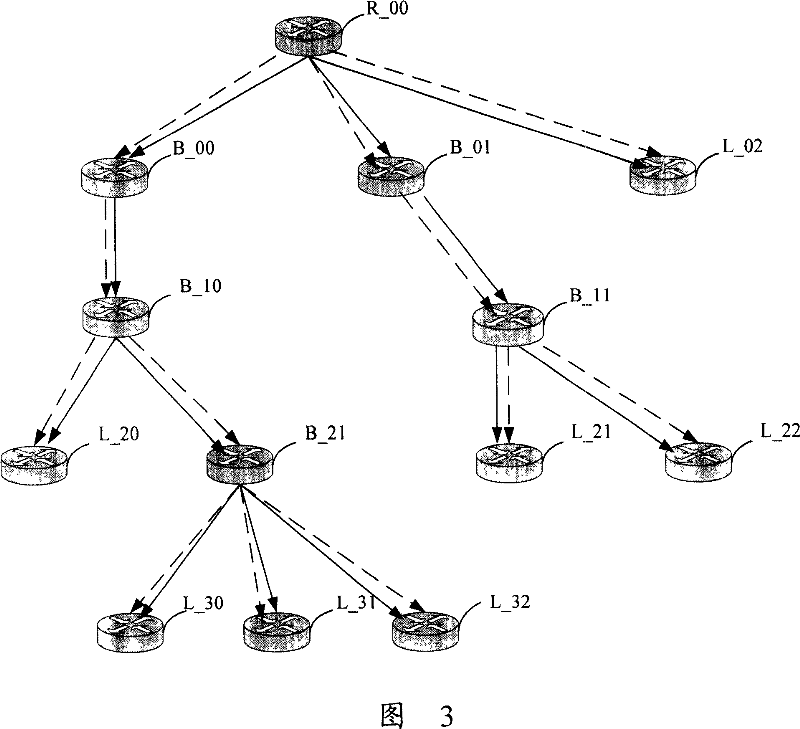

ActiveCN101039167AImplement defect detectionSpecial service provision for substationError preventionNetwork linkMulticast network

The invention discloses a method to detect the defects of a multicast network link. The invention sends a defect detecting report through a source terminal node to all branch links, and a branch node in the branch link receives and forwards the defect detecting report downwards till reaching all terminal node; and then the terminal node detects the defect case of the branch link according to the receiving state of the defect detecting report, which can achieves the detecting for the whole network link defects of the multicast network. The invention discloses a multicast network system. The terminal node in the system can send defect detecting report to all branch links till all terminal node; the terminal node receives the defect detecting report from the upper layer node, and detects the defect of the branch link according to the receiving state of the defect detecting report. The multicast network system can achieve the detecting for the whole network link.

Owner:HUAWEI TECH CO LTD

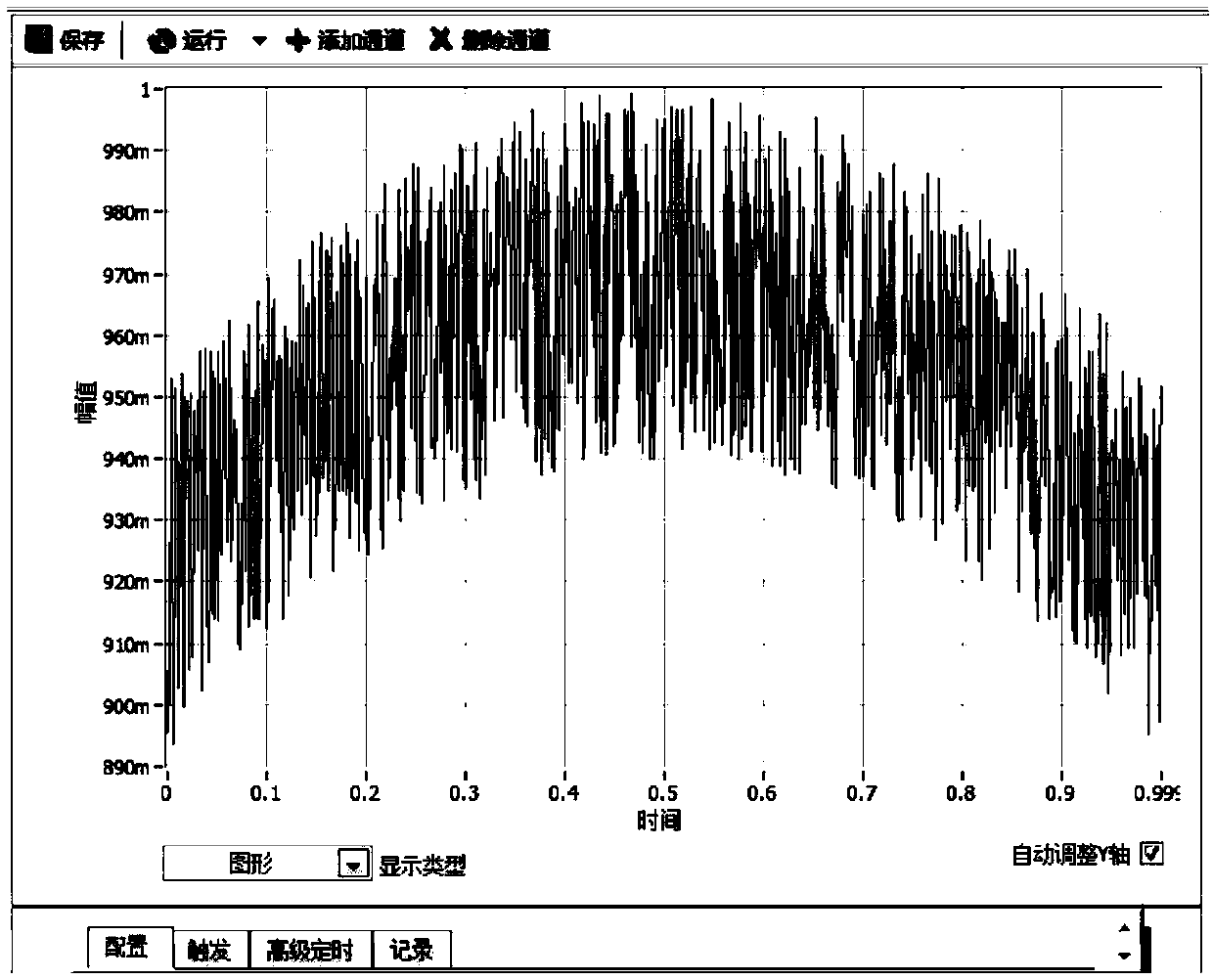

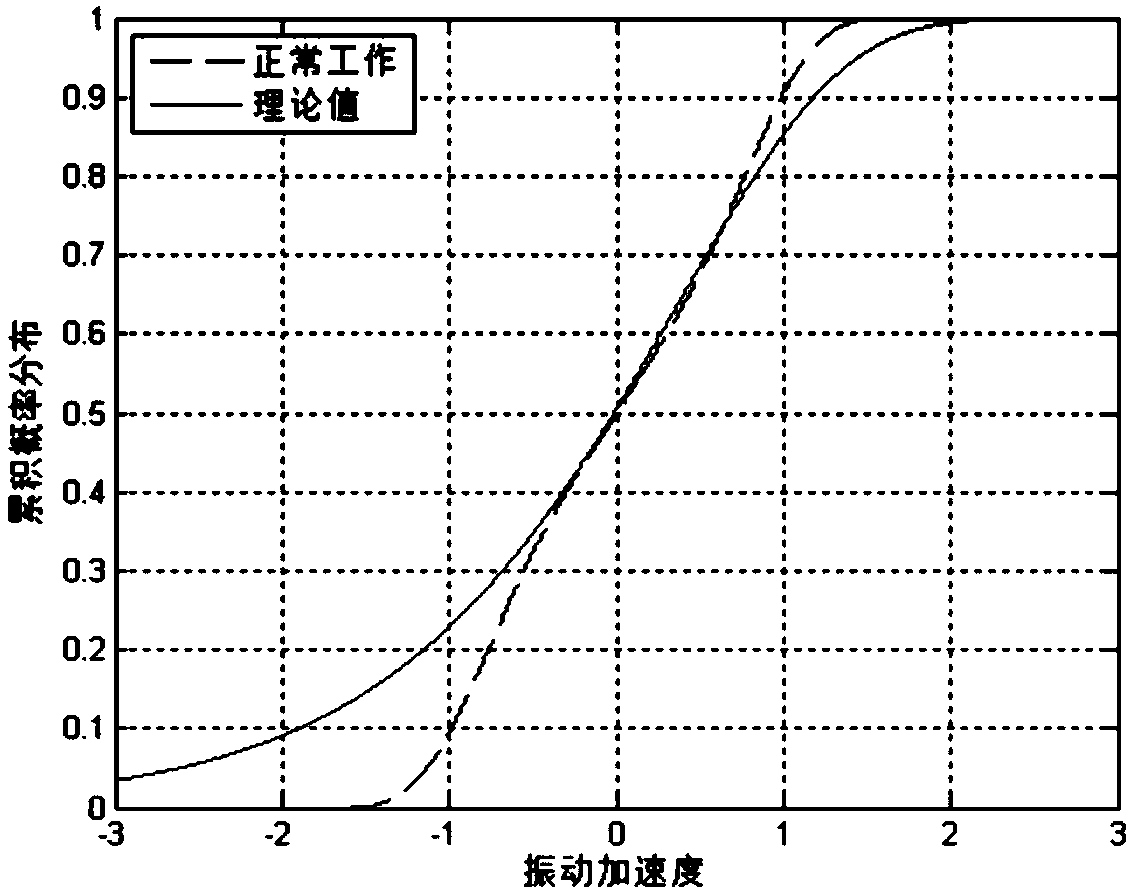

Mathematical statistical probability model based method for identifying internal faults of transformer

