Steam generator heat-transfer pipe ultrasonic inspection system

A steam generator and ultrasonic inspection technology, applied in the field of nuclear engineering, can solve the problems of defect qualitative, quantitative inaccuracy, current can not guarantee the accuracy, crack detection level is low, etc., to achieve high defect detection rate, convenient installation and disassembly, and equipment Reliable and stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention is described in detail below in conjunction with accompanying drawing and embodiment:

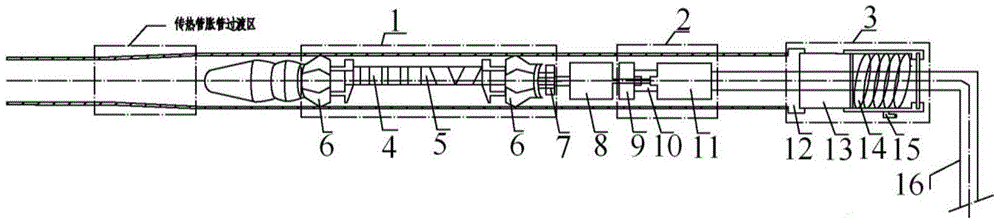

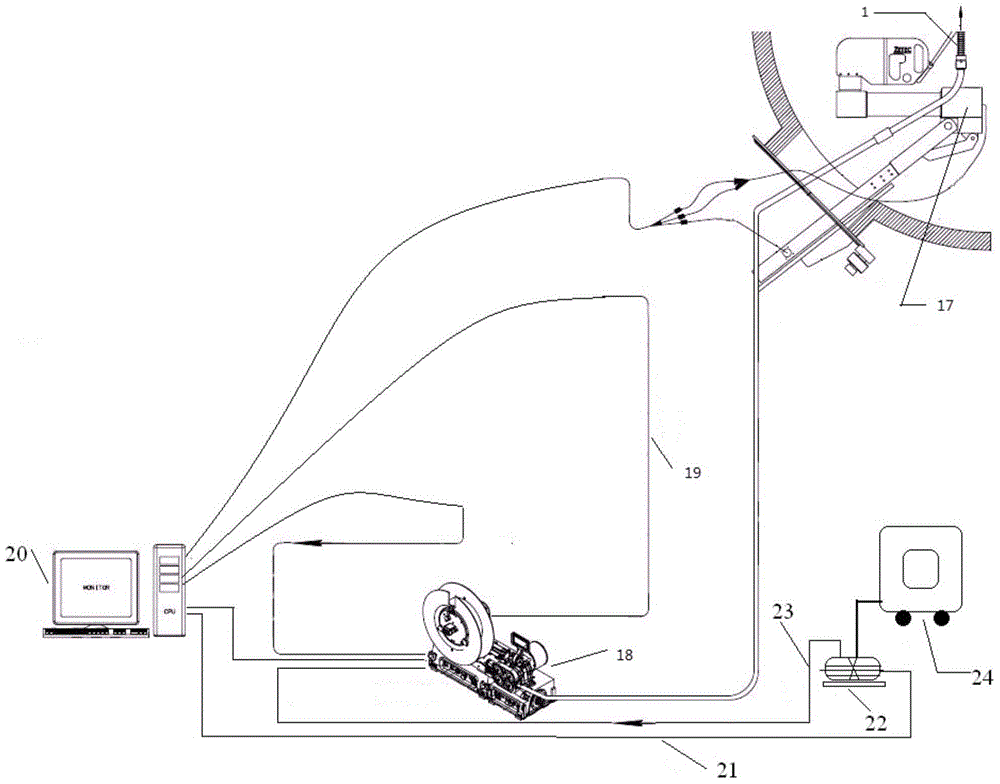

[0026] Such as figure 2 As shown, the steam generator heat transfer tube water immersion ultrasonic inspection system of the present invention includes a probe assembly 1, a probe rotating device 2, a probe door device 3, a probe pusher 18, and the probe positioner 17;

[0027] The probe assembly 1 extends into the heat transfer tube, one end of which is connected to the conduit 16, and the other end of the conduit 16 extends out of the steam generator and is fixed on the probe pusher 18, which is similar to the patent CN201120161378.1 , the structure described in the name "eddy current probe pusher"; the conduit 16 is provided with an ultrasonic long cable 19, a first cable and a water supply pipe 23;

[0028] The probe pusher 18 is connected to the control terminal 20 through a cable, and a control signal is given to the pusher control box 20 through the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com