High-speed rail fastener defect identification method based on heterogeneous image fusion

A heterogeneous image and defect recognition technology, applied in image enhancement, image analysis, image data processing, etc., can solve the problems of missing scene color and texture information, missed detection of fasteners, lack of third-dimensional depth information in two-dimensional images, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

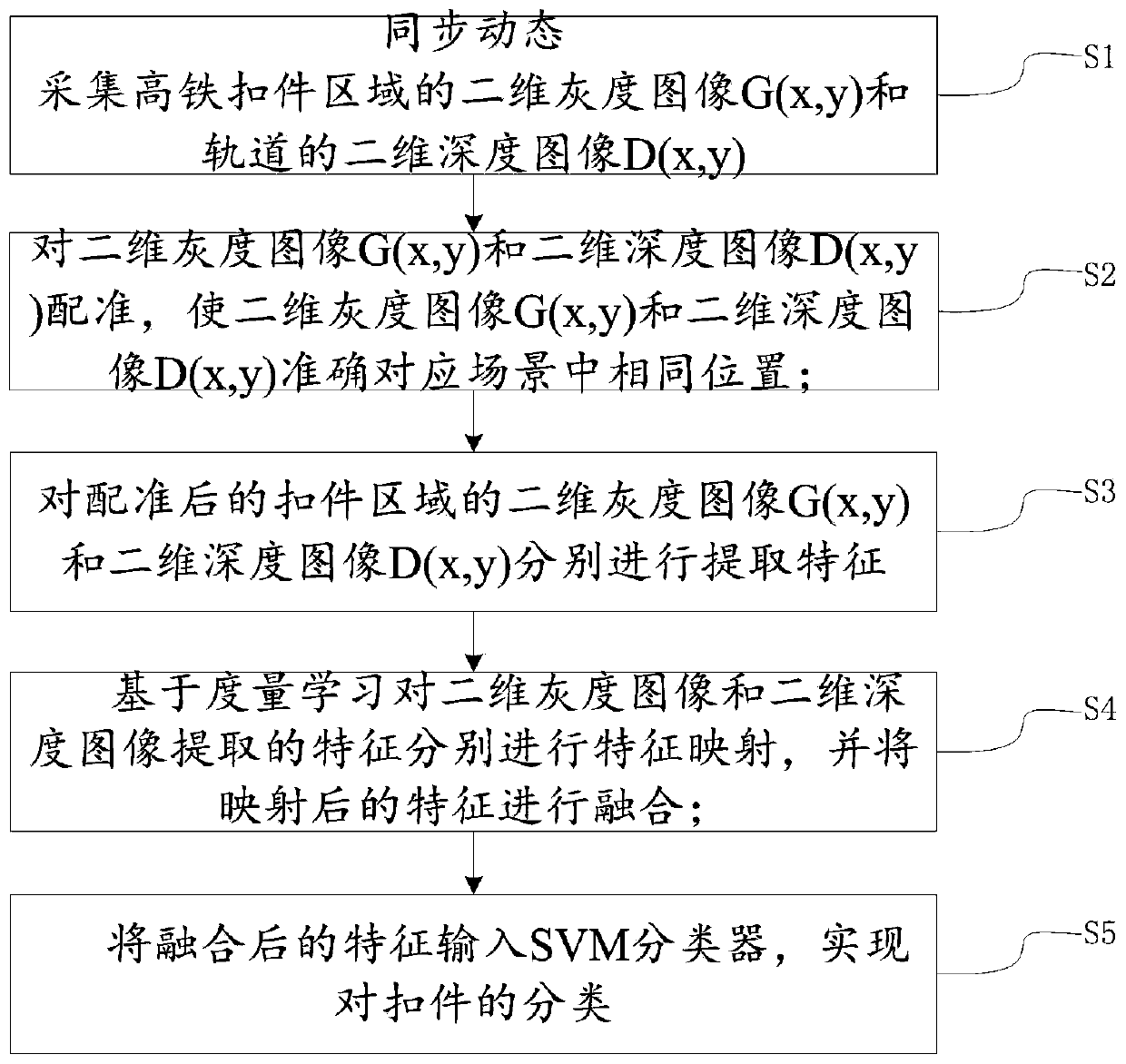

[0083] like figure 1 As shown, a high-speed rail fastener defect recognition method based on heterogeneous image fusion, the method includes the following steps:

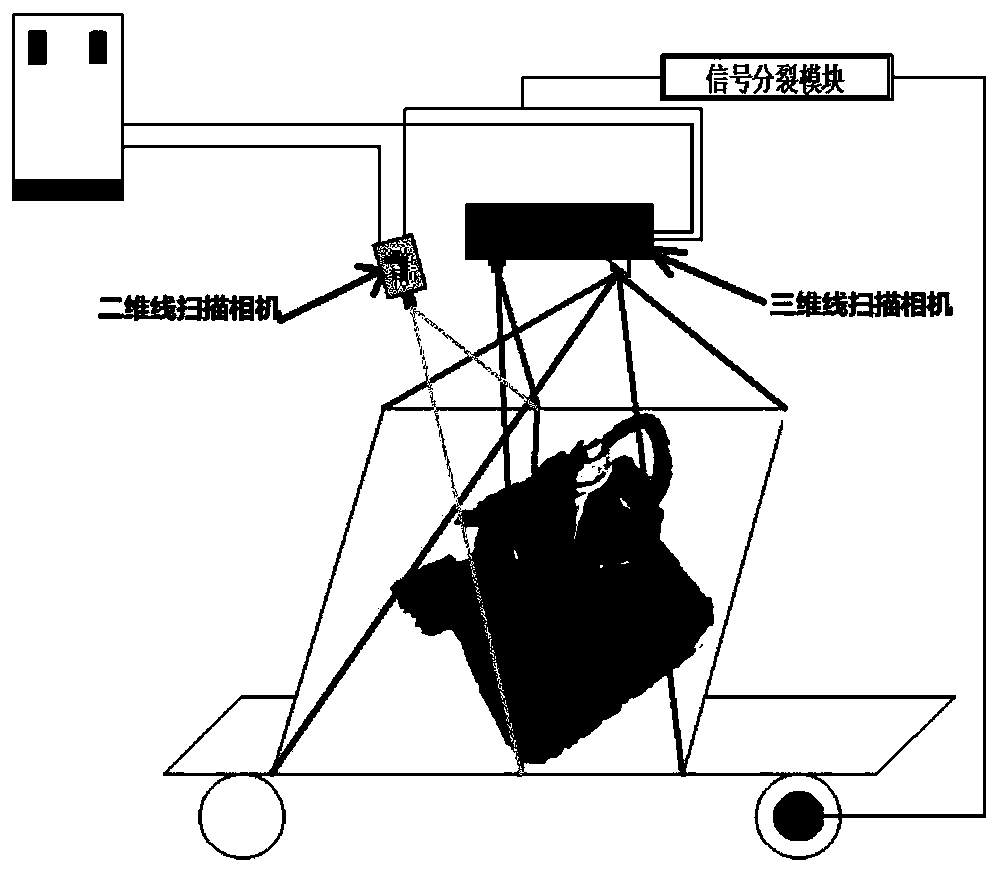

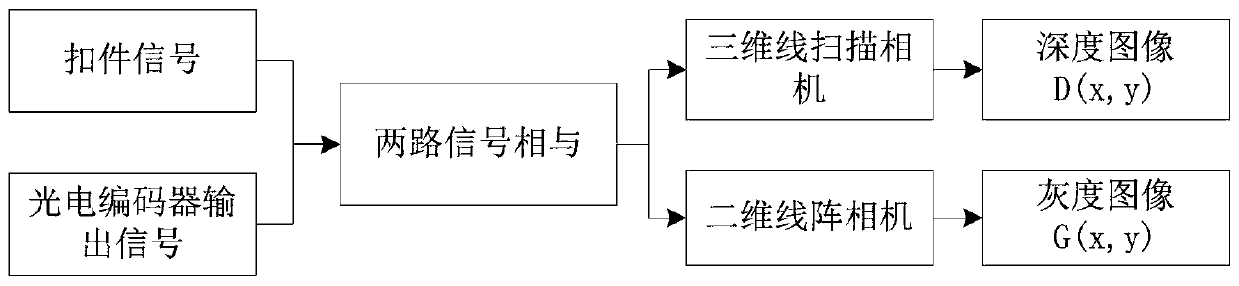

[0084] S1. Synchronously and dynamically collect the two-dimensional grayscale image G(x,y) of the high-speed rail fastener area and the two-dimensional depth image D(x,y) of the track;

[0085] S2. Register the two-dimensional grayscale image G(x,y) and the two-dimensional depth image D(x,y), so that the two-dimensional grayscale image G(x,y) and the two-dimensional depth image D(x,y) ) exactly corresponds to the same position in the scene;

[0086] S3. Perform feature extraction on the two-dimensional grayscale image G(x,y) and the two-dimensional depth image D(x,y) of the registered fastener area respectively;

[0087] S4. Based on metric learning, perform feature mapping on the features extracted from the two-dimensional grayscale image G(x, y) and the two-dimensional depth image, and fuse the mapped features;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com