ActiveCN108844612ARealize the purpose of detecting internal defects of transformersImplement defect detectionVibration measurement in solidsVibration accelerationElectric power system

The invention relates to a mathematical statistical probability model based method for identifying internal faults of a transformer and belongs to the field of a power system. The method comprises thefollowing steps: S1, collecting vibration signals of the transformer and establishing a mathematical model of the vibration signals of transformer faults; S2, extracting acceleration signals from the vibration signals of the transformer; S3: importing the extracted transformer vibration acceleration signals into LabVIEW for data processing and then importing into the established mathematical model for analysis; S4, importing vibration signals of different faults of the transformer into the established mathematical model, and determining a vibration signal cumulative probability distributionfunction diagram under different fault conditions of the transformer; S5: performing least square fitting on the cumulative probability distribution function under different fault conditions of the transformer, and judging transformer faults according to a slope relation. The method of the invention optimizes a prior transformer fault identification method to a certain extent, and provides a new idea for the development of the transformer fault identification field.

Owner:CHONGQING UNIV +1

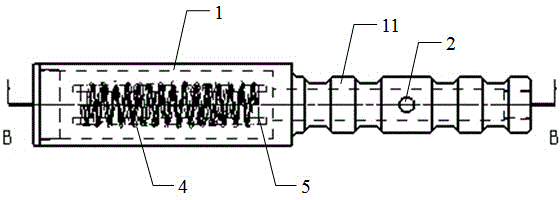

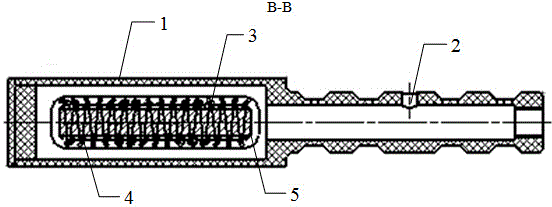

Sensing type grenade probe for blind hole magnetic powder flaw detection

InactiveCN104792860AEasy to detectEnhanced magnetizationMaterial magnetic variablesPhysicsMagnetic powder

The invention discloses a sensing type grenade probe for blind hole magnetic powder flaw detection. The sensing type grenade probe comprises a hollow probe body and a handle, wherein a core rod is arranged in the probe body, a magnetized coil is arranged on the core rod and the handle is arranged at one end of the probe body. By connecting the sensing type grenade probe with various magnetic powder flaw detection devices, the surface or near surface of a blind hole of a work piece can be conveniently magnetized and the flaw at the inner surface of a blind hole forging piece can be detected; the sensing type grenade probe can extend into an inner hole of a forging piece of the oil gas drilling industry, so as to conveniently magnetize the surface of the inner hole and detect the surface flaw; the sensing type grenade probe is particularly convenient to detect the flaw in the inner surface of a blind hole.

