Defect detection method and device, model construction method and computer equipment

A technology of defect detection and defect location, which is applied in the field of image processing, can solve the problems of complex model parameters, difficult definition of features, inability to realize effective detection of surface defects of items or products, and achieve the effect of reducing the cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

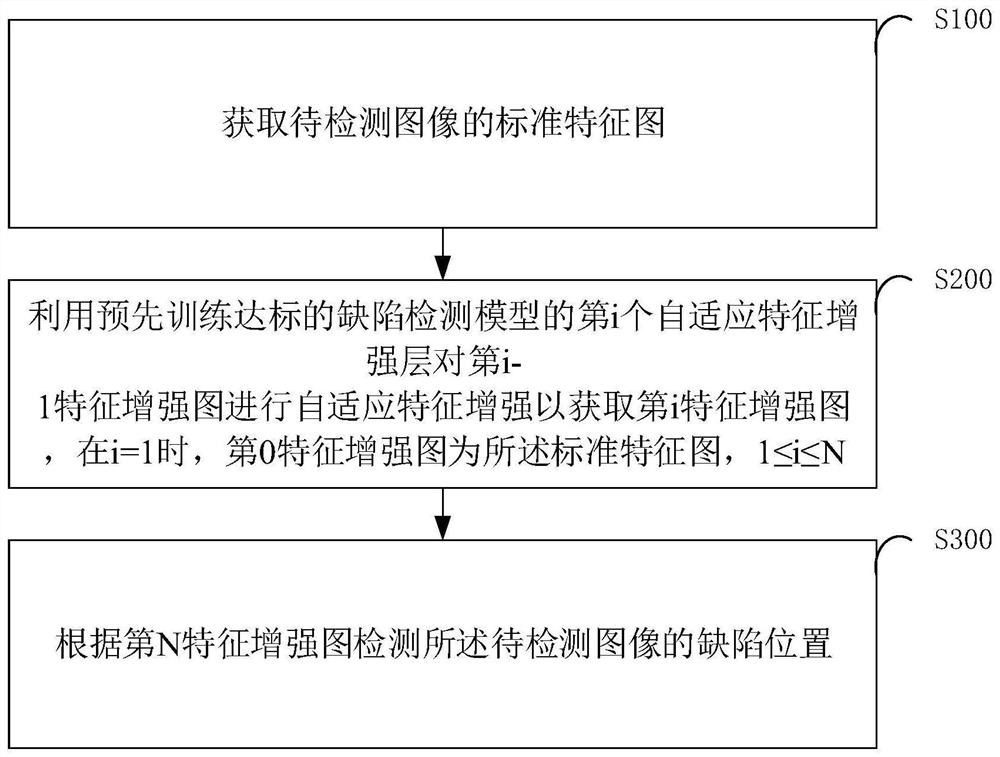

[0058]In this example, seefigure 1 It is shown that a defect detection method includes the following steps:

[0059]S100: Get the standard feature of the image to be detected.

[0060]The image acquisition system can be used to scan the item or product surface to collect items or product surface images, and the image is preprocessed to obtain the image to be detected. The pretreatment method includes cutting and scaling the collected item or product surface image, obtains an image of a predetermined size size, rotating, flipping, adjusting the image to a standard contrast, adjusting the brightness to a standard brightness. It will be appreciated that items or products include medical device products, industrial products, prints, product packaging and food packaging, etc., this embodiment is not limited.

[0061]The defect detection model to be detected to be detected is input to the pre-training standard, and the standard convolution to the detected image is standardized to obtain a standard...

