Detection apparatus for defects of inner and outer walls of pipeline based on remote field eddy current testing

A defect detection and far-field eddy current technology, which is applied to measuring devices, instruments, and material analysis through electromagnetic means, can solve the problem of large errors, mechanical structures that cannot adapt to the size of the pipeline, and the inability to detect the circumferential position of defects and small defects, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

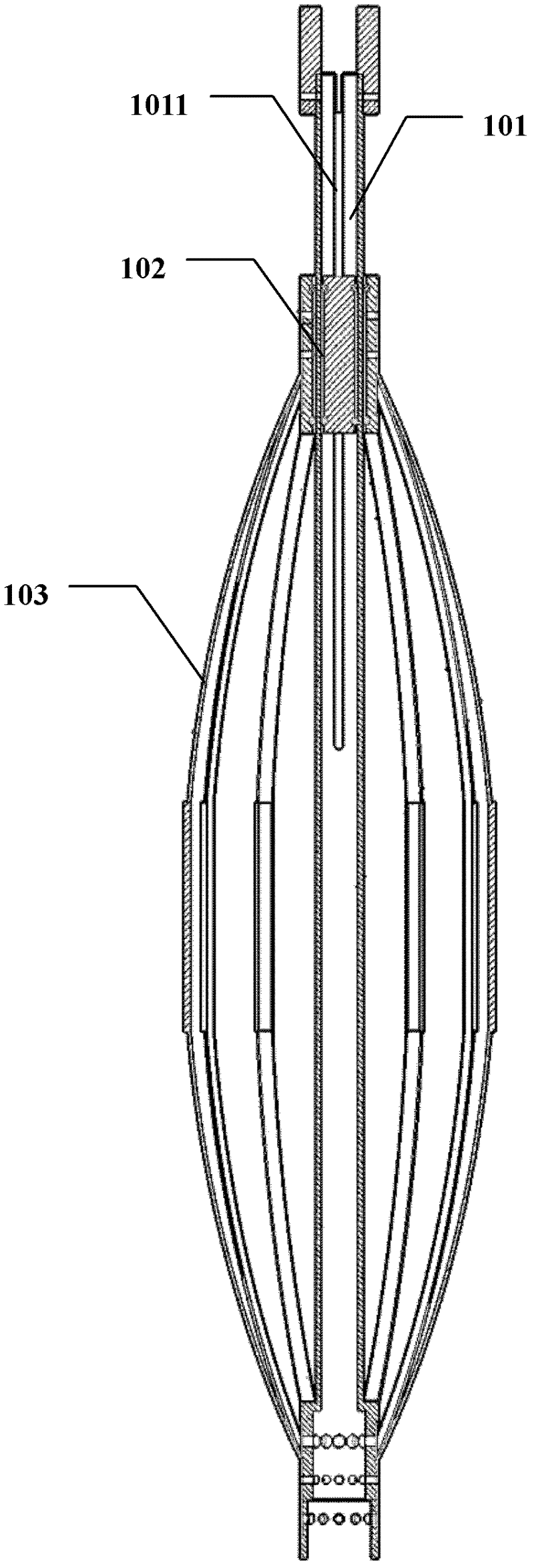

[0024] figure 1 It is a structural diagram of a specific embodiment of the sensor skeleton in the detection device for inner and outer wall defects of pipelines based on far-field eddy currents.

[0025] In this example, if figure 1 As shown, the sensor framework in the device for detecting defects on the inner and outer walls of pipelines based on far-field eddy currents consists of a main shaft 101 , a sliding block 102 sleeved on the main shaft 101 , and a plurality of arcuate spring pieces 103 . In this implementation, there are 12 bow-shaped spring pieces 103 , one end of each bow-shaped spring piece 103 is fixed on one end of the main shaft 101 , and the other end is fixed on the sliding block 102 , and the bow-shaped spring pieces 103 are evenly distributed along the circumference of the main shaft 101 . In this embodiment, there is a micro motor on the sliding block 102, so that the sliding block 102 slides on the main shaft 101, and drives the bow-shaped spring piece...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com