Owner:NANJING DEV ADVANCED MFG

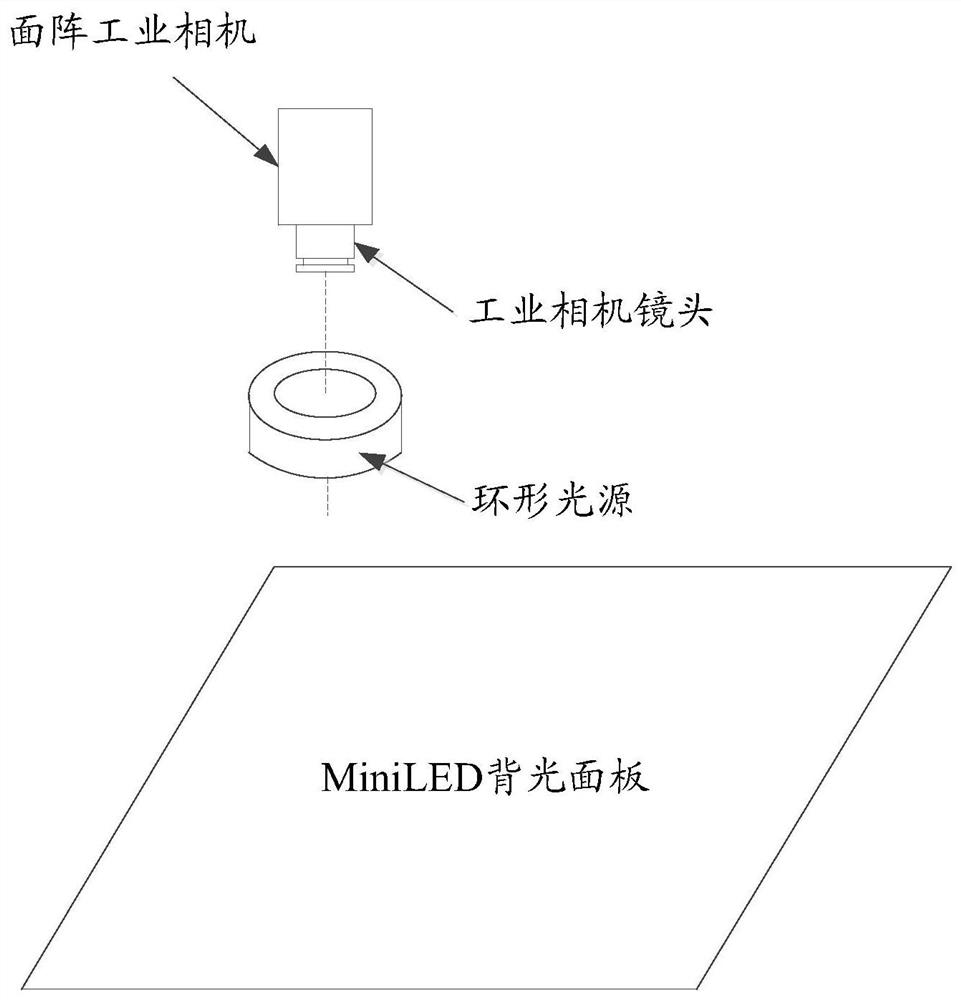

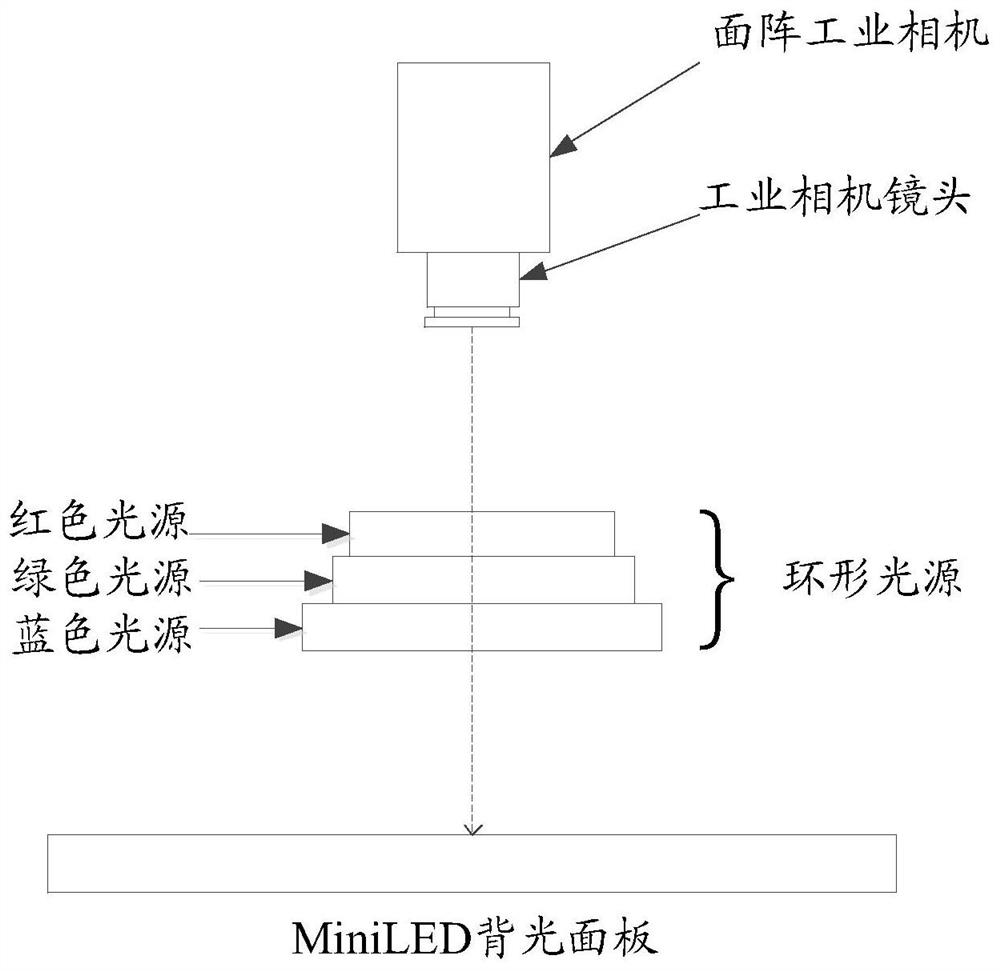

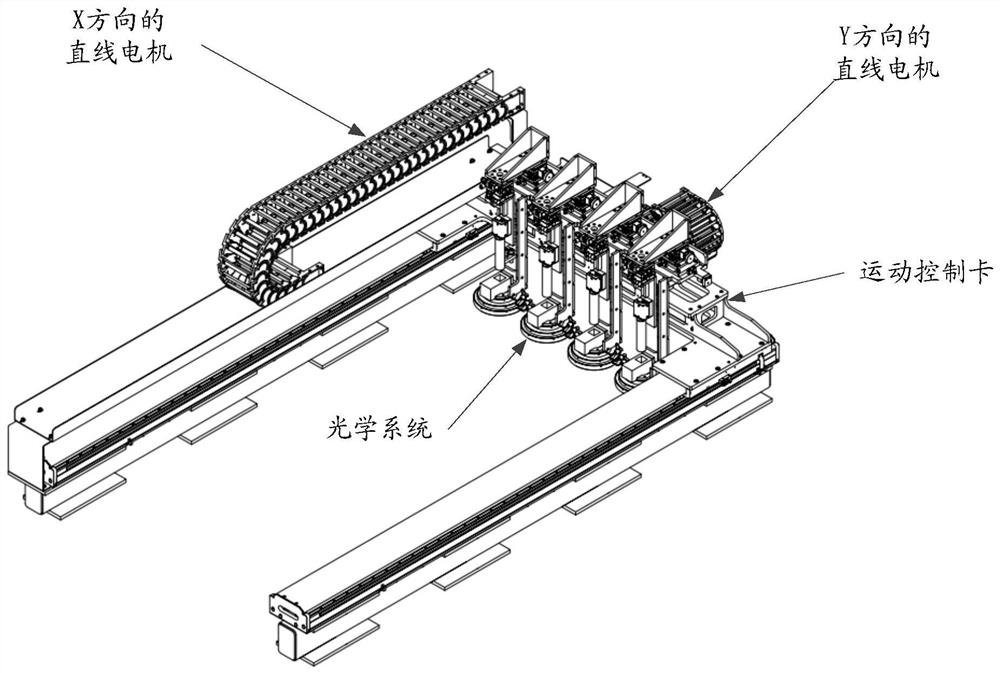

Mini LED backlight panel defect detection method and device

PendingCN114577805AImplement defect detectionImprove detection qualityOptically investigating flaws/contaminationImaging processingEngineering

The invention relates to the technical field of image processing, and provides a Mini LED backlight panel defect detection method and device. The method comprises the following steps: dividing an acquired Mini LED backlight panel image into a plurality of LED images, wherein each LED image comprises an LED particle; and detecting the defect state of the LED particles contained in each LED image by adopting a method matched with the defect type according to the defect type, so that the defects of the LRD particles in the Mini LED backlight panel can be quickly and accurately detected.

Owner:合肥欣奕华智能机器股份有限公司

Hard disk part detection device and detection method

PendingCN112345553AEasy to operateImprove accuracyImage enhancementImage analysisImaging analysisEngineering

The invention discloses a hard disk part detection device and a hard disk part detection method, which can realize detection of different types of defects of a hard disk part, improve the product yield level, and solve the problem that some defects can only be displayed in an image at a specific lighting angle. Therefore, an electric control rotary workpiece table, an electric control light sourcelifting table and a matched image analysis algorithm are specially designed, the detection automation level is improved, and missing detection is avoided; the workpiece table is controlled through software coordination to achieve rotation of a given angle value, and an angle image is collected; And registering of the images with different rotation angles is achieved by using the rotation angle value, a gravity center algorithm and an image correlation matching algorithm. Some defects can only be displayed in the images at a specific lighting angle, so that the registered images have difference in defect positions, and the gray value difference is extracted to realize defect detection.

Owner:CHANGZHOU COLLEGE OF INFORMATION TECH

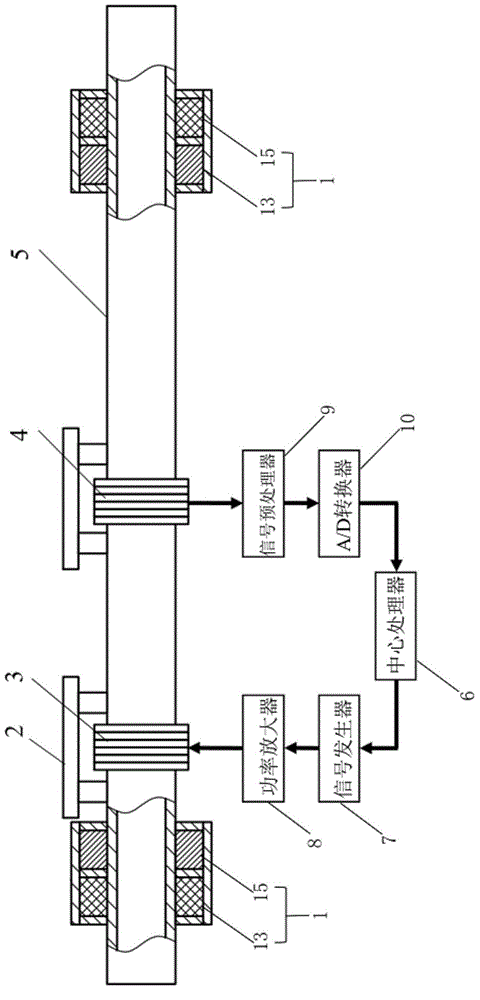

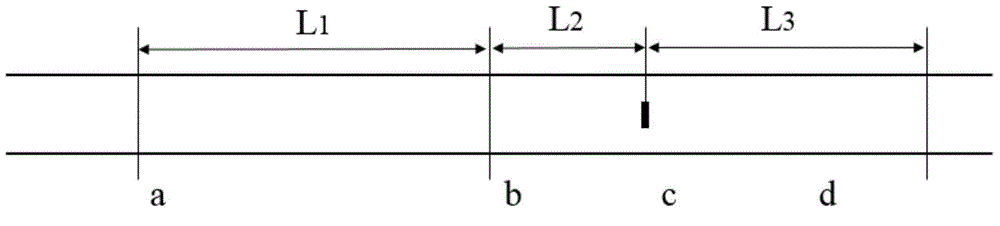

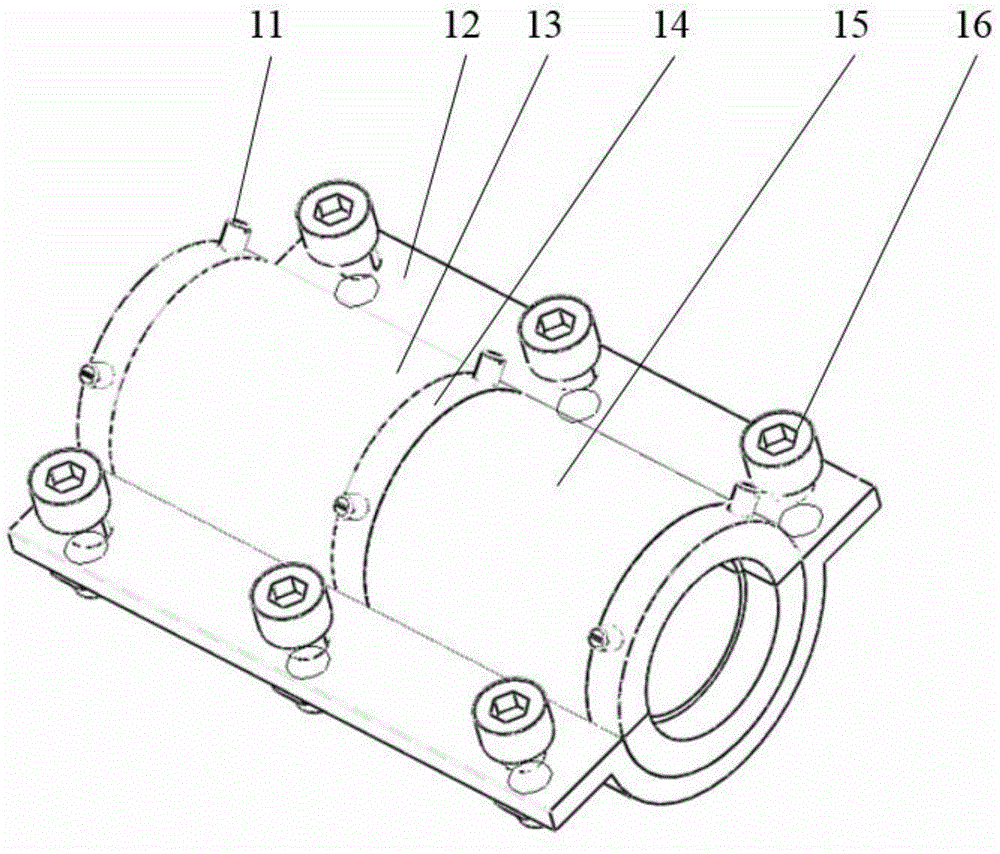

Device and method for improving magnetostrictive guided wave detection sensitivity