Embodiment 2

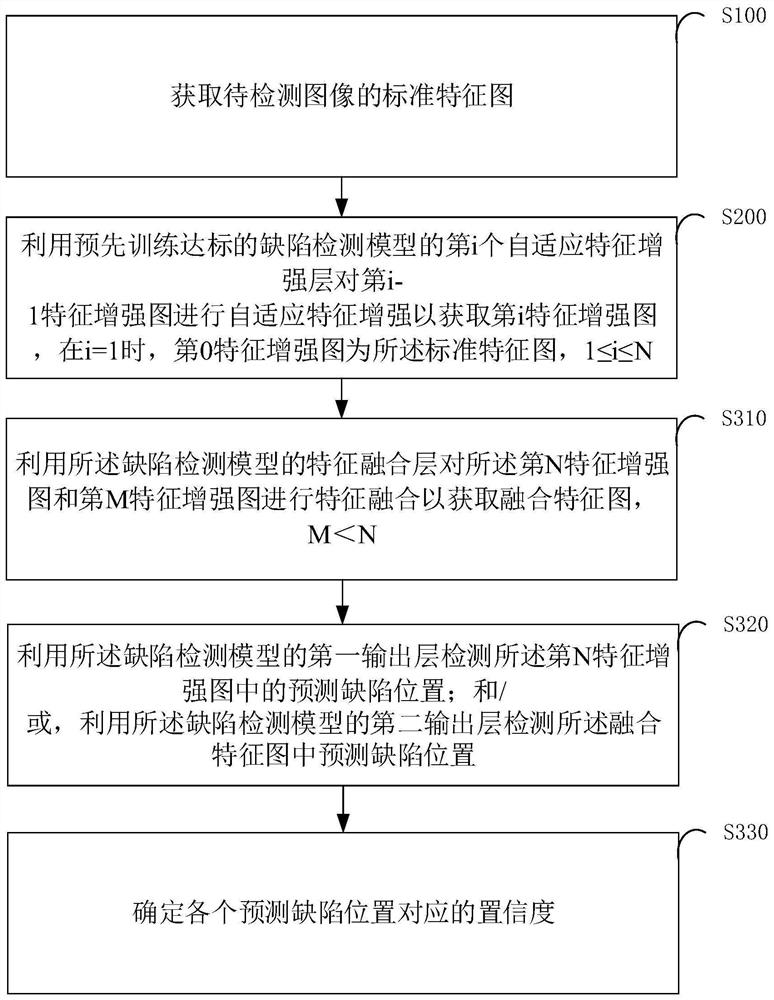

[0092]In this example, seefigure 2 The step S300 shown by the defect detection method includes the following steps:

[0093]S310: Feature fusion of the Nth feature enhancement diagram and the M-characterizing method for feature fusion using the feature fusion layer of the defect detection model to acquire fusion feature, m <n.

[0094]Demonstrative, pre-constructed defect detection models can include six adaptive feature enhancements, as shown in the following table.

[0095]

[0096]Since the objective or product surface defect target is often small, the grayscale is not obvious, so the feature information of the defective target will disappear when the network reaches a certain depth, and therefore, according to the surface defects contained in each layer of the network The feature information determines the depth of the network, built an optimal network frame, as shown in the table below.

[0097]After the various layers of the neural network can be subjected to a reactionary layer, the converg...

Embodiment 3

[0109]In this example, seeFigure 4 A defect detection model constructor is shown, including:

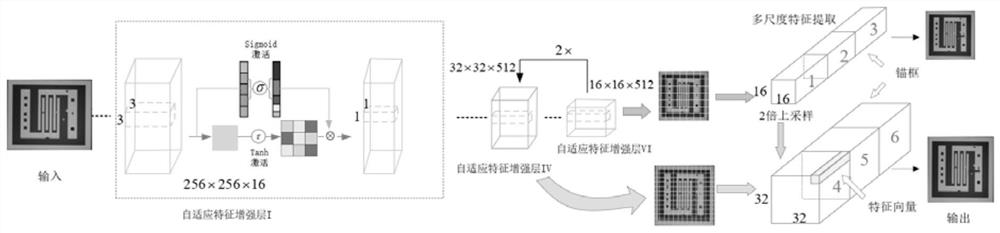

[0110]S10: The adaptive feature enhancement layer is constructed by using the divided convolution layer, the multi-dimensional activation layer, and the point-volume layer.

[0111]A conventional convolution operation can be broken down into 3 × 3 due to fractal decomposition layer and 1 × 1 point volume layer, and a multi-portable activation layer is added between the divided convolution layer and the point-volume layer. , The feature fusion is made by each of the feature figures in the factor decomposition convolution layer to perform feature fusion, enhance the effective feature, and suppress the characteristics of the interference.

[0112]S20: The defect detection model is constructed using a plurality of adaptive feature enhancements.

[0113]S30: Enter the training image to the defect detection model.

[0114]S40: The visualization feature of the training image corresponding to each adaptive featu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com