InactiveCN104990984AHigh detection sensitivityImplement defect detectionAnalysing solids using sonic/ultrasonic/infrasonic wavesSonificationControl signal

The invention discloses a device for improving the magnetostrictive guided wave detection sensitivity, and a method for improving the magnetostrictive guided wave detection sensitivity by using the same; a center processor controls a signal generator to generate an excitation signal, the excitation signal is inputted into an excitation sensor through a power amplifier, and an ultrasonic guided wave is excited at a to-be-detected area and is propagated in the axial direction; after reflection by signal enhancement components, the ultrasonic guided wave is superposed and enhanced, then inputted to a receiving sensor, inputted to an A / D converter through a signal preprocessor, and next is converted into a digital signal, and the digital signal is inputted to the center processor; the center processor analyzes the digital signal, and the position of a defect in the to-be-detected area is concluded. The signal enhancement component is introduced to a traditional magnetostrictive guided wave detection device, so that the defect multiple echo signal amplitude value is enhanced, the purpose of improving the guided wave detection sensitivity is achieved, at the same time, the conventional device has no need of complex modification, and non-blind area defect detection can be realized.

Owner:HUAZHONG UNIV OF SCI & TECH

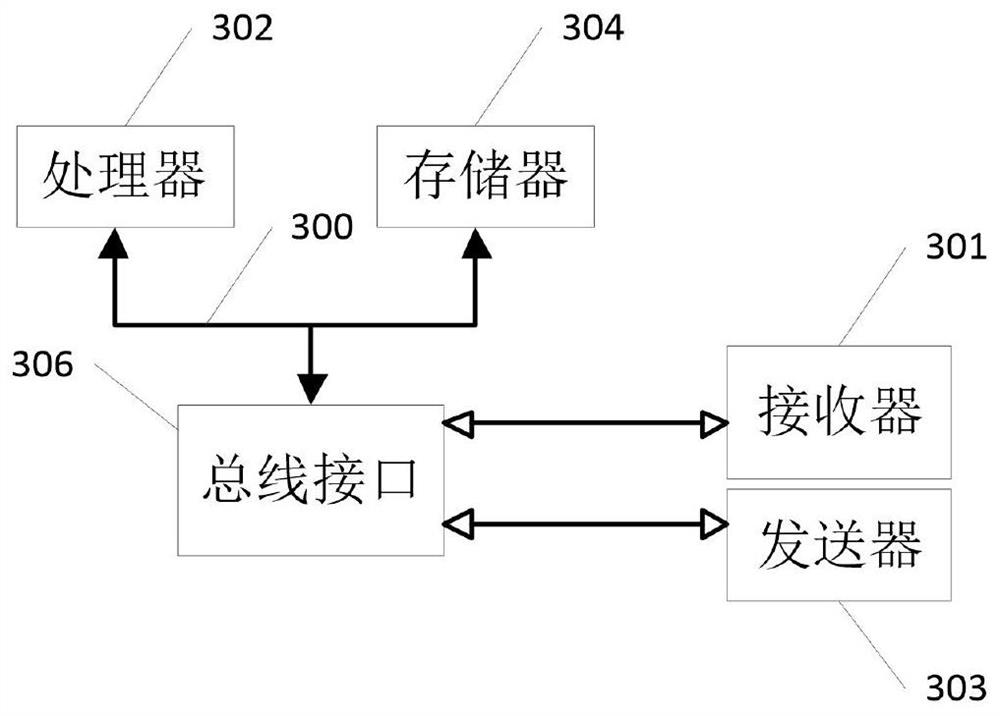

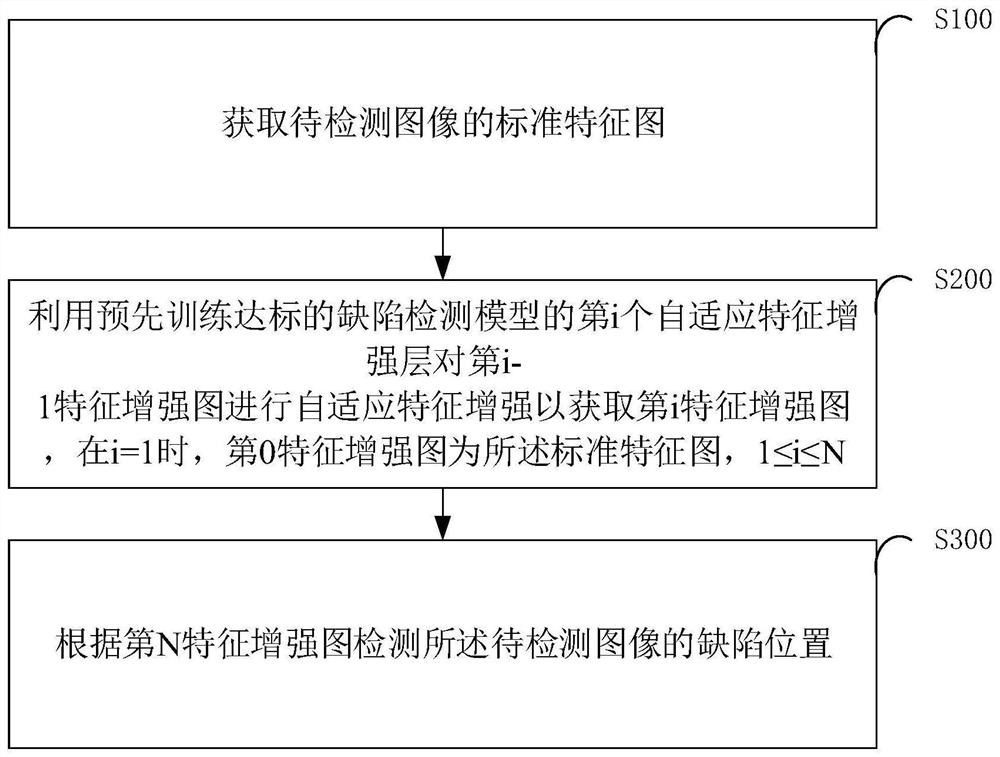

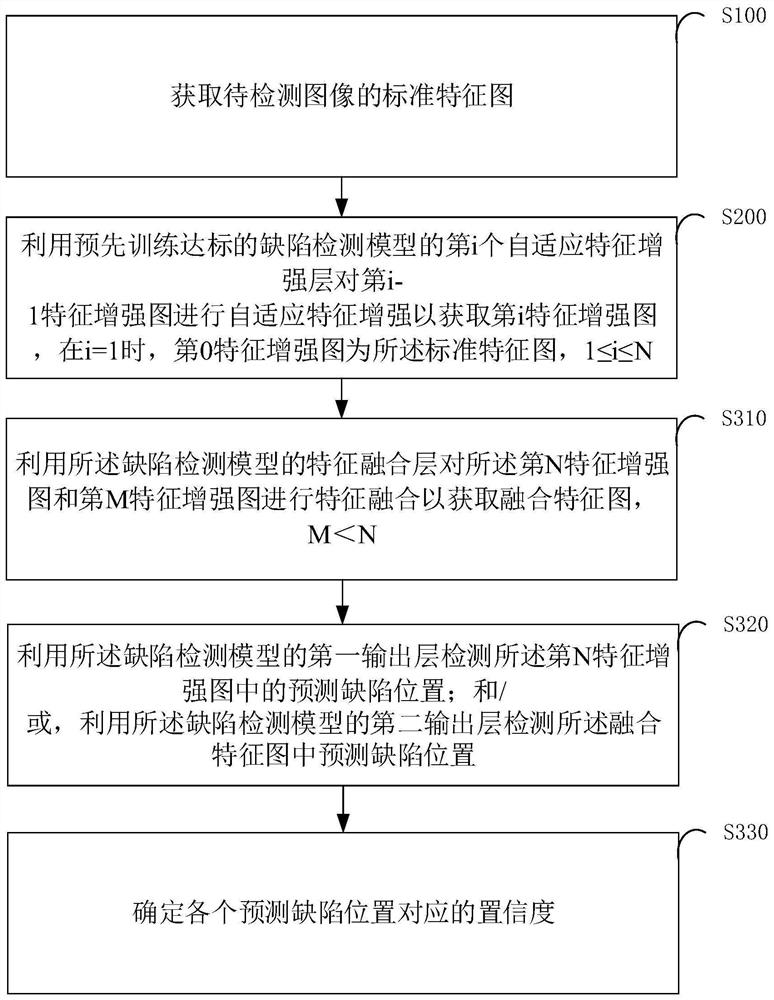

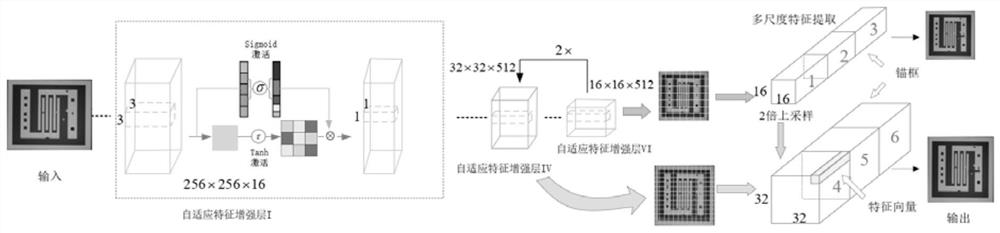

Defect detection method and device, model construction method and computer equipment

ActiveCN112598657AReduce use costImplement defect detectionImage enhancementImage analysisAlgorithmEngineering

The embodiment of the invention discloses a defect detection method and device, a model construction method and computer equipment. The method comprises the steps of obtaining a standard feature map of a to-be-detected image; carrying out adaptive feature enhancement on the i1th feature enhancement graph by utilizing an ith adaptive feature enhancement layer of a pre-trained standard defect detection model so as to obtain an ith feature enhancement graph, and when i is equal to 1, taking the 0th feature enhancement graph as the standard feature graph and i is greater than or equal to 1 and less than or equal to N; and detecting the real defect position of the to-be-detected image according to the Nth feature enhancement image. According to the invention, defect detection on the surface ofthe product can be realized on an embedded system with limited hardware resources and computing resources by utilizing a new lightweight defect detection model, so that the use cost of the hardware resources and the computing resources is effectively reduced.

Owner:锋睿领创(珠海)科技有限公司

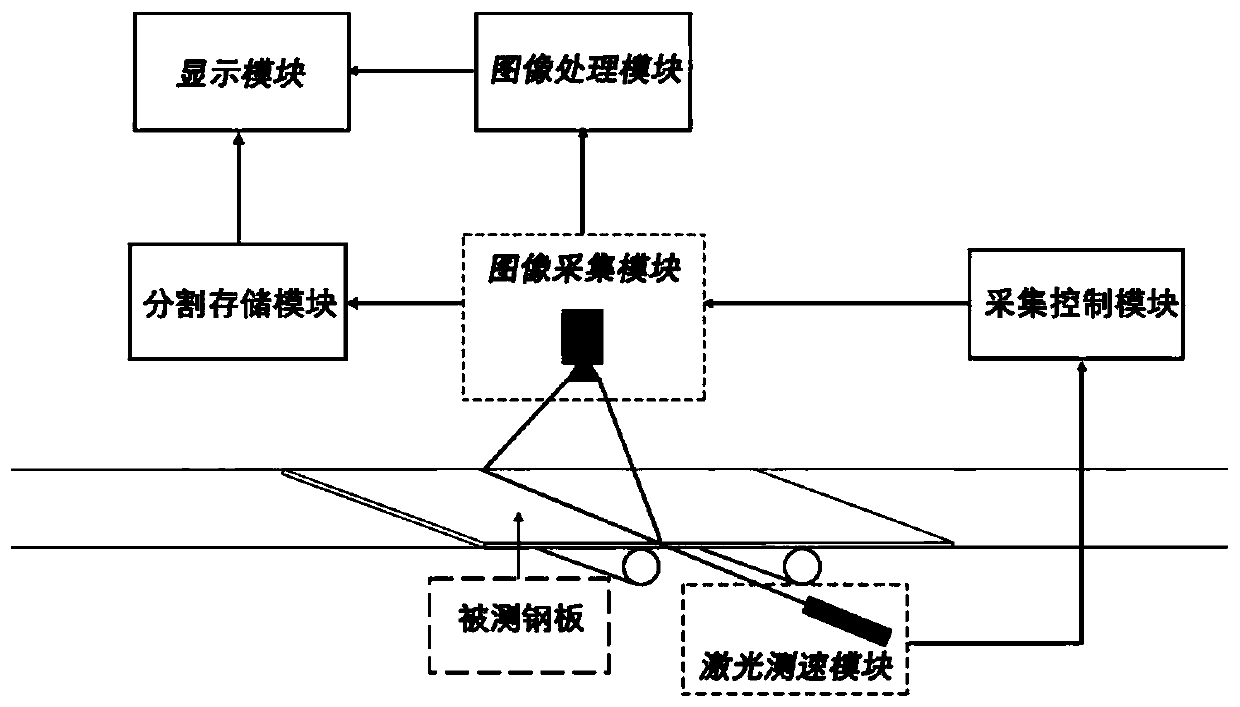

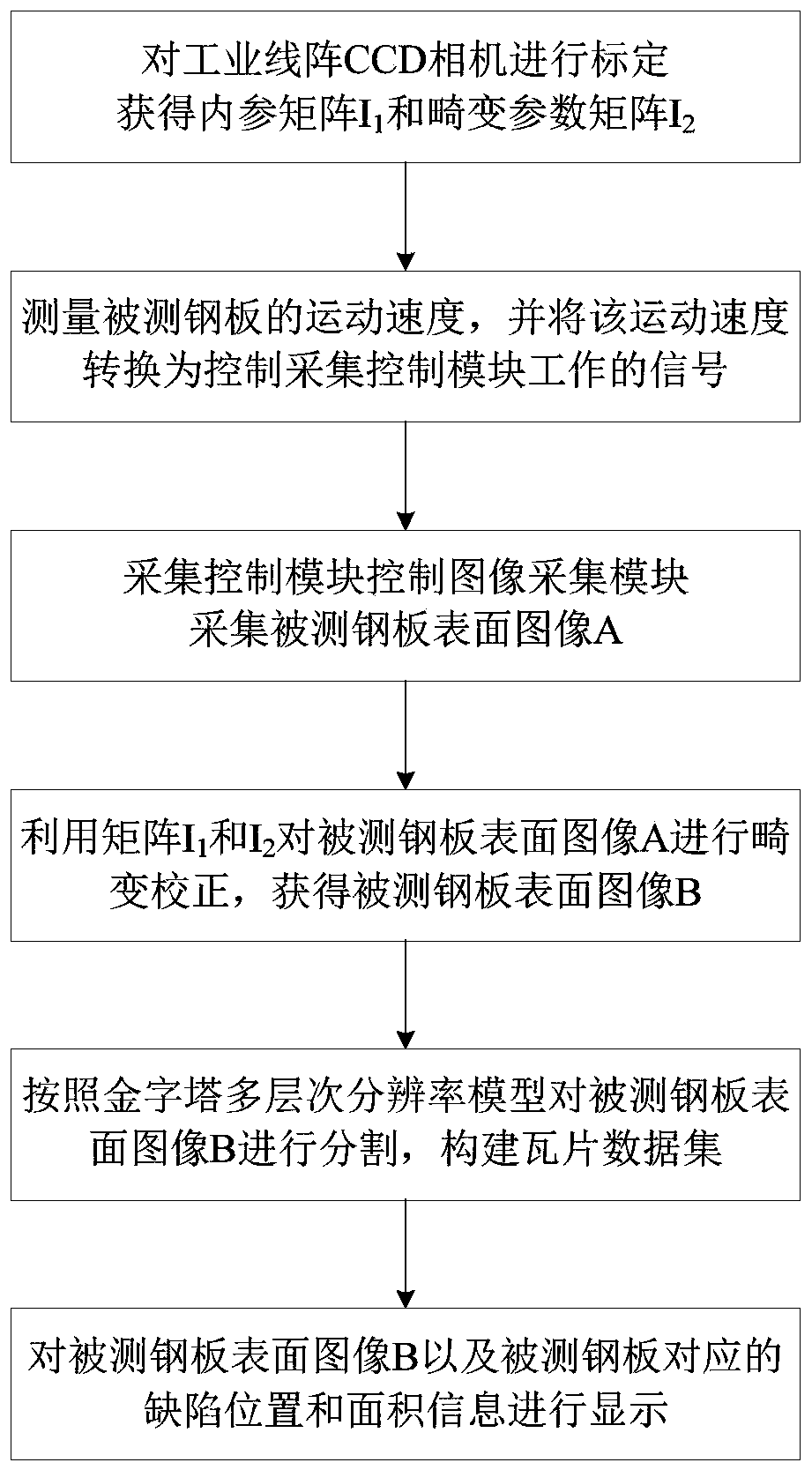

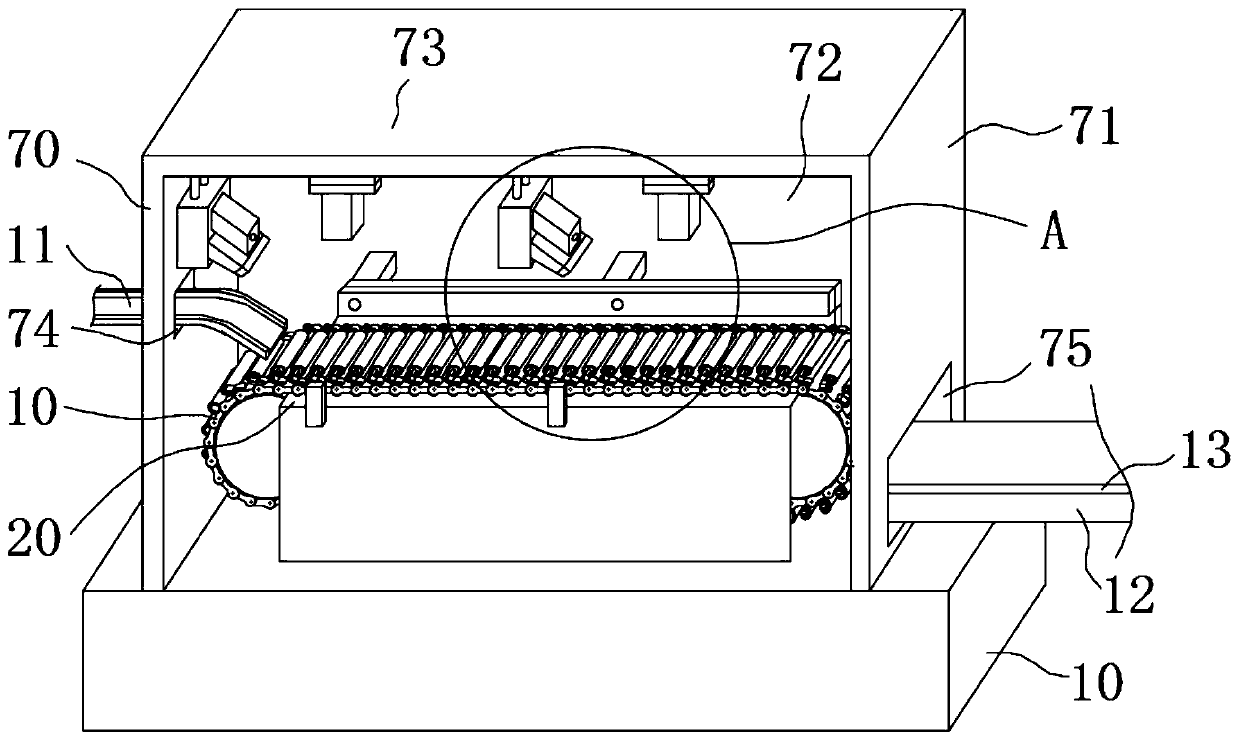

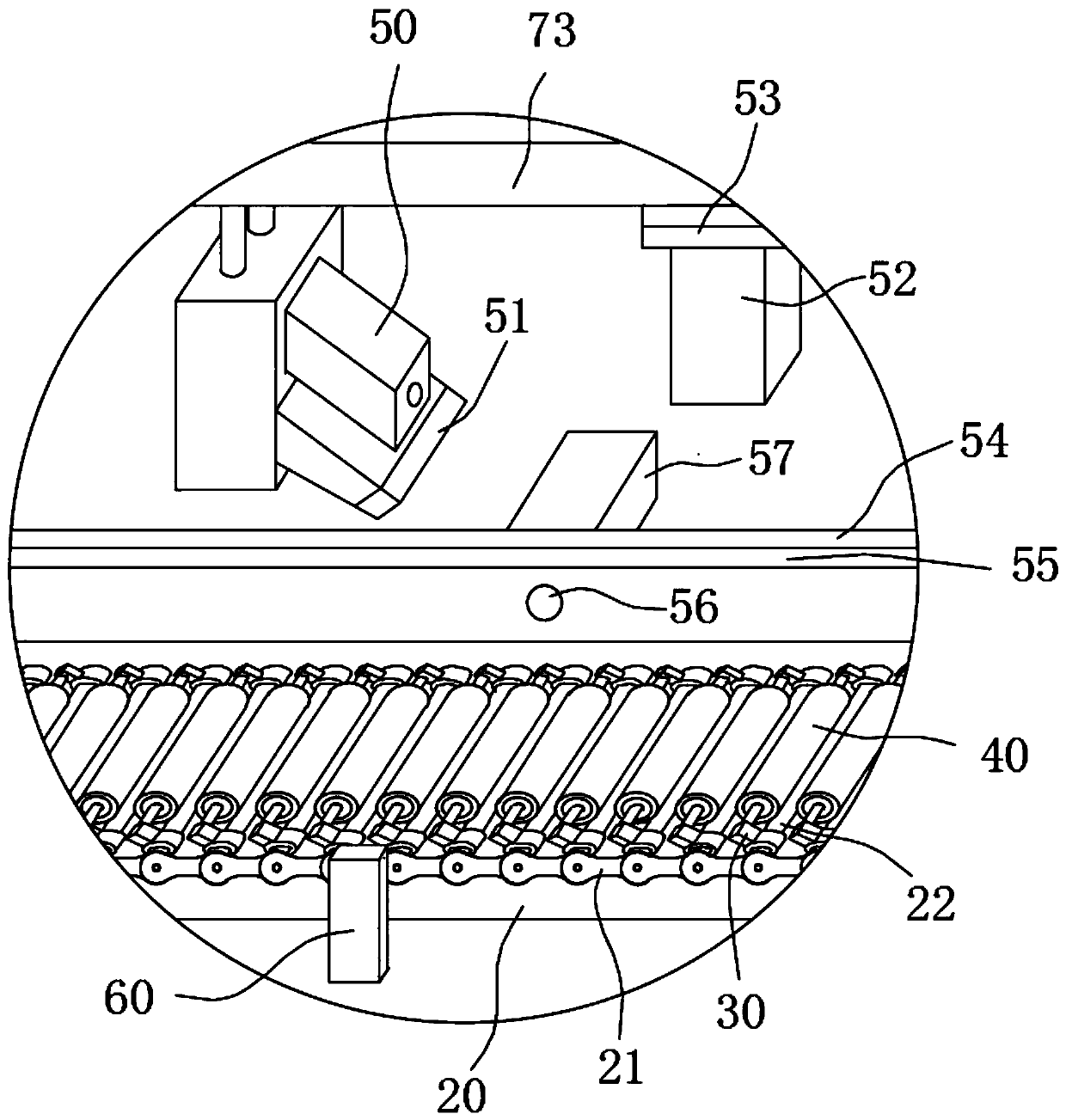

Steel plate surface defect detection system and method based on machine vision

InactiveCN110873718AEffective Geometric Distortion CorrectionAccurate collectionOptically investigating flaws/contaminationEngineeringImage segmentation

The invention discloses a steel plate surface defect detection system and method based on machine vision. The system comprises a transmission module, a laser speed measurement module, an acquisition control module, an image acquisition module, an image processing module, an image segmentation and storage module and an image display module, wherein the transmission module is used for driving a detected steel plate to move; the laser speed measurement module is used for generating a signal for controlling the acquisition control module to work; the acquisition control module is used for controlling the image acquisition module to work; the image acquisition module is used for acquiring a surface image of the measured steel plate; the image processing module is used for carrying out preprocessing and defect detection on the surface image of the detected steel plate; the image segmentation and storage module is used for segmenting the surface image of the measured steel plate; and the image display module is used for displaying the image of the detected steel plate and the defect information corresponding to the detected steel plate. The method implements defect detection based on thesystem. According to the invention, non-contact steel plate defect detection can be achieved, and the high-resolution steel plate surface image and defect information are displayed. The system and method disclosed by the invention have the advantages of high acquisition speed, high resolution, fast and smooth display, high detection accuracy and the like, and have broad application prospects.

Owner:NANJING UNIV OF SCI & TECH

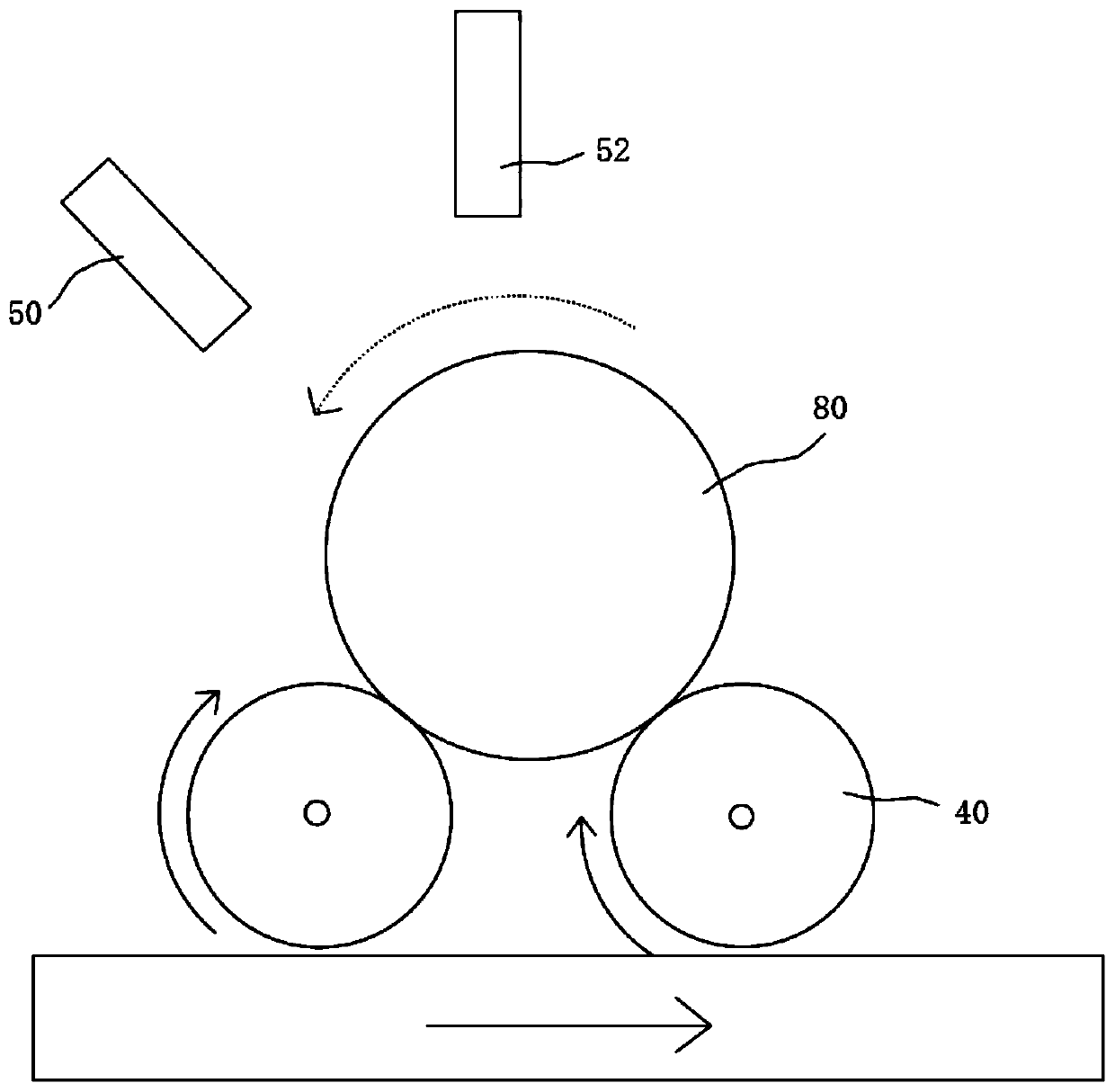

Multi-workpiece defect detection mechanism and method

InactiveCN110018176AEasy transferEasy defect detectionOptically investigating flaws/contaminationEngineeringLight source

The invention discloses a multi-workpiece defect detection mechanism and method. The multi-workpiece defect detection mechanism comprises a base, the base is provided with a platform, a conveying device and a detection device, the conveying device comprises a horizontal-moving assembly and rotating assemblies, the horizontal-moving assembly comprises a first motor, a chain and a gear, the chain isarranged in the mode of surrounding the platform, the gear and the chain are engaged, and the first motor is connected with the gear to drive the chain to horizontally move on the upper side of the platform; the rotating assemblies comprise second motors and cylindrical rolling wheels, the second motors are fixedly arranged on rotating shafts of the chain, the second motors are fixed to the rolling wheels and can drive the rolling wheels to rotate, and each rotating shaft of the chain is provided with the corresponding rotating assembly; the detection device comprises a first detection assembly and a second detection assembly, and the first detection assembly comprises a first camera and a first strip-shaped light source which are located on the upper side of the platform; and the seconddetection assembly comprises a second strip-shaped light source and a second camera which are located on the upper side of the platform. According to the multi-workpiece defect detection mechanism, image collecting and defect pre-detection can be conducted on workpieces, the work efficiency is high, and manpower is saved.

Owner:标景精密科技(苏州)有限公司

High-speed rail overhead line system stay wire defect detection method based on deep learning

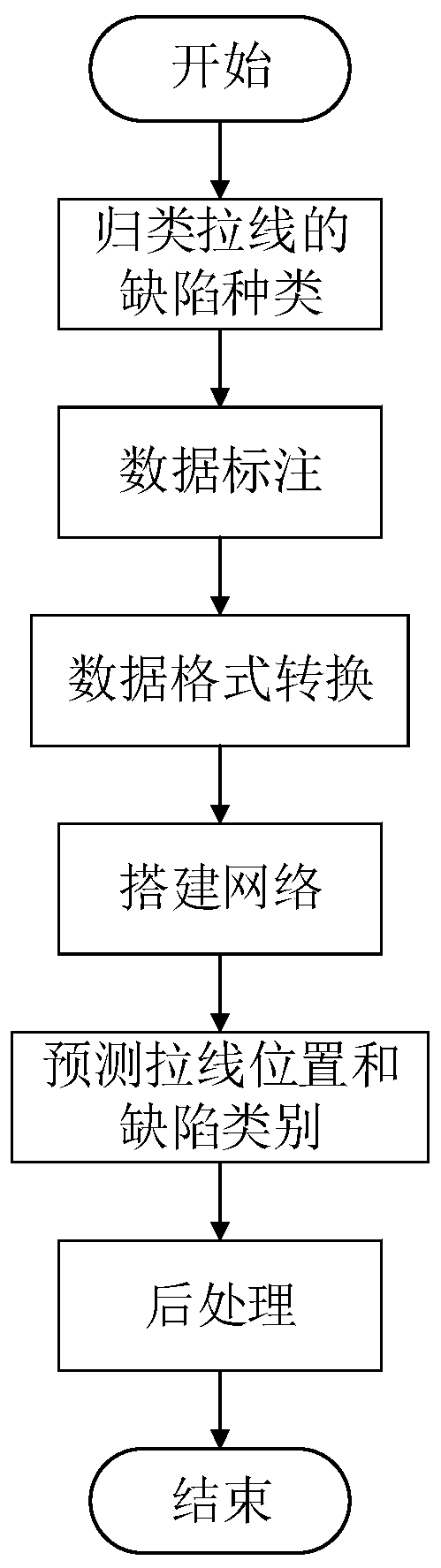

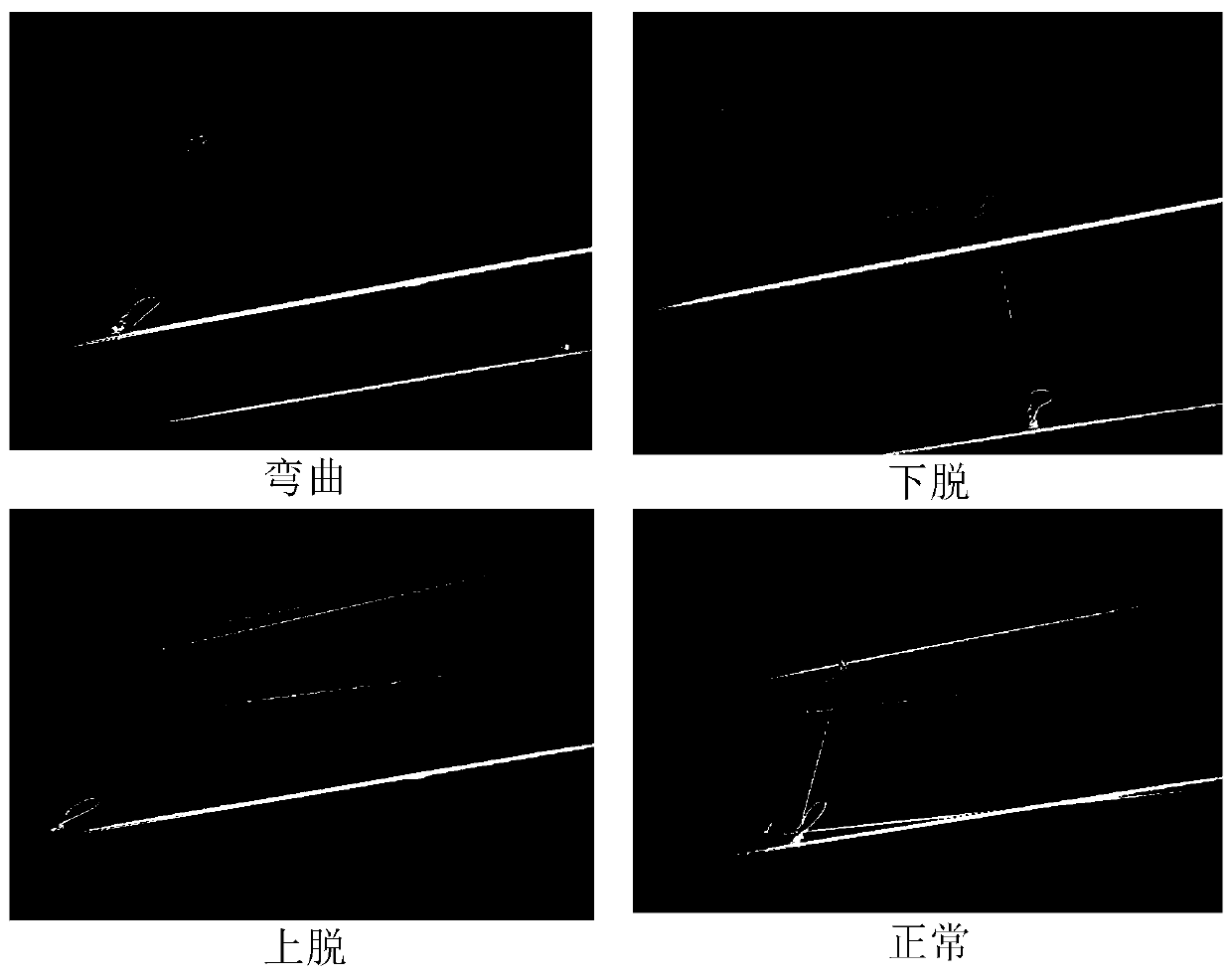

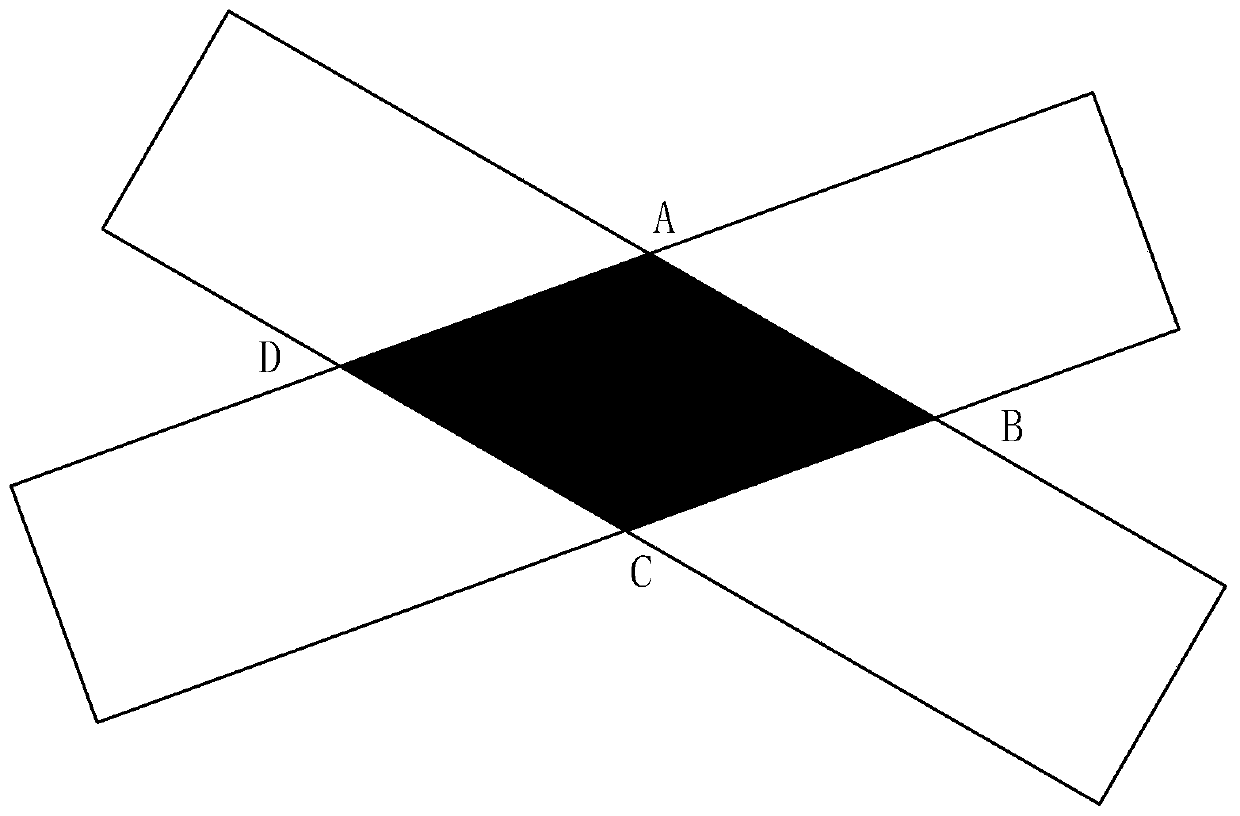

InactiveCN110428398AImprove robustnessImprove accuracyImage enhancementImage analysisAlgorithmFeature learning

The invention discloses a high-speed rail overhead line system stay wire defect detection method based on deep learning, and the method comprises the steps: carrying out the classification of defectsof a stay wire, and carrying out the labeling of a data sample containing a to-be-detected target according to the defect types of the stay wire; preprocessing the labeled data sample and converting the format of the labeled data sample; inputting the data sample of which the format is converted into a built network model, and outputting a prediction result; and carrying out post-processing on theprediction result to obtain a final defect detection result. By modeling the inherent attributes of the artificial object, the robustness of the network to the stay wire angle is improved, and the accuracy of traditional positive frame target detection is also improved. Meanwhile, according to the method provided by the invention, a complicated process of manually designing features is abandoned;defect features of key components are extracted by directly utilizing strong feature learning capability of a deep network, end-to-end defect detection is realized, a process of manually screening defect images is replaced, the workload of people is reduced, and a process from defect discovery to maintenance is shortened.

Owner:HUAZHONG UNIV OF SCI & TECH

Magnetic shoe surface defect detection method

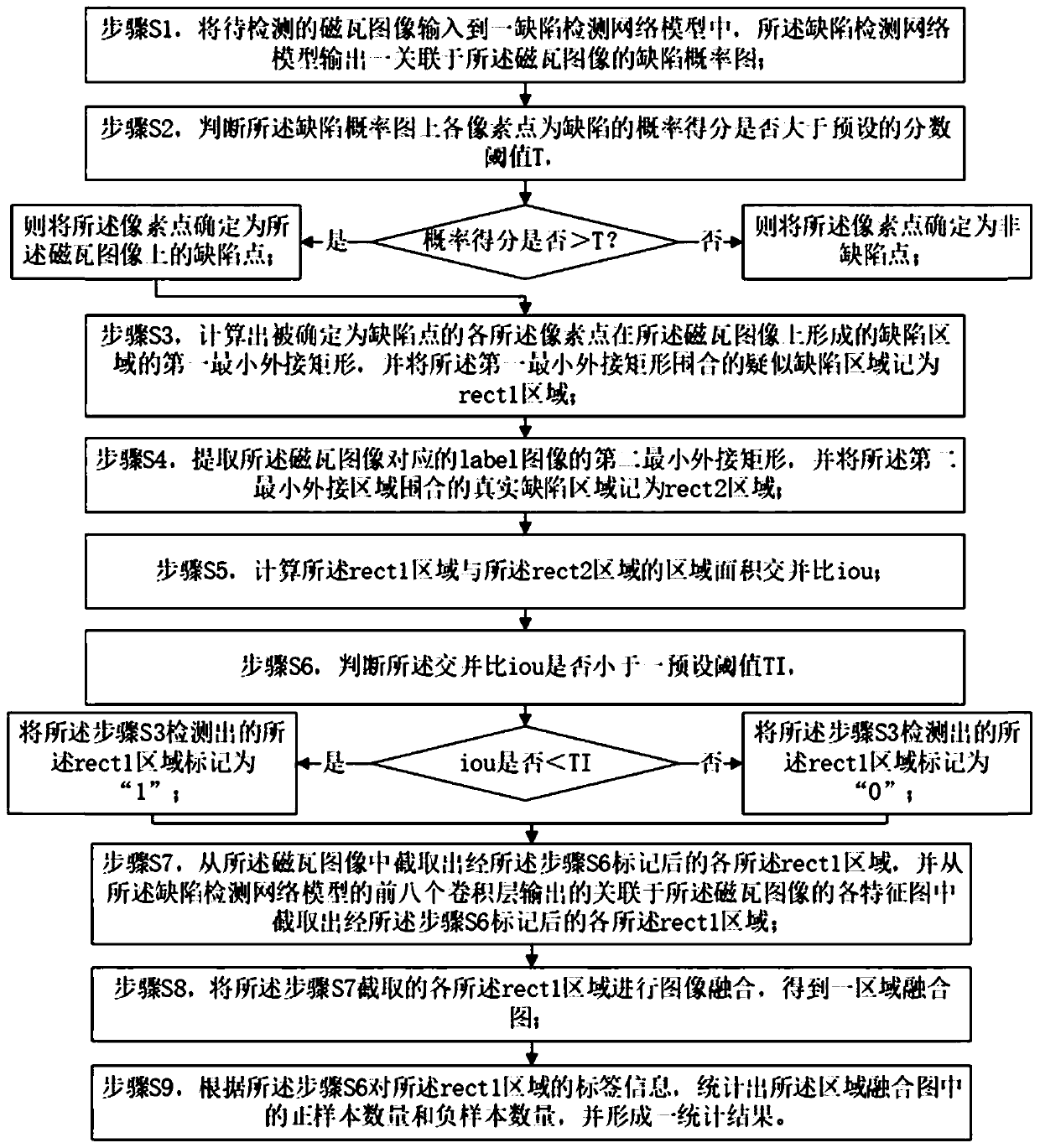

ActiveCN111105411AImplement defect detectionReduce the false detection rate of defectsImage analysisNeural architecturesComputational physicsNetwork model

The invention discloses a magnetic shoe surface defect detection method. The method comprises the following steps of: inputting a magnetic shoe image into a defect detection network model, and outputting a defect probability graph; judging whether each pixel point on the defect probability graph is a defect point or not; extracting a suspected defect area enclosed by each defect point, and recording the suspected defect area as rect1; extracting a real defect area on the label image corresponding to the magnetic tile image, and recording the real defect area as rect2; calculating a regional area intersection ratio of the rect1 to the rect2; judging whether the prediction result of the model is correct or not according to the cross-parallel ratio, and marking the rect1 area as '1'or '0' according to the prediction result; intercepting each marked rect1 area from the magnetic shoe image and each feature map output by the model; and fusing the intercepted rect1 regions to obtain a area fusion graph. According to the method, the false detection rate of the magnetic shoe defects is reduced.

Owner:创新奇智(青岛)科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com